Flange hole vibration cleaning device

A technology for cleaning device and flange hole, which is applied in the field of flange hole vibration cleaning device, can solve the problems of iron slag not being blown out by wind and not being cleaned properly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

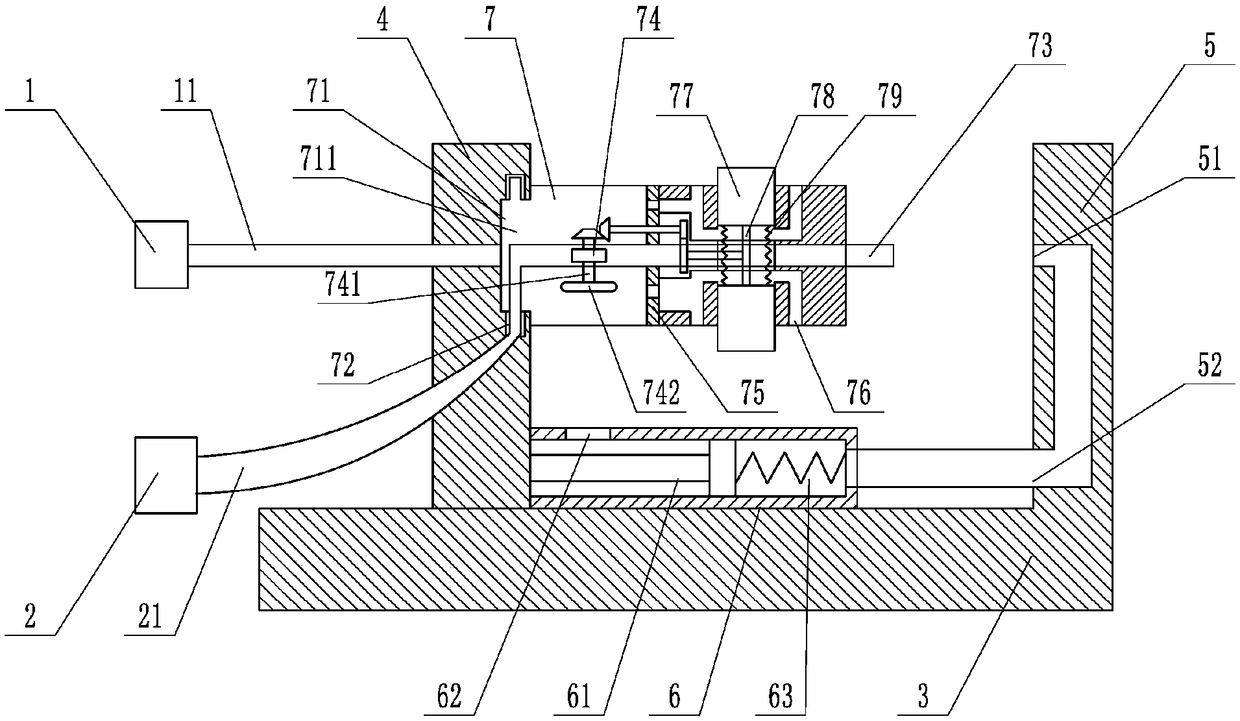

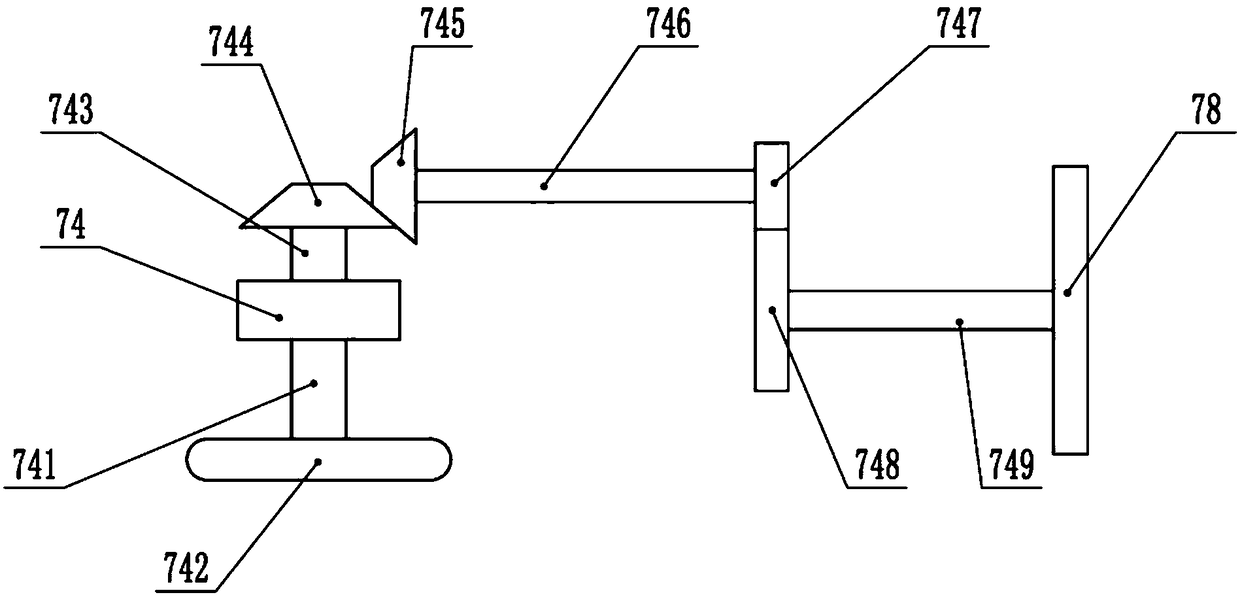

[0021] The reference signs in the drawings of the description include: motor 1, power rod 11, fan 2, air guide pipe 21, frame 3, fixed plate 4, connecting seat 5, first connecting hole 51, second connecting hole 52, piston Cylinder 6, piston rod 61, pressure relief port 62, first spring 63, hollow cleaning rod 7, connecting part 71, ventilation channel 711, fixing ring 72, blowing pipe 73, wind wheel 74, first connecting rod 741, negative pressure Blade 742, second connecting rod 743, first bevel gear 744, second bevel gear 745, first rotating rod 746, first gear 747, second gear 748, second rotating rod 749, filter screen 75, negative pressure hole 76, grinding block 77, cam 78, extension spring 79.

[0022] Such as figure 1 As shown, the flange hole vibration cleaning device includes a frame 3, a disc-shaped connecting seat 5 is welded on the right side of the frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com