Patents

Literature

34results about How to "Small axial length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

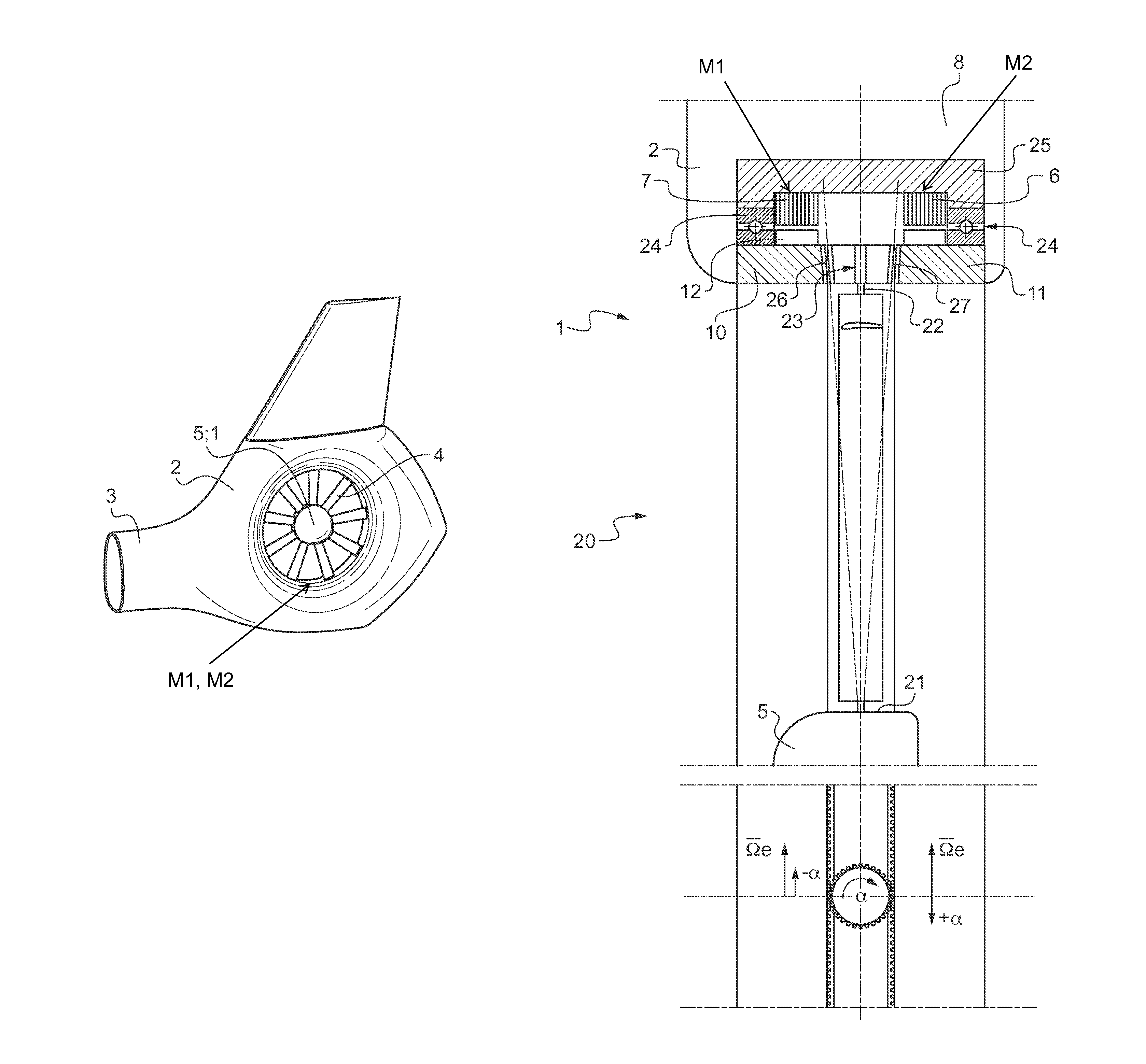

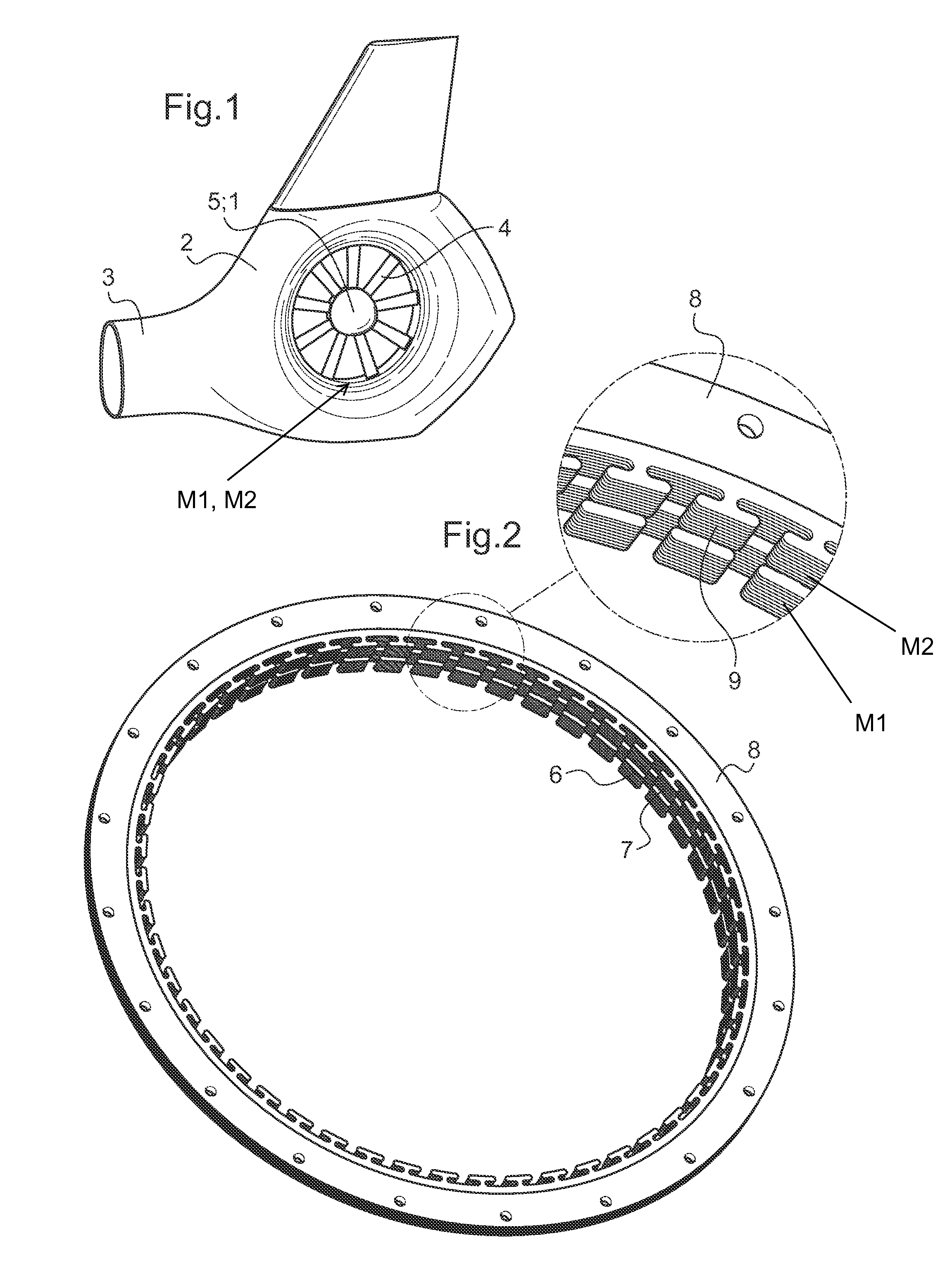

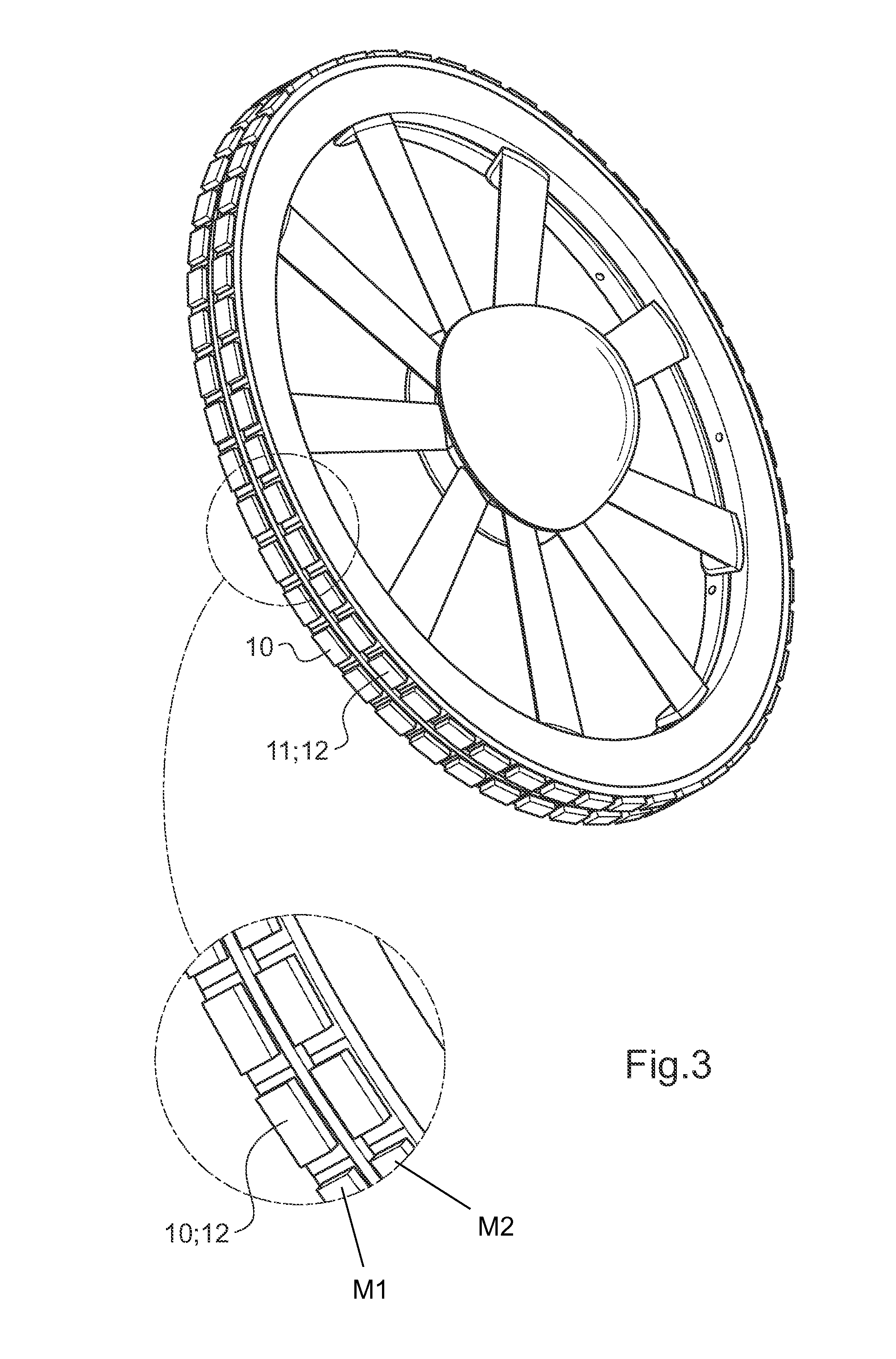

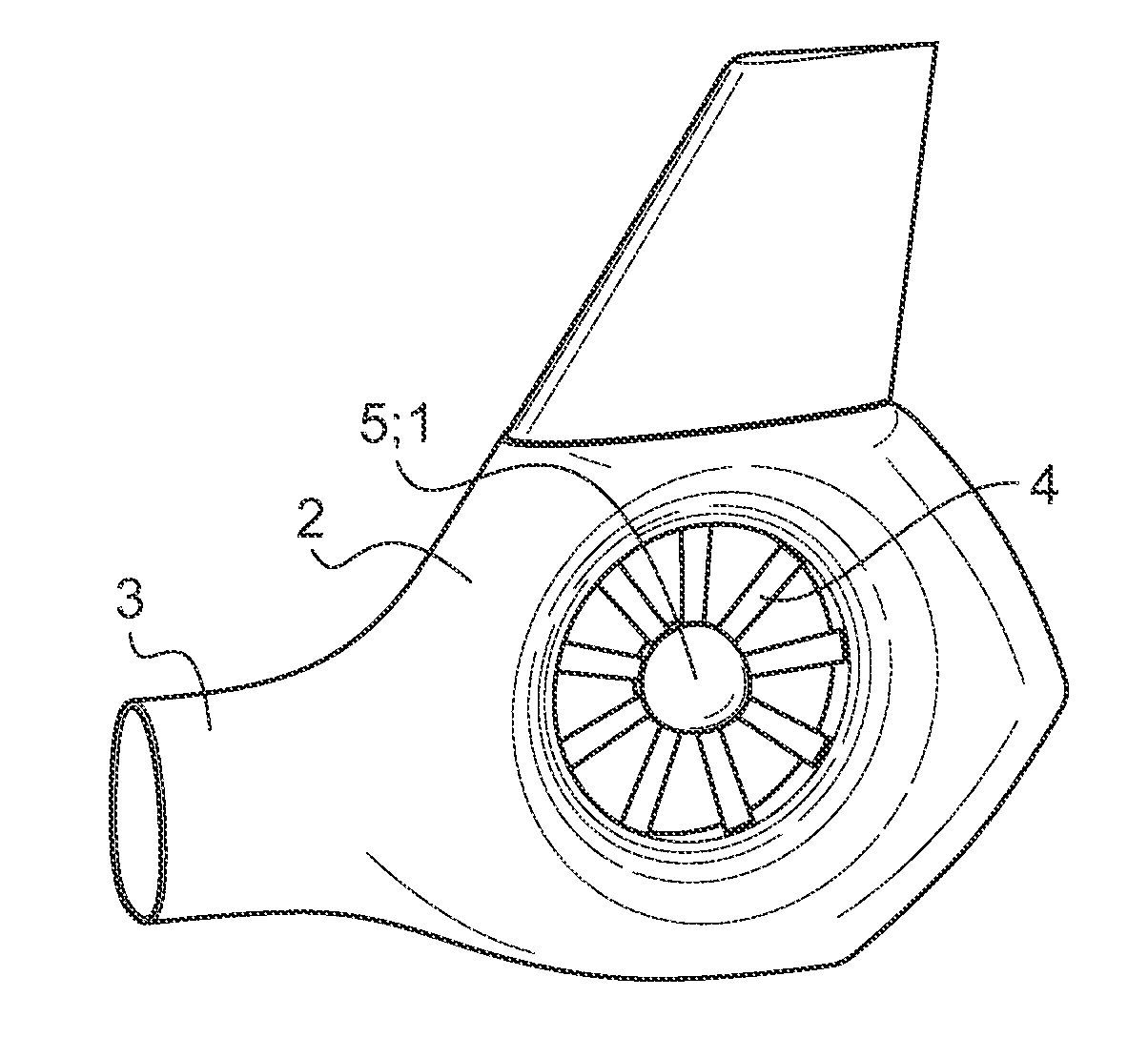

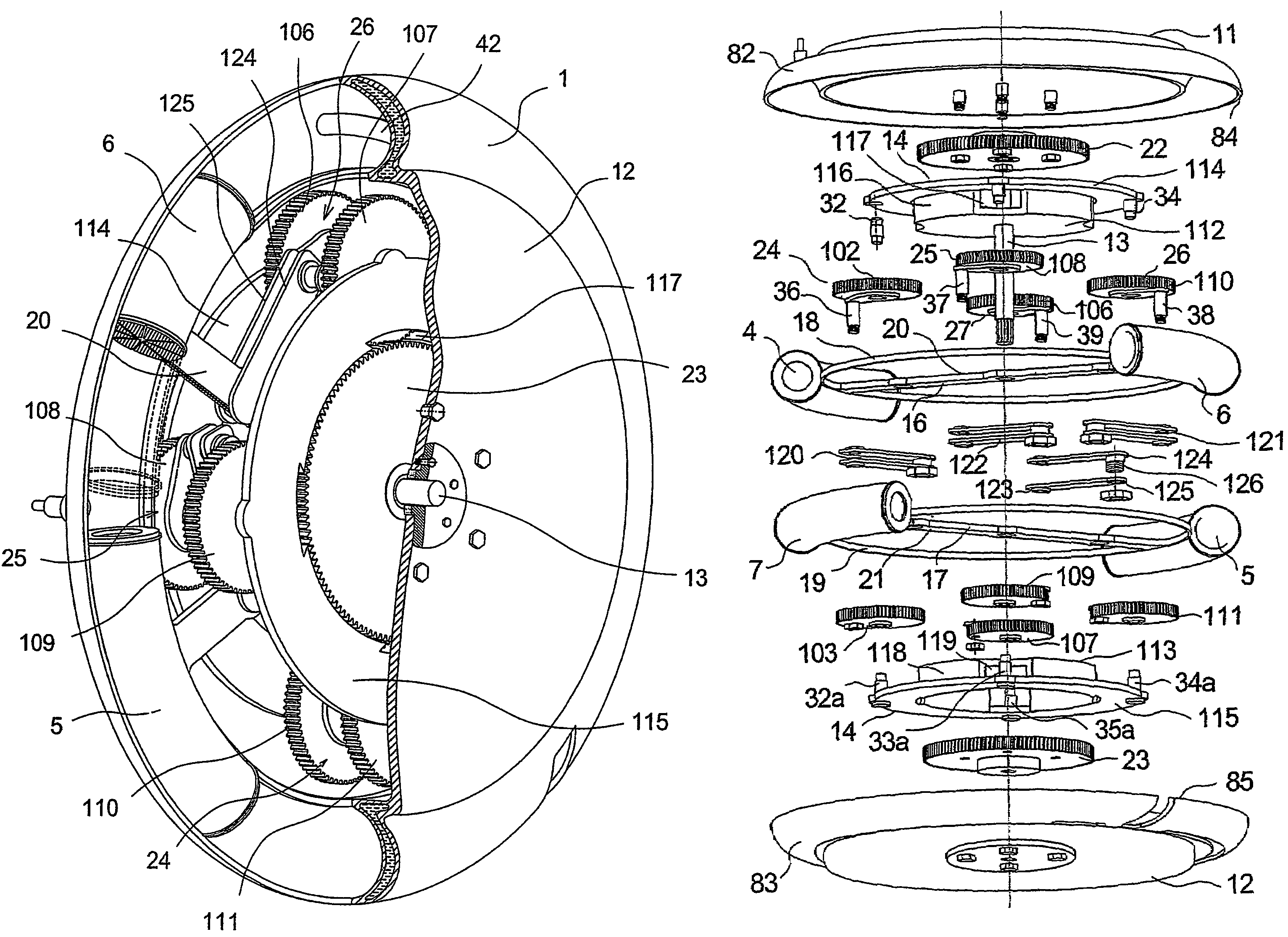

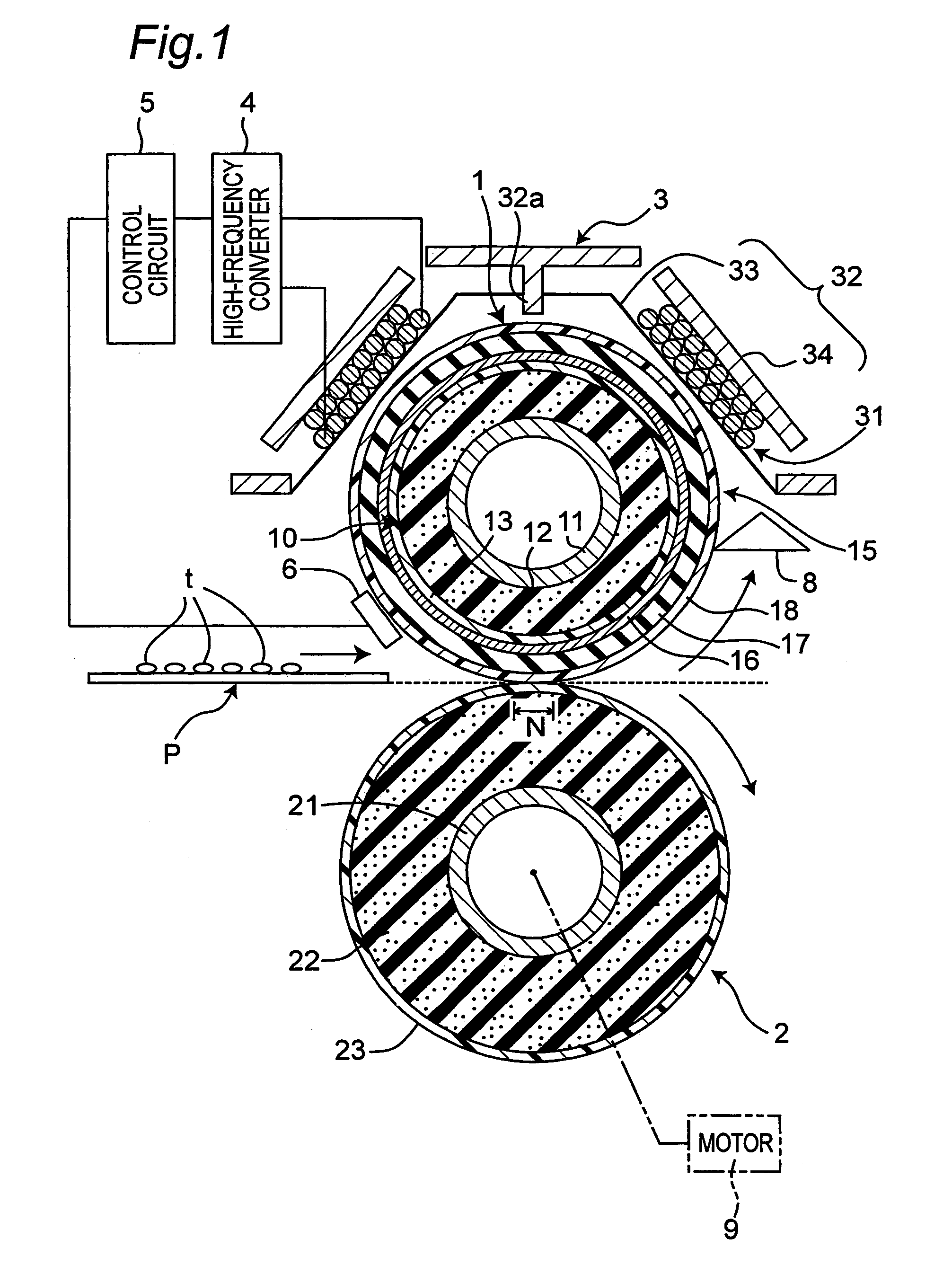

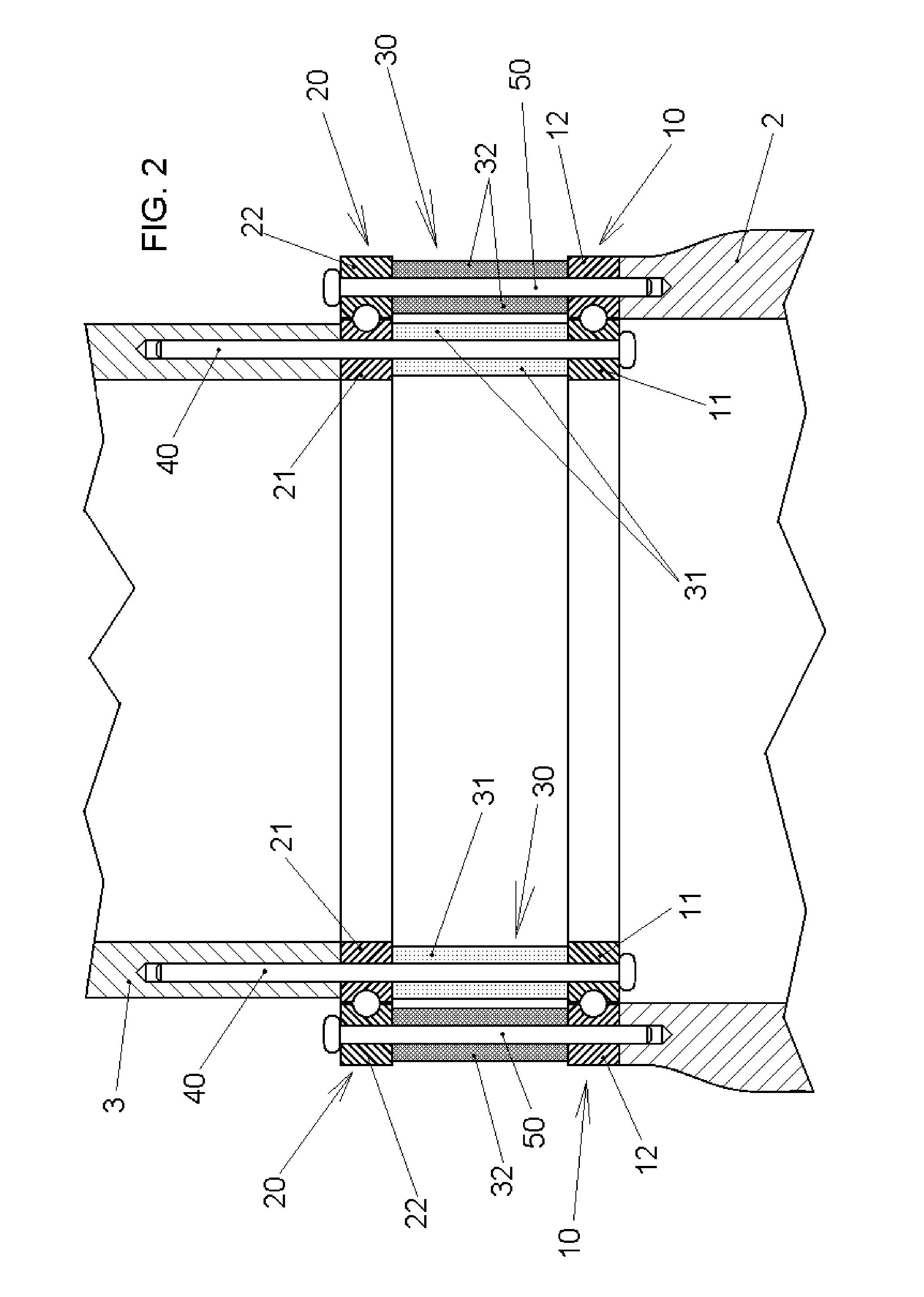

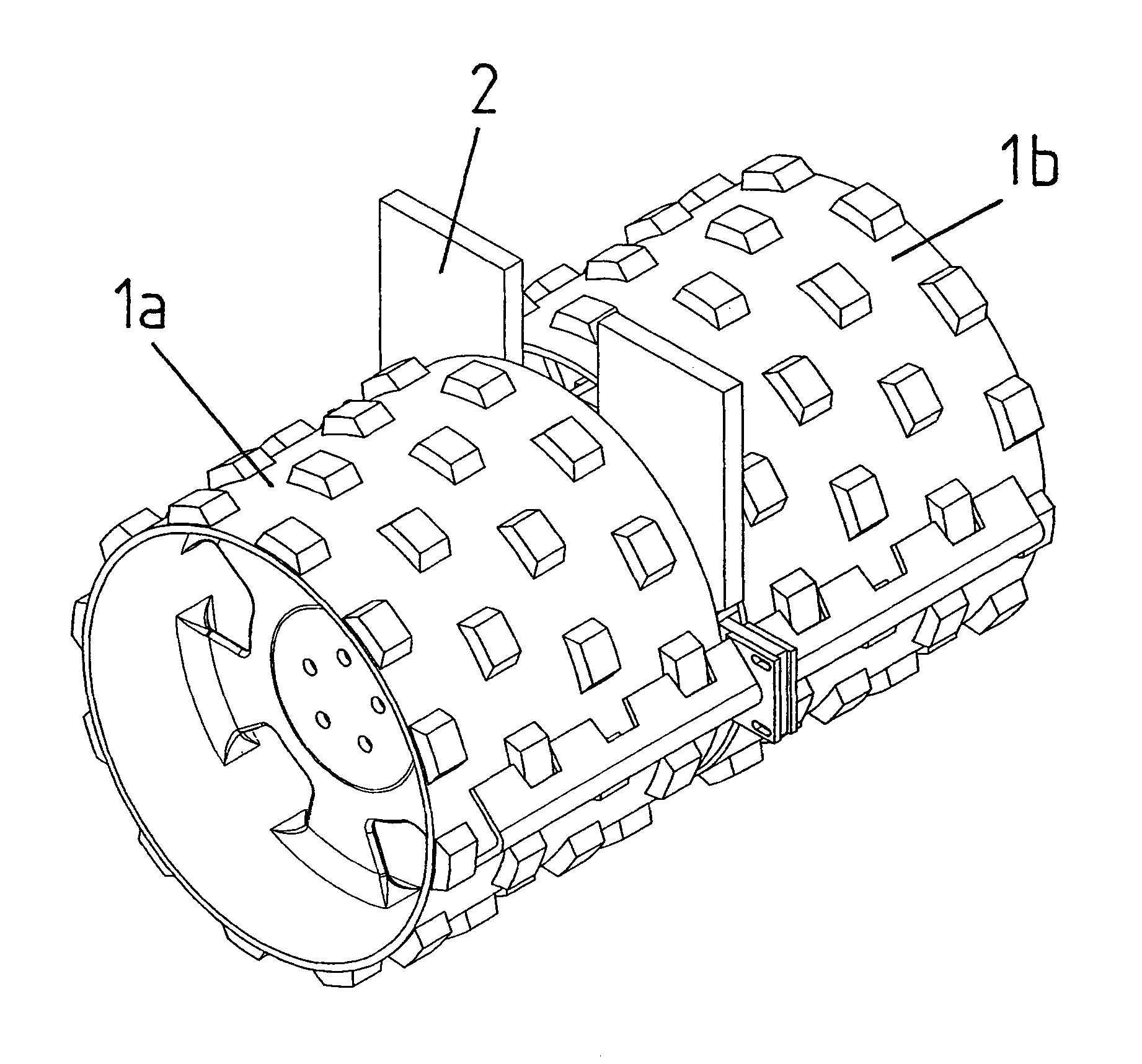

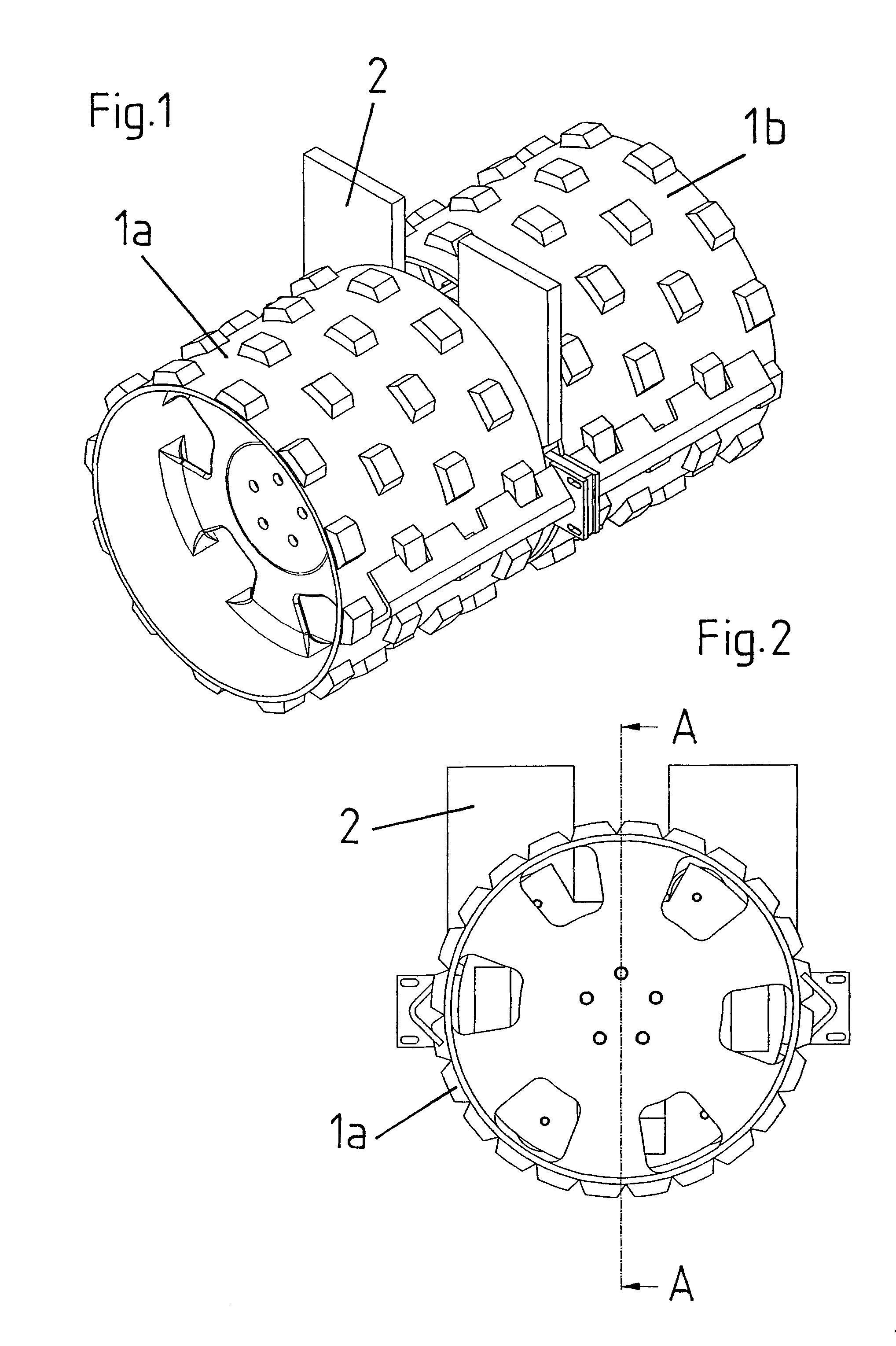

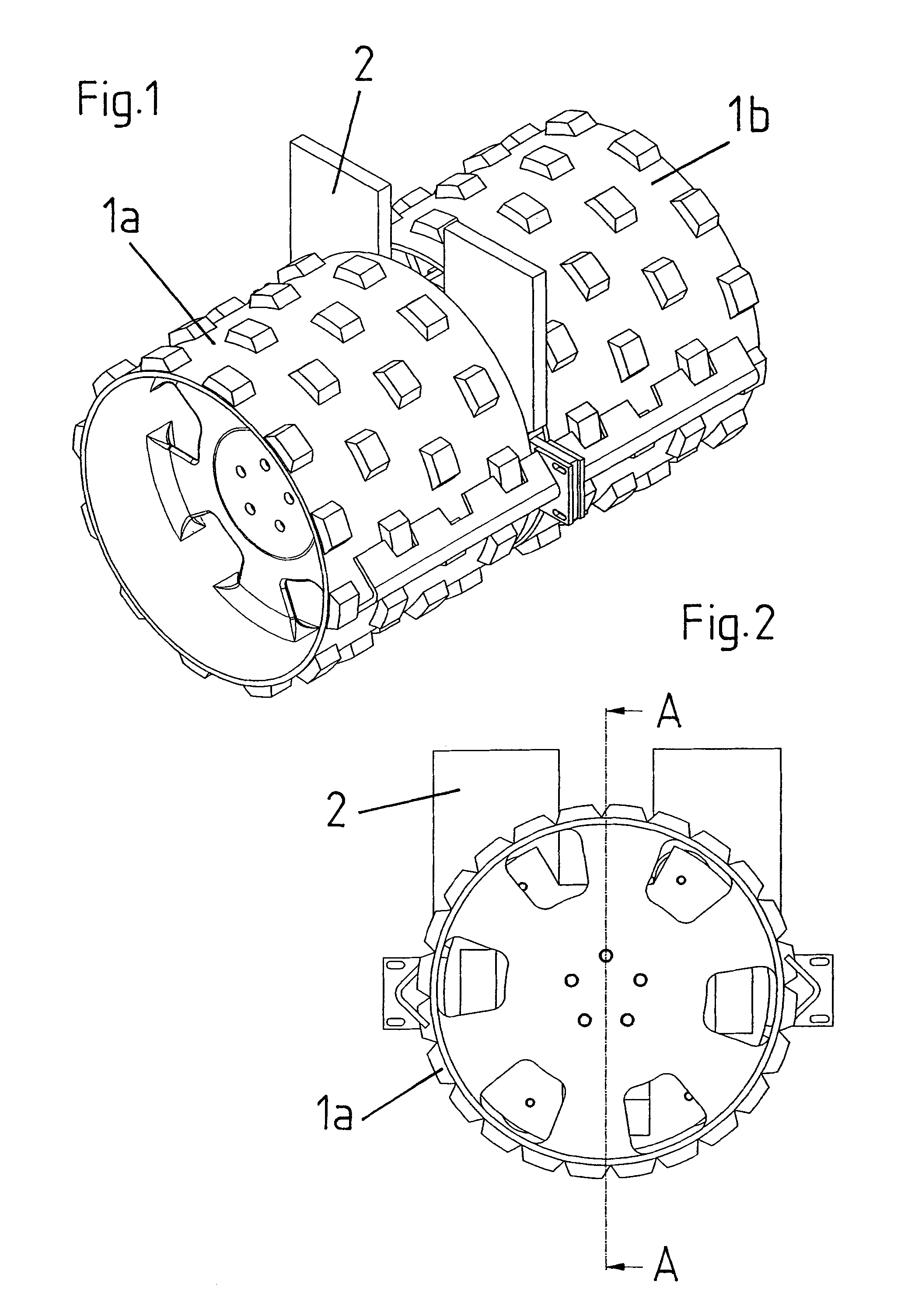

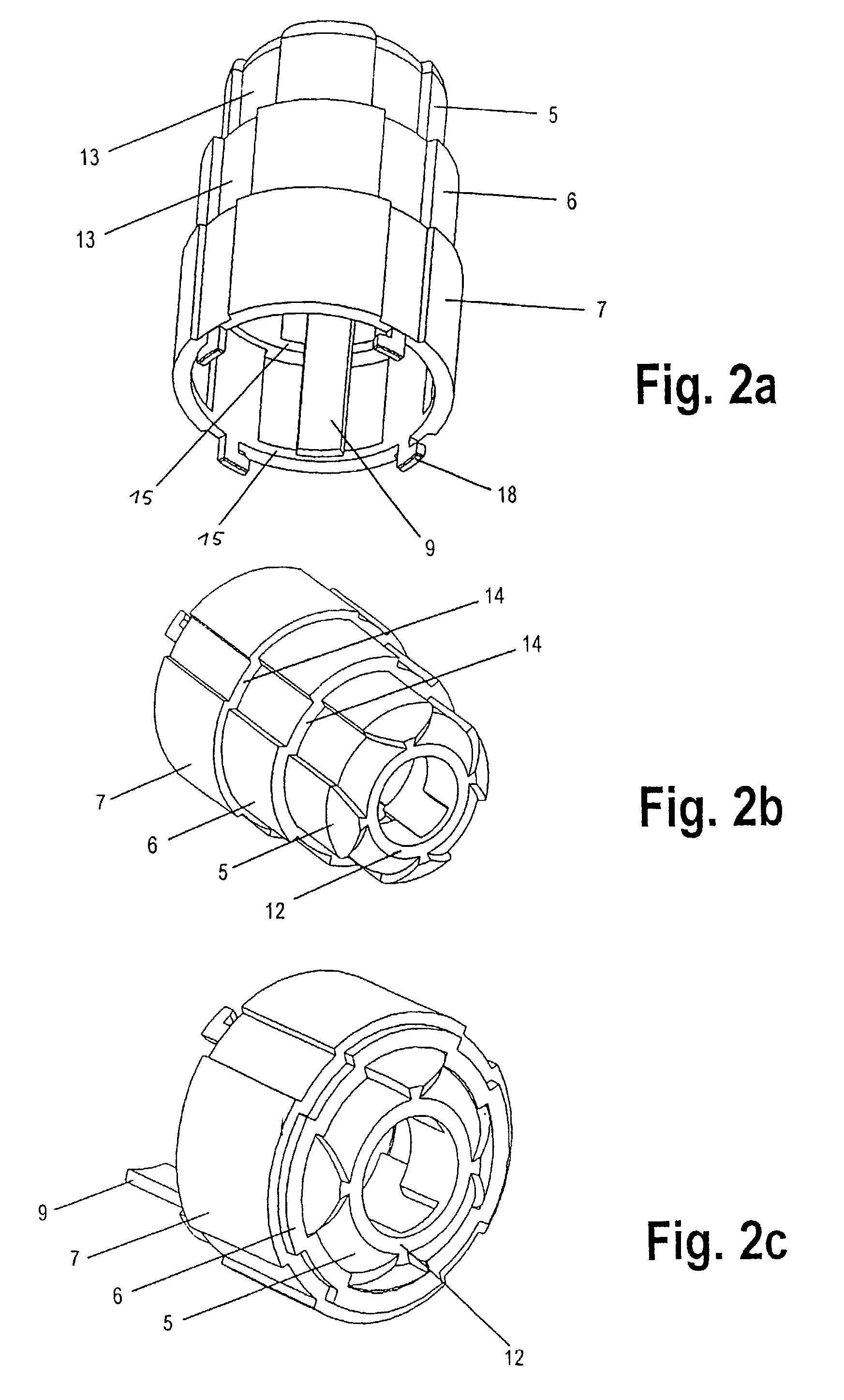

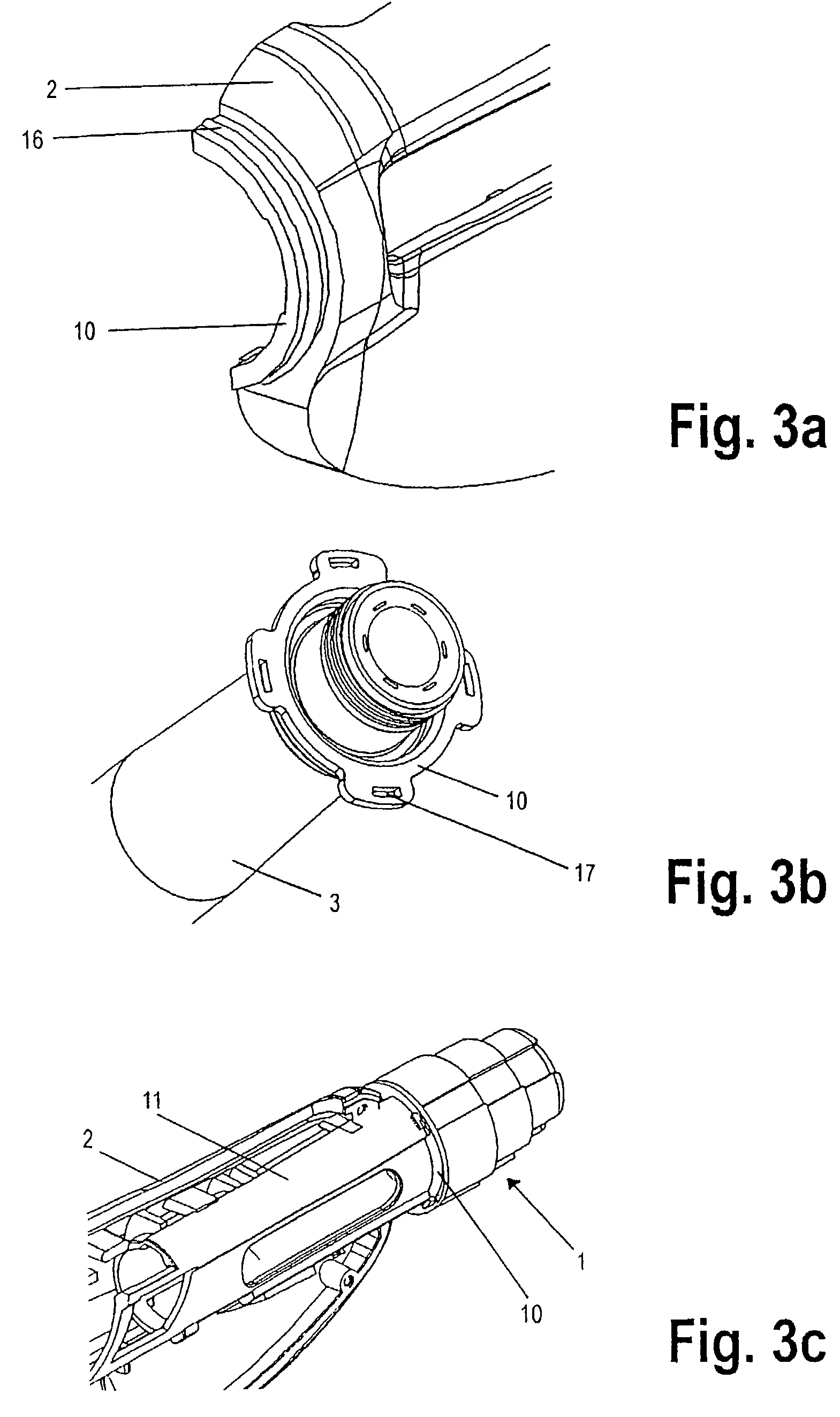

Electrical powered tail rotor of a helicopter

ActiveUS9174728B2Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

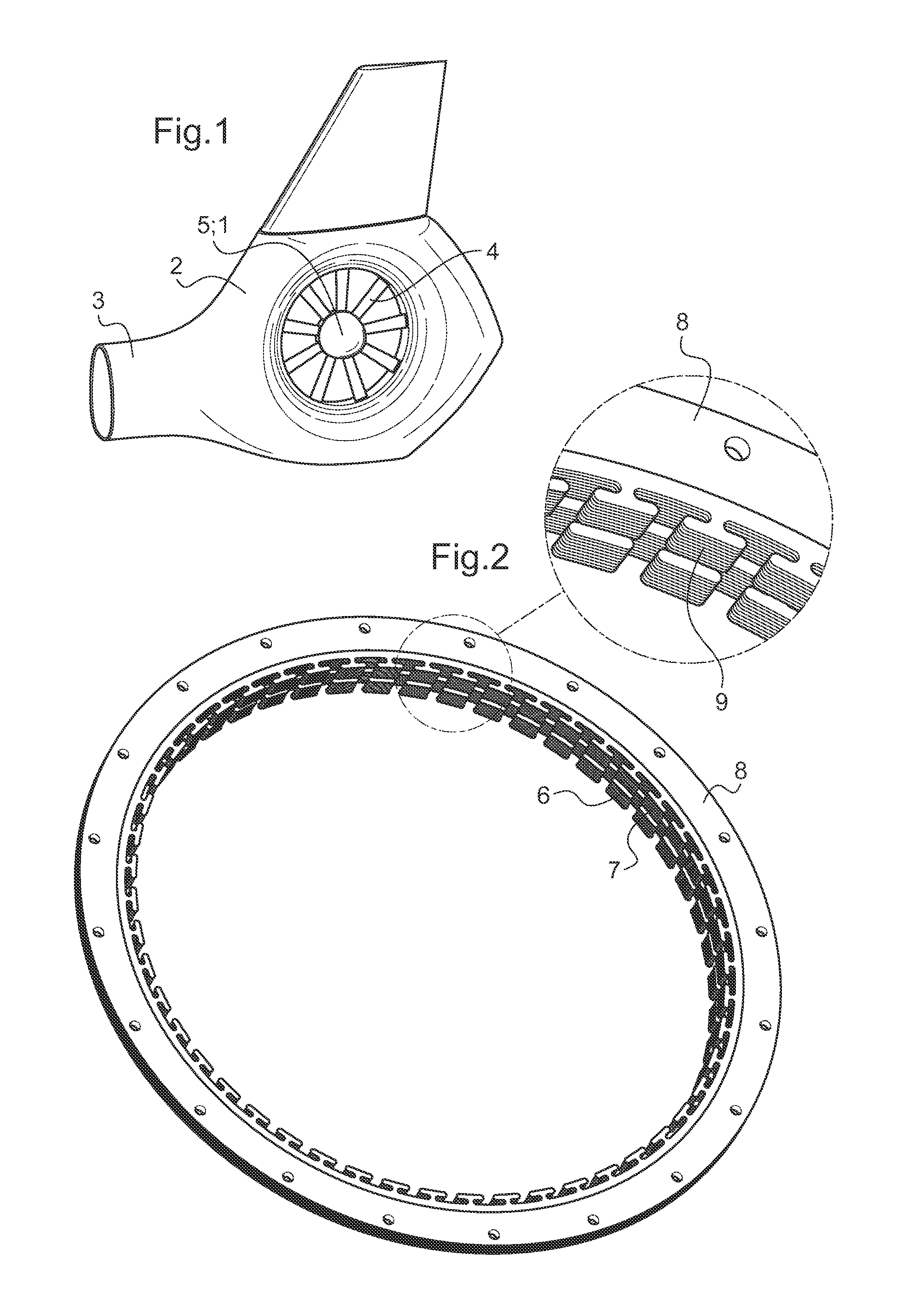

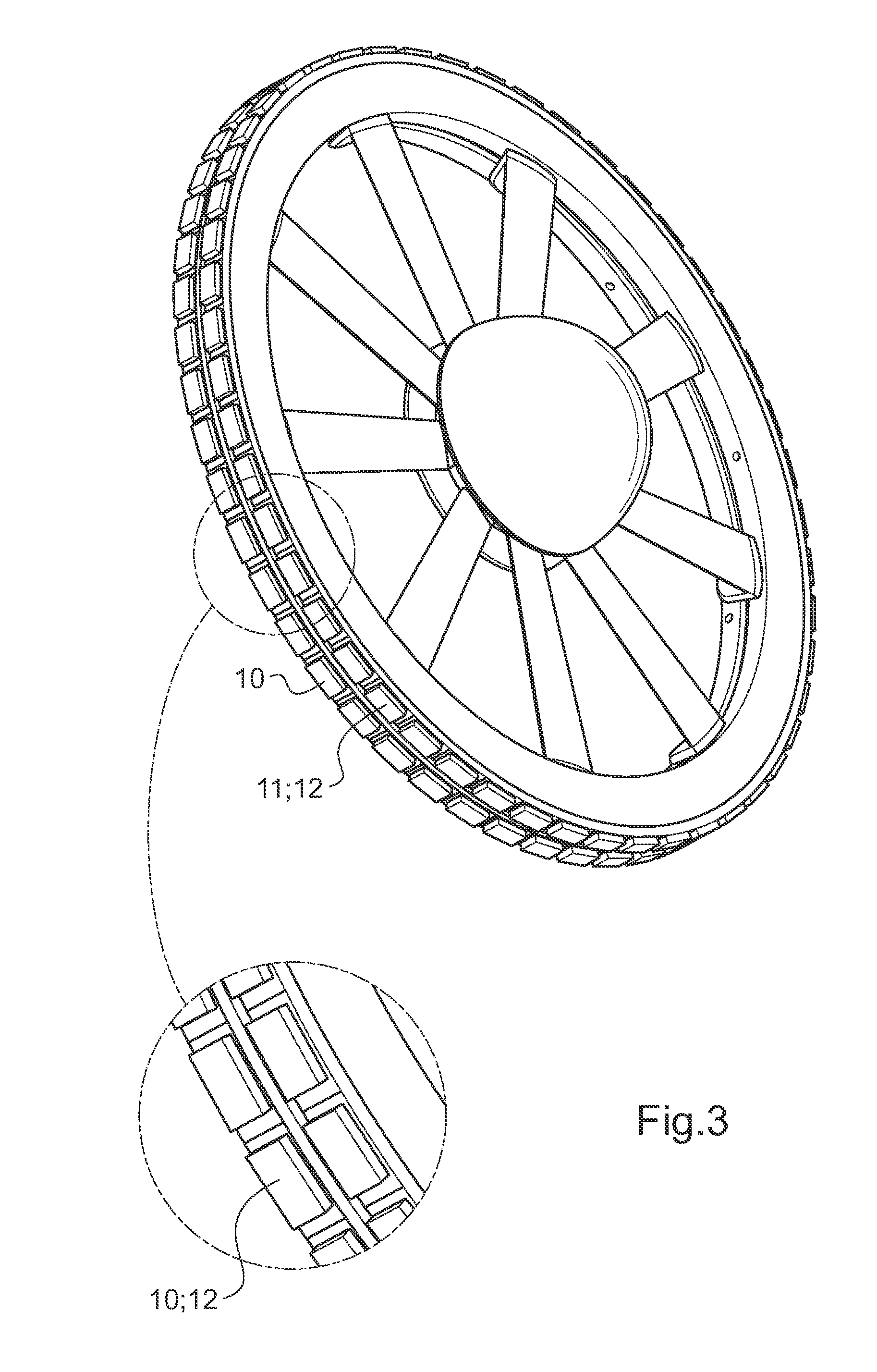

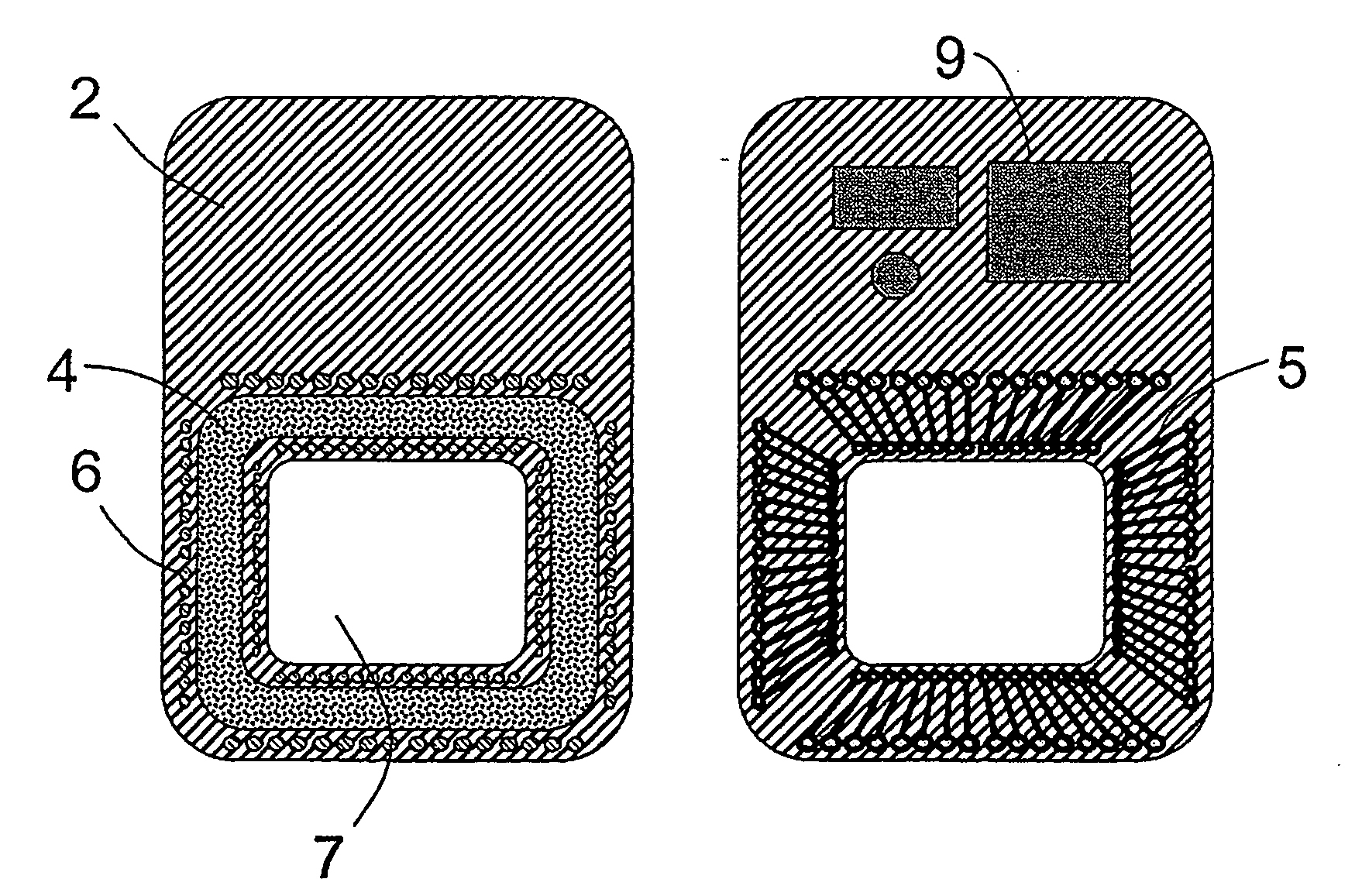

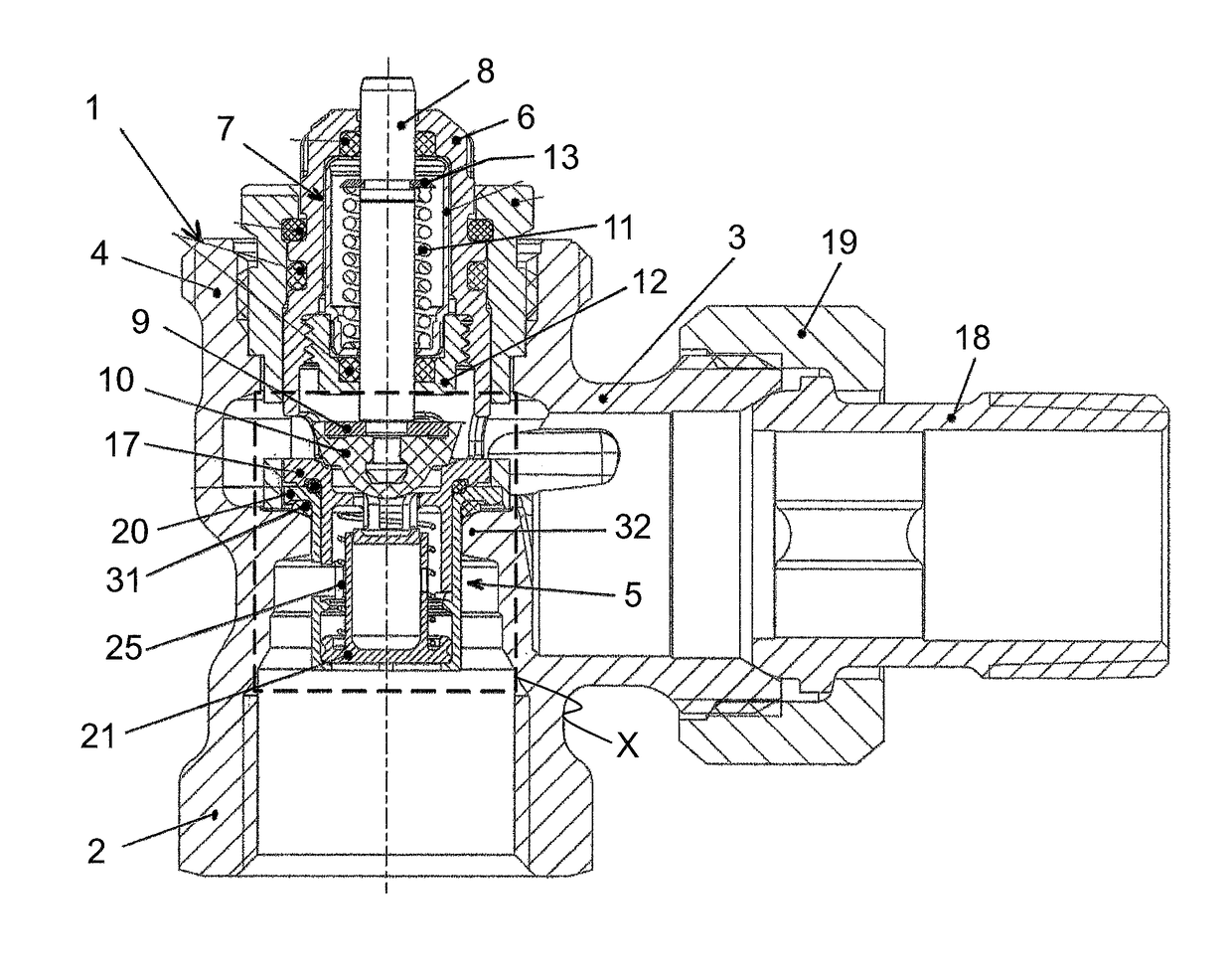

