Dual-machine two-dimensional integrated three-phase asynchronous hub motor and frequency conversion driving control system

A three-phase asynchronous, variable frequency drive technology, used in control systems, motor speed or torque control, electrical components and other directions, can solve problems such as low function conversion efficiency, improve insulation level, extend continuation mileage, increase The effect of inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

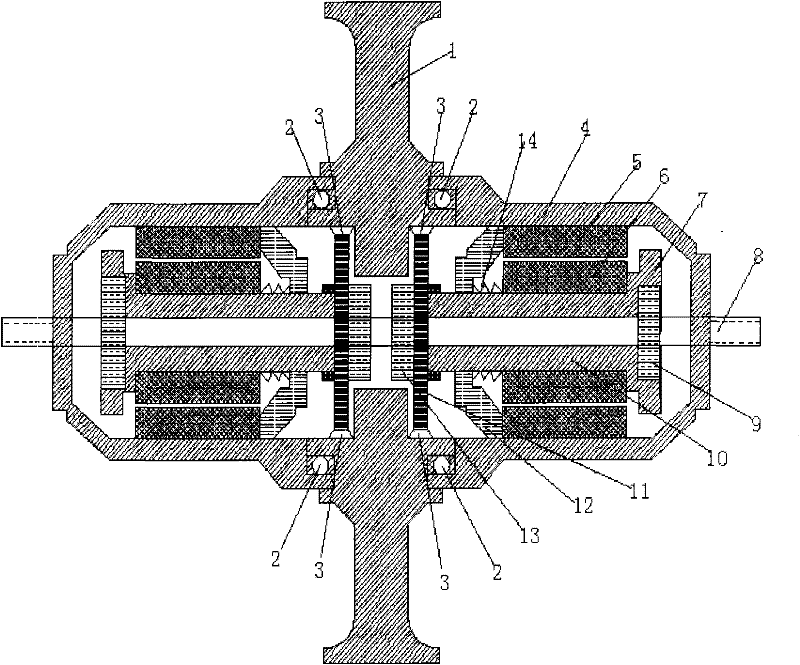

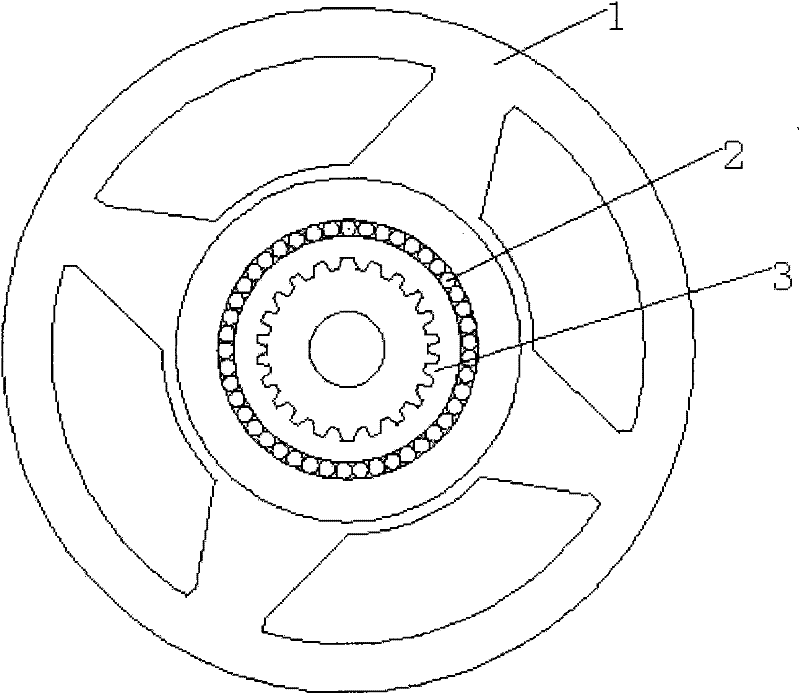

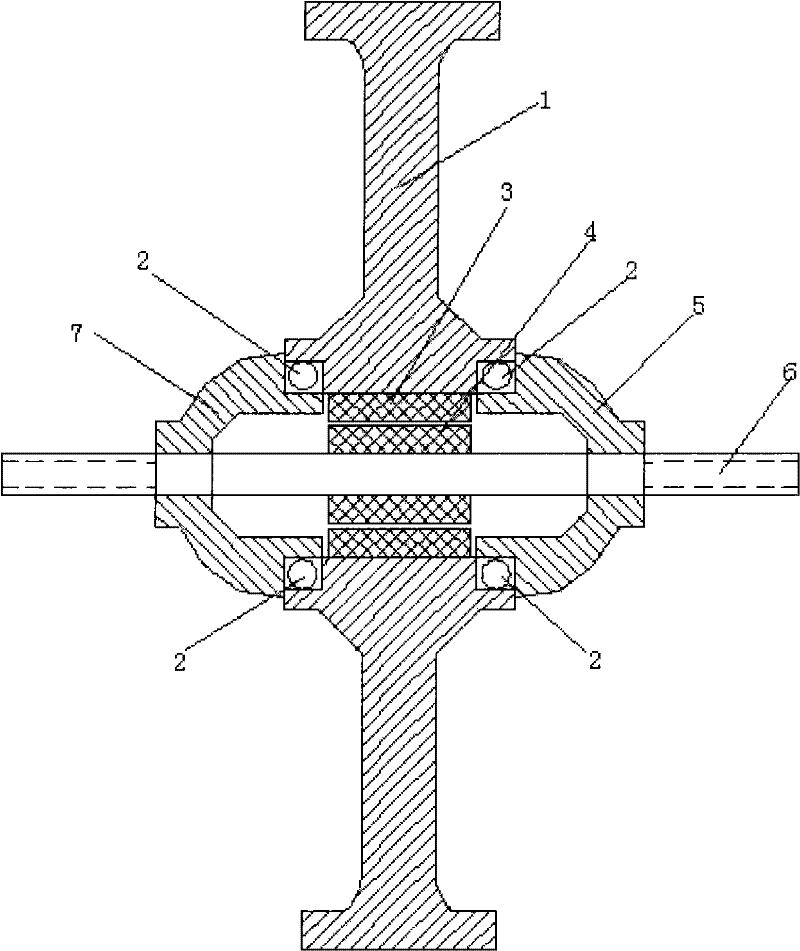

[0015] exist figure 1 , figure 2 In , the two-dimensional integrated model of the rear wheel is composed of the hub 1 and the left and right two motors with the same structure. The casing parts of the left and right motors are combined with the steel balls 2 to form a rolling sliding fit; the motor rotor shaft 10 is a hollow shaft, and the two-machine positioning fixed shaft 8 passes through the inner hole of the rotor shaft, and the two form a rolling sliding fit. The rotor shafts 9 and 13 are contact sliding parts. When the right motor is energized and working, the motor stator 5 generates an electromagnetic field, and the attractive force of the magnetic field moves the position of the motor rotor 6 to the left, so that the rotor shaft drive gear 11 and the hub drive gear 3 are closed. And drive the hub. When the left motor was energized, the left motor rotor shaft gear and the hub gear closed to drive the hub, and the right motor clutch spring 14 made the rotor move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com