Automatic drying device

A drying device and automatic technology, which is applied in drying, drying machines, heating devices, etc., can solve the problems of artificial feeding and unloading, and achieve the effects of prolonging service life, reducing wear and tear, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

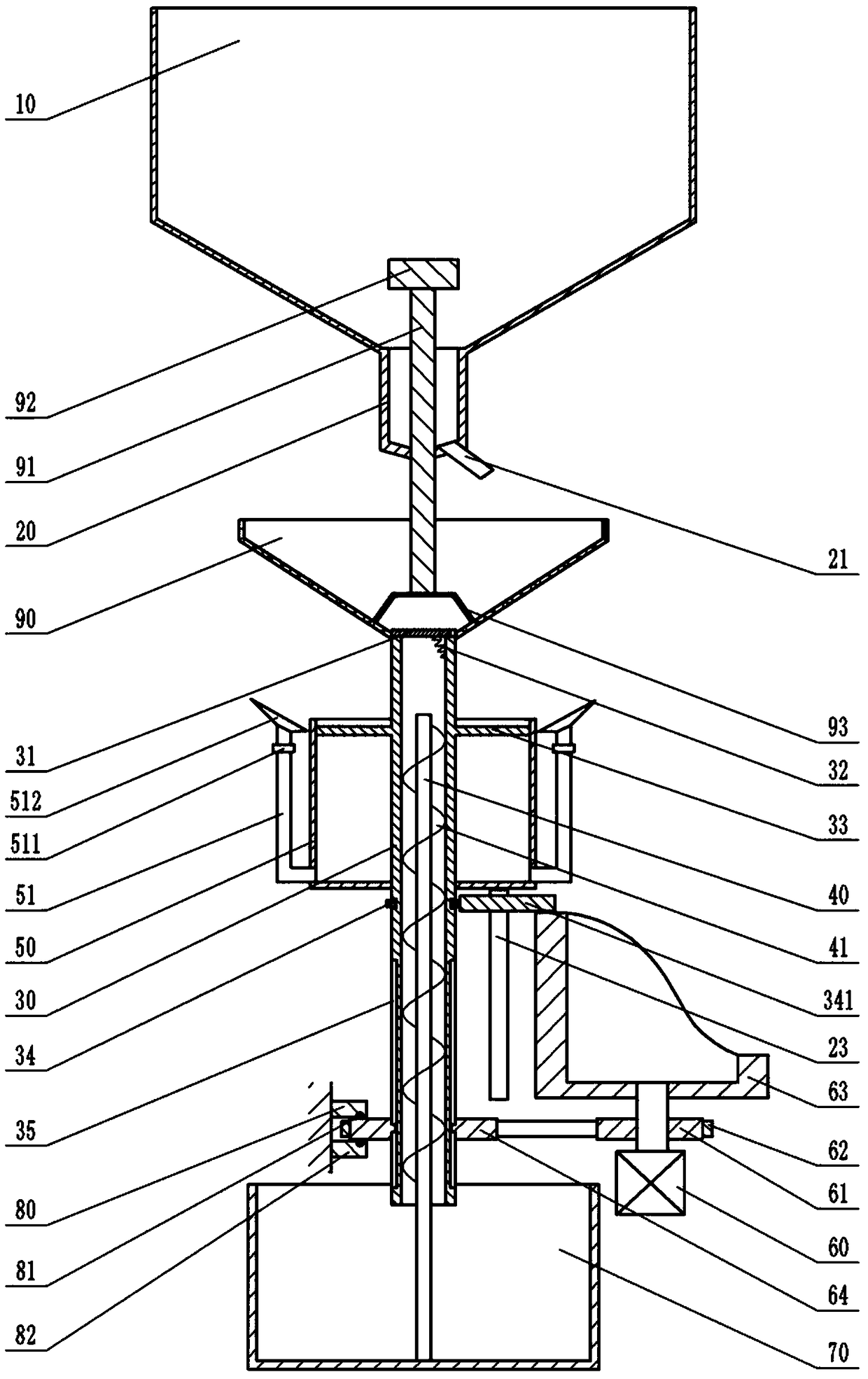

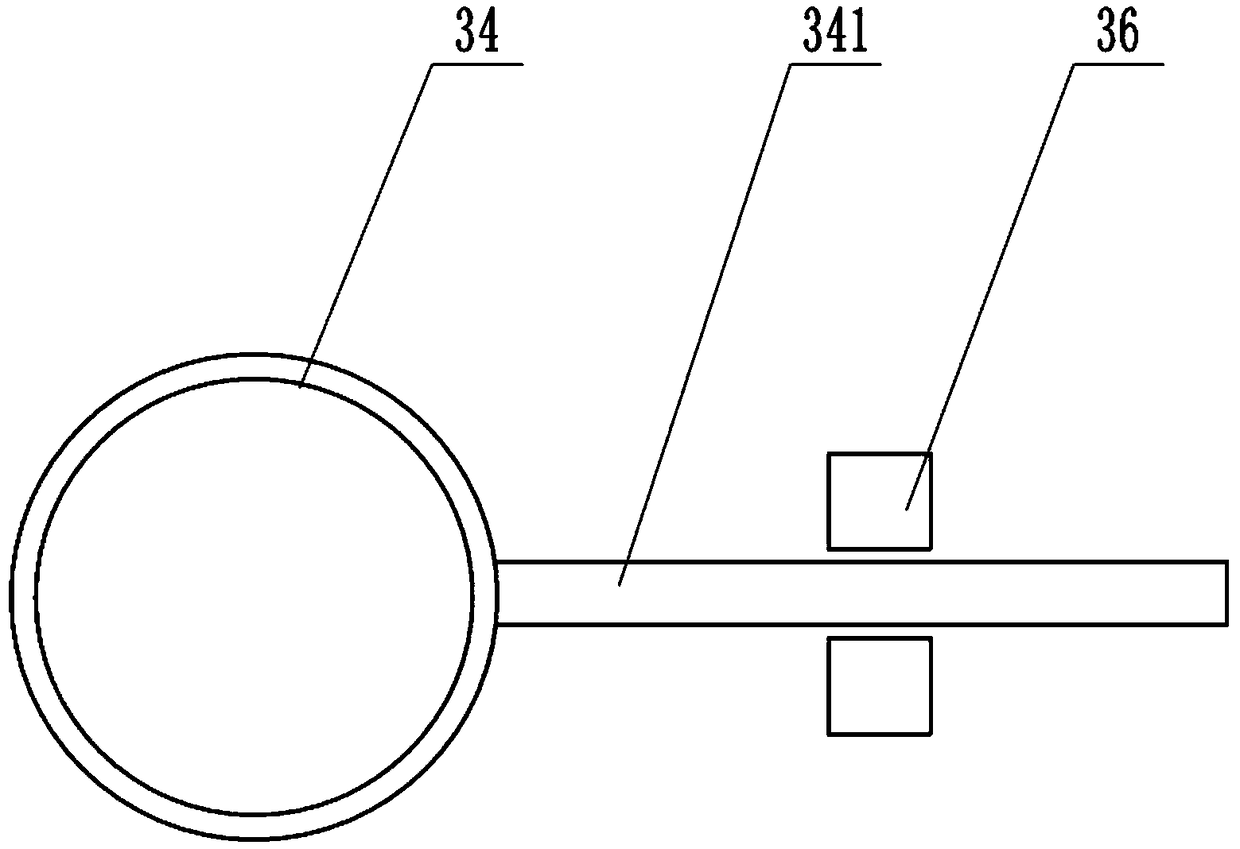

[0020] Instructions attached Figures 1 to 2 The reference signs in include: hopper 10, discharge pipe 20, output pipe 21, connecting column 30, material gate 31, spring 32, pressure plate 33, annular ring 34, connecting rod 341, chute 35, limit bar 36, Push rod 40, helical blade 41, piston barrel 50, exhaust pipe 51, one-way exhaust valve 511, jet nozzle 512, motor 60, first sprocket wheel 61, chain 62, cylindrical cam 63, second sprocket wheel 64, Collecting box 70, upper block 80, rolling ball 81, lower block 82, rotating disk 90, ejector bar 91, block 92, support 93.

[0021] Such as figure 1 As shown, the automatic drying device includes a rack, a drying unit, a power unit and a storage unit located above the drying unit. The storage unit includes a hopper 10 and a discharge pipe 20 communicating with the lower end of the hopper 10. The hopper 10 is used to place materials to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com