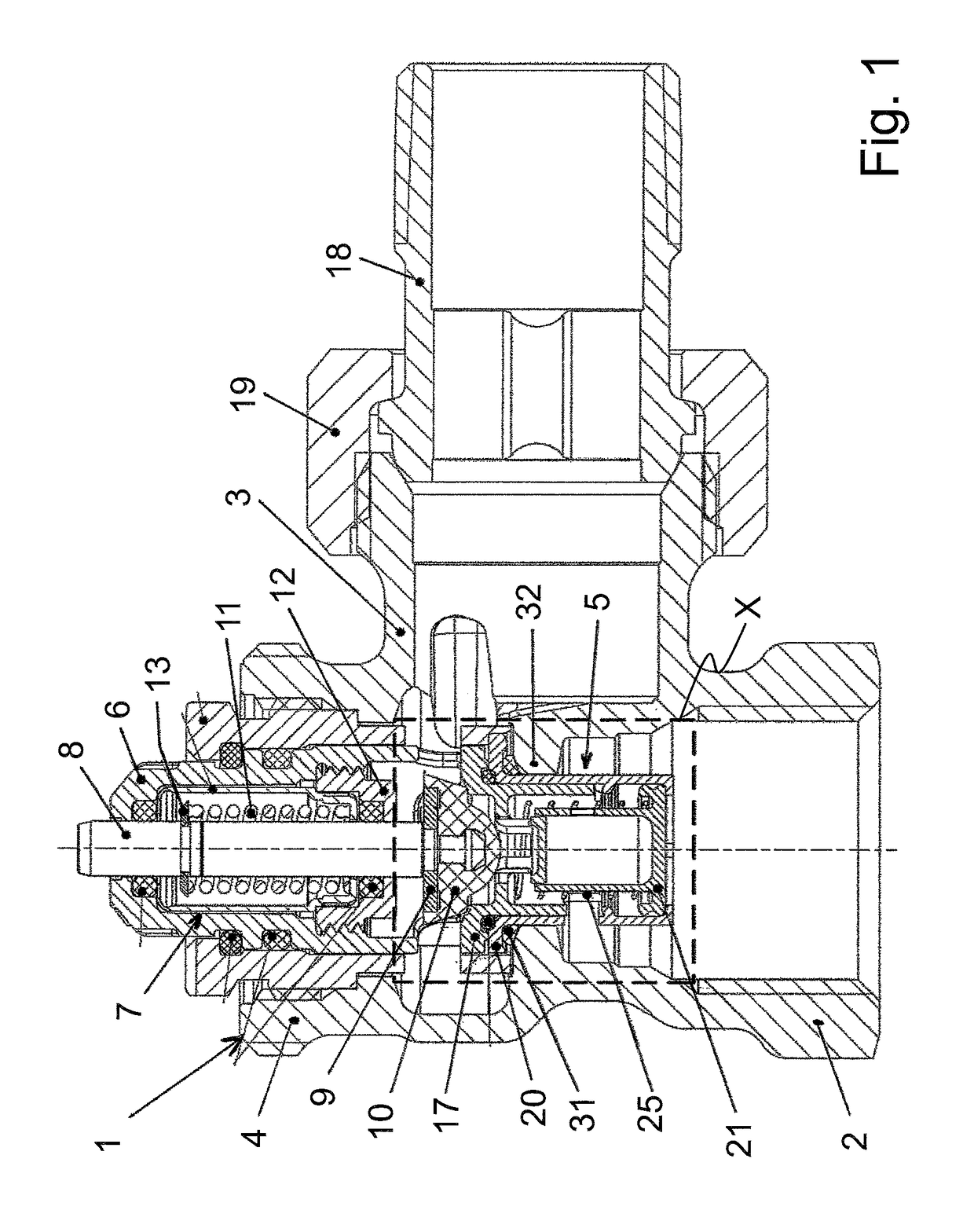

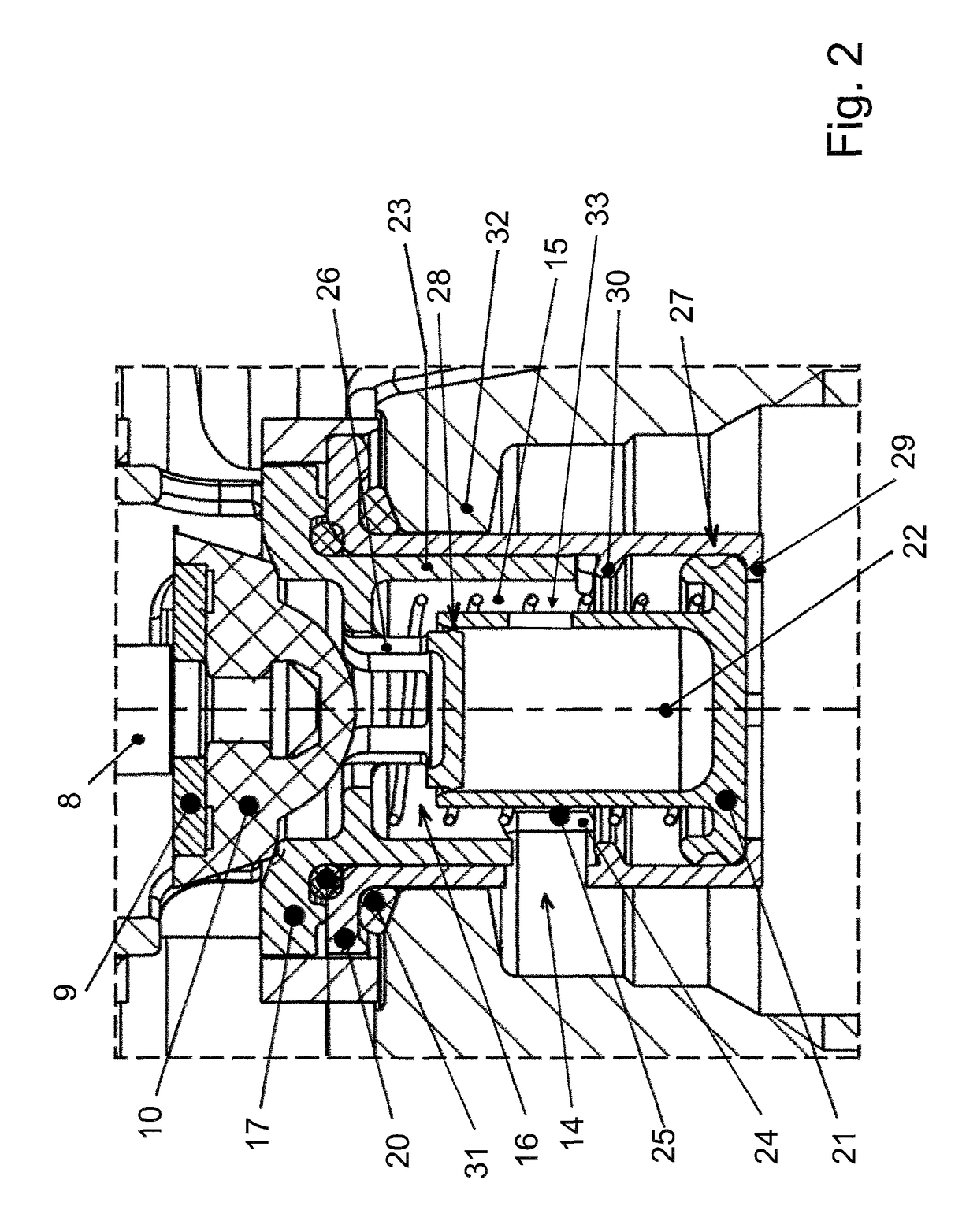

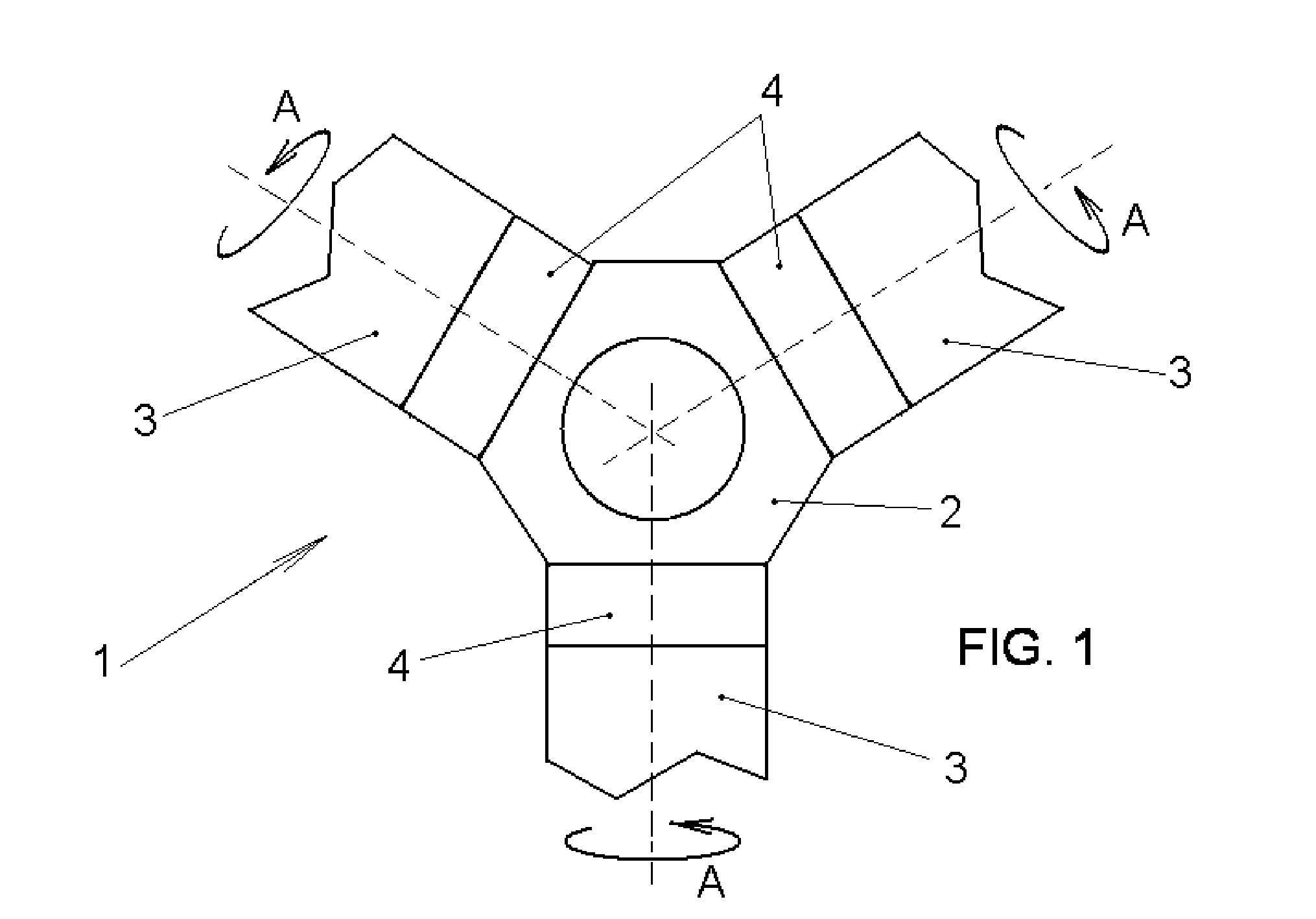

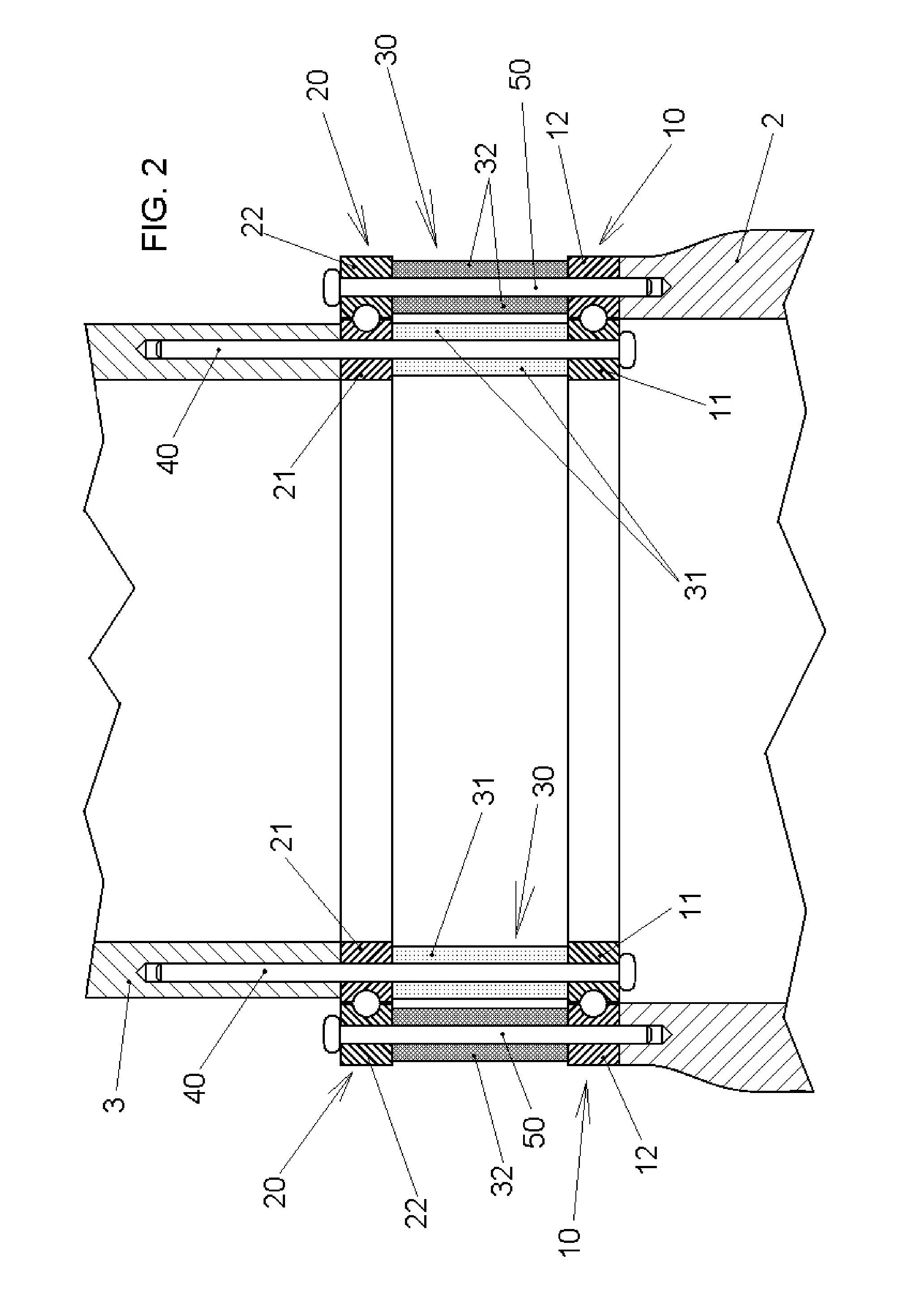

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

Electrical powered tail rotor of a helicopter

ActiveUS20130170985A1Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

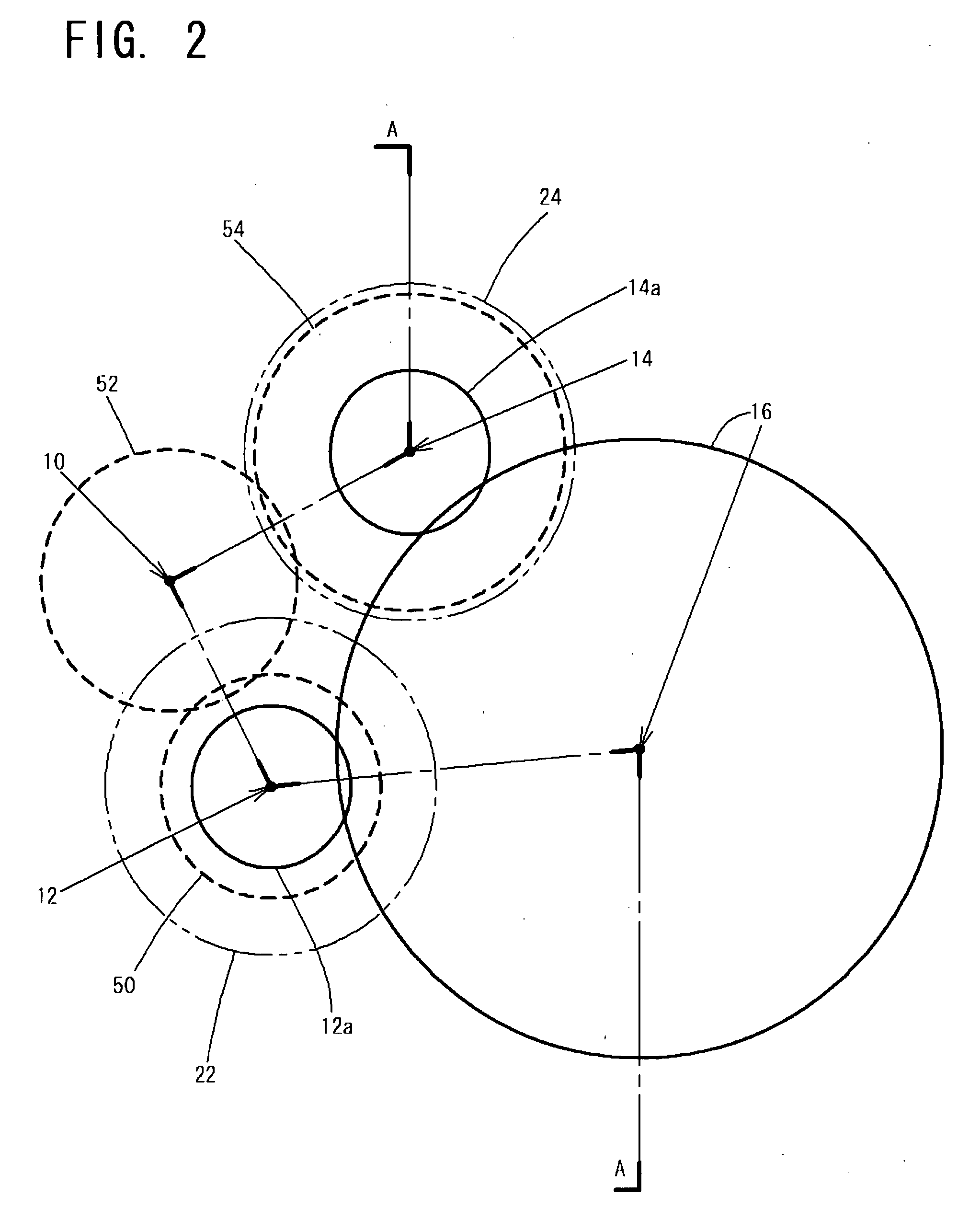

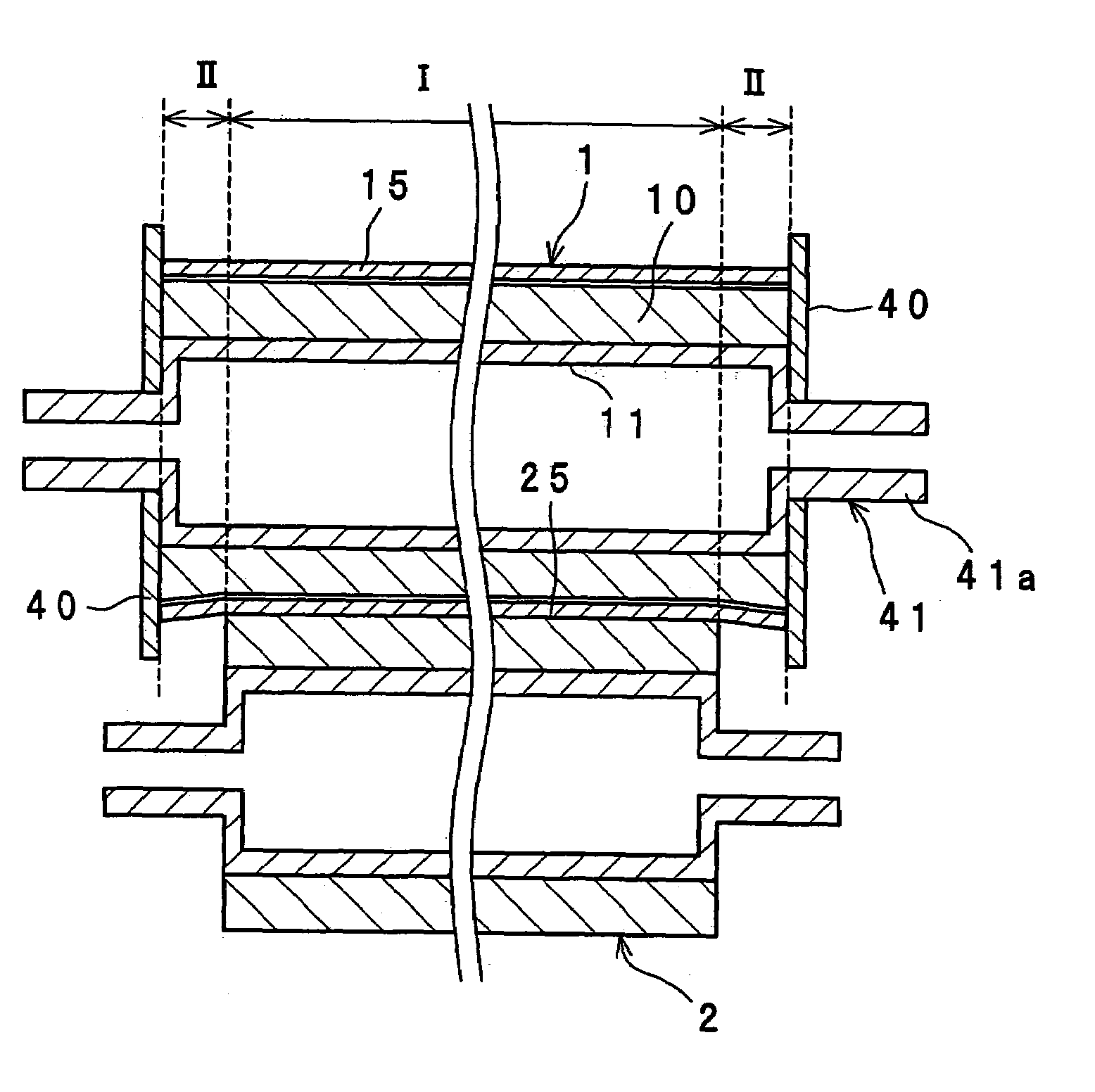

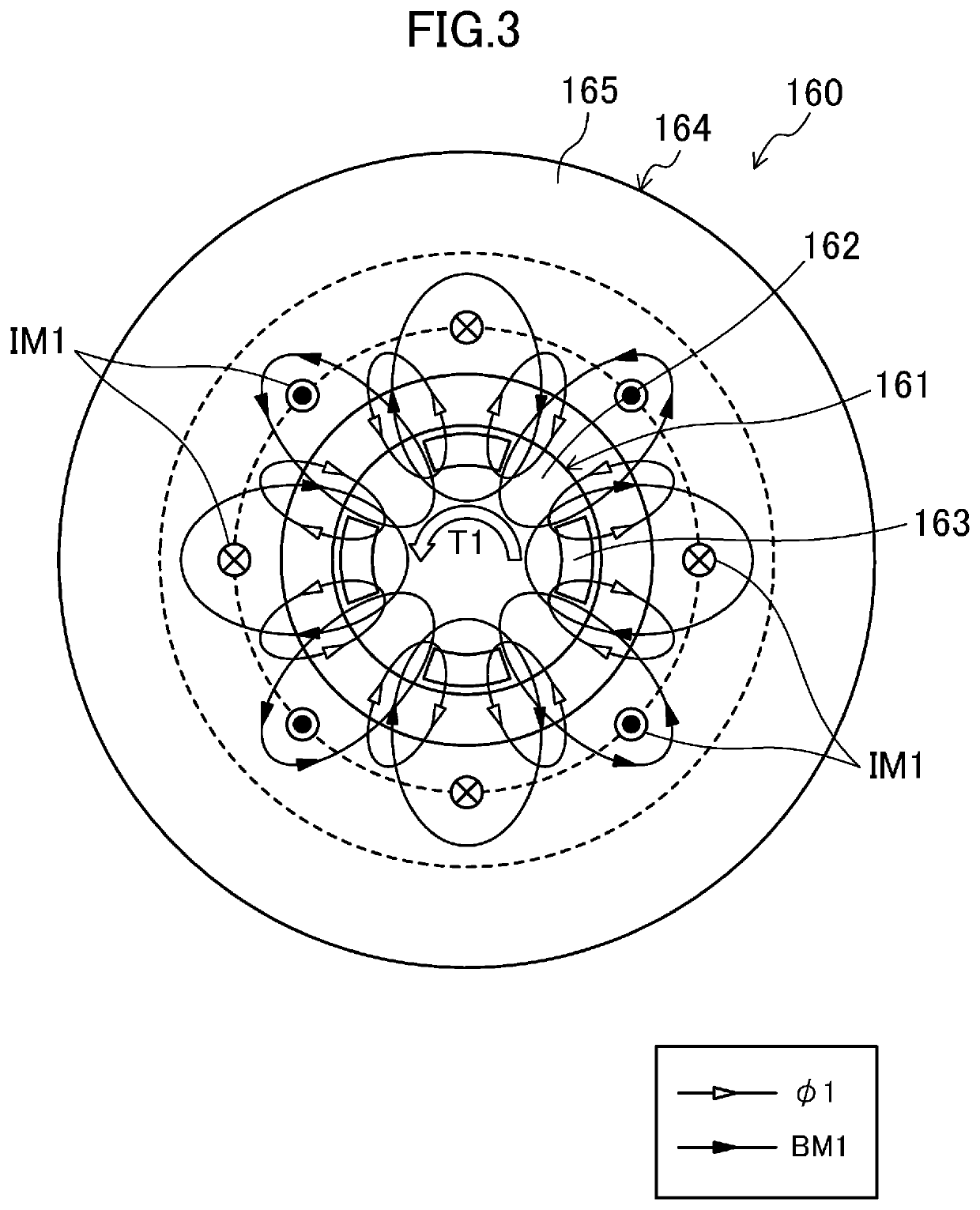

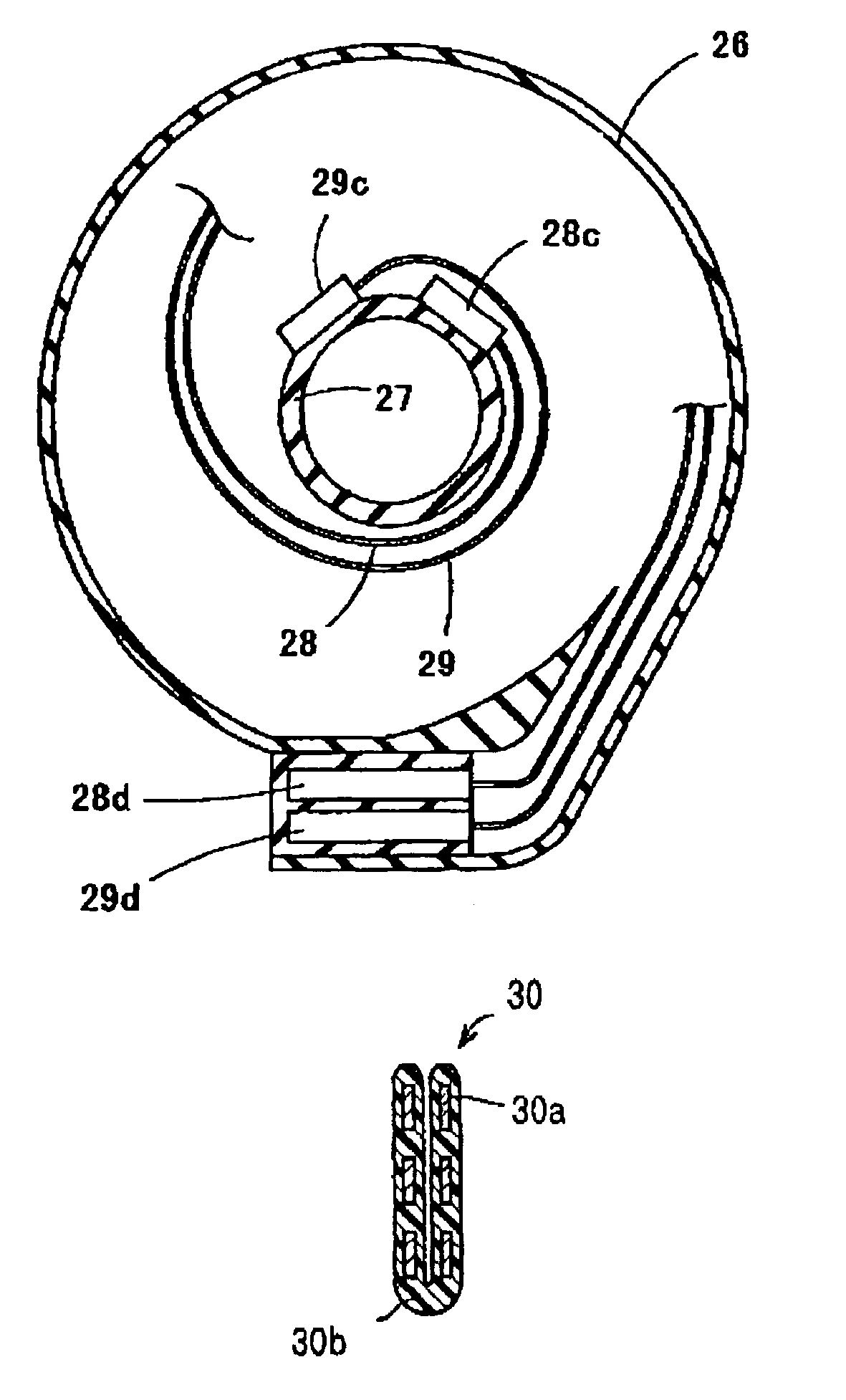

Inductive conductivity sensor

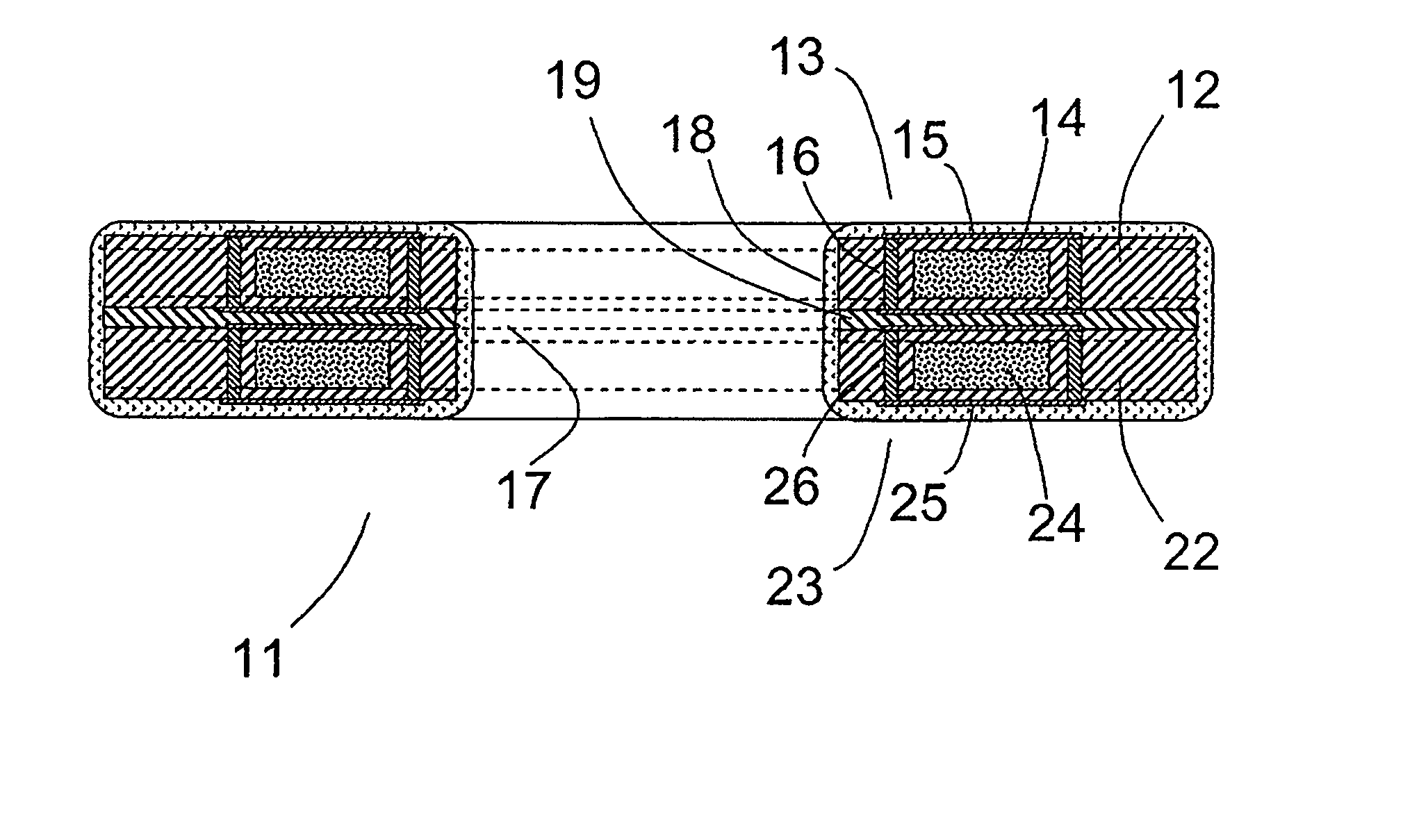

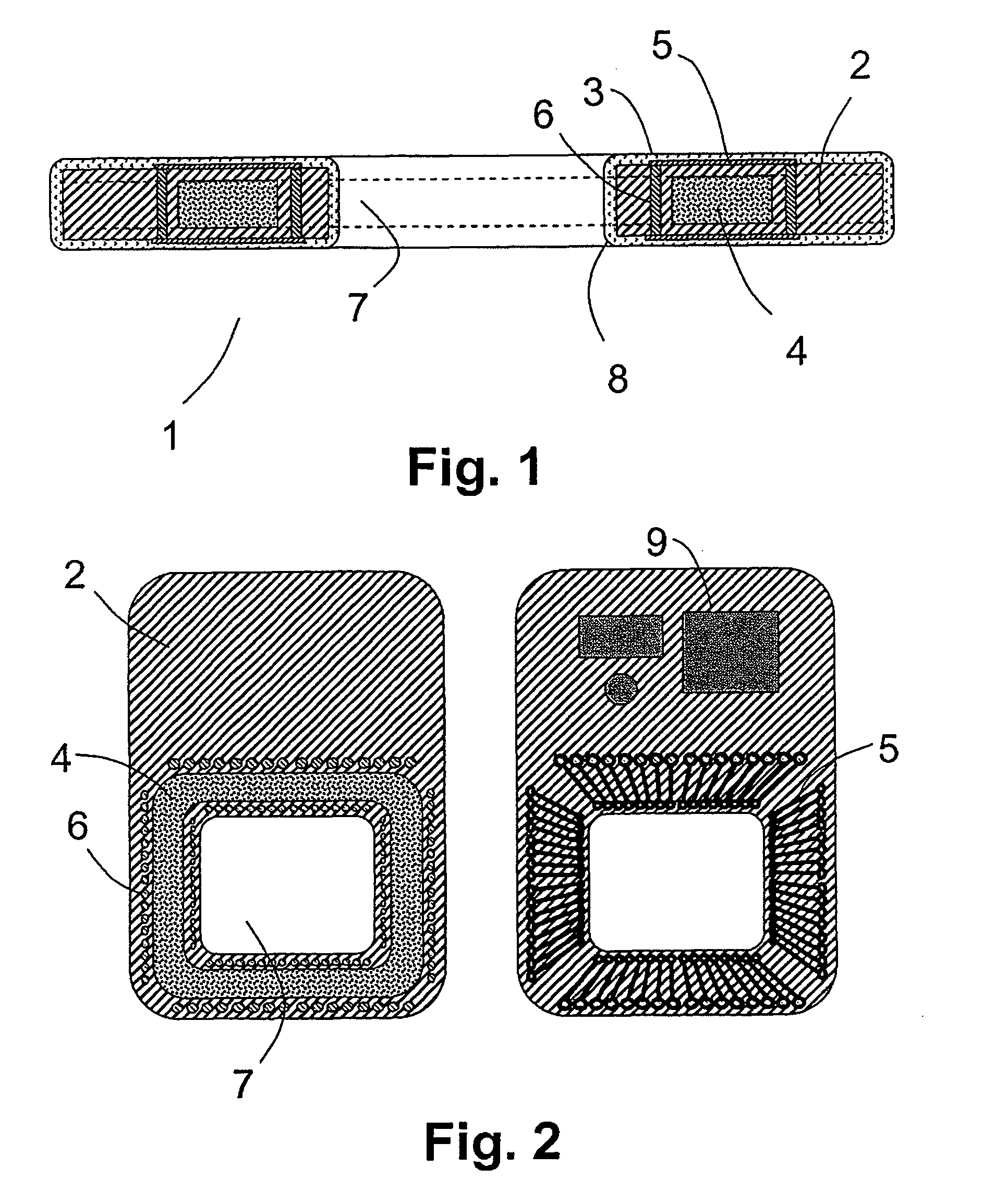

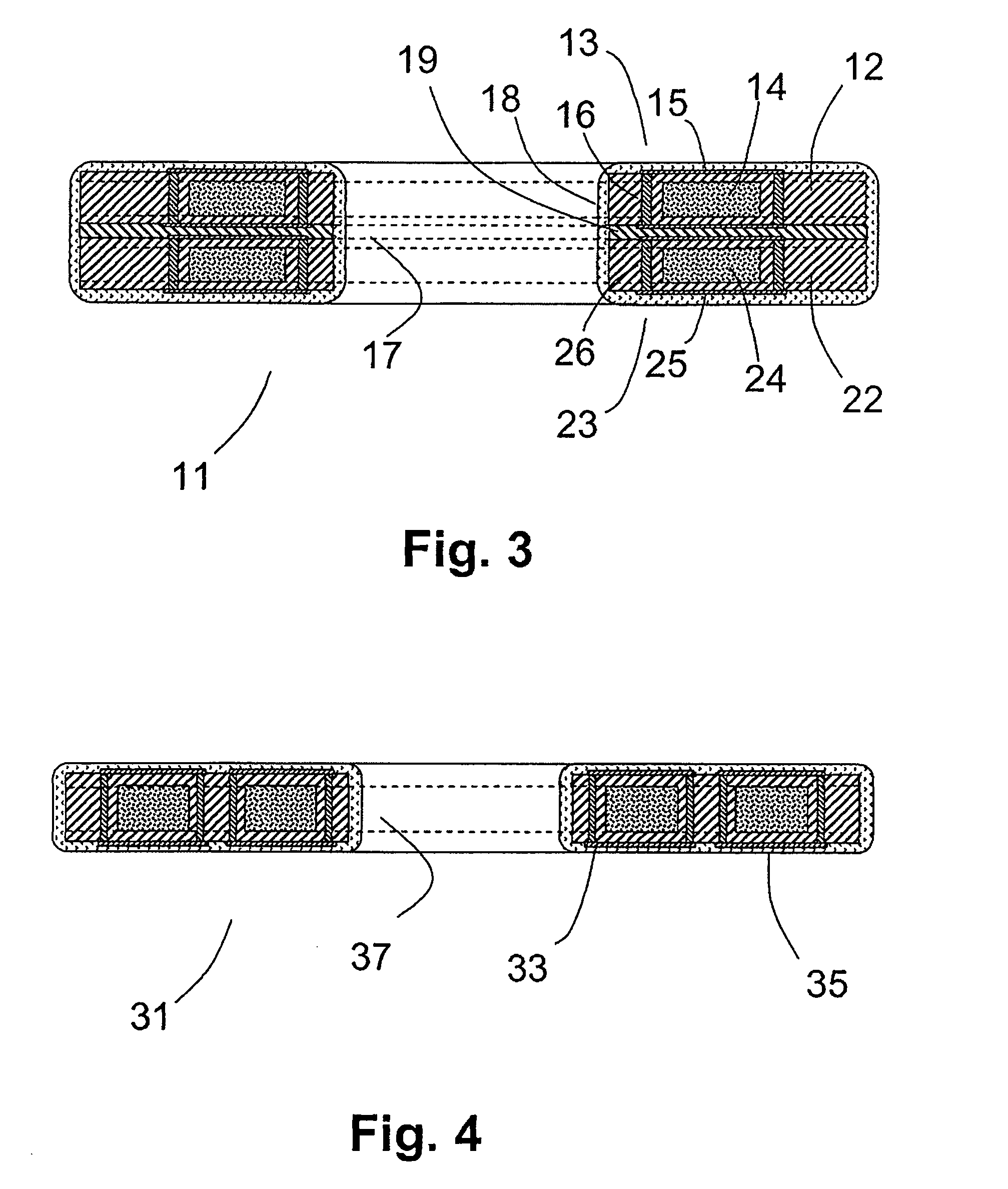

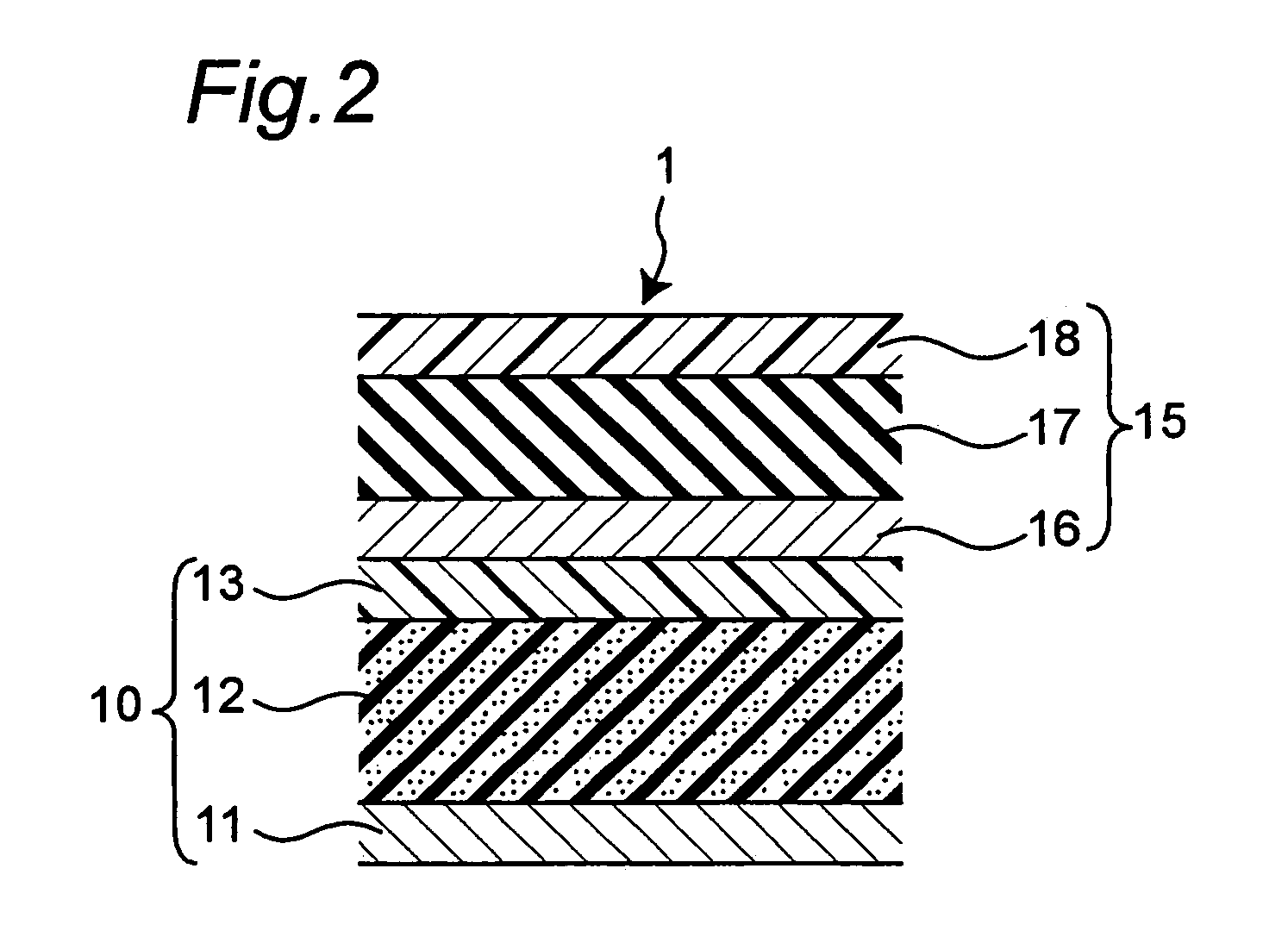

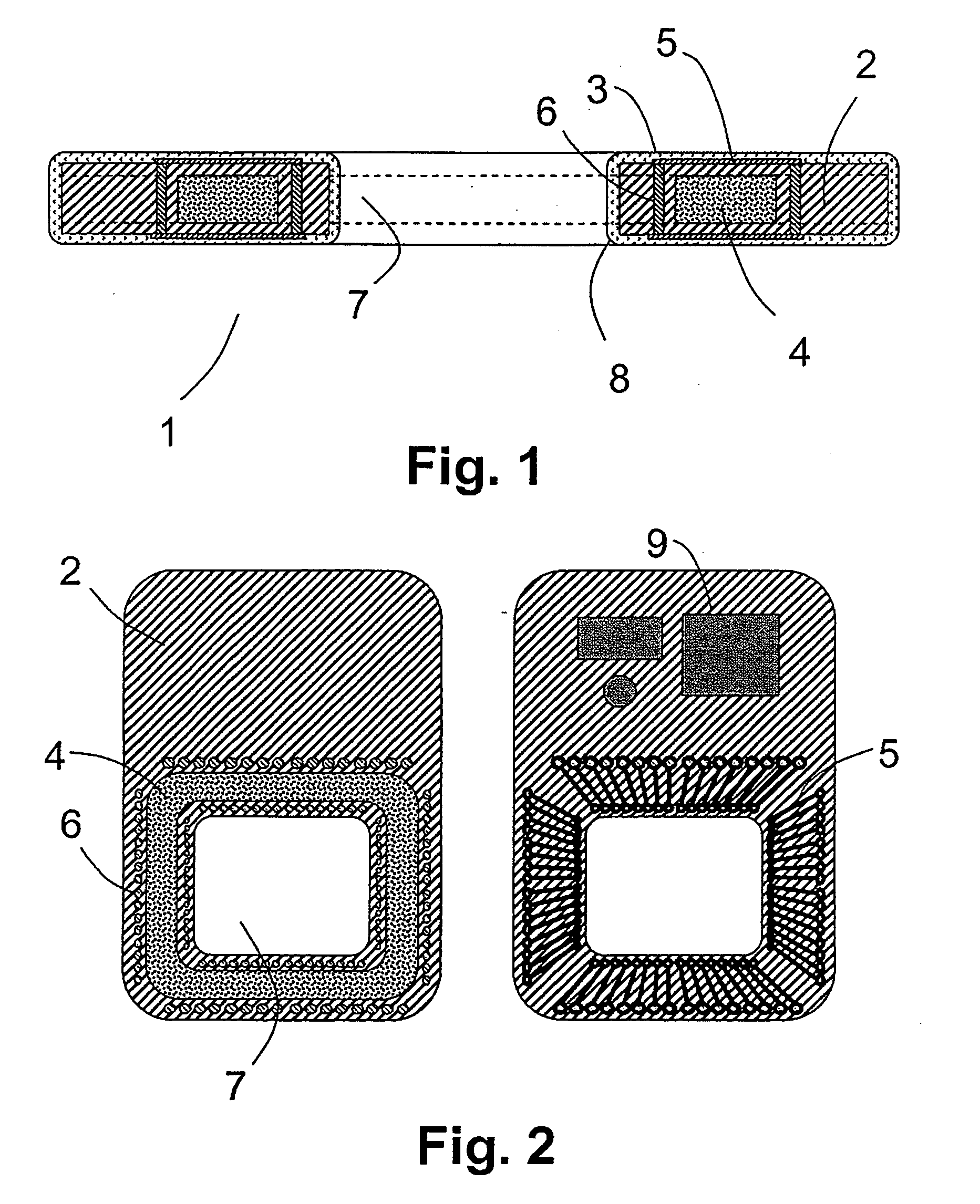

InactiveUS7965167B2Small axial lengthEasy to processTransformers/inductances coils/windings/connectionsMaterial impedanceElectrical conductorToroidal coil

A conductivity sensor for measuring conductivity of a medium surrounding the conductivity sensor includes a first toroidal coil bounding a medium-receiving passageway and serving for inducing an electrical current in the medium, and a second toroidal coil also bounding the passageway and serving for registering a magnetic field produced by the electrical current. At least one of the toroidal coils has a plurality of first conductor segments, which extend in a plane of a multi-ply circuit board, a plurality of second conductor segments, which extend in a second plane of the circuit board, and a plurality of through-contacts, which connect the first conductor segments with the second conductor segments, wherein the first conductor segments, the second conductor segments and the through-contacts form, together, the windings of a toroidal coil.

