Combined type purification equipment with monitoring and cleaning system

A technology of purification equipment and cleaning system, which is applied in the direction of electrode cleaning, lighting and heating equipment, heating methods, etc. It can solve the problems of unable to clean the static electrode plate, oil accumulation in the exhaust pipe, and high risk of fire, so as to improve the efficiency of oil fume purification , avoid waste, prolong the effect of motion stroke and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

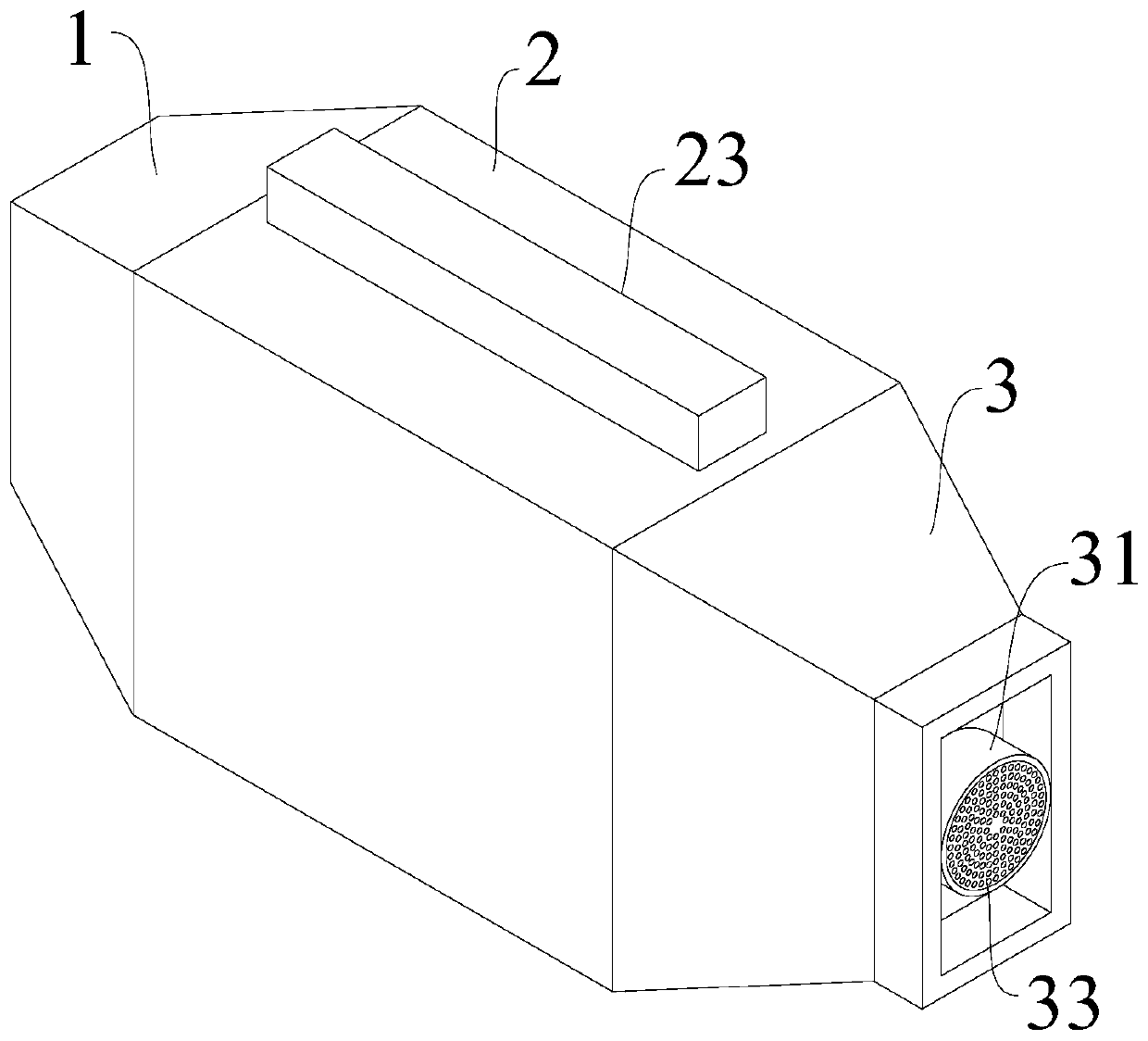

