Two-axis rocking platform system driven by reverse communication of cylinders

A platform and reverse technology, which is applied in the field of the double-axis rocking platform system that drives the reverse connection of the cylinders, can solve the problems of the difficulty of controlling the redundant drive of the multi-cylinder direct drive, the asymmetry of the direct drive force of the two cylinders, and the small stiffness difference. , to achieve the effect of increasing the anti-heavy and eccentric load capacity, wide application range, and improved driving and structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

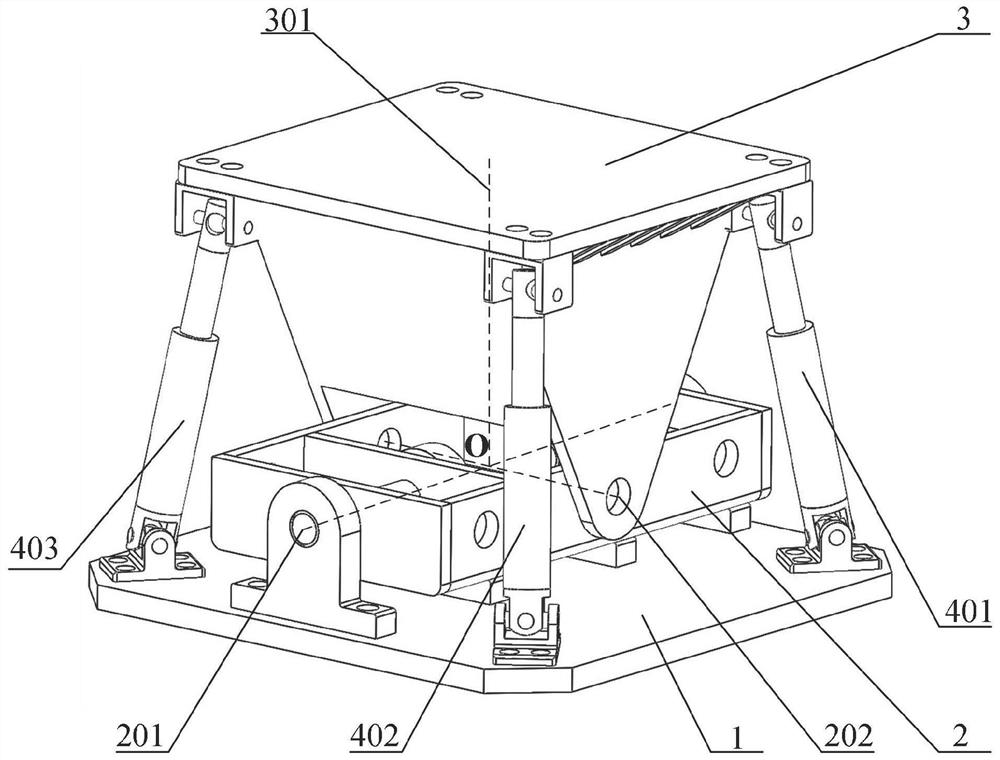

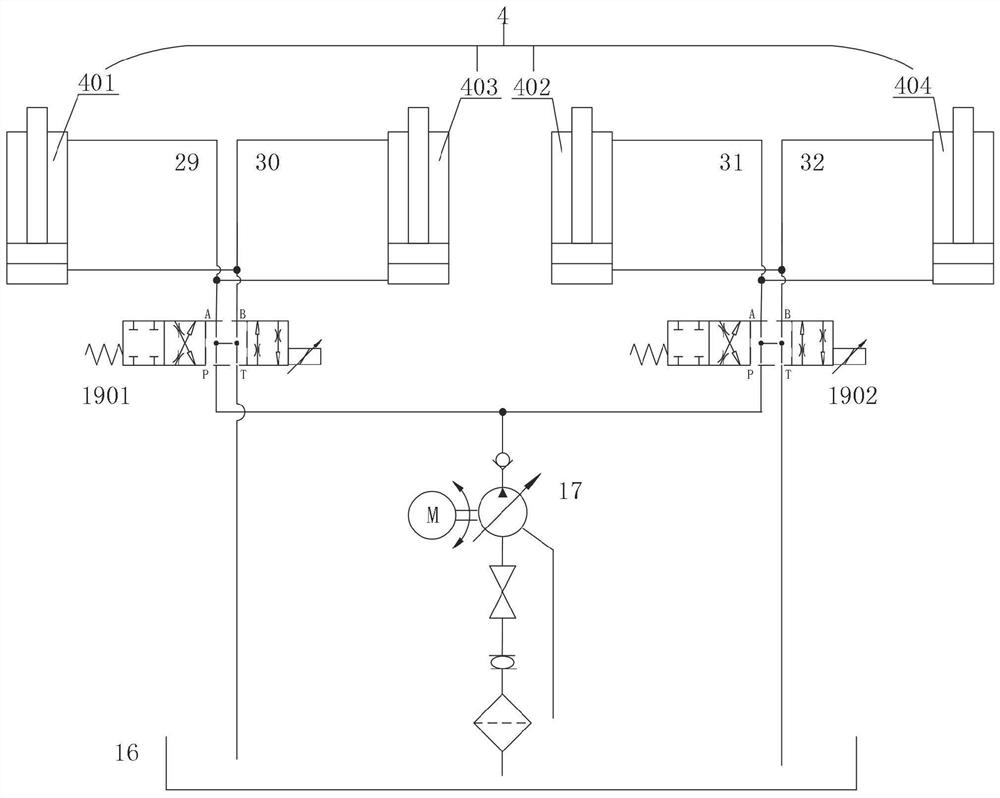

[0057] Such as figure 1 , figure 2 and Figure 10 As shown, when the working conditions need to compensate for rolling and pitching motions or to provide lateral and longitudinal swings, first, the hydraulic oil pump 17 is used as a power source to send hydraulic oil into the oil pipe, and the hydraulic oil passes through port A of the reversing valve 21 into the P port of the first servo valve 1901, the hydraulic oil flows out from the A port of the first servo valve 1901, enters the upper chamber of the first driving cylinder 401 and the lower chamber of the third driving cylinder 403 through the first oil pipe 29, and drives The cylinder rod moves, so that the hydraulic oil in the lower chamber of the first driving cylinder 401 and the hydraulic oil in the upper chamber of the third driving cylinder 403 enter the B port of the first servo valve 1901 through the second oil pipe 30, and flow from the T port of the first servo valve 1901. At this time, the first oil pipe 29...

Embodiment 2

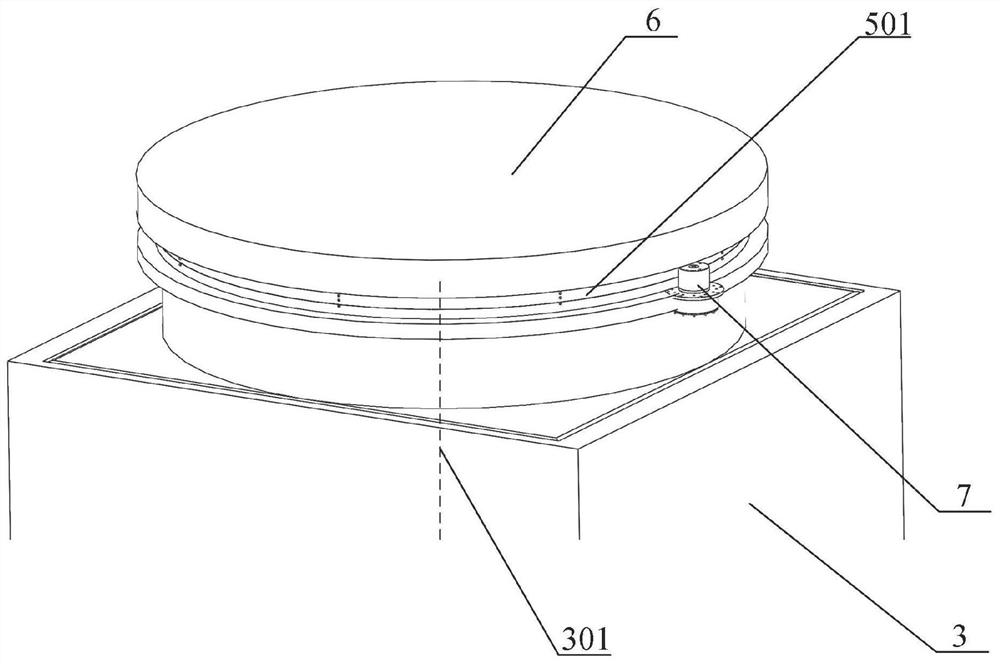