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

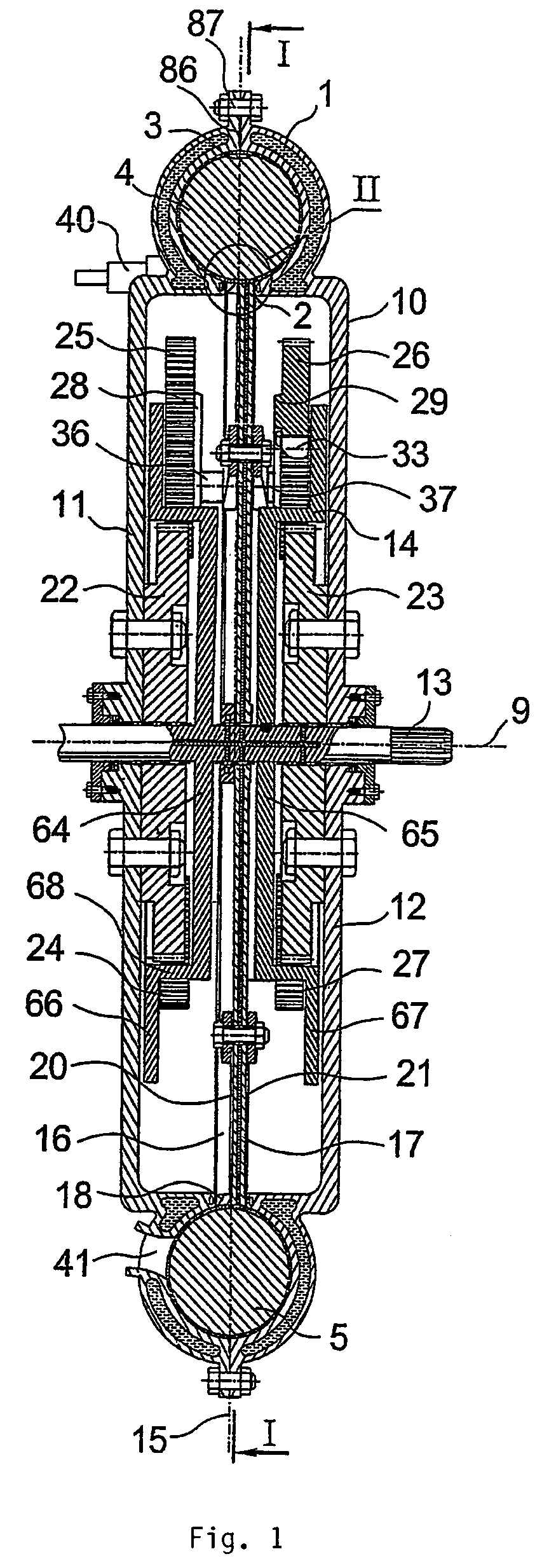

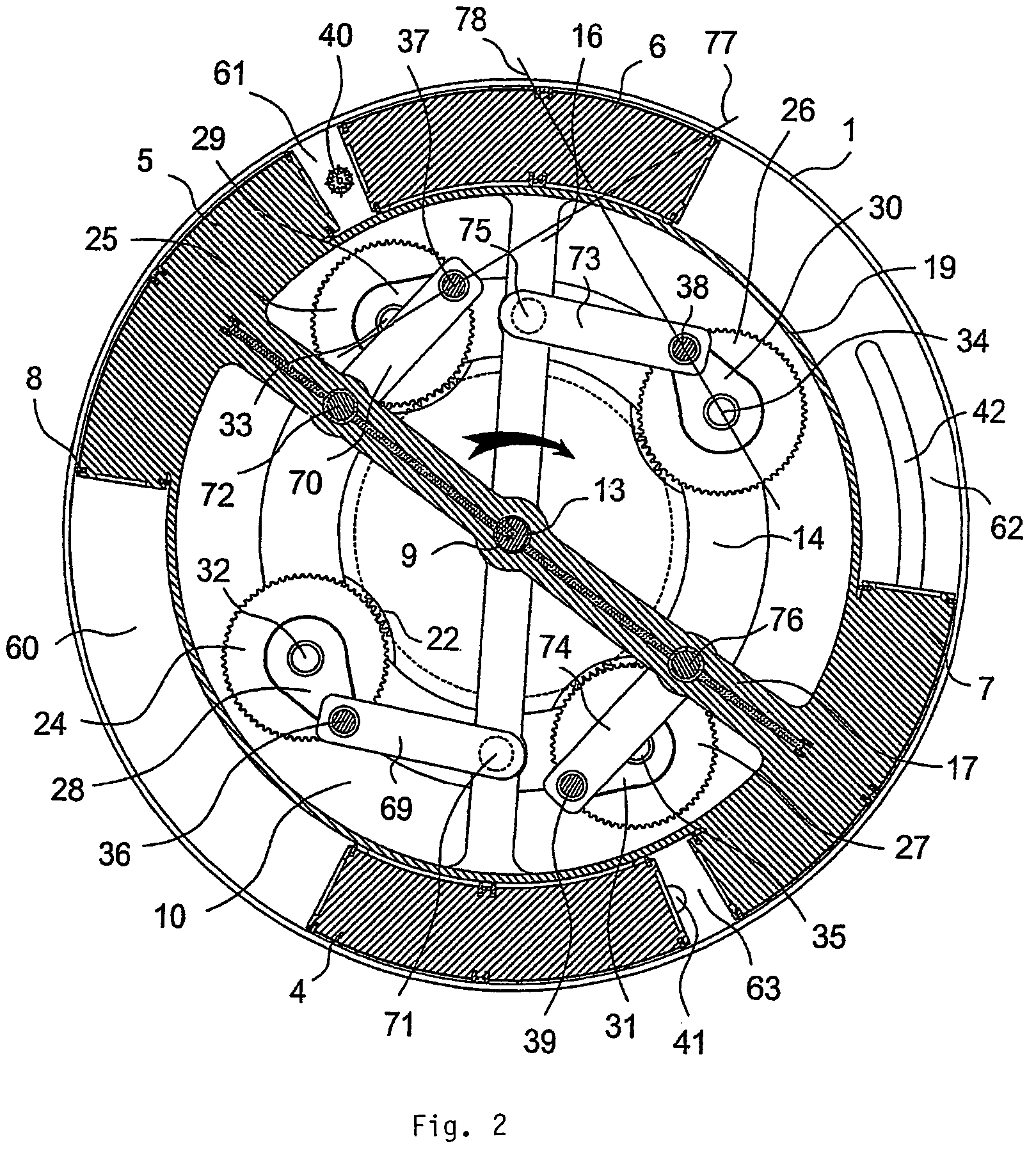

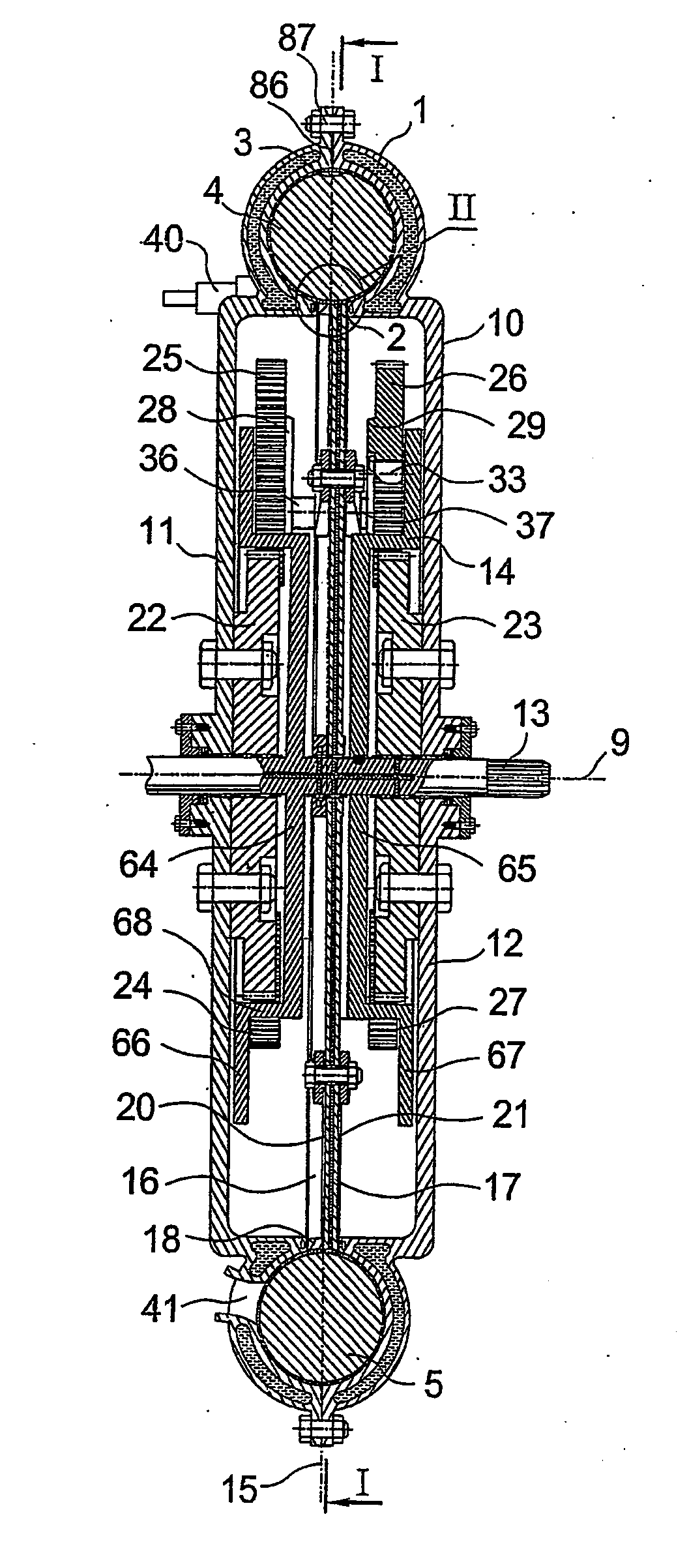

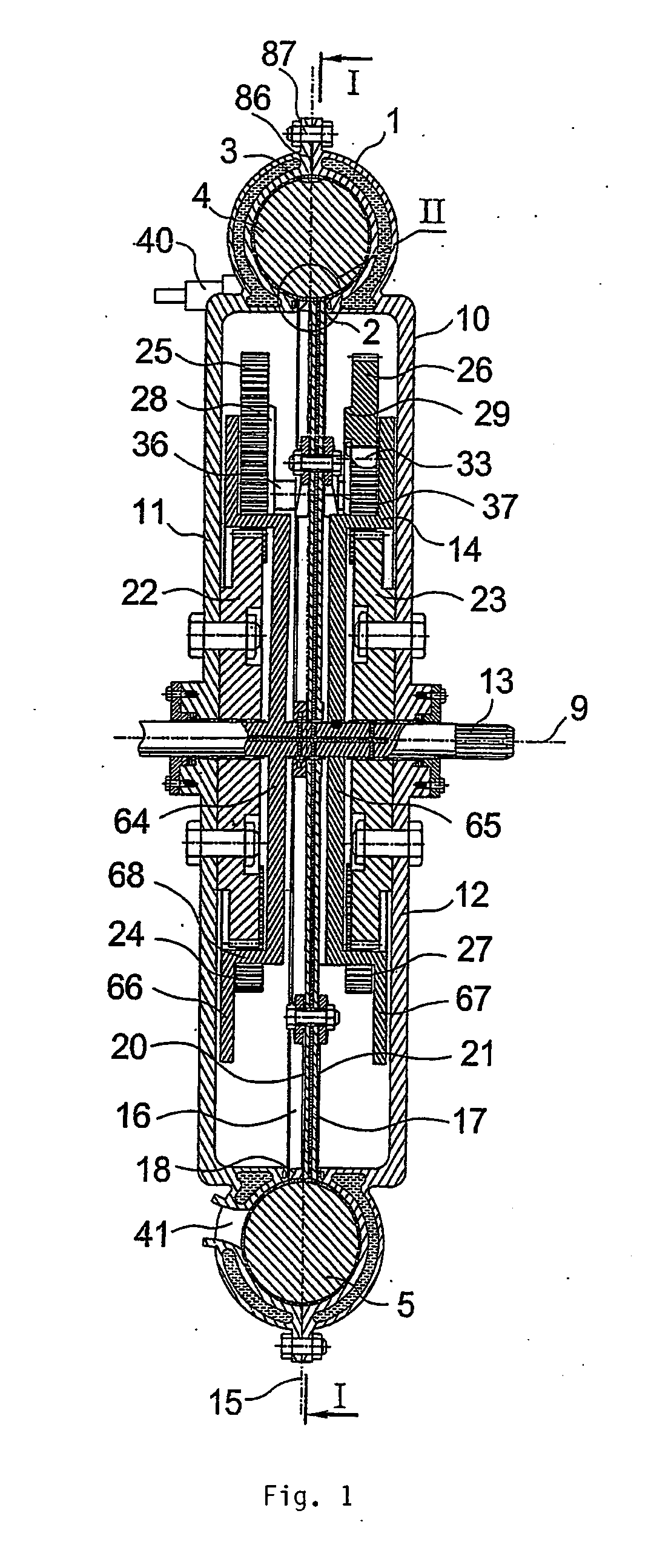

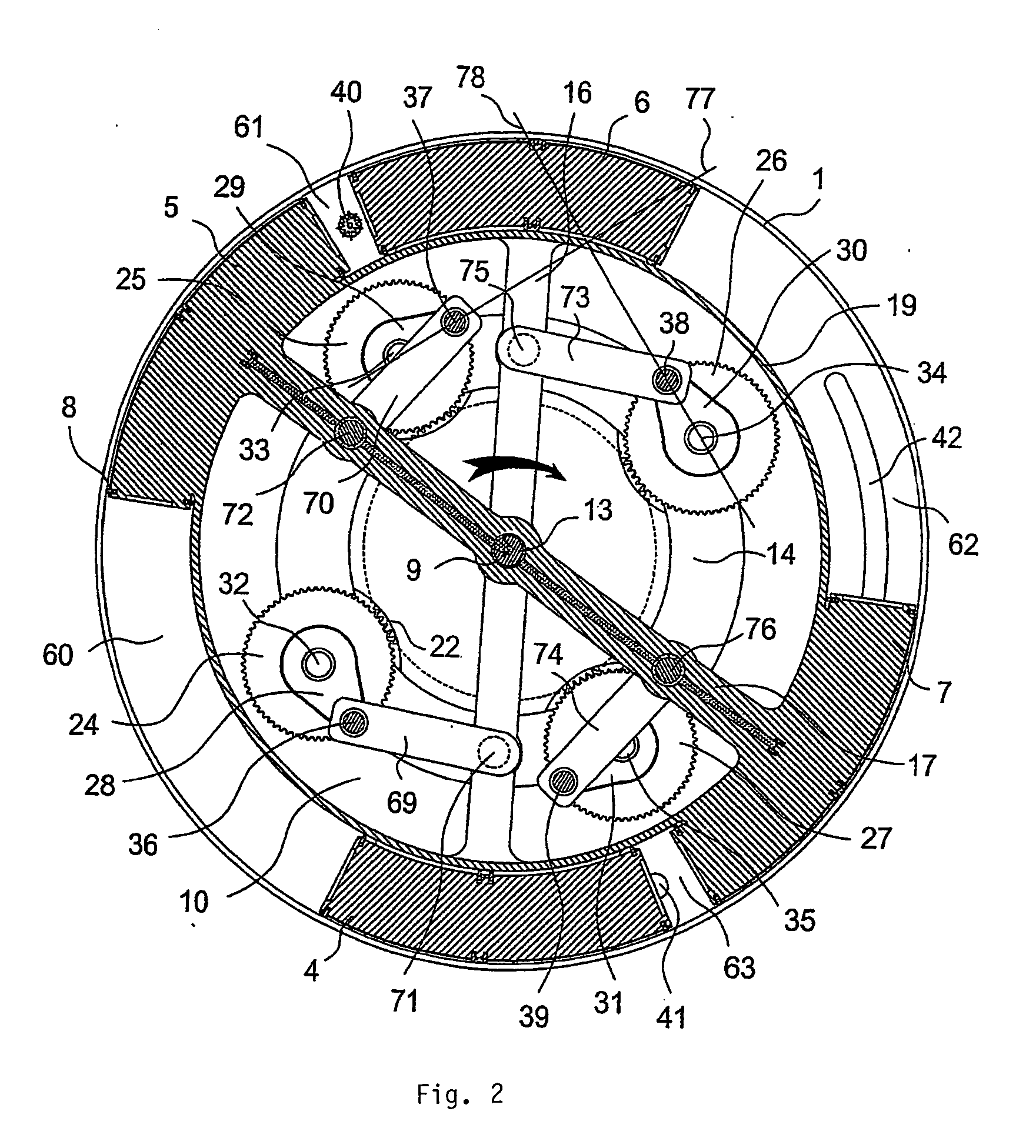

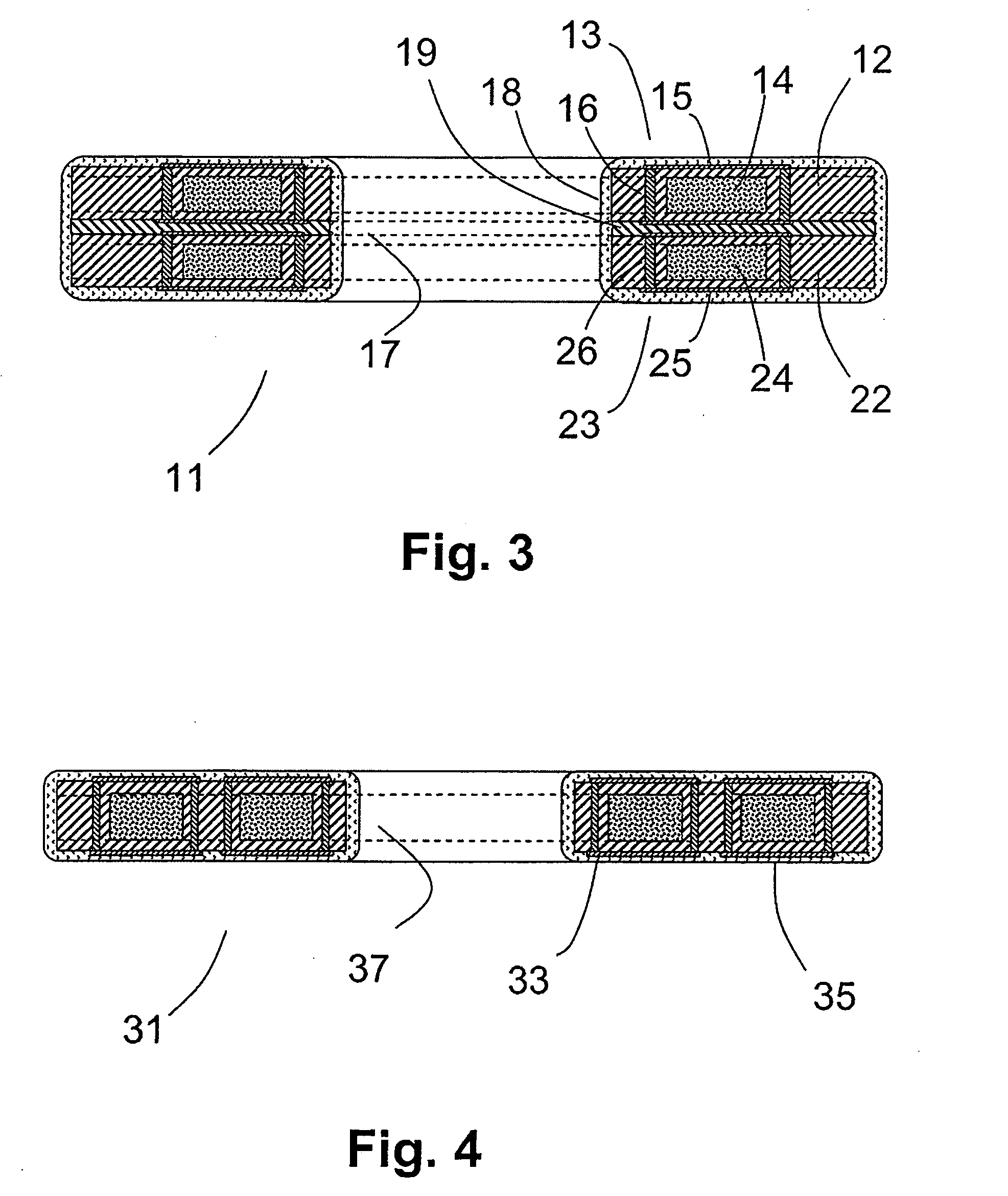

Rotary internal combustion engine

InactiveUS7255086B2Eliminate shock loadsReduce loadInternal combustion piston enginesEngine of arcuate-engagement typeCombustionPower station

The invention can be used for transport means, sports cars and power plants. The inventive engine comprises a hollow toroidal working cylinder provided with a continuous circular slot embodied along the small diameter thereof, a nozzle or a spark plug and arc-wise extended input and output orifices embodied in the wall thereof for admitting air or air-fuel mixture and exhausting combustion gases. The transmission gear is provided with four eccentrics whose crankshaft necks are fixed to the axial holes of the pinions and arranged in the four bores of a fly wheel, whose axes are circumferentially disposed at an even pitch. The crankshaft necks are connected to the bearing elements through connecting rods each of which is arranged by the ends thereof in such a way that they are rotatable about the crankshaft neck and an axis disposed in the wall of one of the bearing elements.

