Switch reluctance motor of distributed multiple driving units

A switched reluctance motor and drive unit technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as torque and speed drop, system inoperability, noise surge, etc., to improve safety and stability , avoid group effect, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

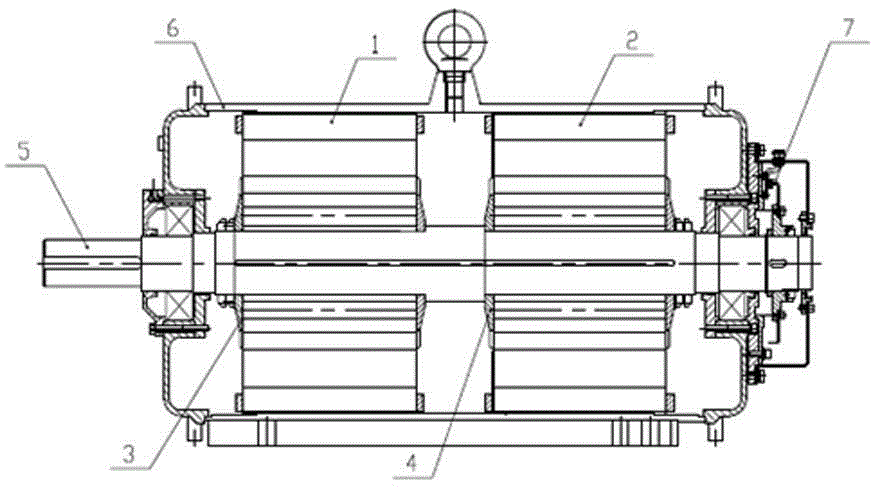

[0020] Depend on figure 1 It can be seen that the present invention includes a controller, a switched reluctance motor and a position detector, the rotor position detector is installed at one end of the motor, and the stator and rotor of the switched reluctance motor include two or more The stator and rotor core.

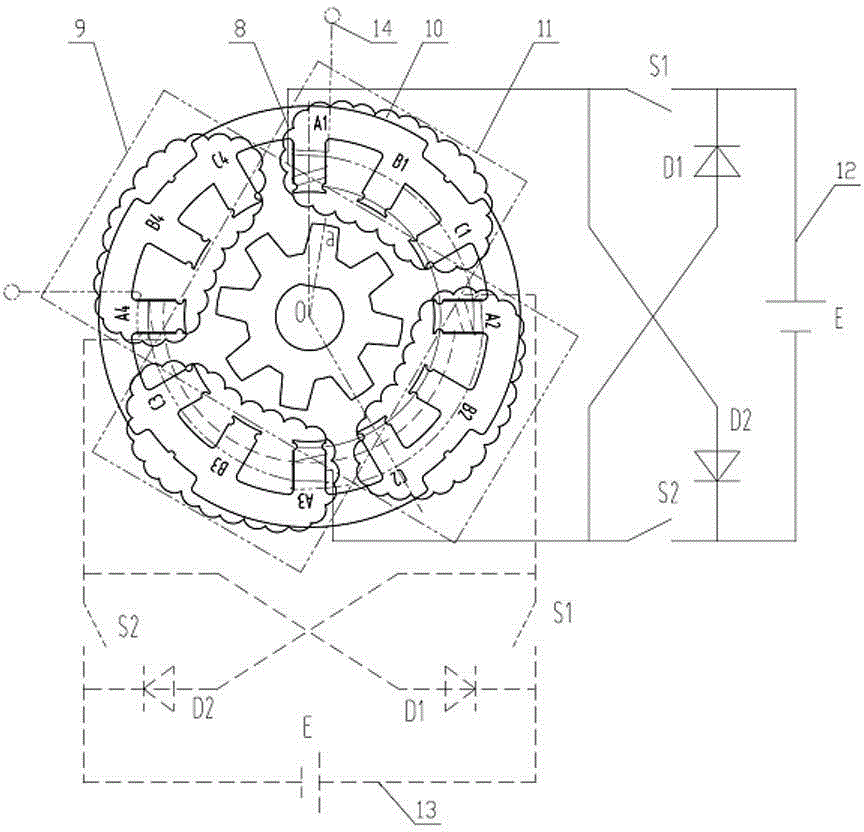

[0021] figure 2 According to the present invention, it is described as a three-phase 12 / 8 pole motor. The stator core and the rotor of the present invention adopt a multi-pole structure with double salient poles, which are all laminated by ordinary silicon steel sheets. The rotor has neither winding nor permanent magnet, and there is a concentrated winding on the stator. secondary winding. Among them, the stator has 12 magnetic poles, and each phase of the stator contains 2 pairs of radially opposite magnetic poles, and the magnetic poles are arranged in sequence according to the three phases of A, B, and C. The magnetic poles are divided into A1-A4, B1-B4, C1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com