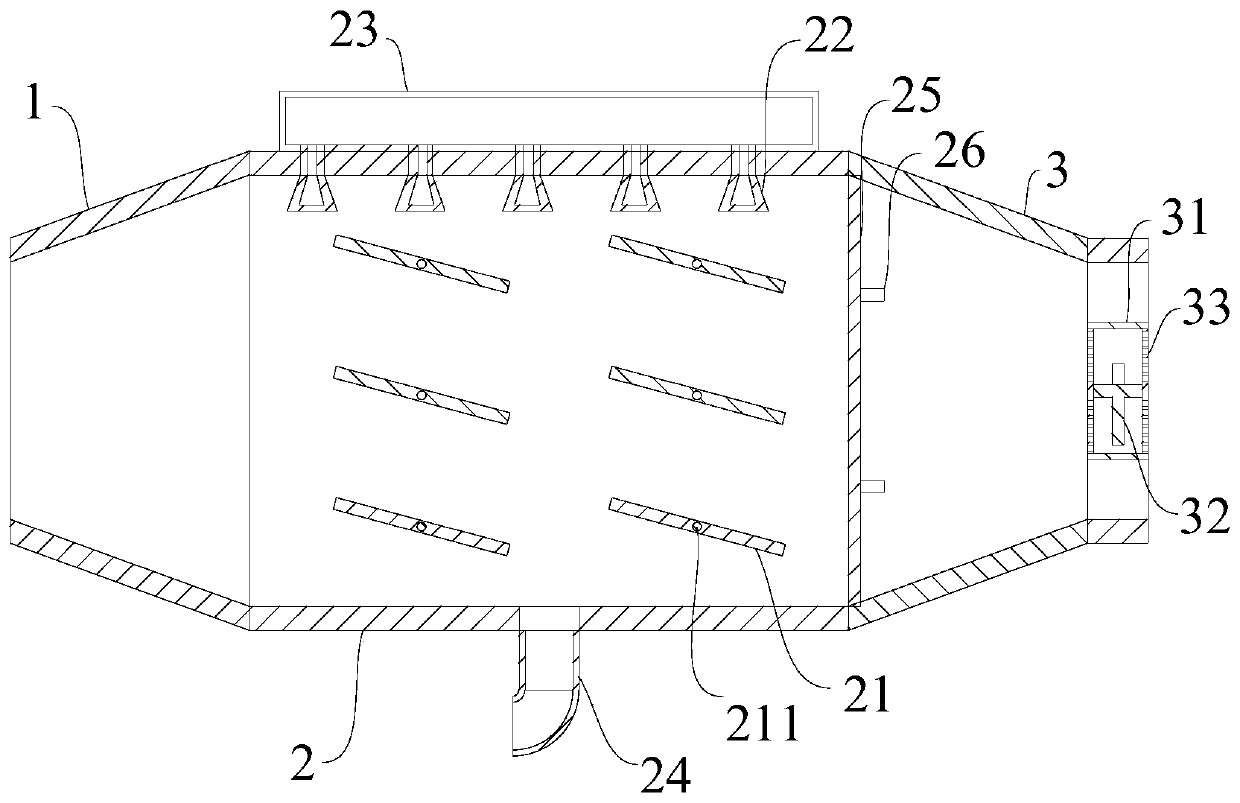

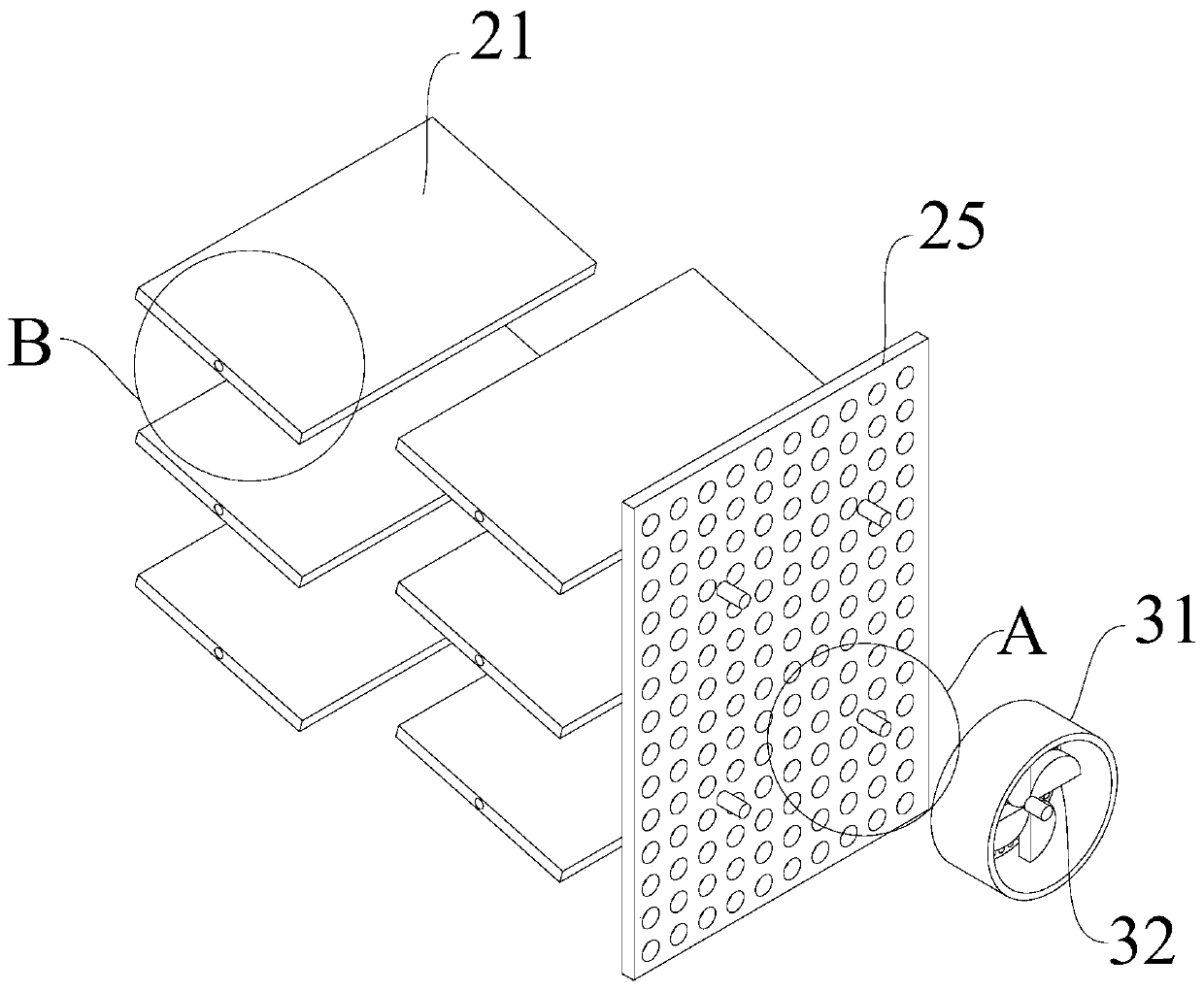

[0031] Such as Figure 1-5 As shown, a compound purification device with a monitoring and cleaning system includes an air inlet 1, a smoke purification mechanism, a cleaning mechanism and an exhaust port 3 that communicate with each other. The oil fume purification chamber 2 connected to the end of 1, the inside of the oil fume purification chamber 2 is horizontally provided with several rotating shafts 211, and the rotating shafts 211 are driven by a motor a (not shown) arranged on the outer wall of the oil fume purification chamber 2 , the motor a is connected to the output end of the controller (not shown) arranged on the outer wall of the oil fume purification chamber 2, and the motor a is controlled by the controller to drive the rotation shaft 211 to rotate, and the rotation shaft 211 is sleeved with The static electrode plate 21 cooperating with it, the static electrode plate 21 and the rotating shaft 211 are fixed to each other, when the rotating shaft 211 rotates, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com