Owner:KOVALENKO VYACHESLAV I

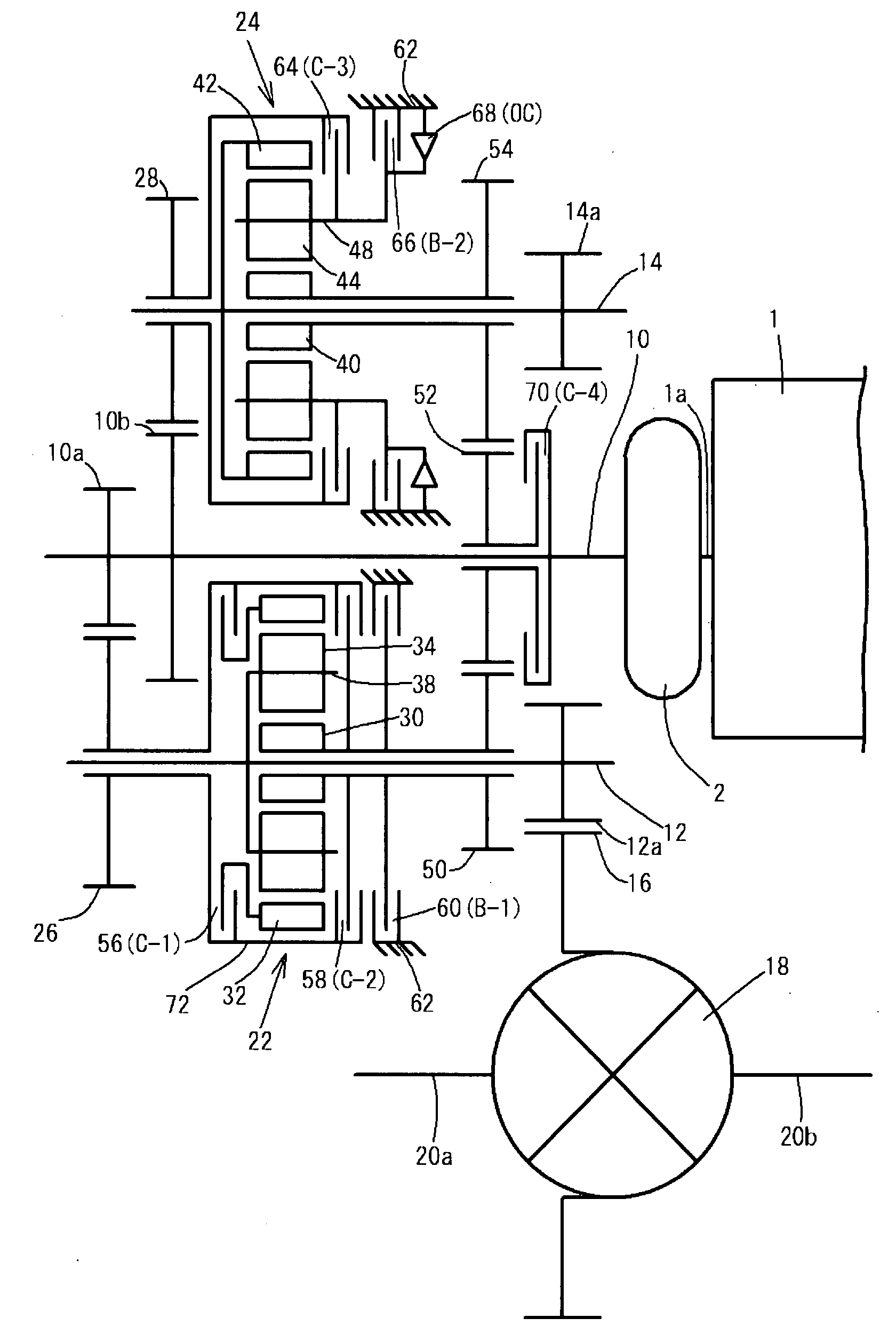

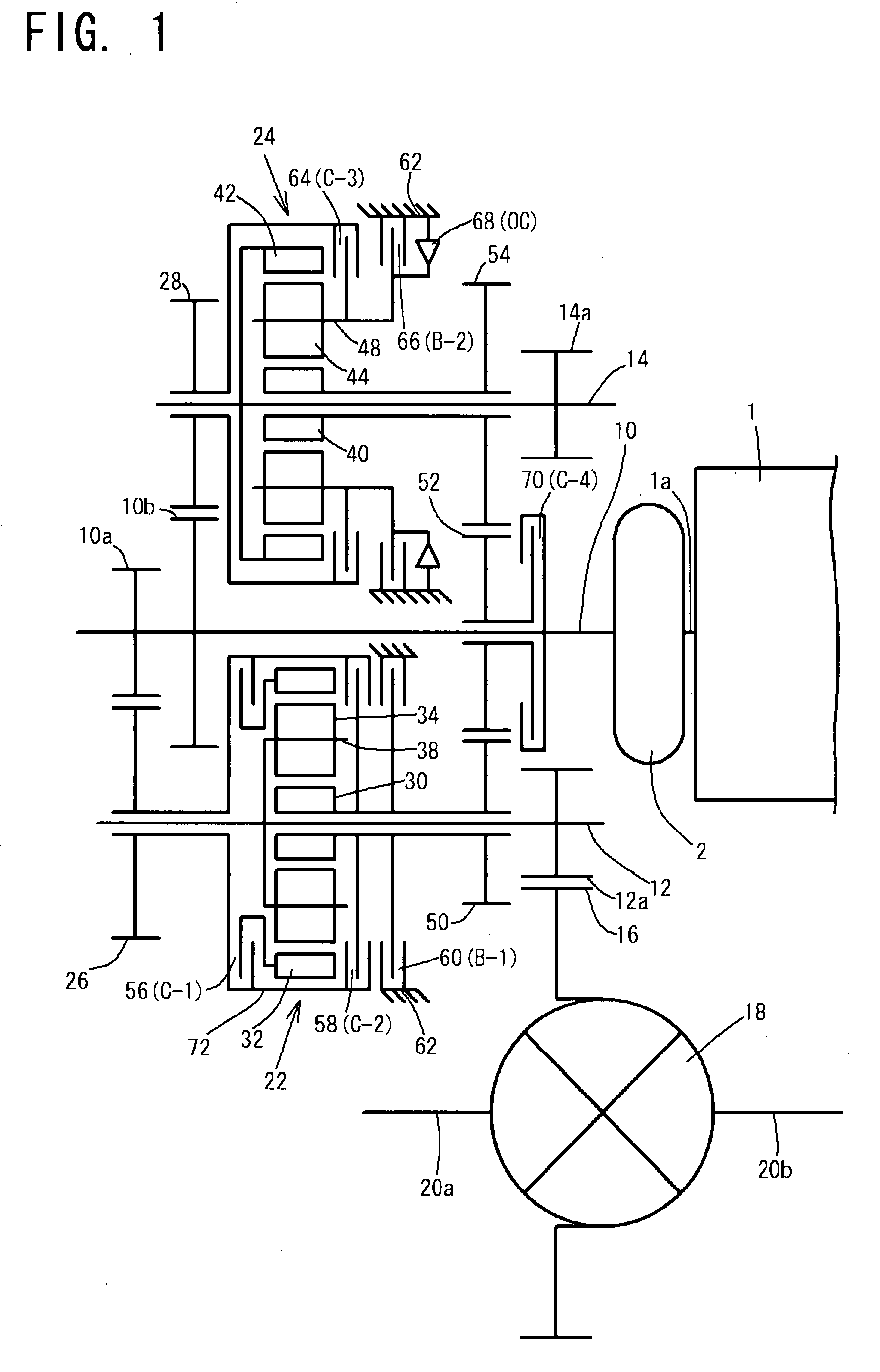

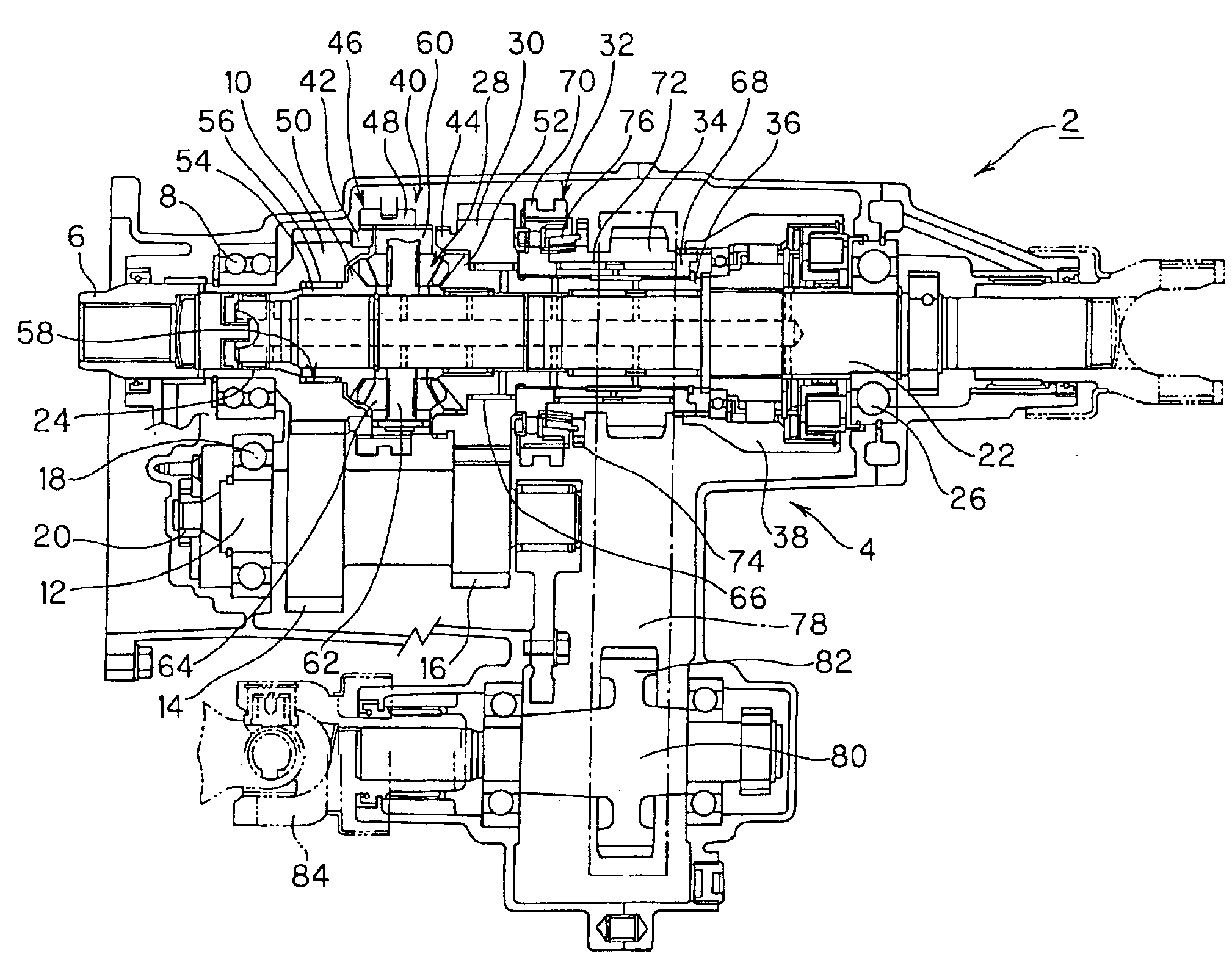

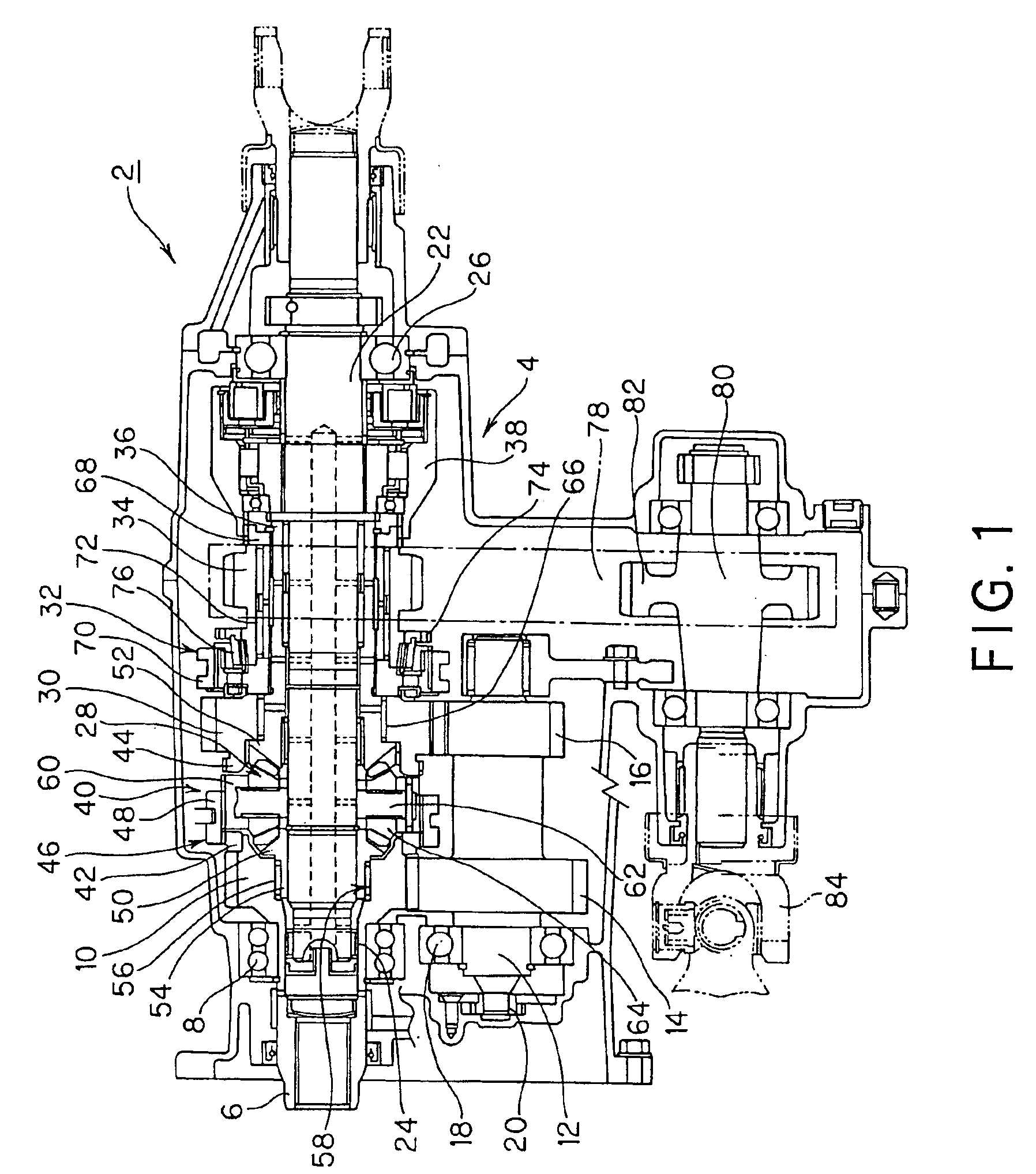

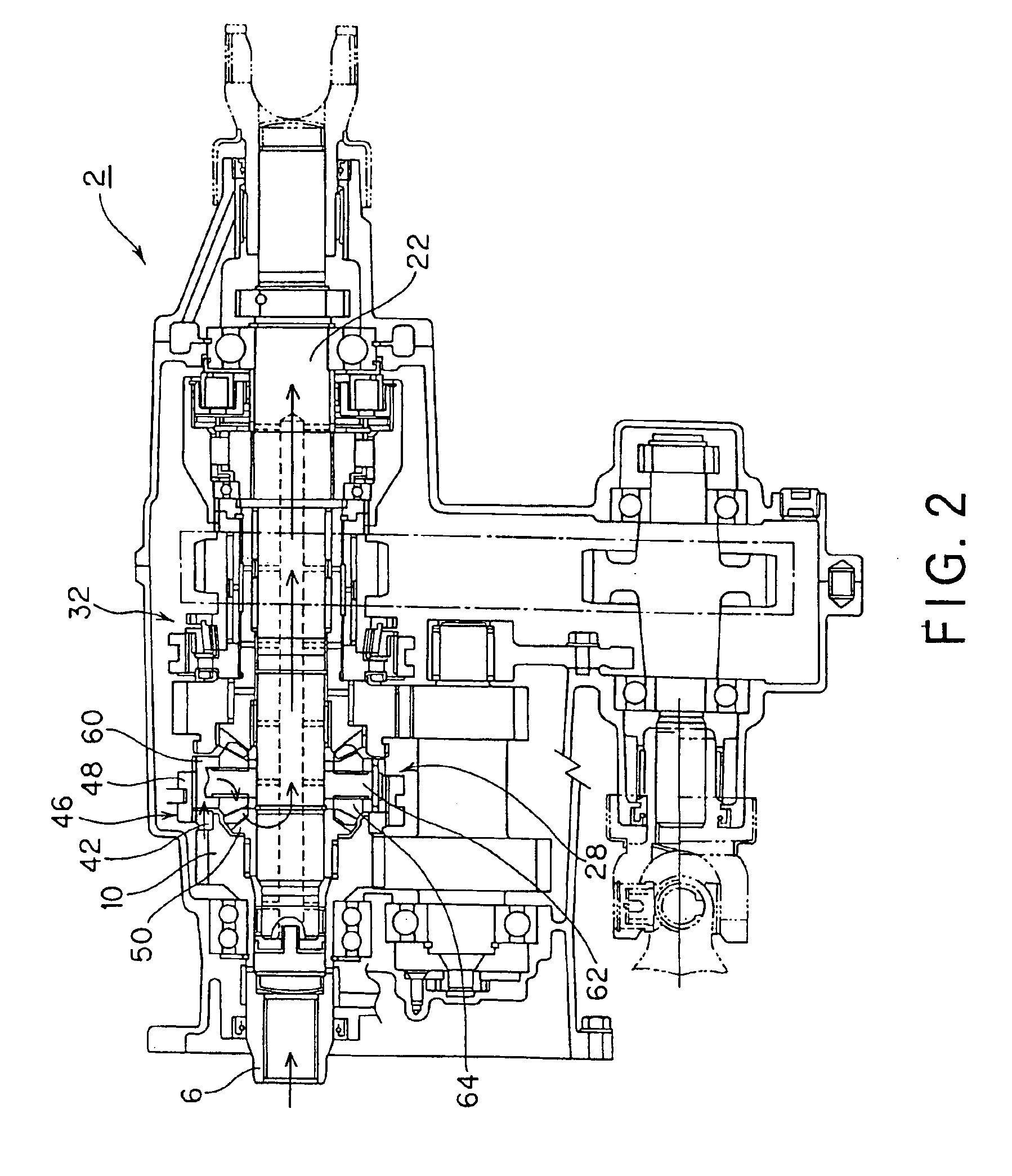

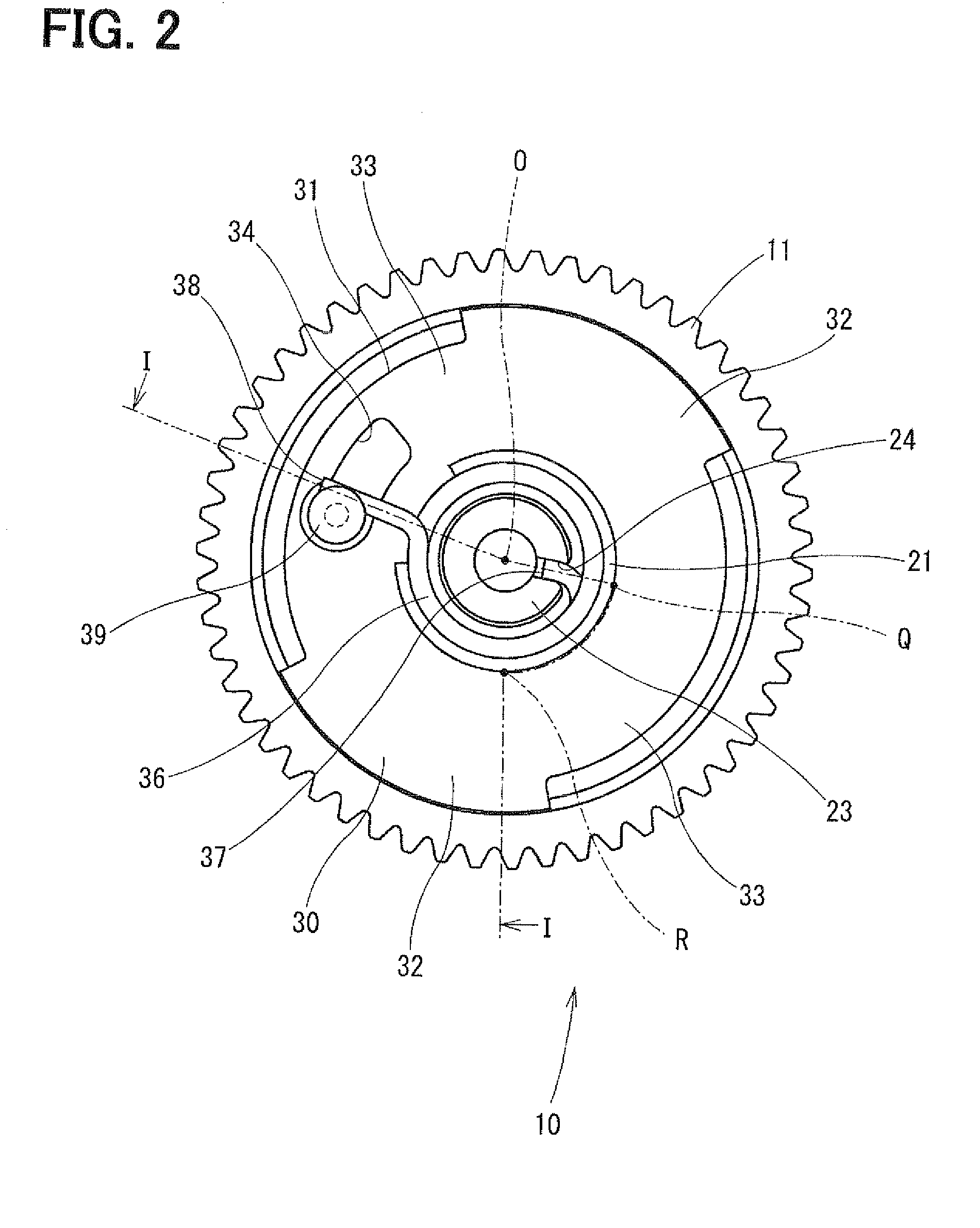

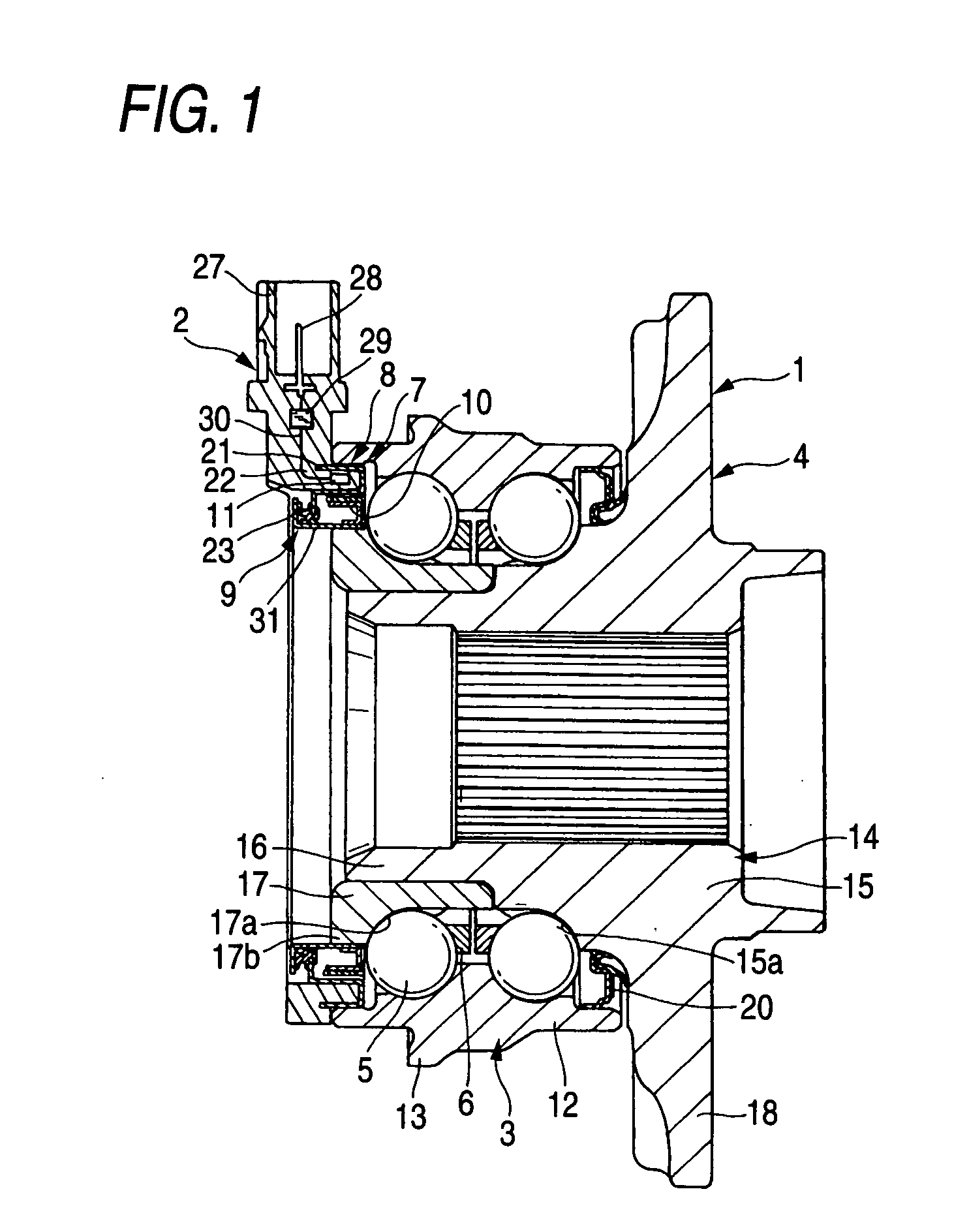

Multi-speed automatic transmission adapted for motor vehicle

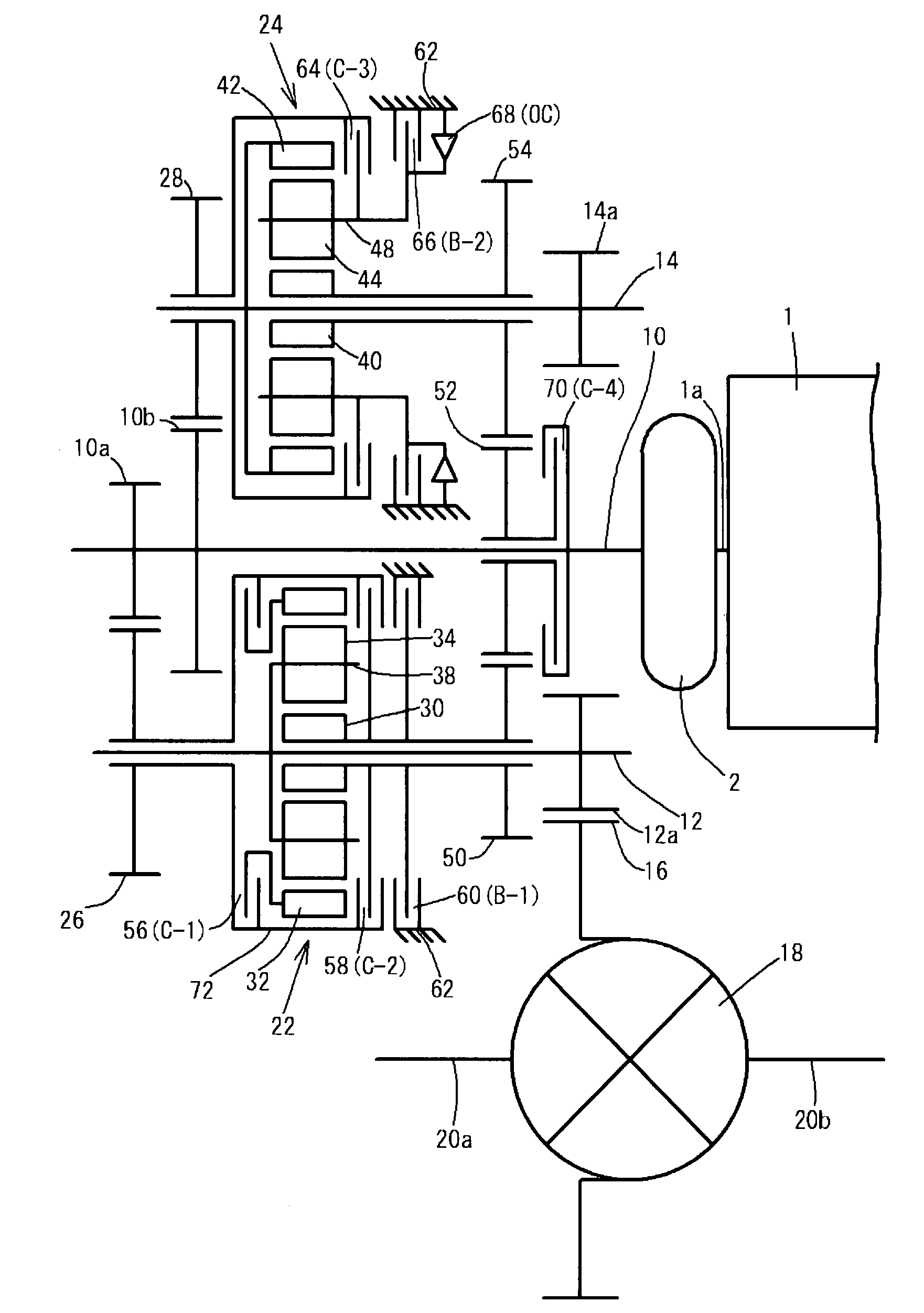

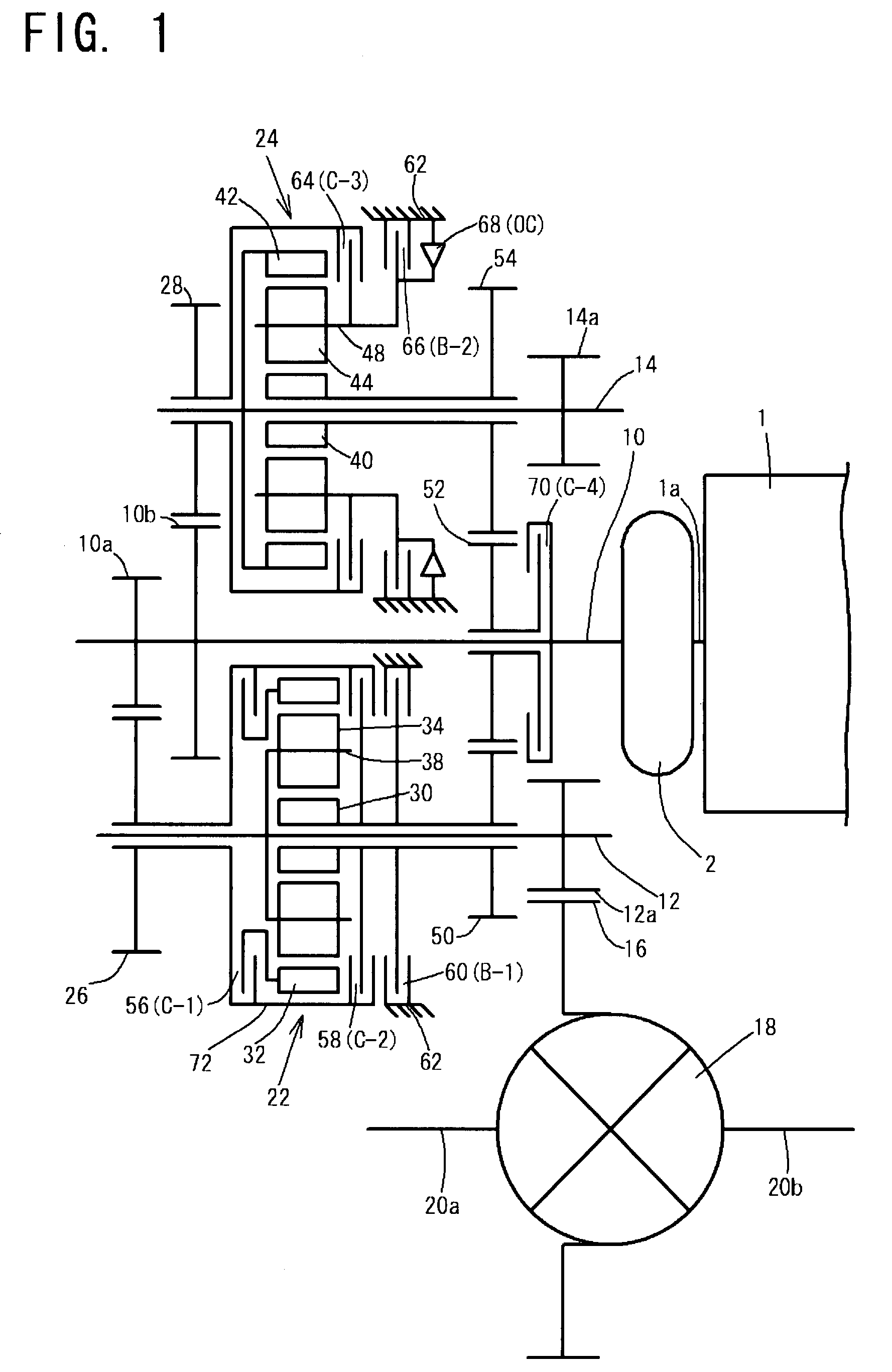

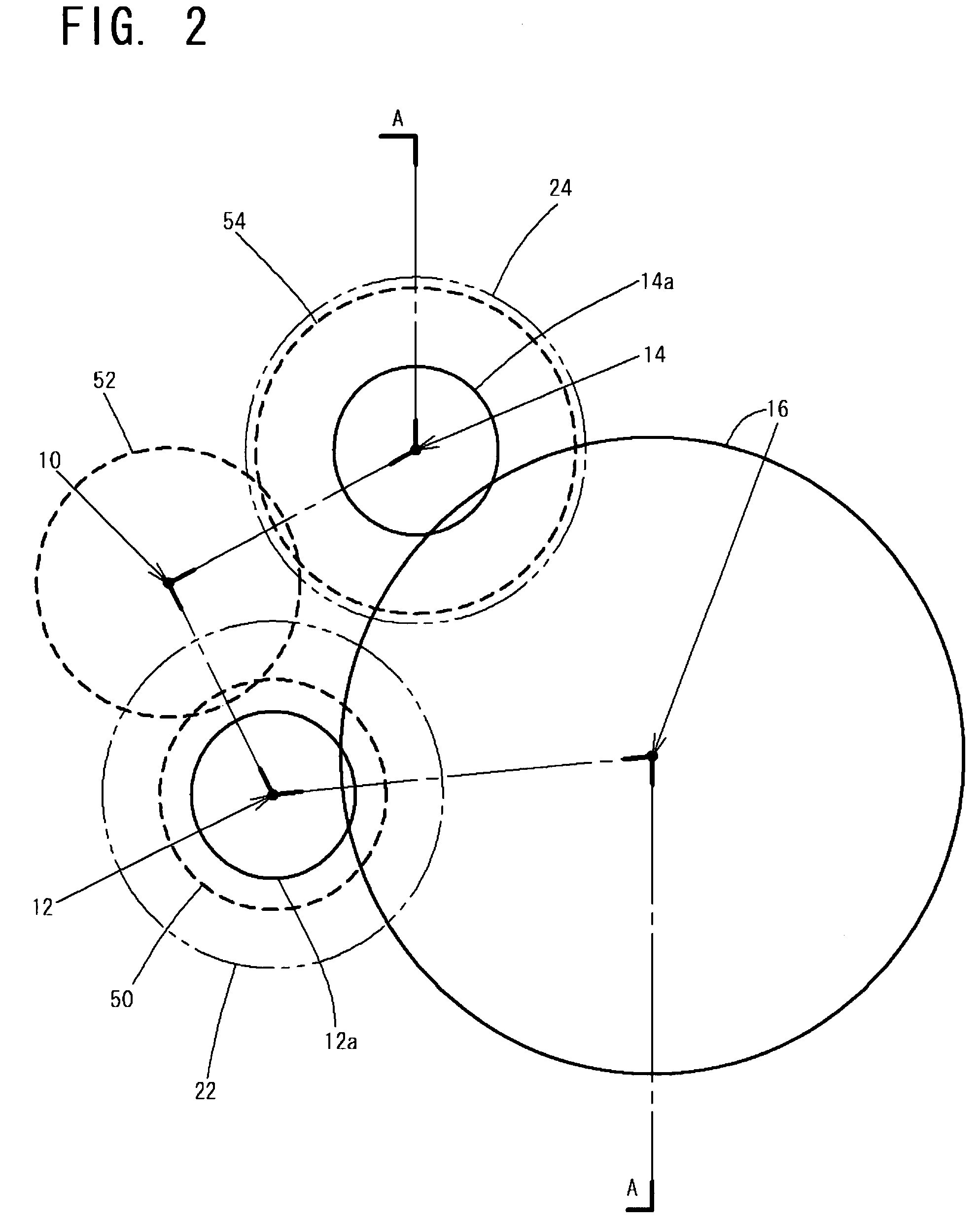

InactiveUS20070254766A1Small axial lengthShorten the axial lengthToothed gearingsTransmission elementsAutomatic transmissionEngineering

A multi-speed automatic transmission includes a first planetary gear set and a second planetary gear set, which are arranged in parallel on a first output shaft and a second output shaft, respectively. An input shaft is connectable with a first ring gear through first input drive and driven gears of the input shaft and the first output shaft, being connectable with a second pinion carrier through a second input drive and driven gears of the input shaft and the second output shaft. The first output shaft is connectable with a first pinion carrier, the second output shaft being connectable with a second ring gear. A second pinion carrier is fixable to a transmission case. The first and second sun gears are connectable with the input shaft through the first input drive and driven gears and through the intermediate gear, being fixable to the transmission case.

Owner:KYOWA METAL WORKS

Rotary internal combustion engine

InactiveUS20060150949A1Eliminate shock loadsReduce loadInternal combustion piston enginesEngine of arcuate-engagement typePower stationCombustion

Said invention can be used for transport means, sports cars and power plants. The inventive engine comprises a hollow toroidal working cylinder provided with a continuous circular slot embodied along the small diameter thereof, a nozzle or a spark plug and arc-wise extended input and output orifices embodied in the wall thereof for admitting air or air-fuel mixture and exhausting combustion gases. The novelty of the inventive engine lies in that the transmission gear thereof is provided with four eccentrics whose crankshaft necks are fixed to the axial holes of the pinions and arranged in the four bores of a fly wheel, whose axes are circumferentially disposed at an even pitch. The crankshaft necks are connected to the bearing elements through connecting rods each of which is arranged by the ends thereof in such a way that they are rotatable about the crankshaft neck and an axis disposed in the wall of one of the bearing elements. The particular embodiments of the invention relates to the relative positions of the fly wheel and bearing elements determining the different forms of the fly wheel embodiment and the connections thereof to the pinions. The invention makes it possible to exclude load impacts to the transmission gear, reduce other loads applied thereto and the friction power loss and to ensure more flexible connections there between, thereby increasing the engine performance, the reliability and overhaul period thereof, reduce the size and mass of the elements of the transmission gear and extend the possibility for specifying the behaviour of speed variation of the relative motion of the bearing elements.

Owner:KOVALENKO VYACHESLAV I

Fixing device

ActiveUS7218884B2Suppresses bending deformationIncreased durabilityOhmic-resistance heatingElectrographic process apparatusEngineeringMechanical engineering

A fixing device has a fixing roller including an inside roller, an outside roller and a regulation member. The regulation member is disposed outside of both ends of the outside roller in the axial direction to regulate axial movement of the outside roller. An axial length of the contact face, where the pressure roller contacts with the outside roller, is smaller than an axial length of the outside roller. Thereby, both ends of the outside roller hardly receive bending deformation caused by pressure of the pressure roller. This makes it possible to reduce stress exerted to both ends of the outside roller, and therefore, the ends of the fixing roller are prevented from being damaged to enhance durability of the fixing roller.

Owner:KONICA MINOLTA BUSINESS TECH INC

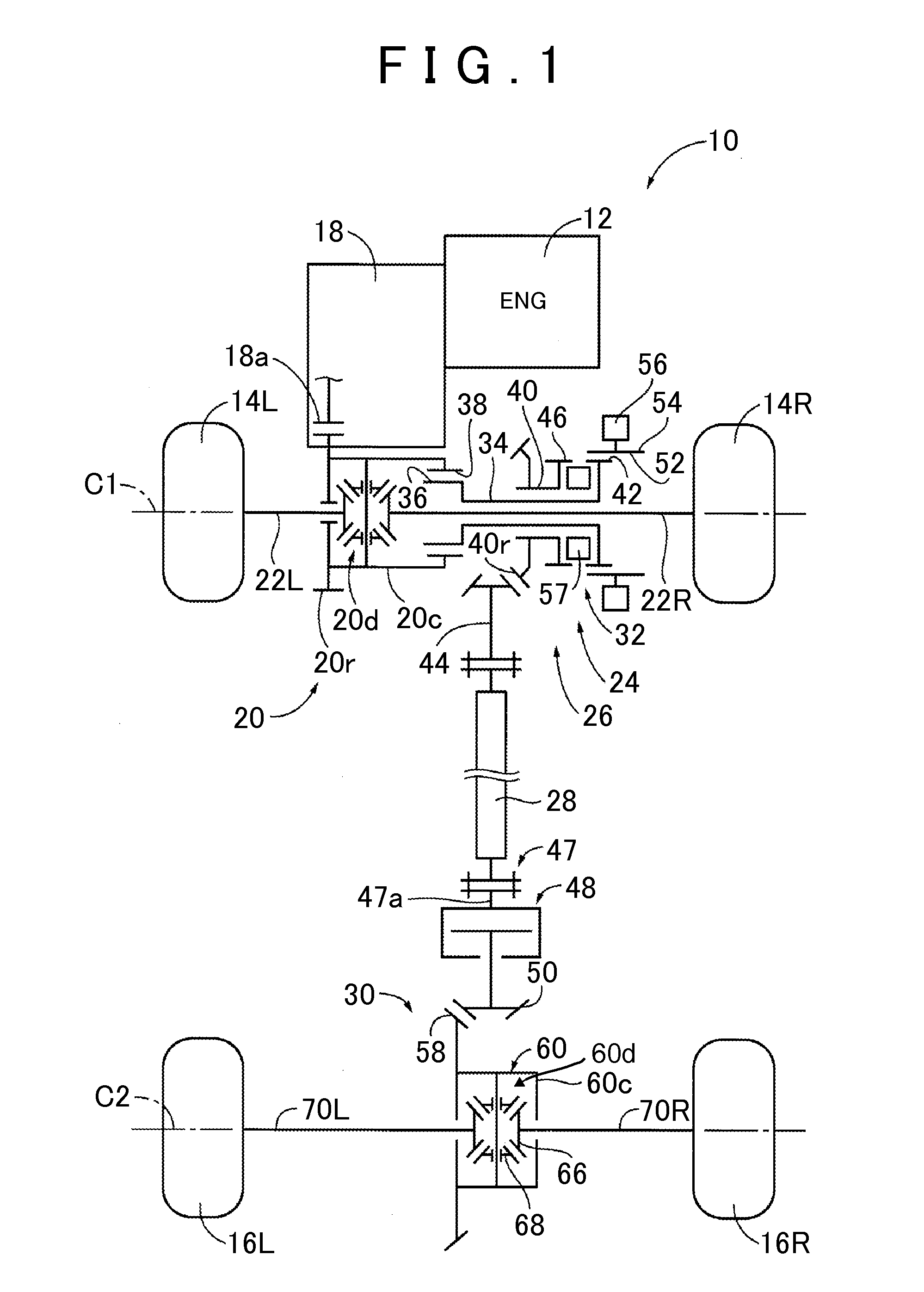

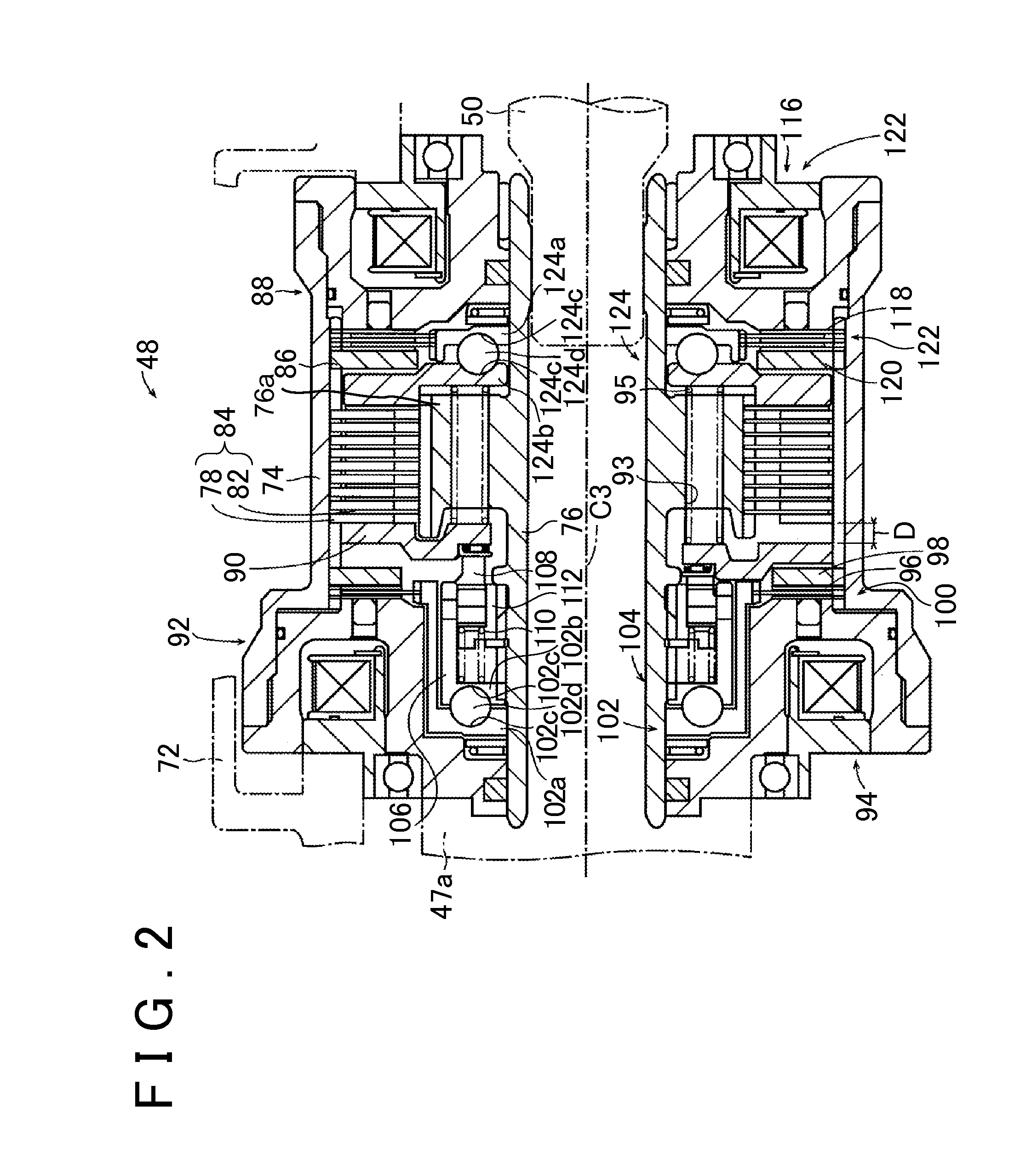

Multi-speed automatic transmission adapted for motor vehicle

InactiveUS7637839B2Shorten the axial lengthSmall widthToothed gearingsTransmission elementsAutomatic transmissionEngineering

A multi-speed automatic transmission includes a first planetary gear set and a second planetary gear set, which are arranged in parallel on a first output shaft and a second output shaft, respectively. An input shaft is connectable with a first ring gear through first input drive and driven gears of the input shaft and the first output shaft, being connectable with a second pinion carrier through a second input drive and driven gears of the input shaft and the second output shaft. The first output shaft is connectable with a first pinion carrier, the second output shaft being connectable with a second ring gear. A second pinion carrier is fixable to a transmission case. The first and second sun gears are connectable with the input shaft through the first input drive and driven gears and through the intermediate gear, being fixable to the transmission case.

Owner:KYOWA METAL WORKS

Inductive conductivity sensor

InactiveUS20080218302A1Small axial lengthSimplified automated manufactureTransformers/inductances coils/windings/connectionsMaterial impedanceElectrical conductorToroidal coil

A conductivity sensor for measuring conductivity of a medium surrounding the conductivity sensor includes a first toroidal coil bounding a medium-receiving passageway and serving for inducing an electrical current in the medium, and a second toroidal coil also bounding the passageway and serving for registering a magnetic field produced by the electrical current. At least one of the toroidal coils has a plurality of first conductor segments, which extend in a plane of a multi-ply circuit board, a plurality of second conductor segments, which extend in a second plane of the circuit board, and a plurality of through-contacts, which connect the first conductor segments with the second conductor segments, wherein the first conductor segments, the second conductor segments and the through-contacts form, together, the windings of a toroidal coil.

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

Transfer for a four-wheel drive vehicle

A transfer arrangement for a four-wheel drive vehicle having an input shaft, a transmission, and a center differential. The transmission includes a first gear attached to the input shaft, a first counter gear attached to a countershaft in parallel with the input shaft to receive the rotation of the first gear, a second counter gear fixed to the countershaft and rotating therewith, and a second gear aligned with the input shaft and rotatably supported along the input shaft to receive the rotation of the second counter gear. High speed-side and low speed-side output parts are attached to the first and second gears respectively. The center differential is disposed between the high speed-side and low speed-side output parts. An engaging device disposed adjacent the center differential selectively engages with the high speed-side and low speed-side output parts.