[0061] Such as image 3 As shown, when the working conditions not only need to compensate the rolling and pitching motions or need to provide lateral and longitudinal swings, but also need to turn the amplitude, firstly, the upper end of the swinging platform 3 is installed with a third rotating pair 501, and the turning platform 6 is installed At the upper end of the third rotating pair 501, the rotary driver 7 is installed on one side of the third rotating pair 501. The rotary driver 7 drives the third rotating pair 501 to rotate and then drives the rotating platform 6 to rotate. The axis of the third rotating pair 501 is normal to the swing platform 3. The center line 301 coincides; at this time, the movement of the swing platform 3 and the hem frame 2 and the action of the hydraulic system are the same as those in Embodiment 1, and the movement platform can have three degrees of freedom at most.

Embodiment 3

[0063] Such as Figure 4 As shown, when the working conditions not only need to compensate rolling and pitching motions or provide lateral and longitudinal swings, but also need to compensate for heave motions or provide lifting motions, firstly, the swinging platform 3 is a hollow cylinder, and the swinging platform 3 is internally installed There is a lifting column 8 and a linear driver 9. The lifting column 8 and the swinging platform 3 form a first moving pair 302. The direction of the first moving pair 301 is parallel to the normal centerline direction 302 of the swinging platform 3. The linear driver 9 drives the lifting column 8 in the The swinging platform 3 performs a heave movement, the inner plane of the upper end of the lifting column 8 is connected to the upper end of the linear driver 9 through a hinge, the lower end of the linear driver 9 is connected to the plane on the bottom plate of the hem frame 2 through a hinge, and the axis of the linear driver 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com