Owner:SUZUKI MOTOR CORP

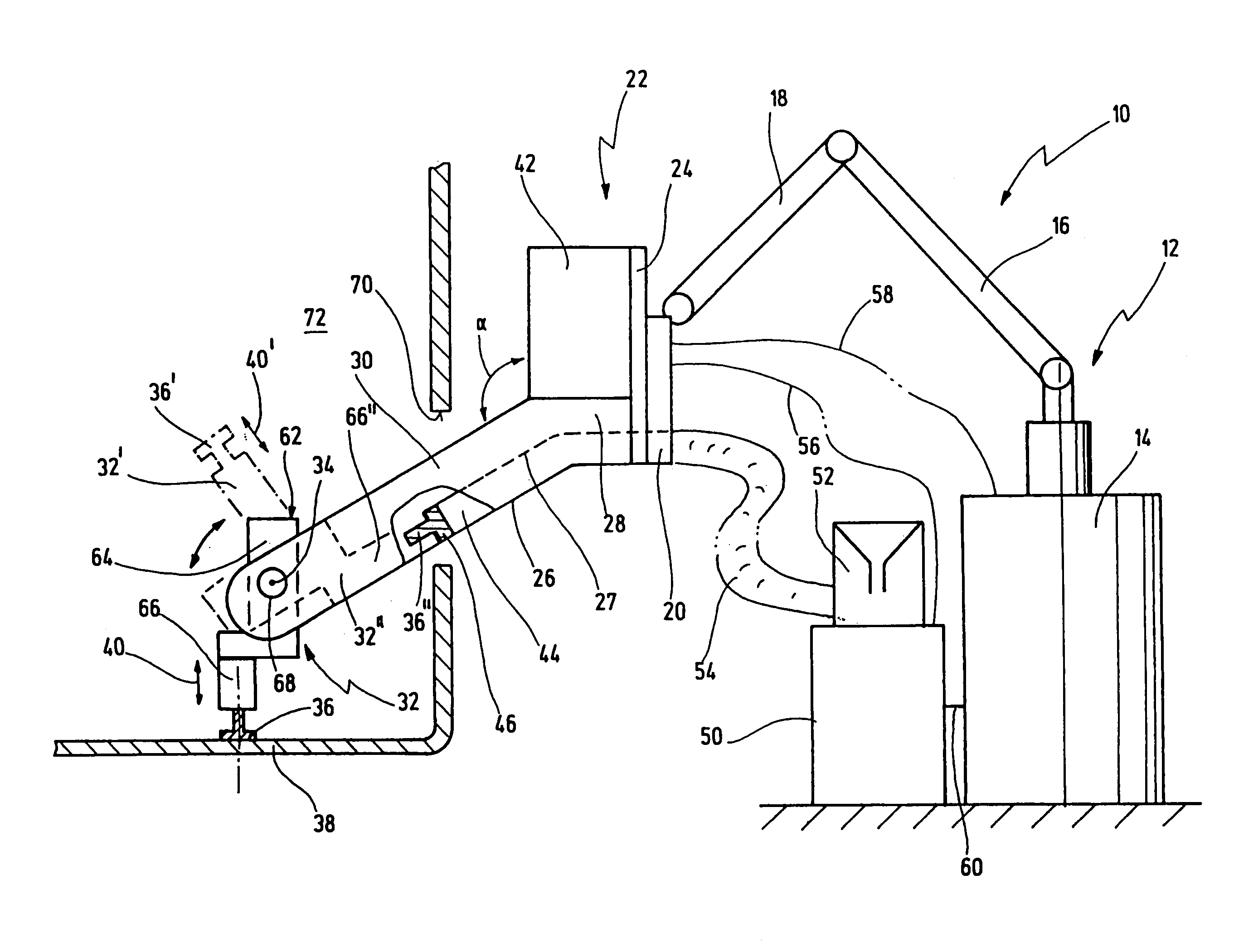

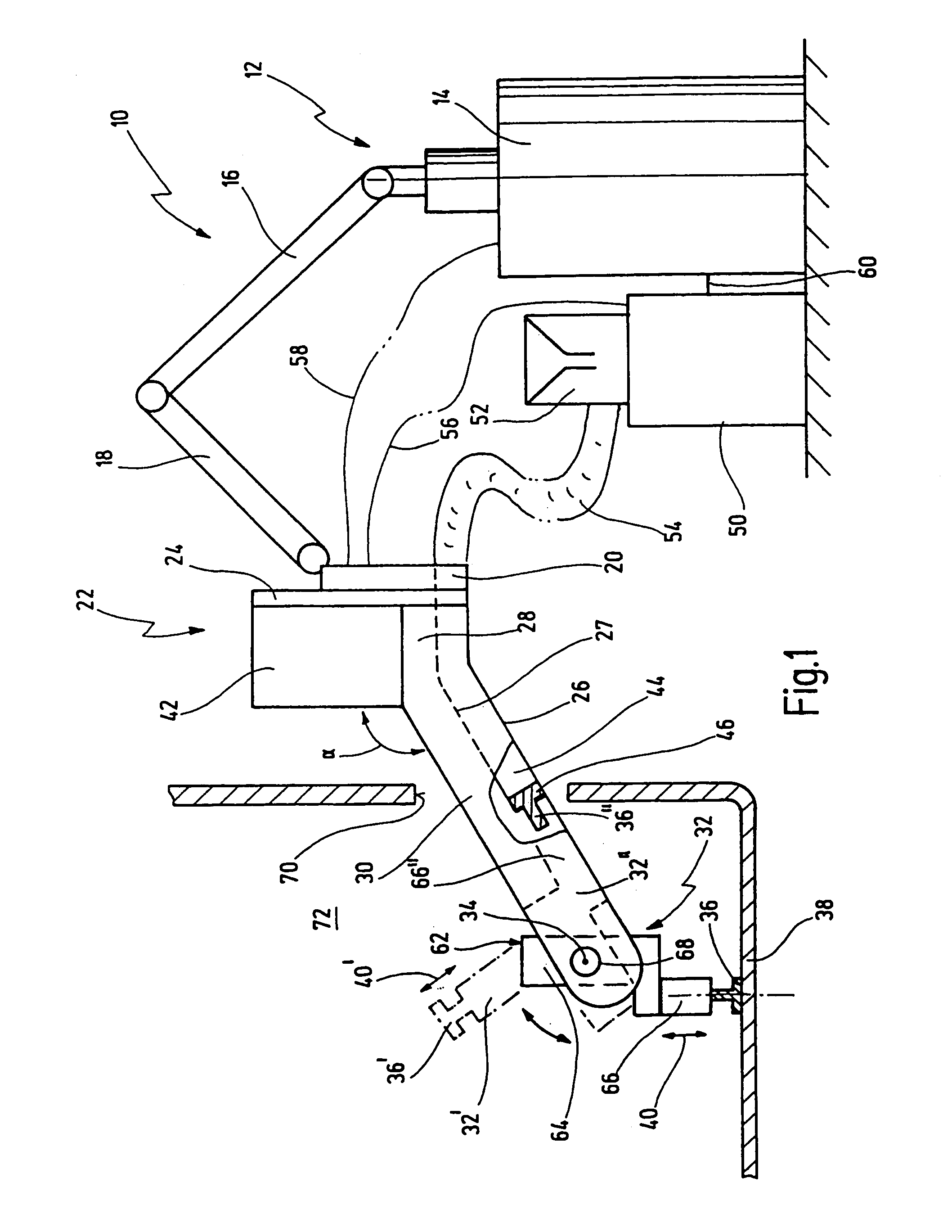

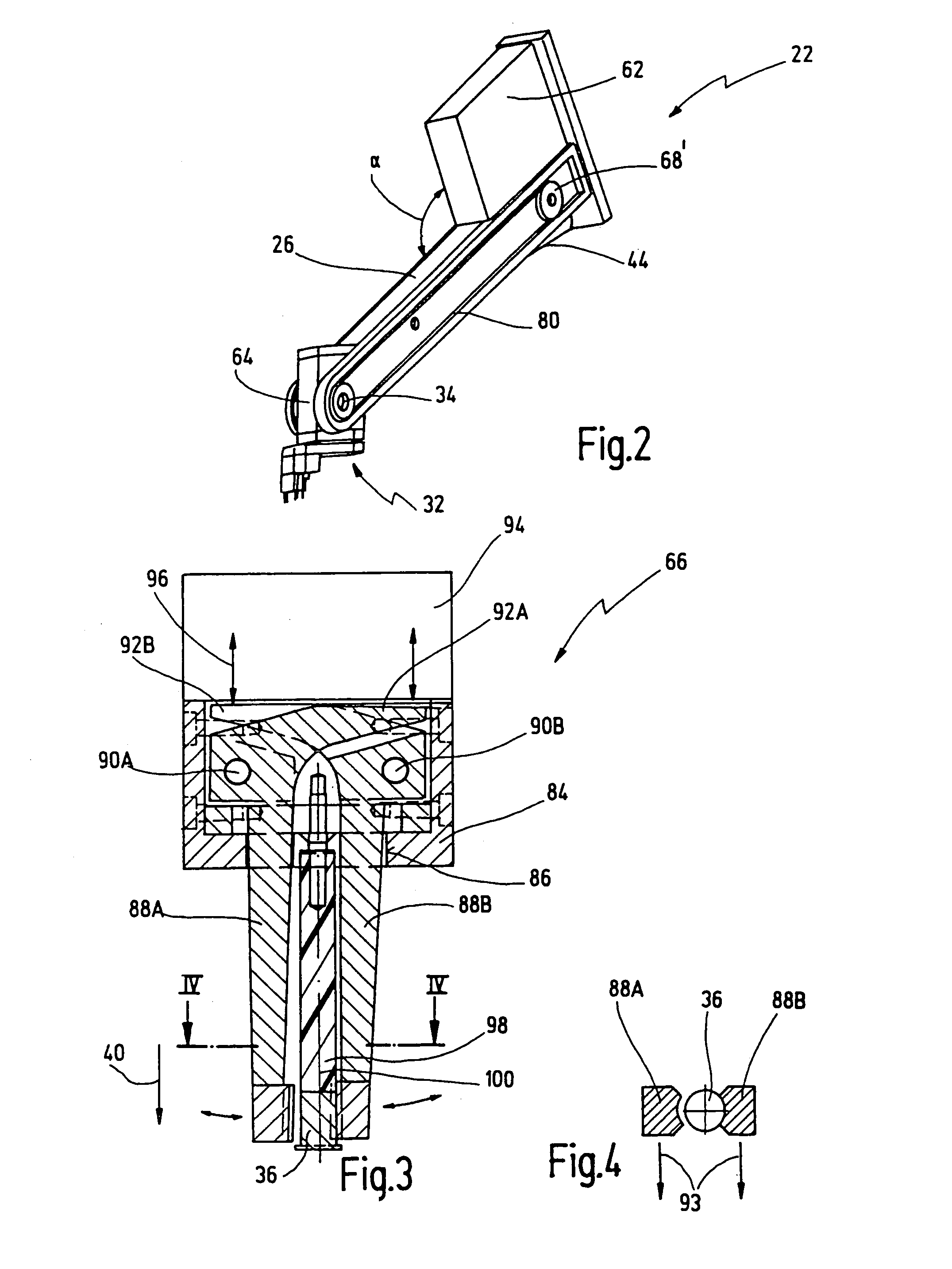

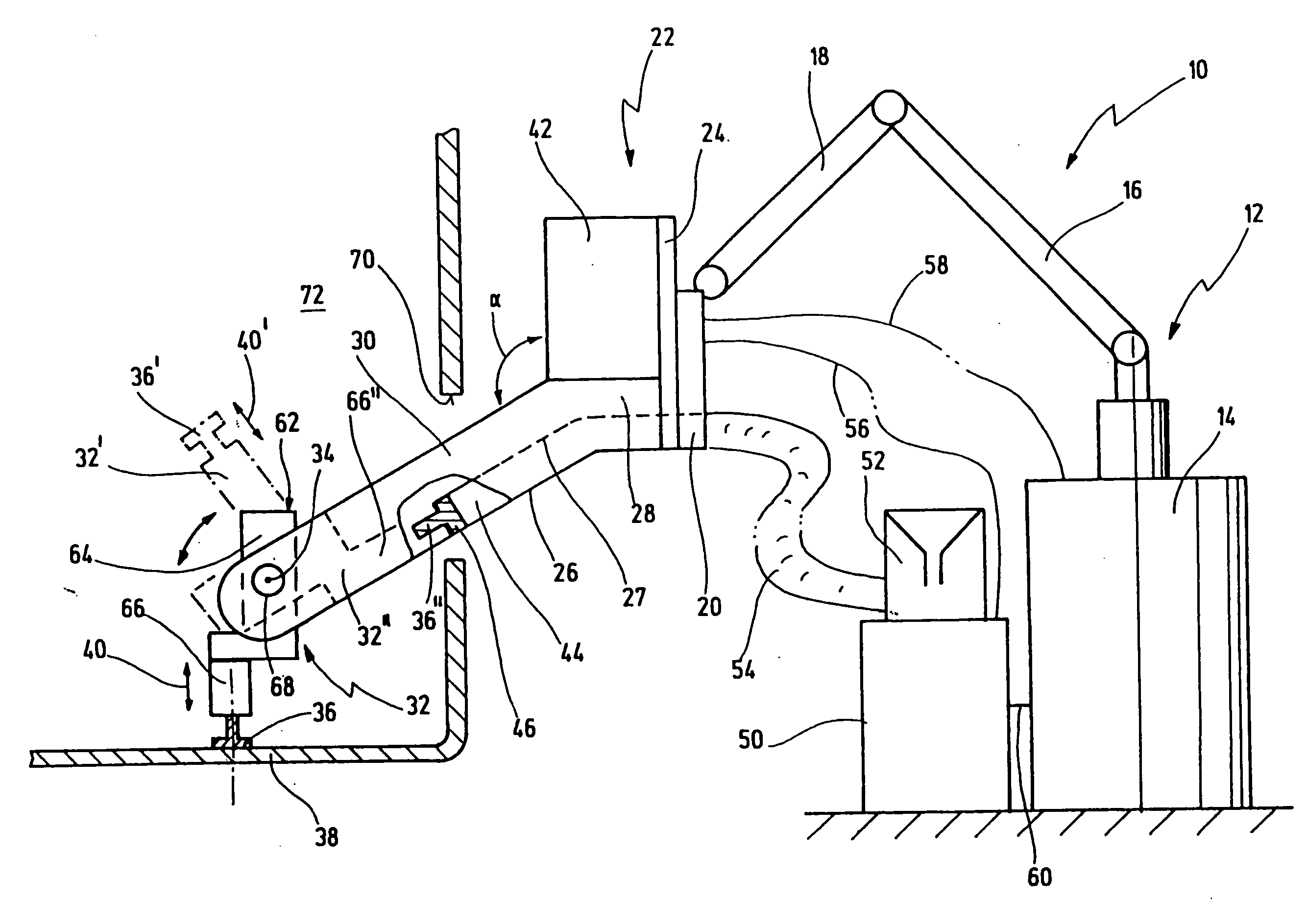

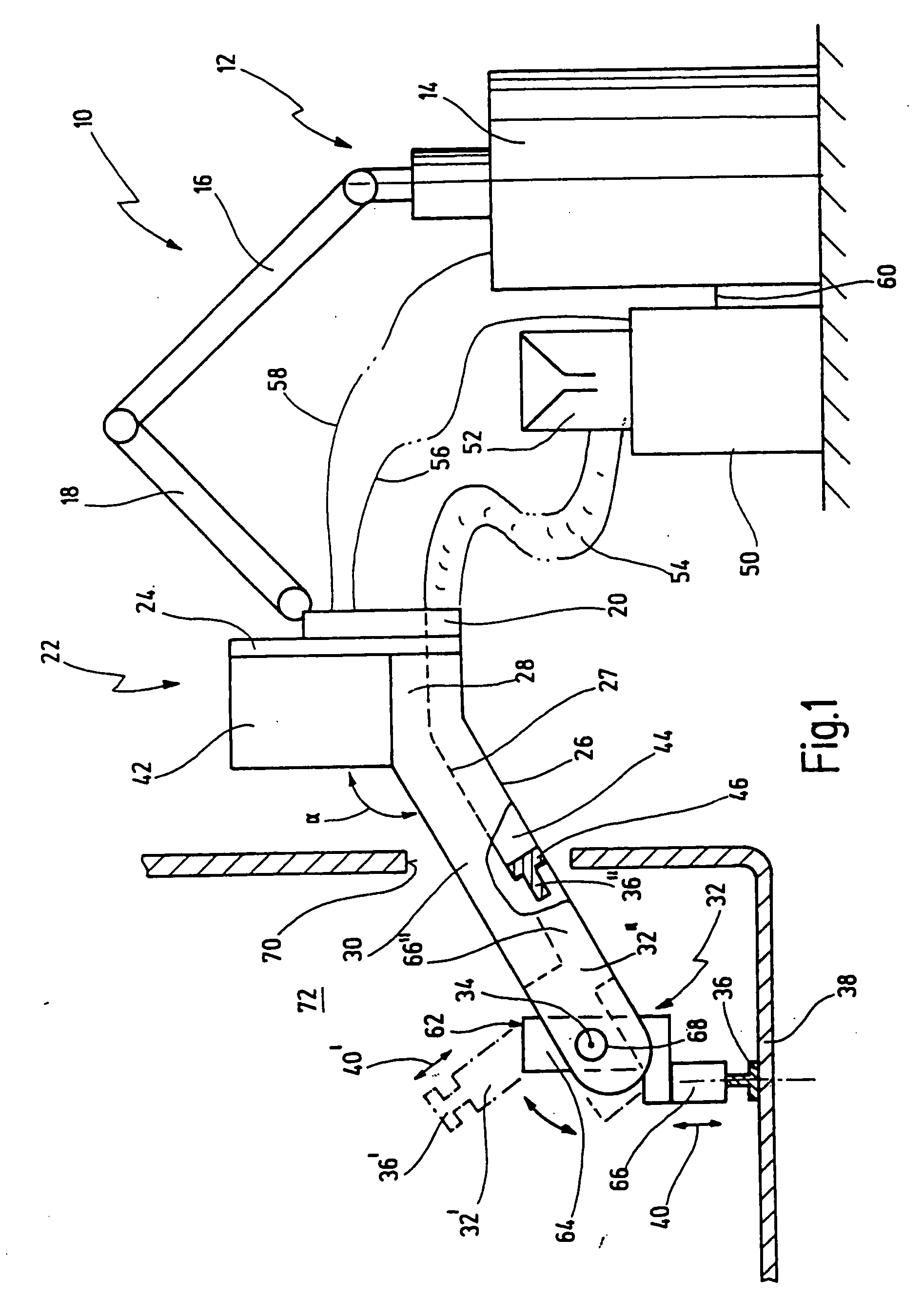

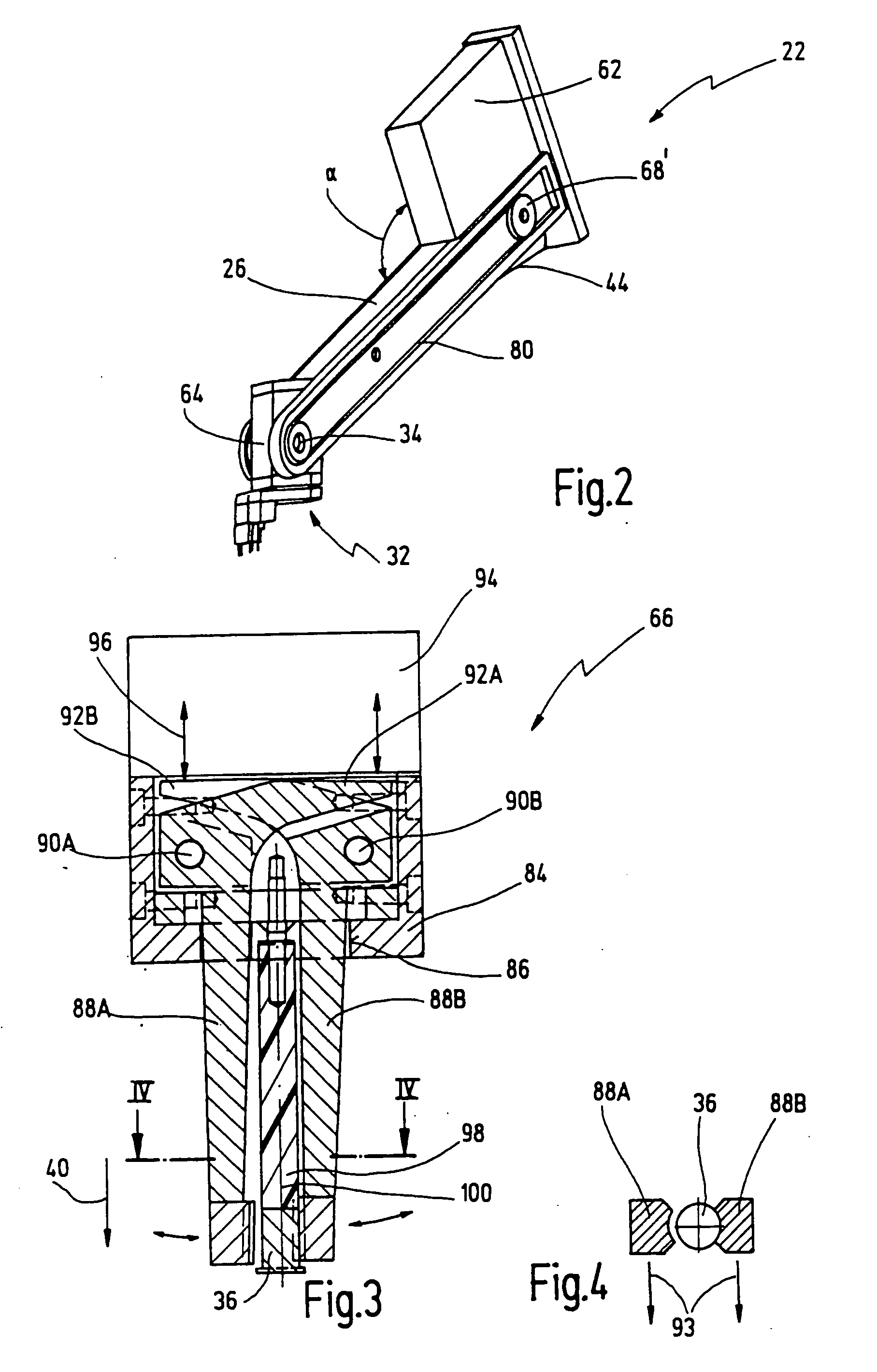

Joining system head, joining system, and method of feeding and joining elements

InactiveUS7291802B2Small axial lengthArc welding apparatusConnectionsMechanical engineeringTransfer station

A joining system head (22) is proposed for fixation to a movable frame (12), in particular to a robot (12), havinga holding means (66) for an element (36) to be joined to a part (38),a joining drive means (64) to move the holding means (66) along a joining direction (40) for joining, anda feeding means (44) for feeding elements (36) to the joining system head (22).Here a control means (42) to control the joining drive means (64) is arranged at the joining system head (22) spatially distanced from the holding means (66) and the joining drive means (64), so that the holding means (66) and the joining drive means (64) form a joining tool (32) of small dimensions, and means (68) are provided to pass on the elements (36) fed to a transfer station (46) of the feeding means (44) in each instance to the holding means (66) from in front.

Owner:NEWFREY

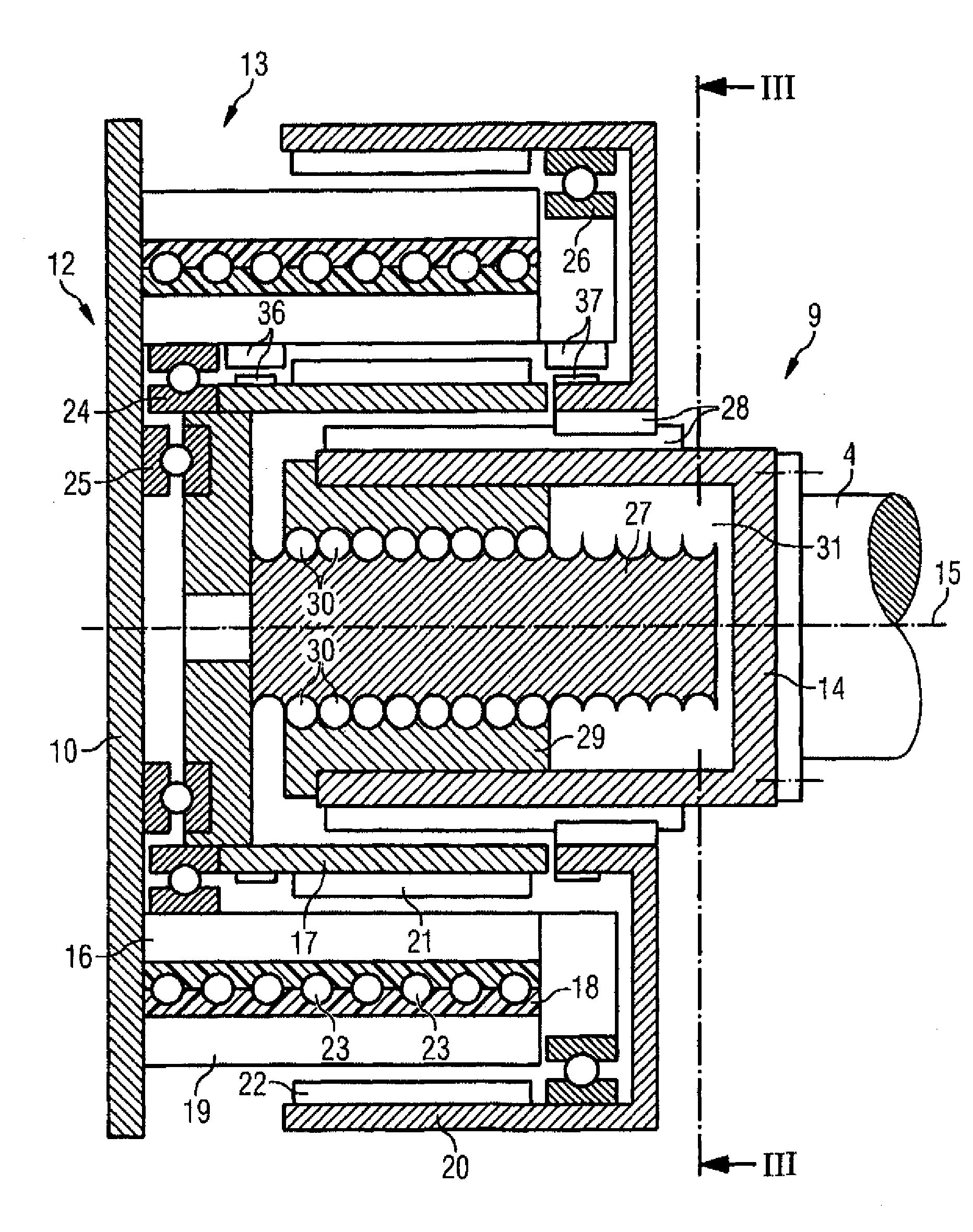

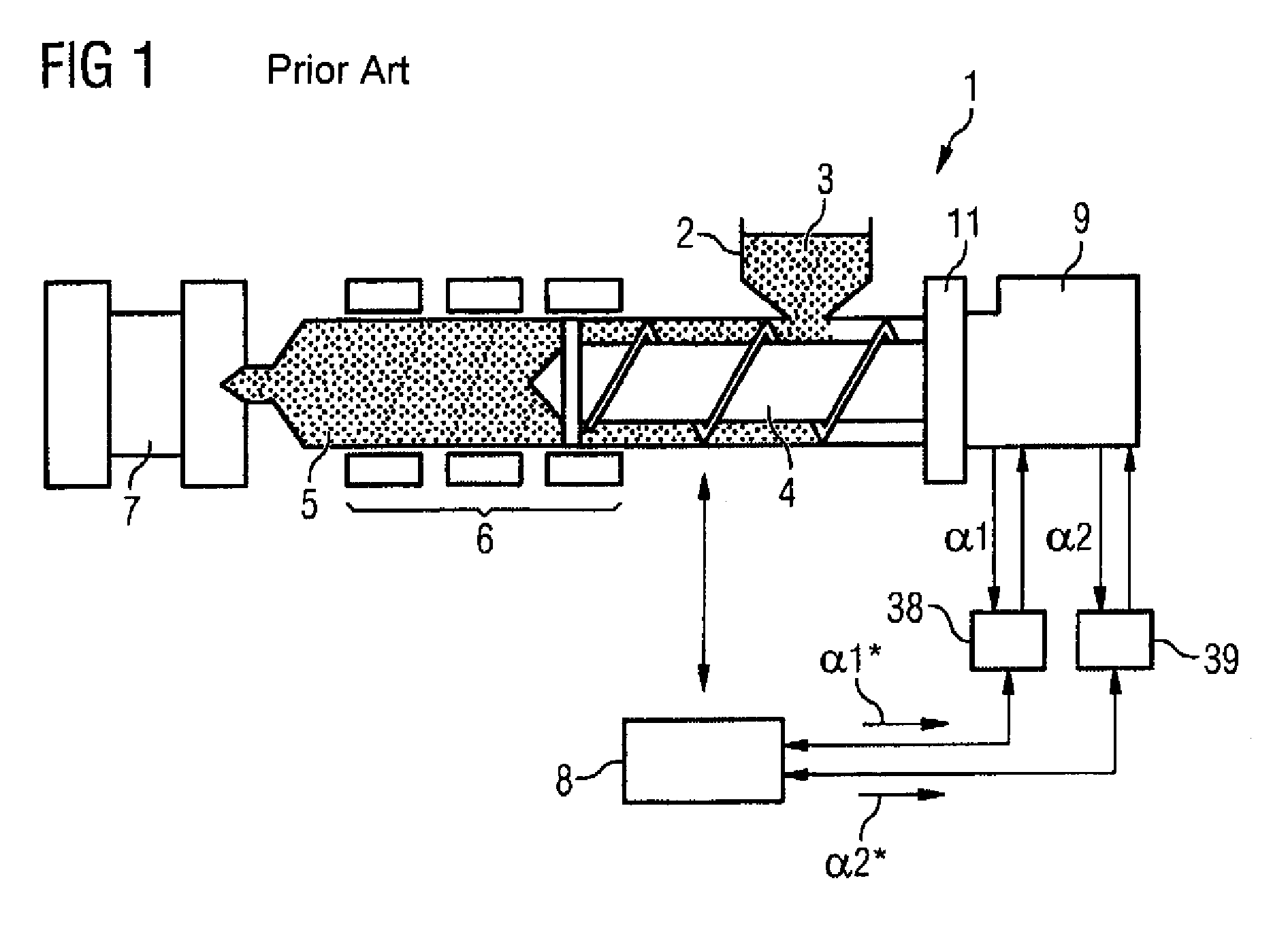

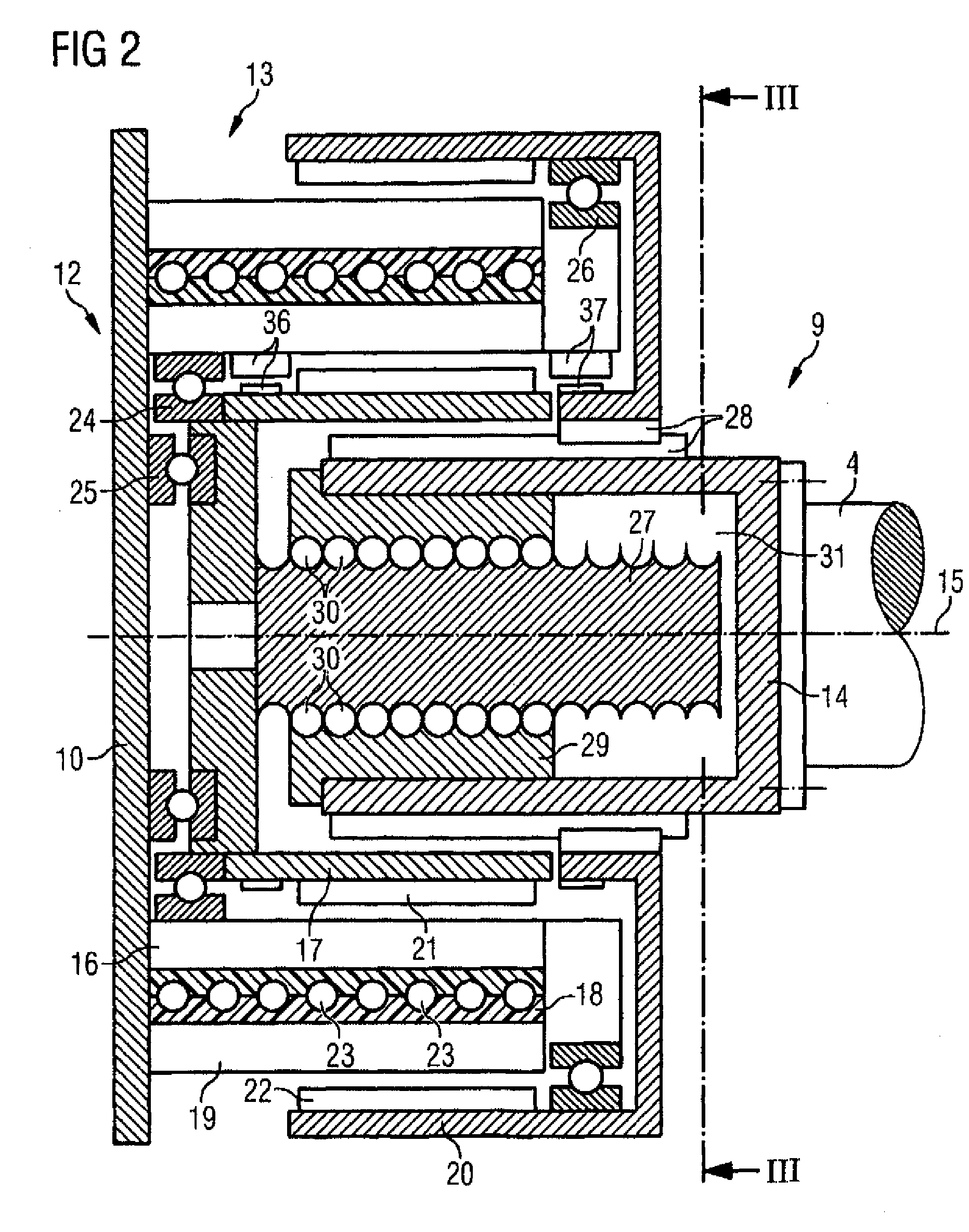

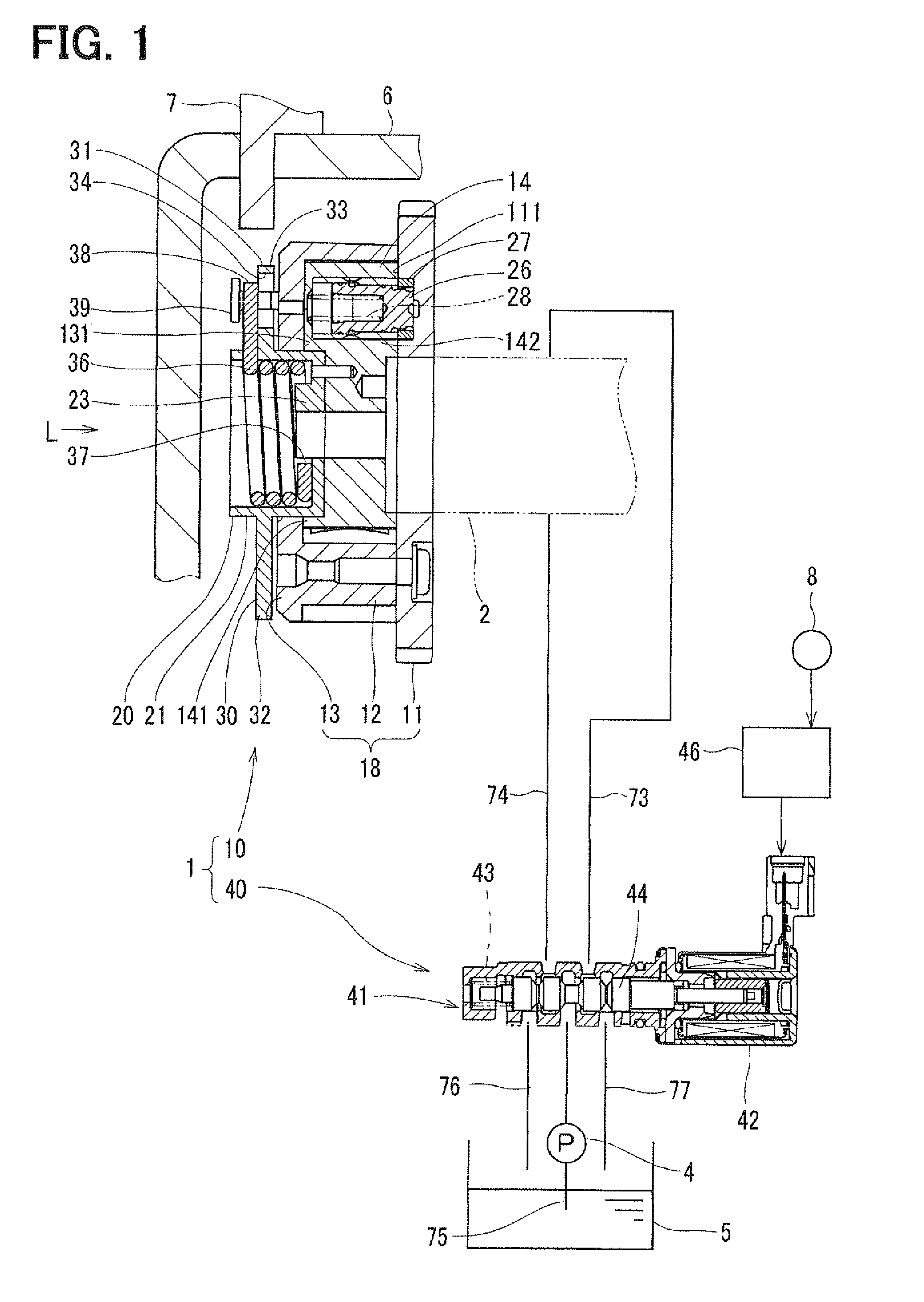

Drive device

InactiveUS7841250B2Easy to manufactureIncreased torsional stiffnessToothed gearingsMechanical energy handlingDrive shaftEngineering

The invention relates to a drive device (9) comprising a housing (10), a drive shaft (14) which is mounted in the housing (10) and which comprises a shaft axis (15) and a first and a second electric drive (12,13). The drive shaft (14) can be rotated about the shaft axis (15) by means of a drive (12,13) and can be displaced in an axial manner along the shaft axis (15). The drives (12, 13) are aligned on the shaft axis (15) and comprise, respectively, a stator (16,19) and a rotor (17,20). The stators (16,19) are secured to the housing (10). The rotors (17,20) are embodied as hollow shafts and are mounted on the housing (10). The rotor (20) of the second drive (13) is rotationally secured to the drive shaft (14) by means of a linear bearing device (28), and in a manner which enables it to be axially displaced. The rotor (17) of the first drive (12) is rotationally secured to a threaded spindle (27) and is connected in such a manner that it cannot be axially displaced. Said drive shaft (14) is rotationally connected to a threaded nut (29) which co-operates with the threaded spindle (27) and in such a manner that it cannot be axially displaced. The drive shaft (14) comprises a recess (31) which is used to receive the threaded spindle (27).

Owner:SIEMENS AG

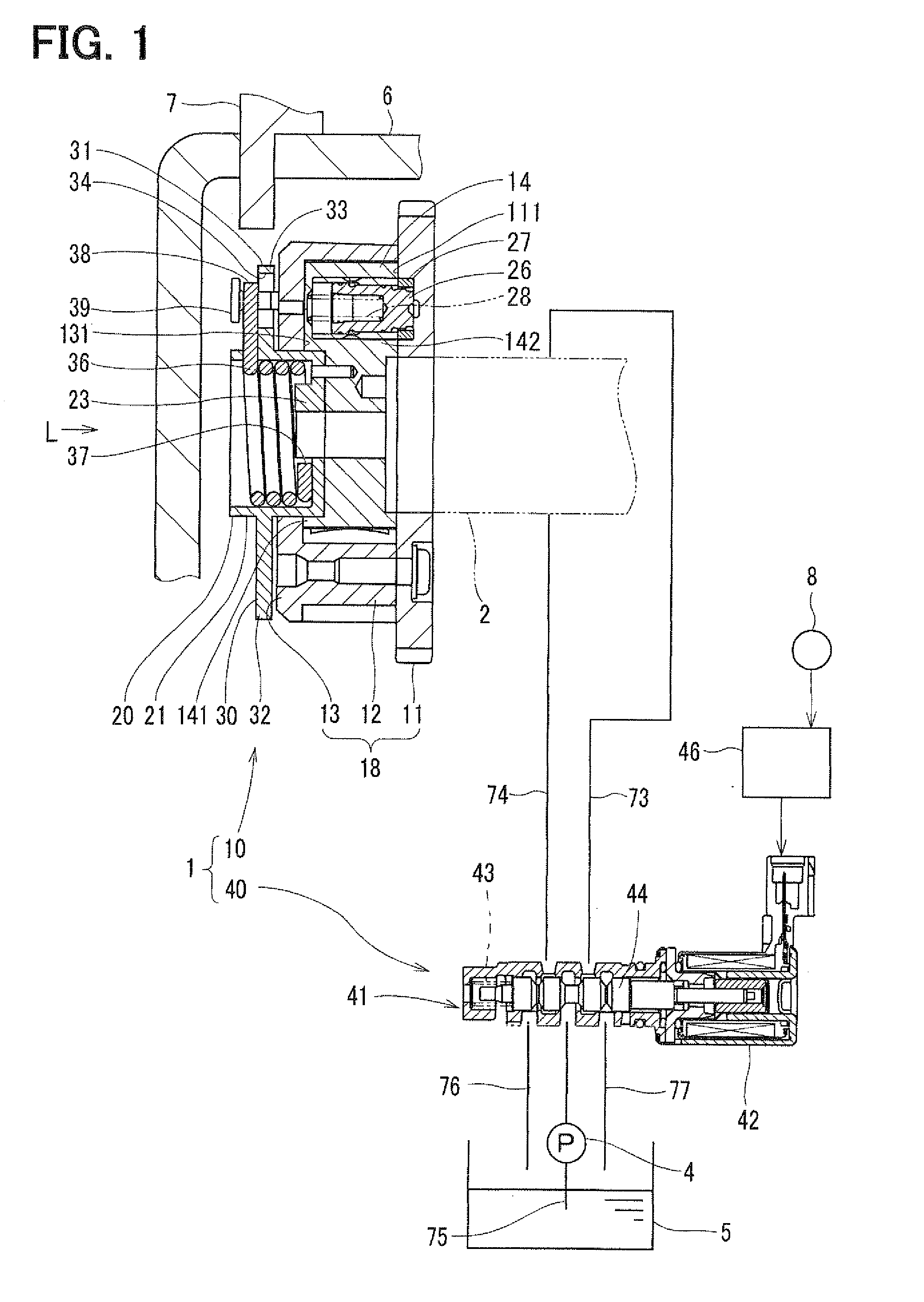

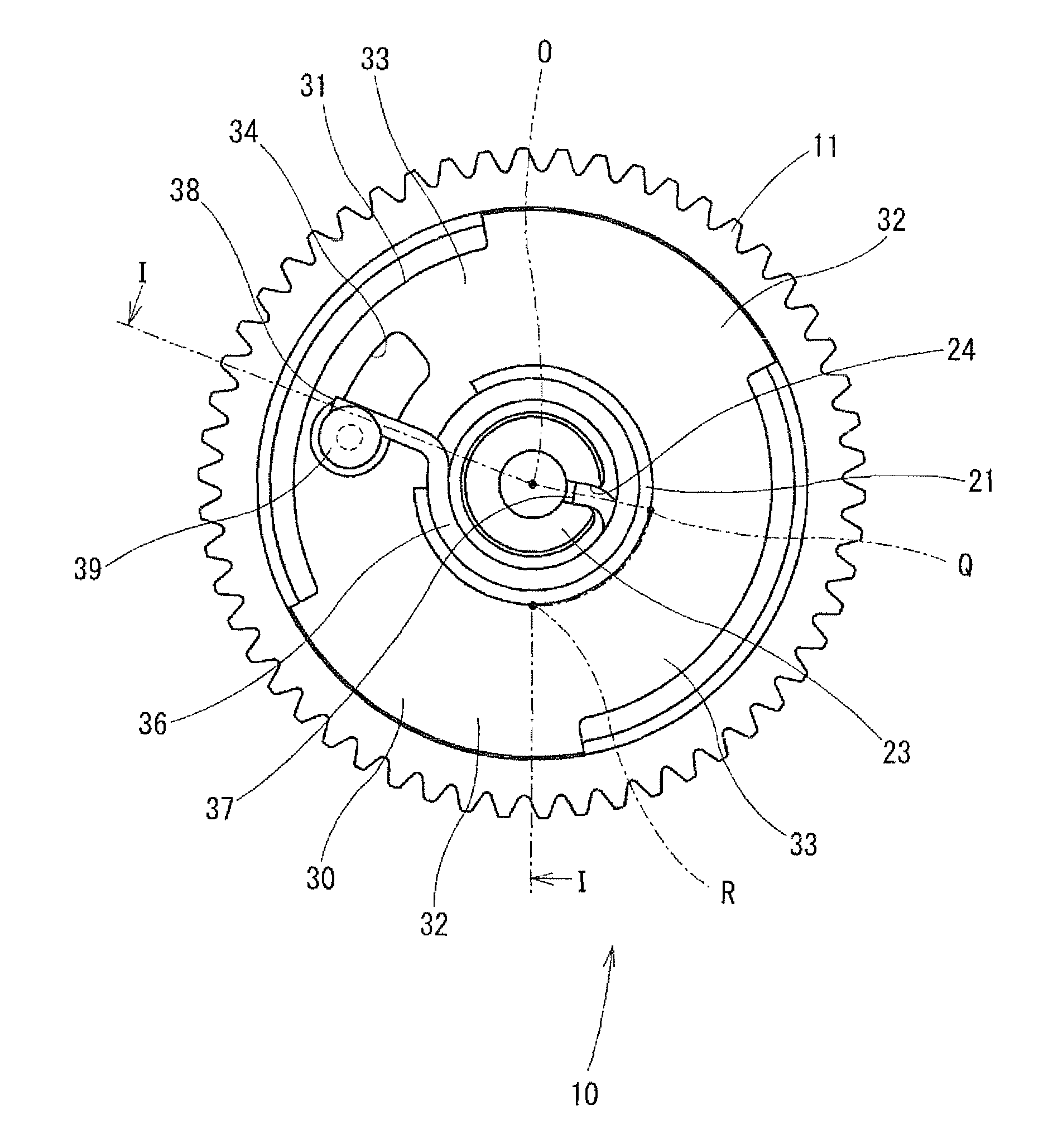

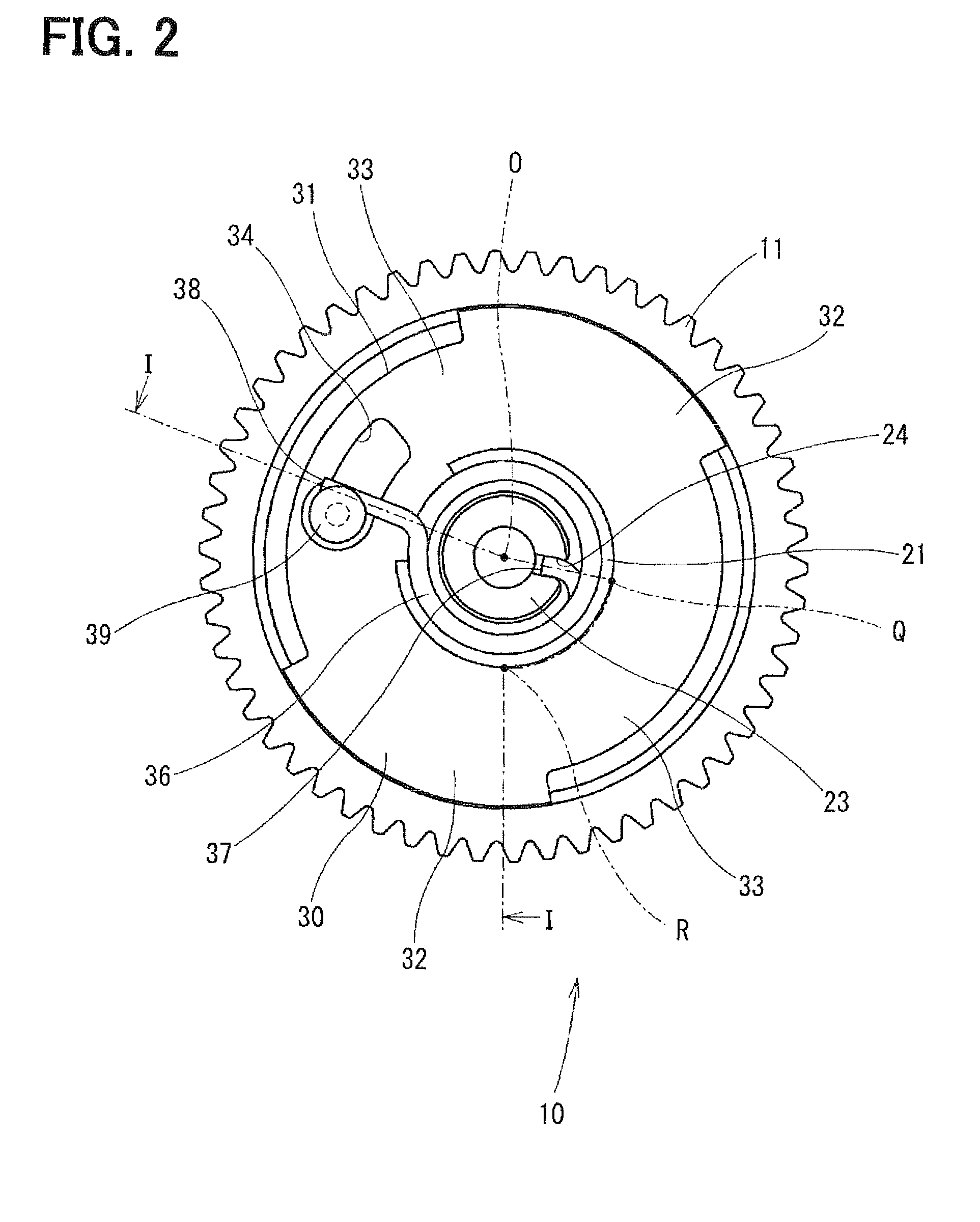

Valve timing control apparatus

ActiveUS20100258069A1Low number of componentsReduce the number of partsValve arrangementsMachines/enginesEngineeringCam

An assist spring is fixed at its one end to a vane rotor and at its other end to a spring hook provided at an outside of a housing 18. A signal plate is fixed to the vane rotor on a side of the spring hook. A cam angle sensor is provided at an outer peripheral side of the signal plate for detecting a rotational angle of the signal plate. The assist spring and the spring hook are arranged in an area, which is inside of an outer periphery of the signal plate in a radial direction, so that the cam angle sensor may not misidentify the assist spring and the spring hook and thereby exactly detects the rotational angle of the signal plate.

Owner:DENSO CORP

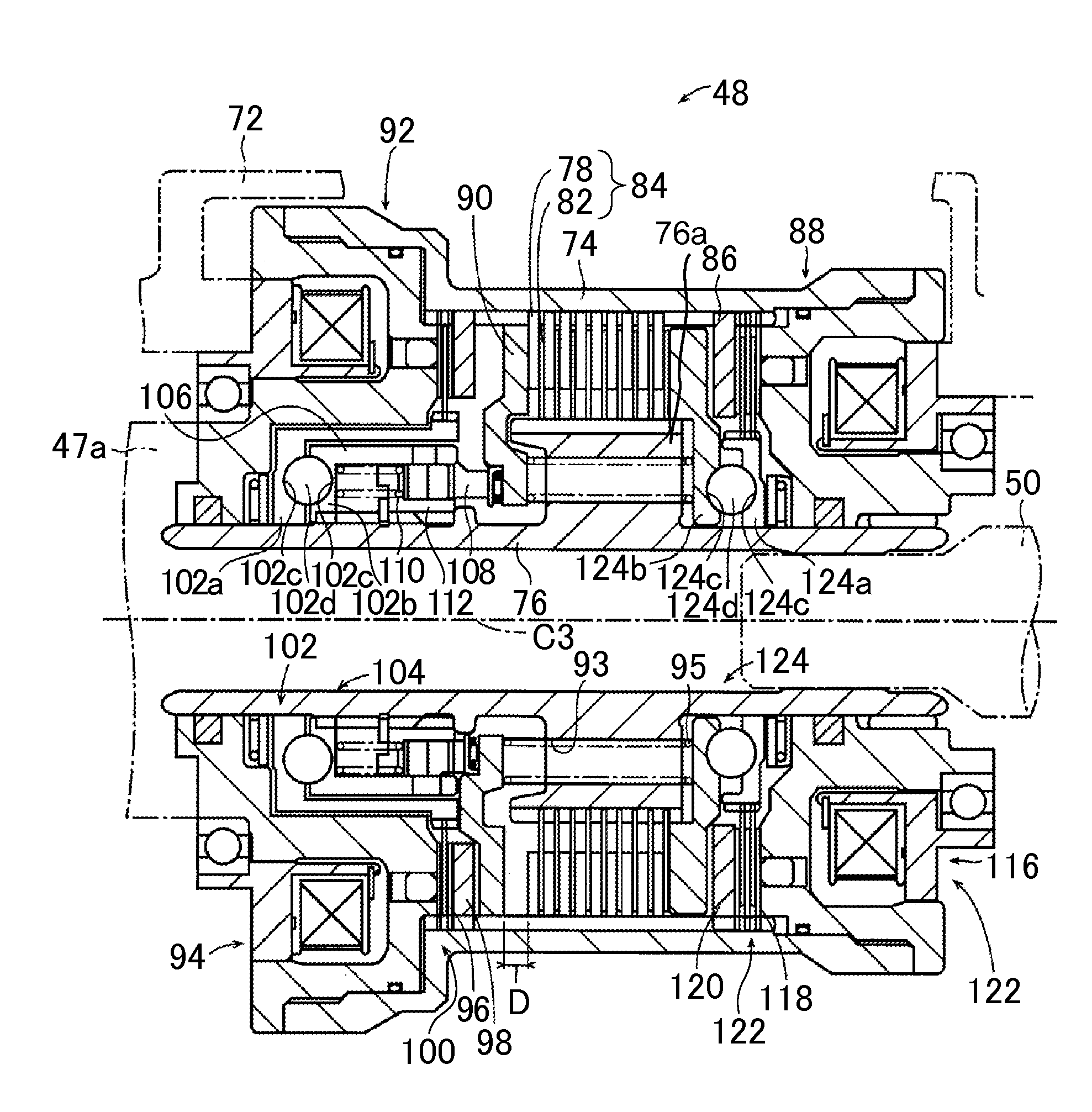

Multiple disc clutch device for vehicle

InactiveUS20150267761A1Drag torque of the multiple disc clutch device is significantly reducedImprove vehicle efficiencyMagnetically actuated clutchesFriction clutchesEngineeringClutch

A reaction member is arranged on one side of a main clutch in a direction of a rotation axis. The reaction member is configured to generate a reaction force by receiving a pressing force in the direction of the rotation axis via the main clutch, the pressing force being applied from the other side of the main clutch in the direction of the rotation axis. A reaction member actuating device is configured to position the reaction member between a reaction force generating position for causing the reaction member to generate the reaction force and a non-reaction force generating position. The non-reaction force generating position is farther from the main clutch than the reaction force generating position and a position that is located a predetermined distance apart from the reaction force generating position in the direction of the rotation axis.

Owner:TOYOTA JIDOSHA KK

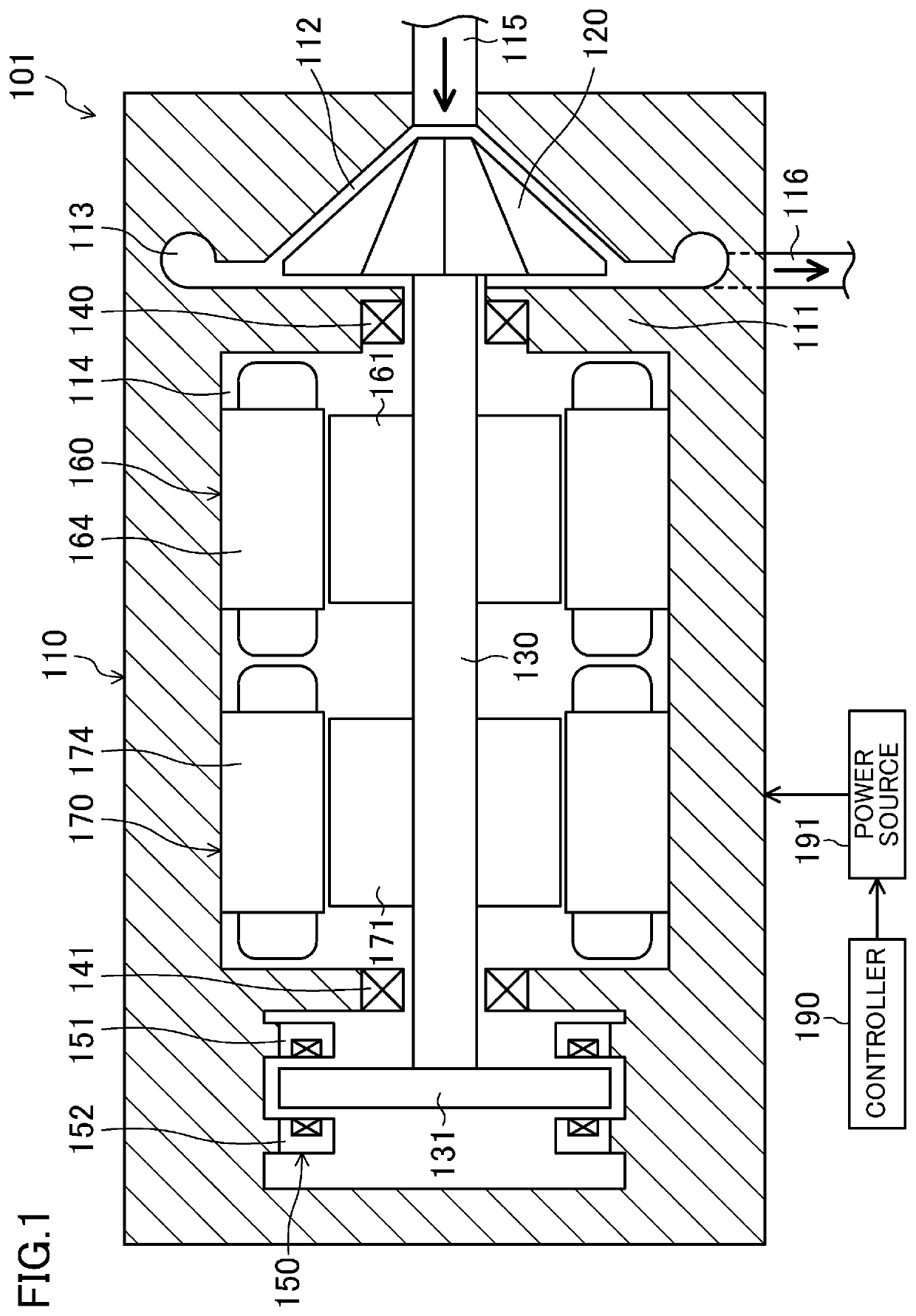

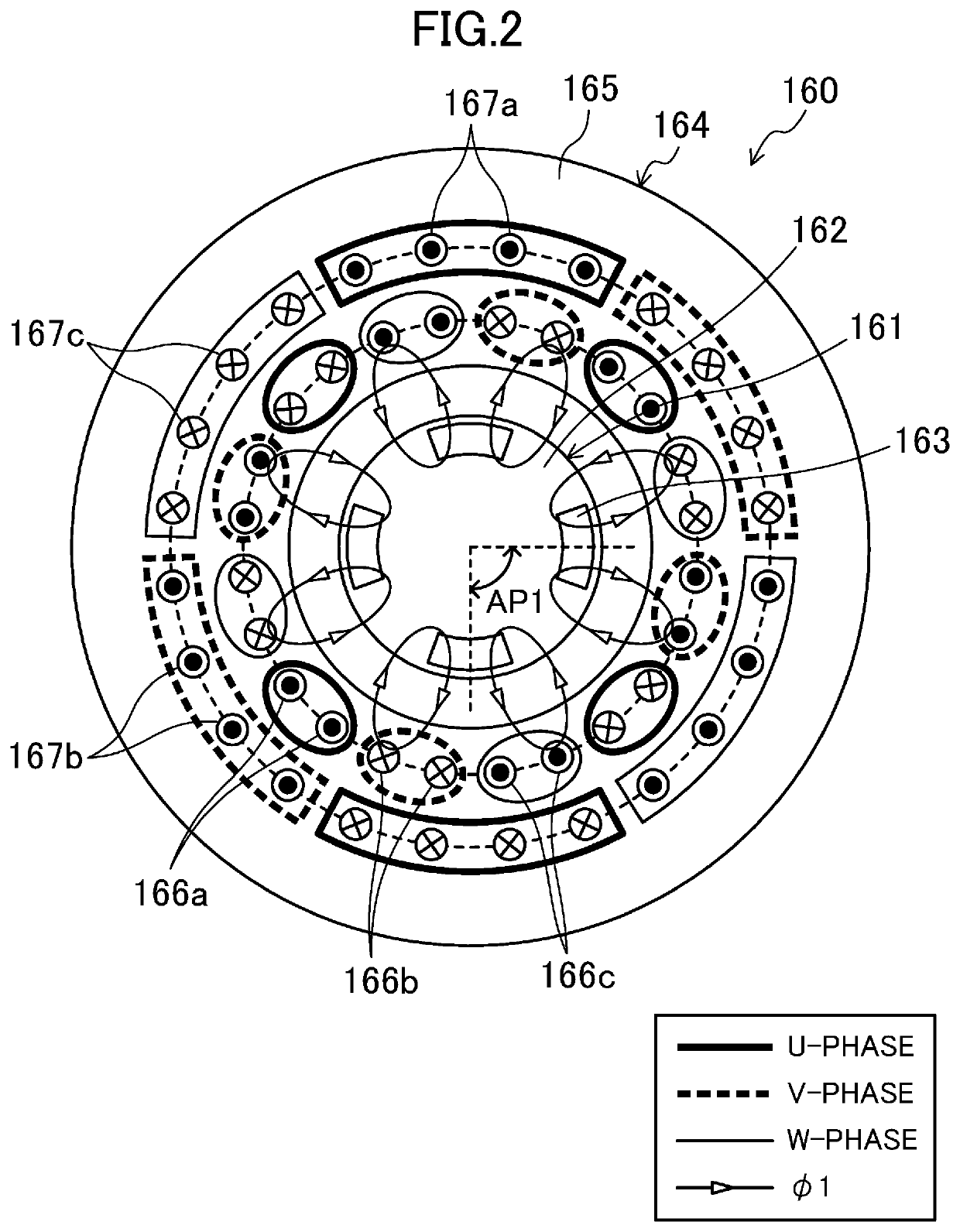

Turbo compressor

PendingUS20210115929A1Easy to controlAchieving Reliability RequirementsCompressorAC motor controlDrive shaftElectric machinery

A drive support unit of a turbo compressor includes at least one bearingless motor. The at least one bearingless motor includes a rotor-stator pair constituted by a rotor and a stator, and is configured to rotationally drive a drive shaft and to support a radial load of the drive shaft in a contactless manner. Accordingly, it is possible to provide a turbo compressor to which a bearingless motor is applied.

Owner:DAIKIN IND LTD

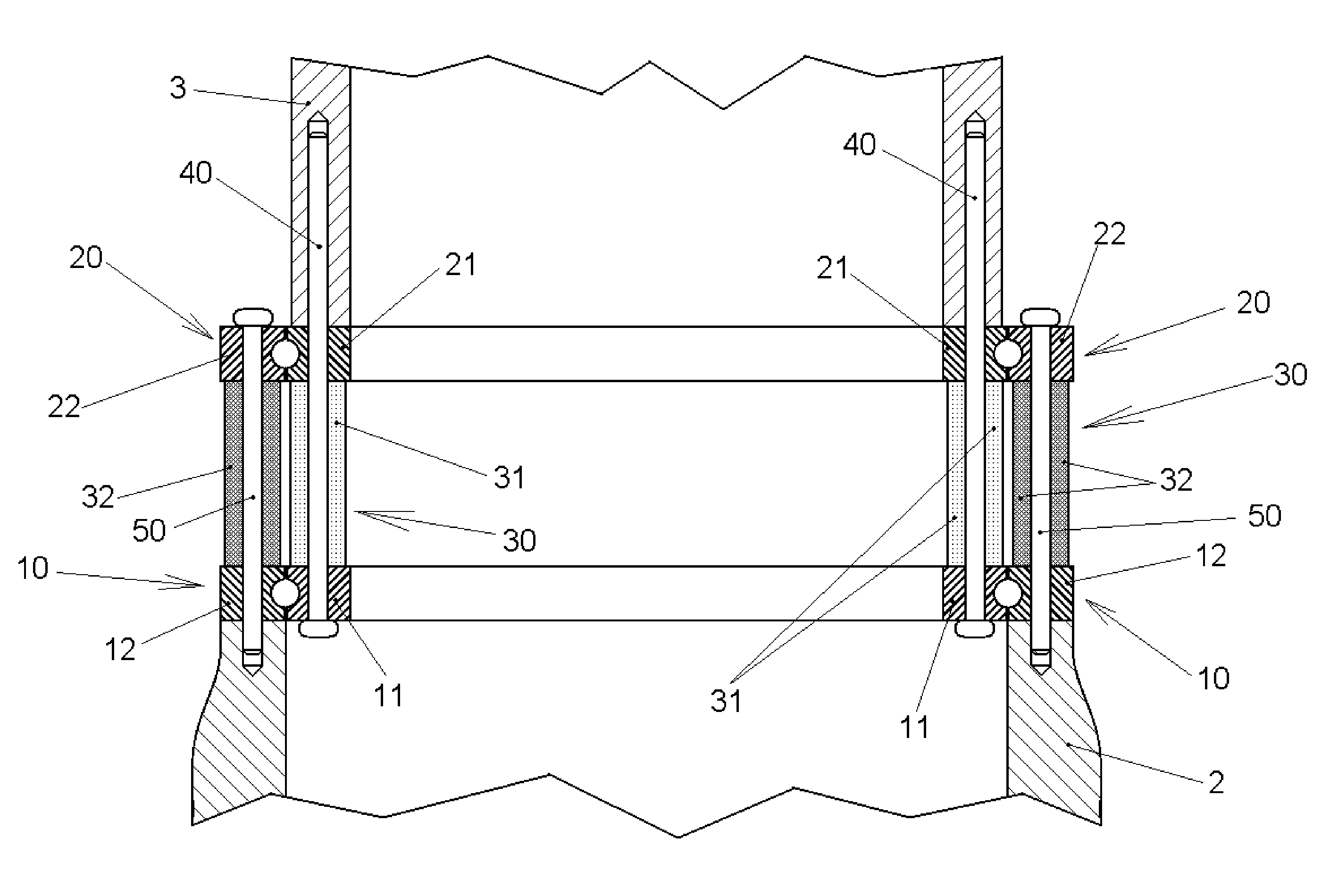

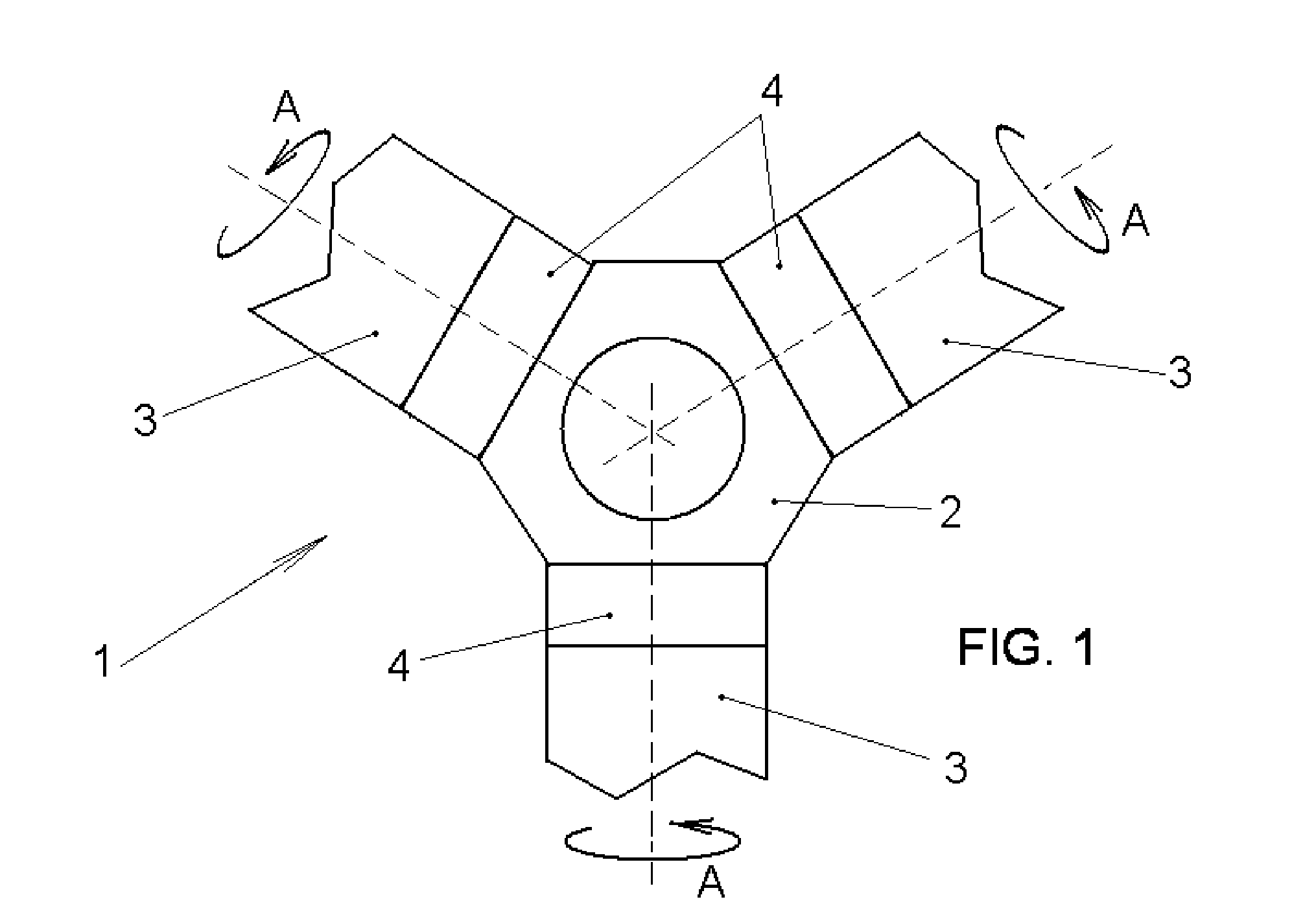

Pitch system for a wind turbine rotor

ActiveUS20140003944A1Simpler and cheap provideIncrease stiffnessPropellersPump componentsBlade pitchWind force

A pitch system for a wind turbine rotor, comprising a first bearing and a second bearing, each provided with an outer race, an inner race, and at least one row of rolling elements, the first and second bearings being adapted to be arranged between a hub and a blade root portion or extender, to allow rotation of the blade with respect to the hub, wherein the first bearing is adapted to be arranged nearer to the hub than the second bearing in the axial direction, the pitch system further comprising an intermediate body arranged between the first bearing and the second bearing in the axial direction, said intermediate body comprising at least a blade-side part extending between the race of the first bearing that is associated with the blade and the race of the second bearing that is associated with the blade.

Owner:GE RENEWABLE TECH WIND BV

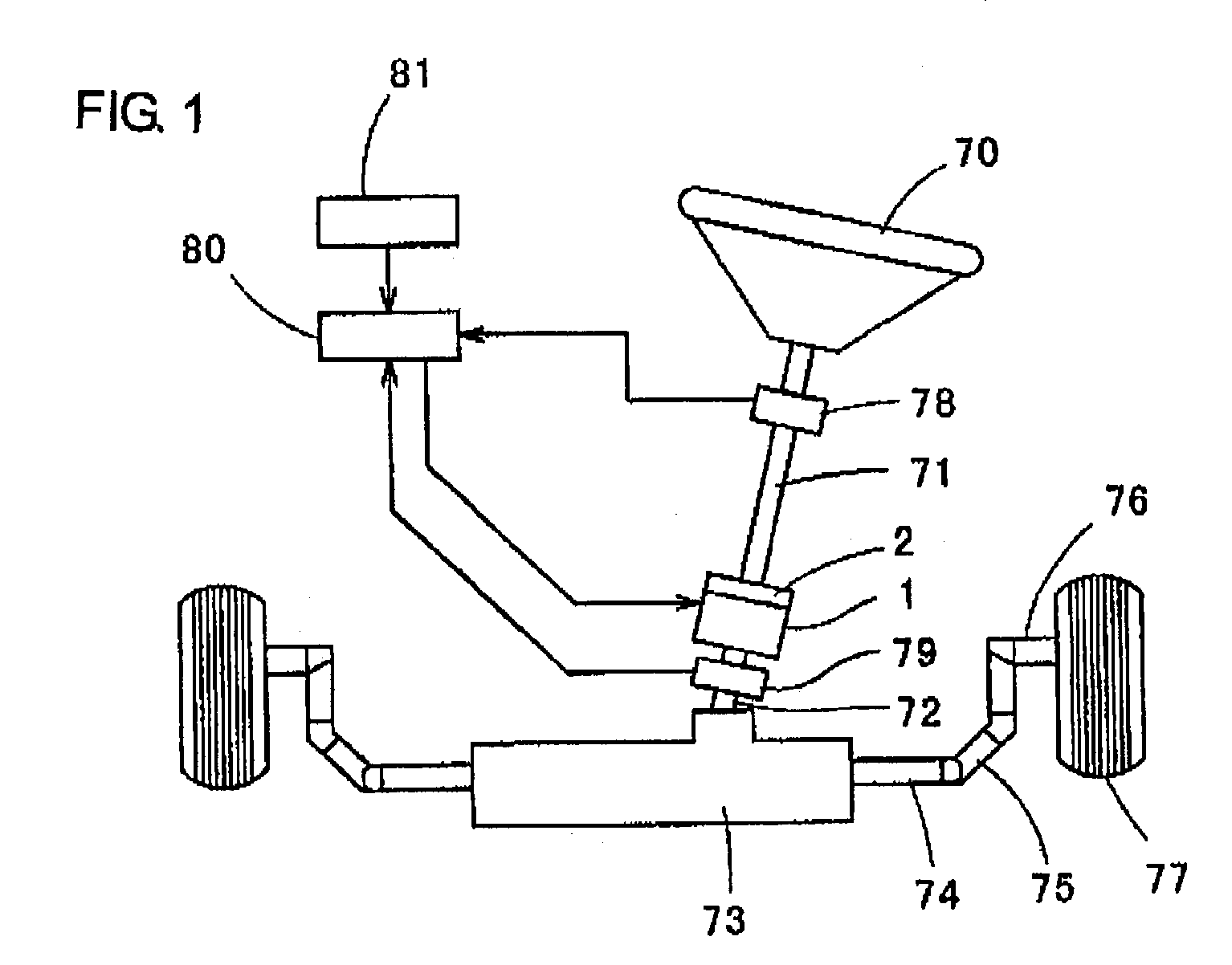

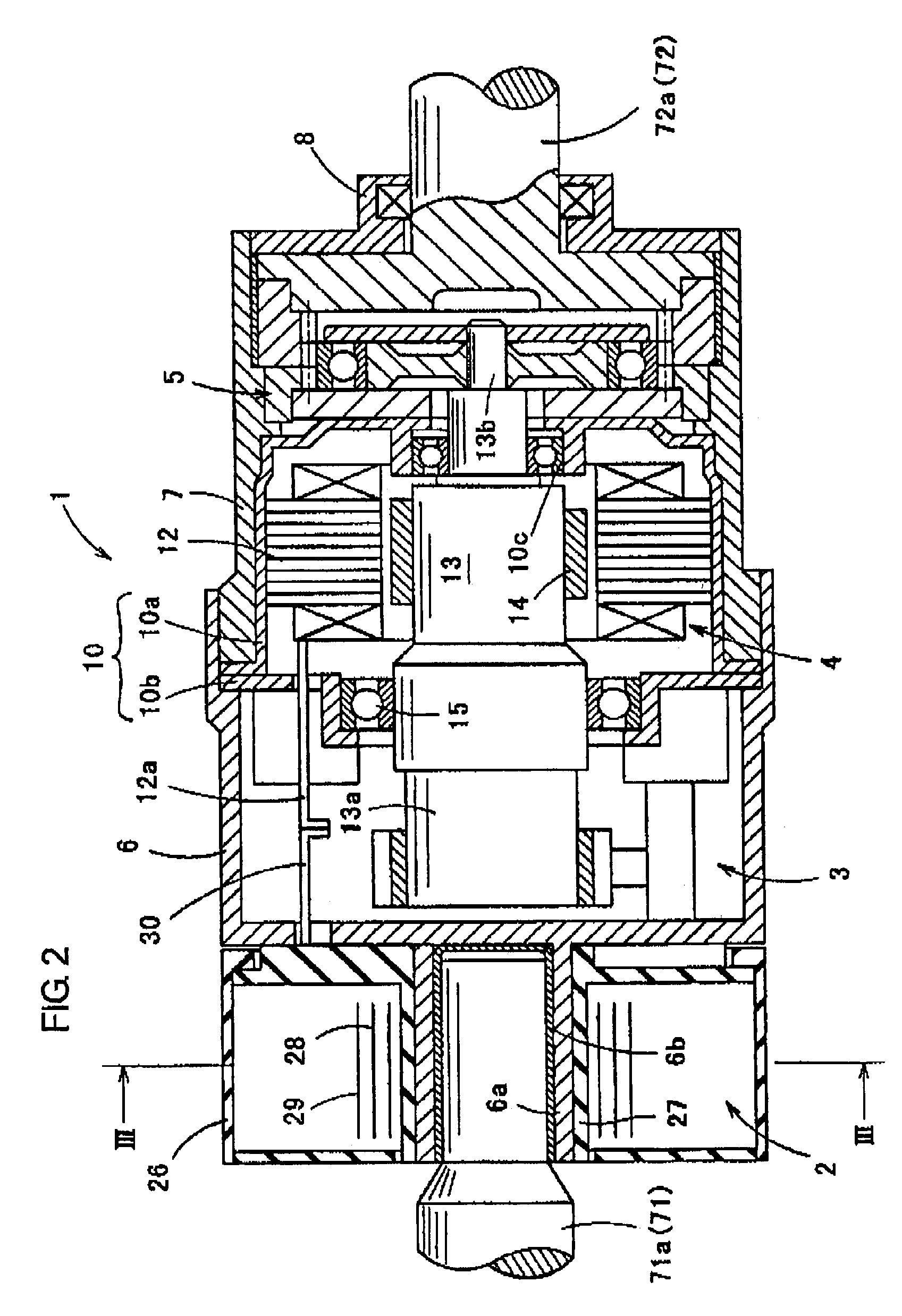

Spiral cable device

InactiveUS7038139B2Small widthReduce in quantityElectrically conductive connectionsFlat/ribbon cablesEngineeringMechanical engineering

A spiral cable device is provided with a cylindrical casing, an inner cylinder rotatable relative to the cylindrical casing, and a flexible flat cable connected to the inner cylinder at one end thereof and to the cylindrical casing at the other end thereof. The flexible flat cable has plural leads arranged in a single layer and is folded to form multiple layers of the leads, so that even where the flexible flat cable is to have many leads, the spiral cable device can be made short in the axial direction thereof.

Owner:TOYODA MASCH WORKS LTD +1

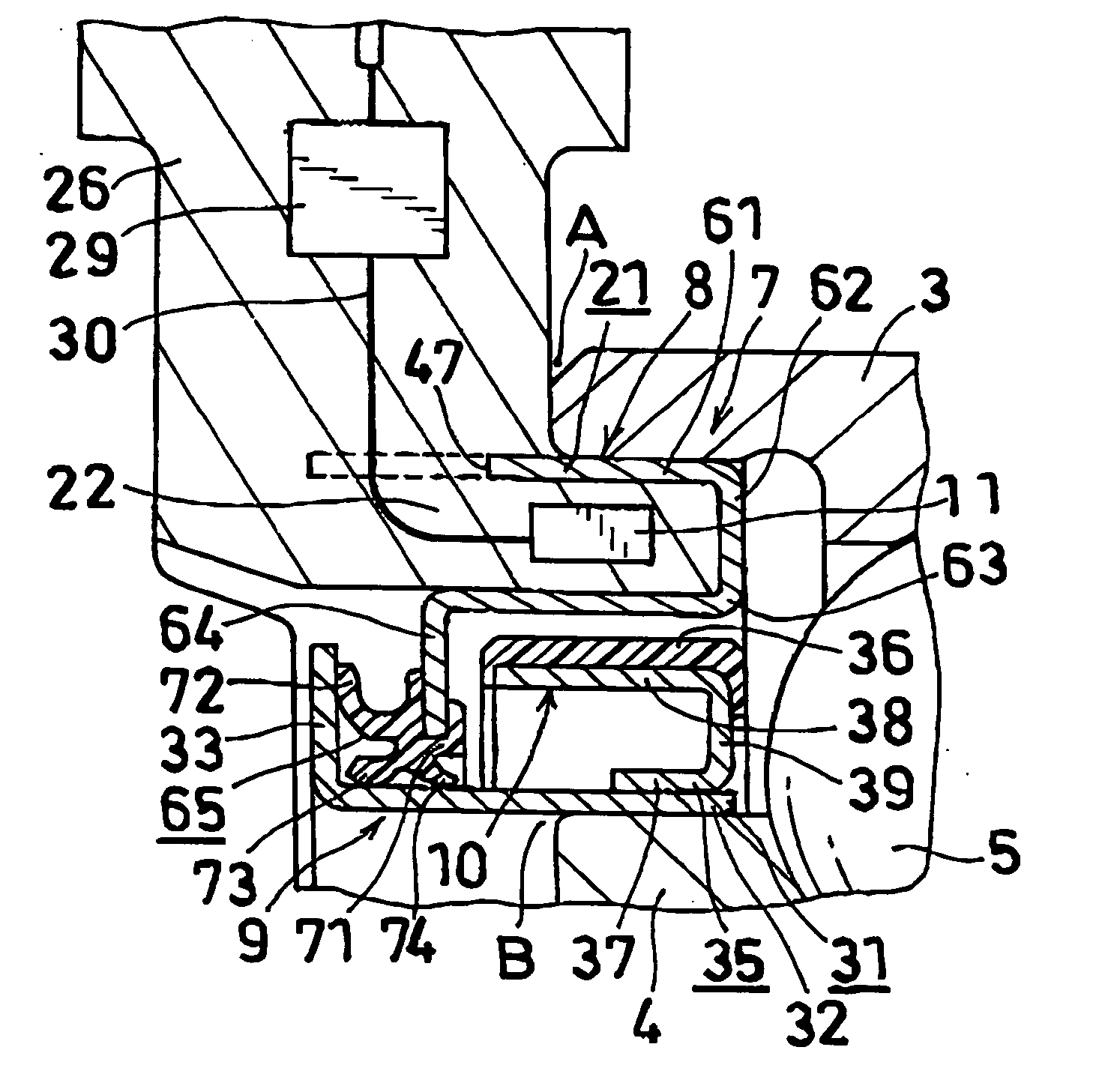

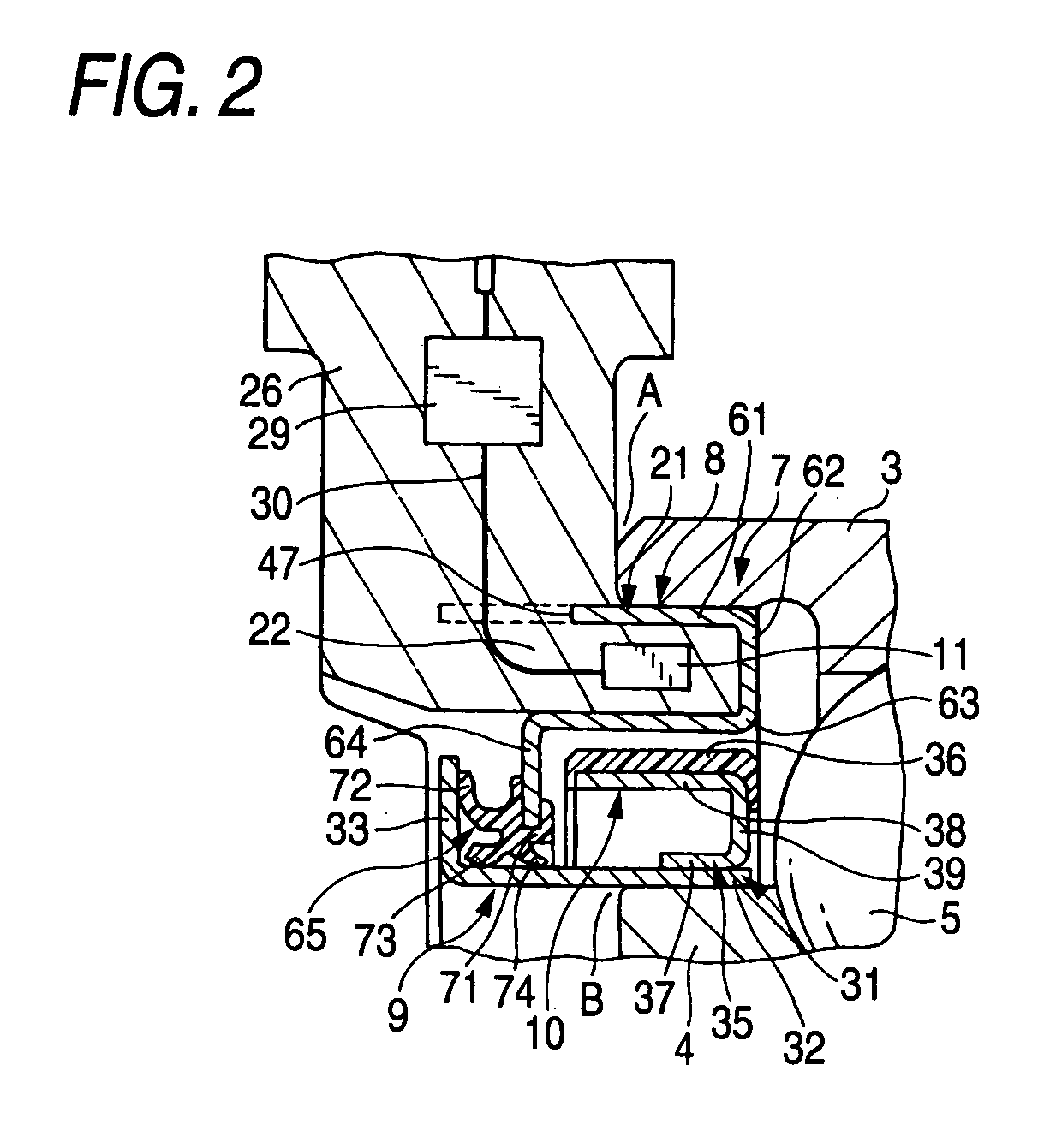

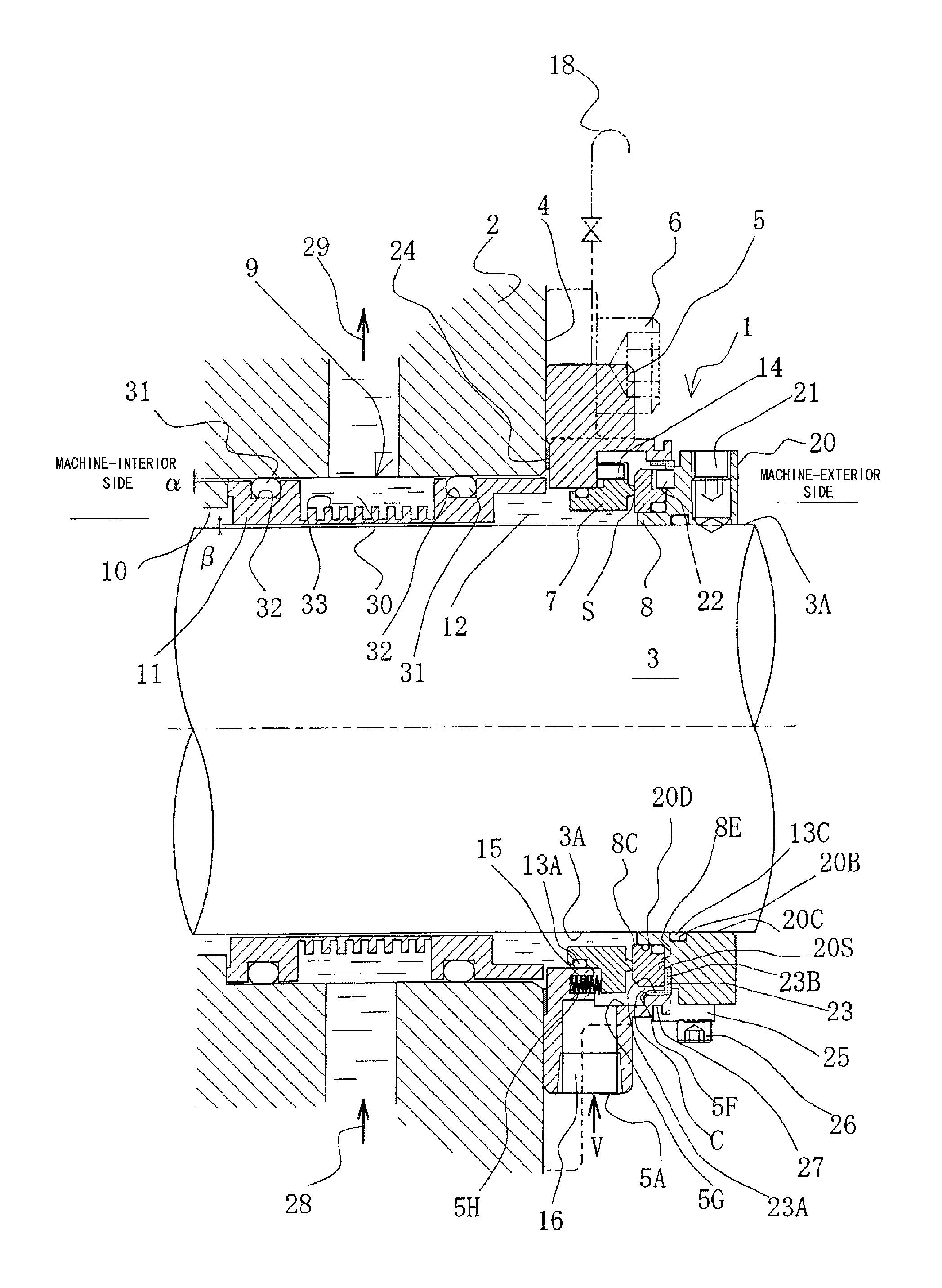

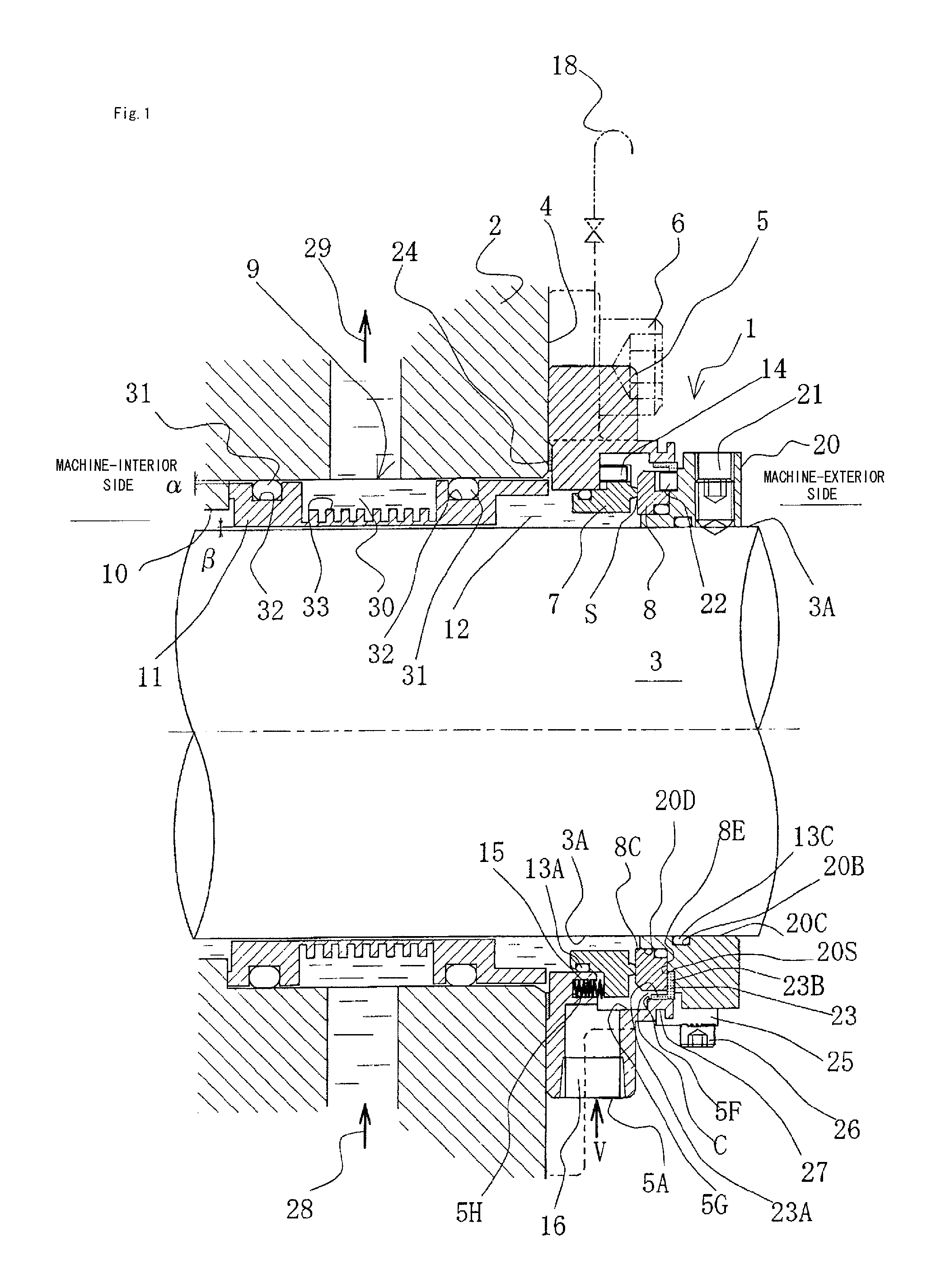

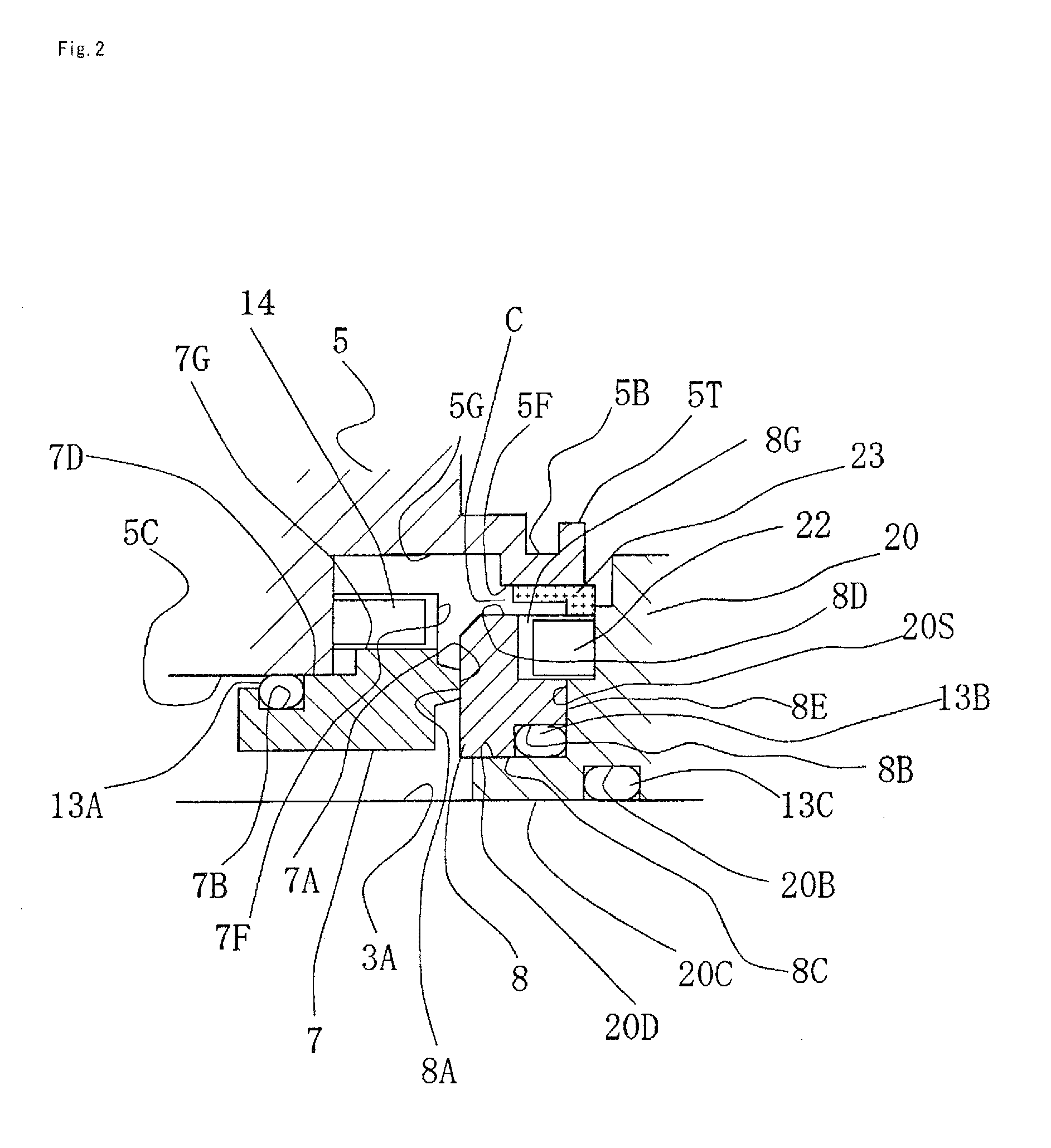

Seal device with sensor and rolling bearing device using the same

InactiveUS20070104402A1Easy to embedReduce axial sizeEngine sealsRolling contact bearingsRolling-element bearingMechanical engineering

A seal device with a sensor includes a fixed seal member fixed to a body-side raceway member and a rotated seal member fixed to a body-side raceway member. The rotated seal member comprises a pulsar provided with a support member and a magnetized body. The support member of the pulsar includes a small-diameter cylindrical portion fitted and fixed to a cylindrical portion of the rotated seal member, a large-diameter cylindrical portion having the magnetized body provided therein, and a connecting portion connecting both of the cylindrical portions. The support member of the pulsar is fitted and fixed to the axial inner portion of the cylindrical portion of the rotated seal member such that the connecting portion is set inward in the axial direction.

Owner:JTEKT CORP +1

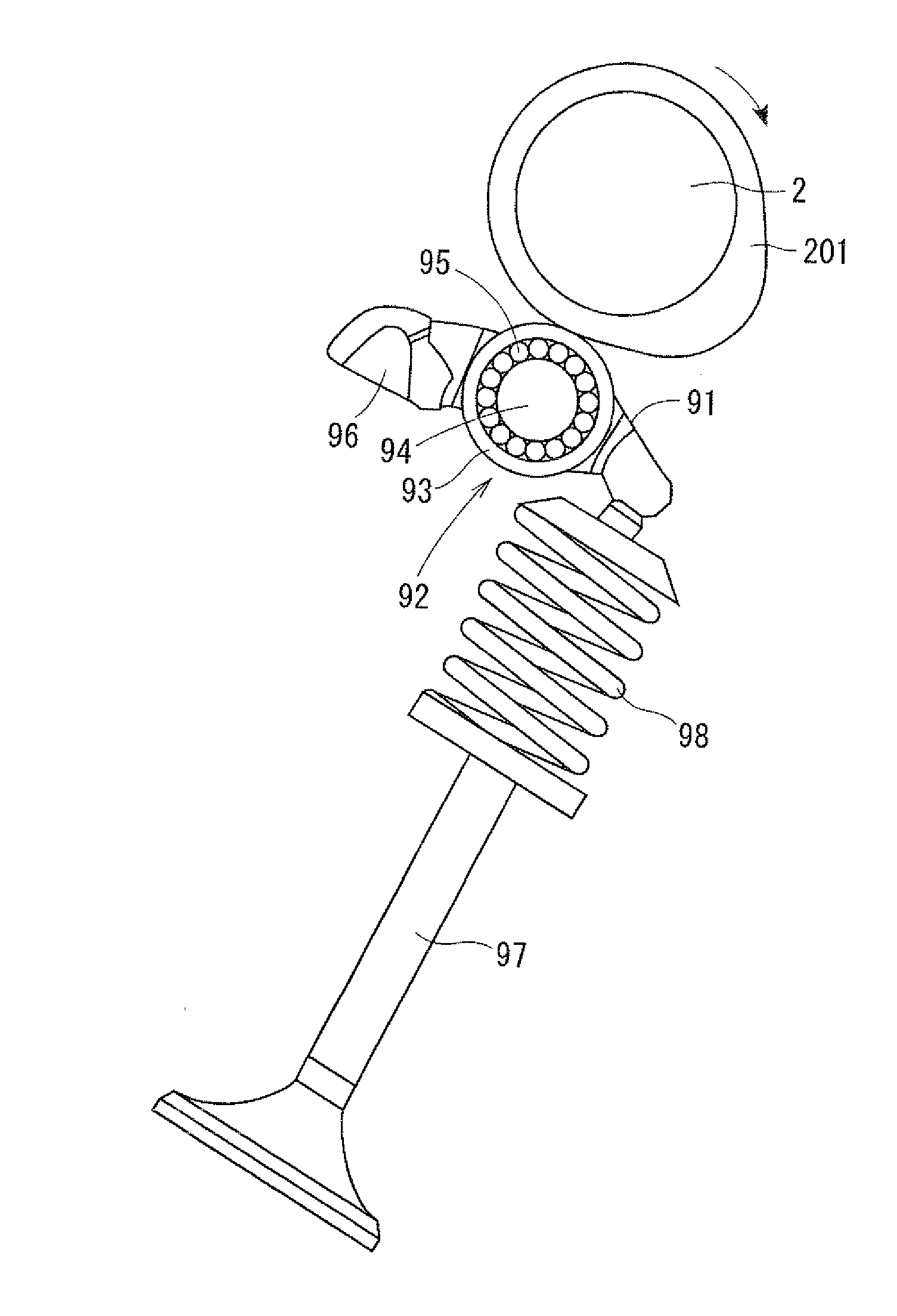

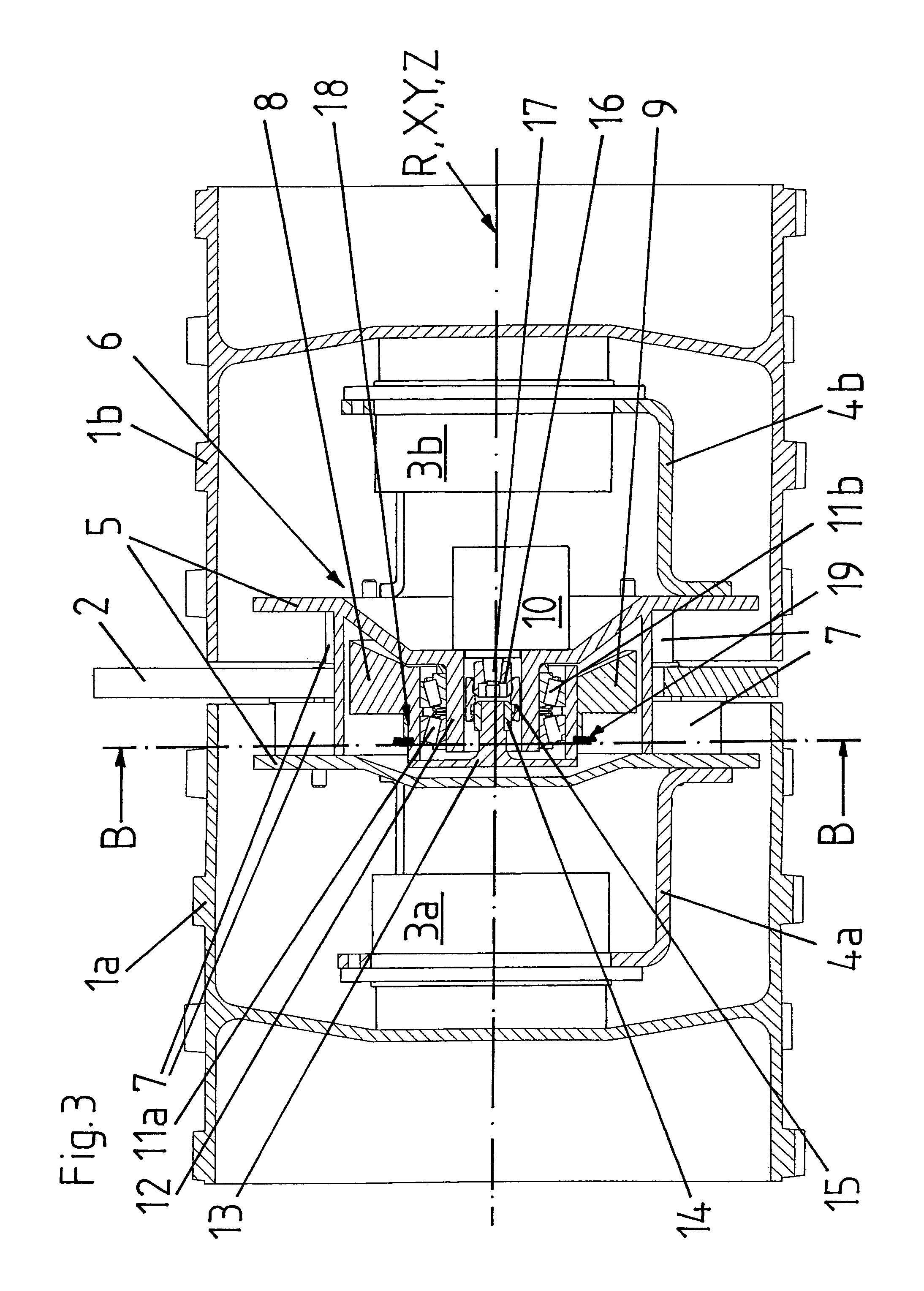

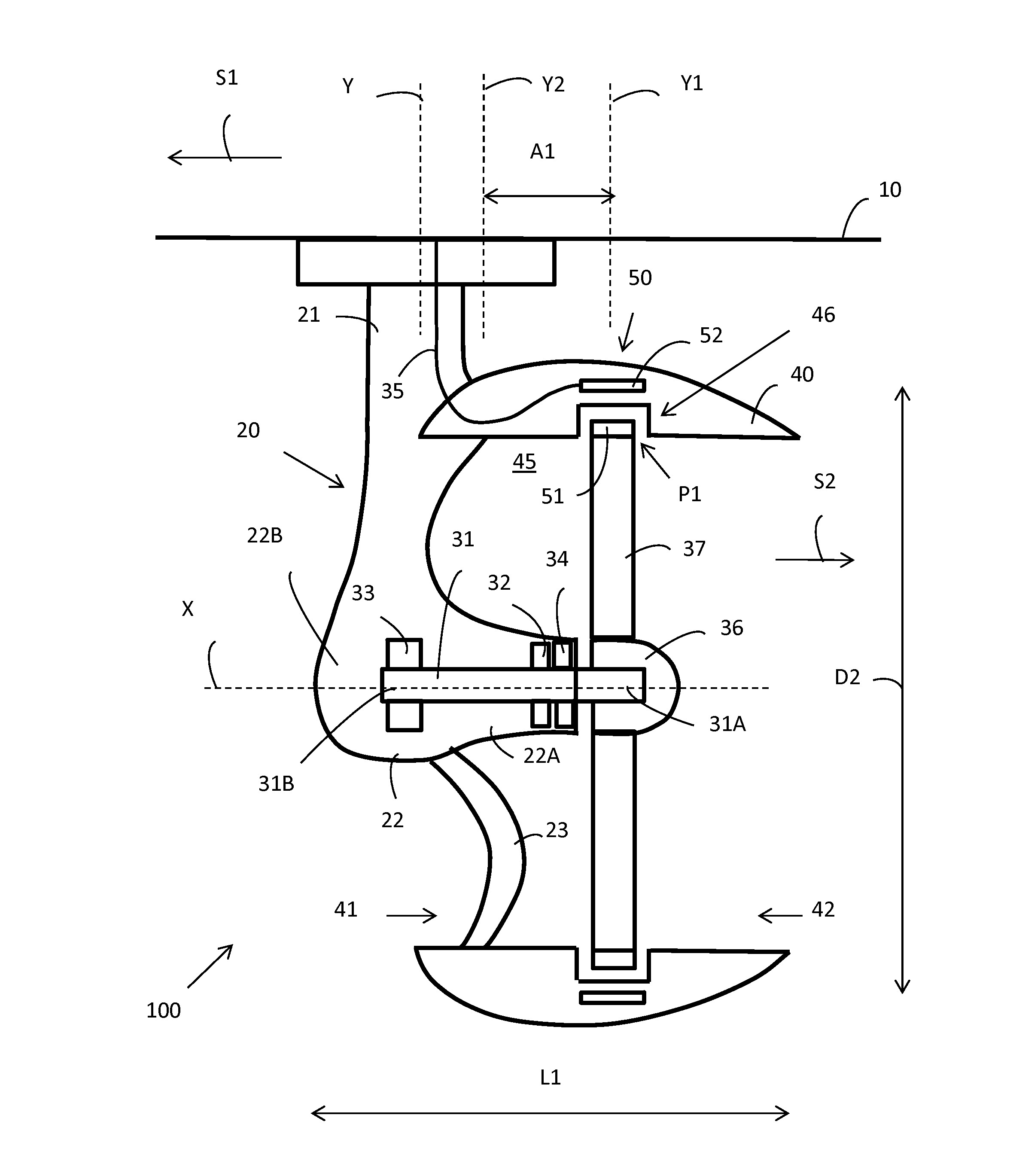

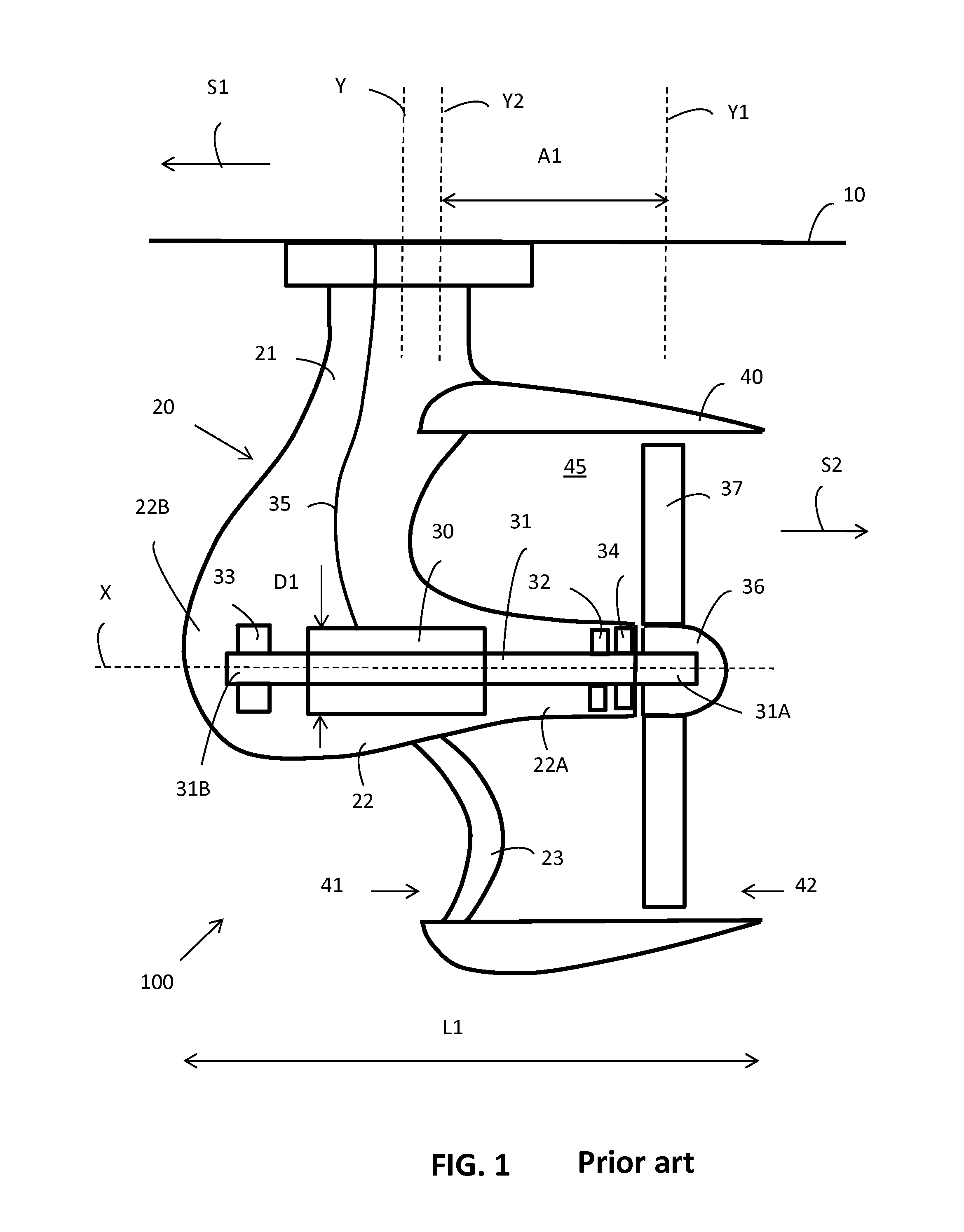

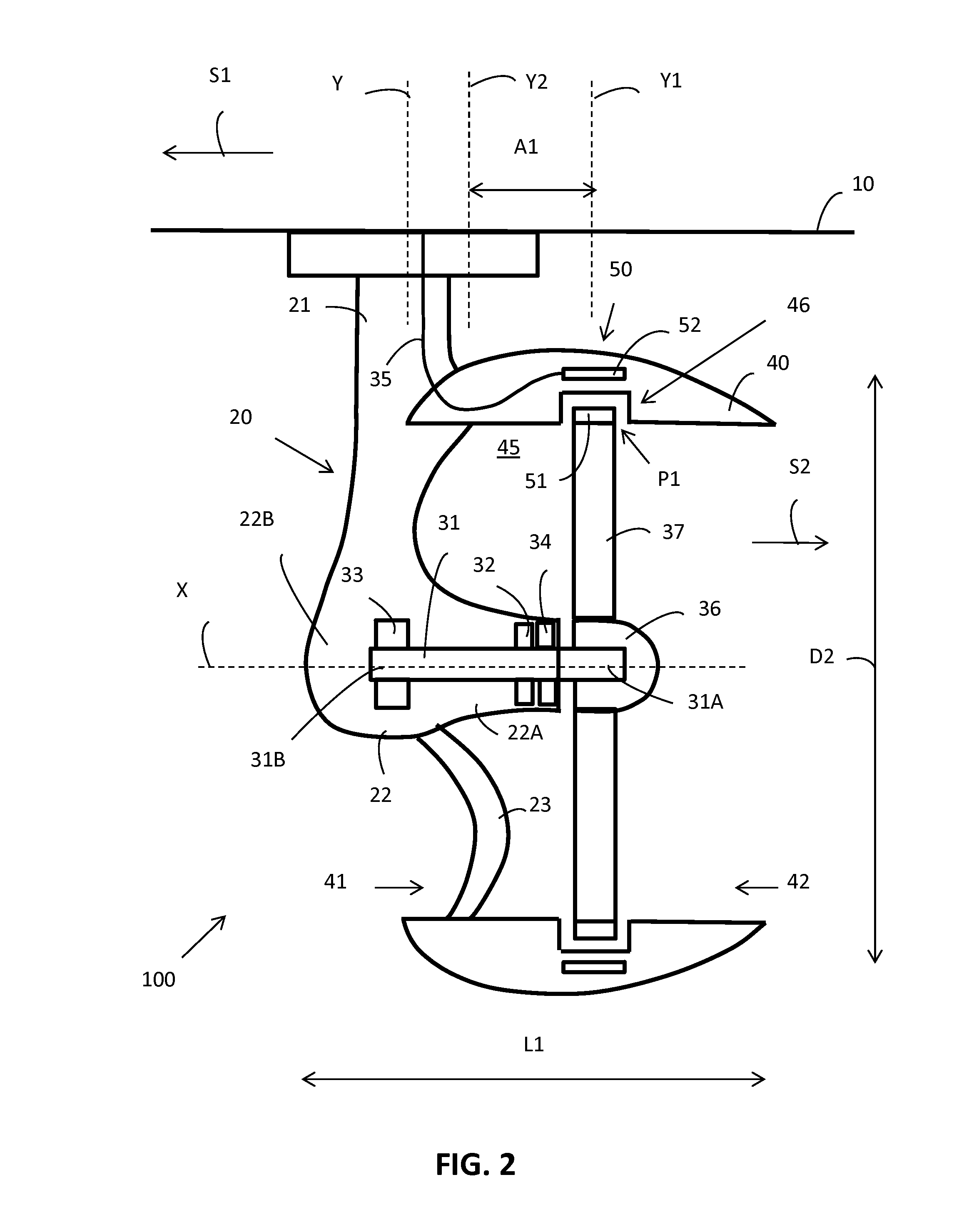

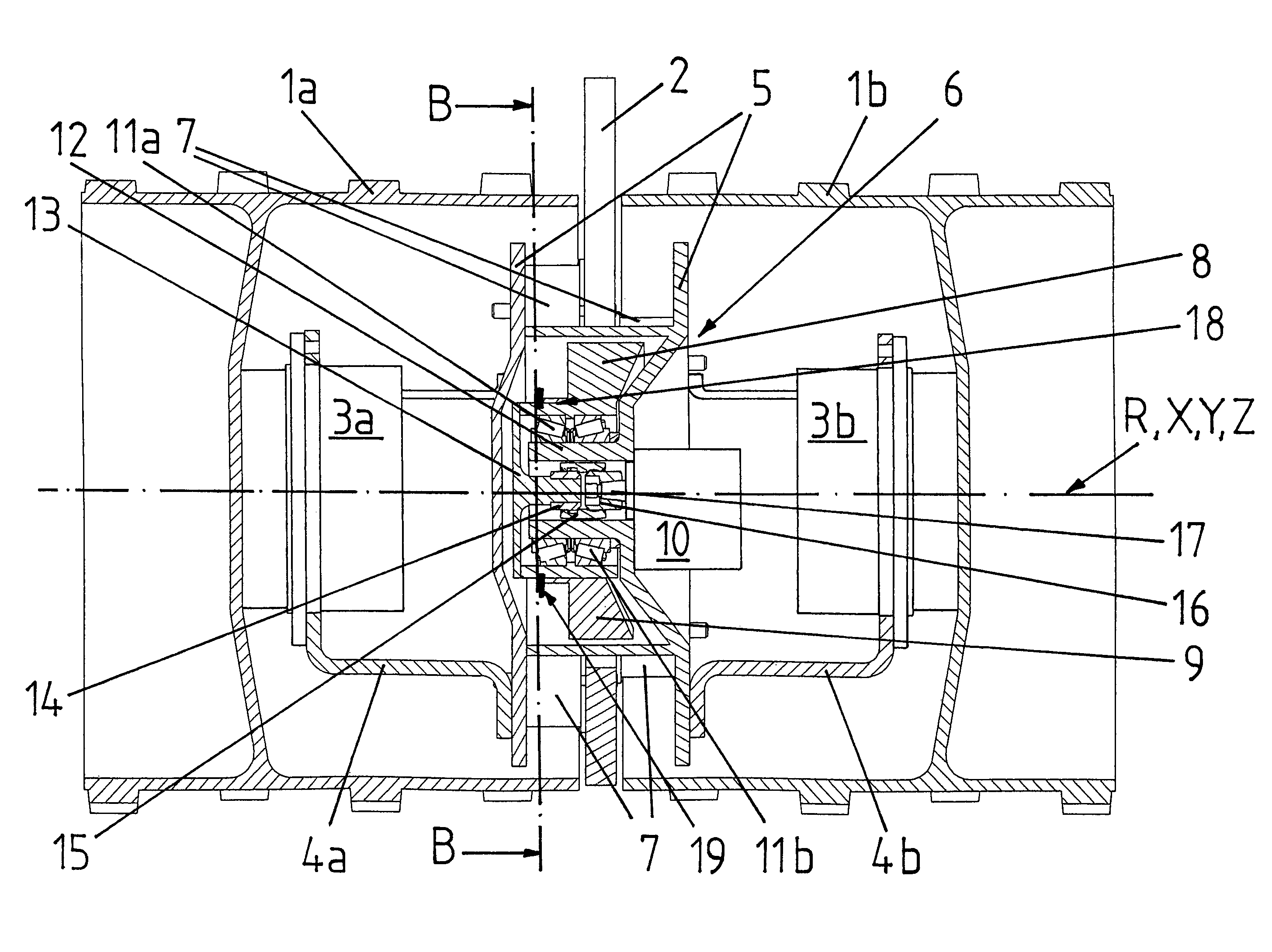

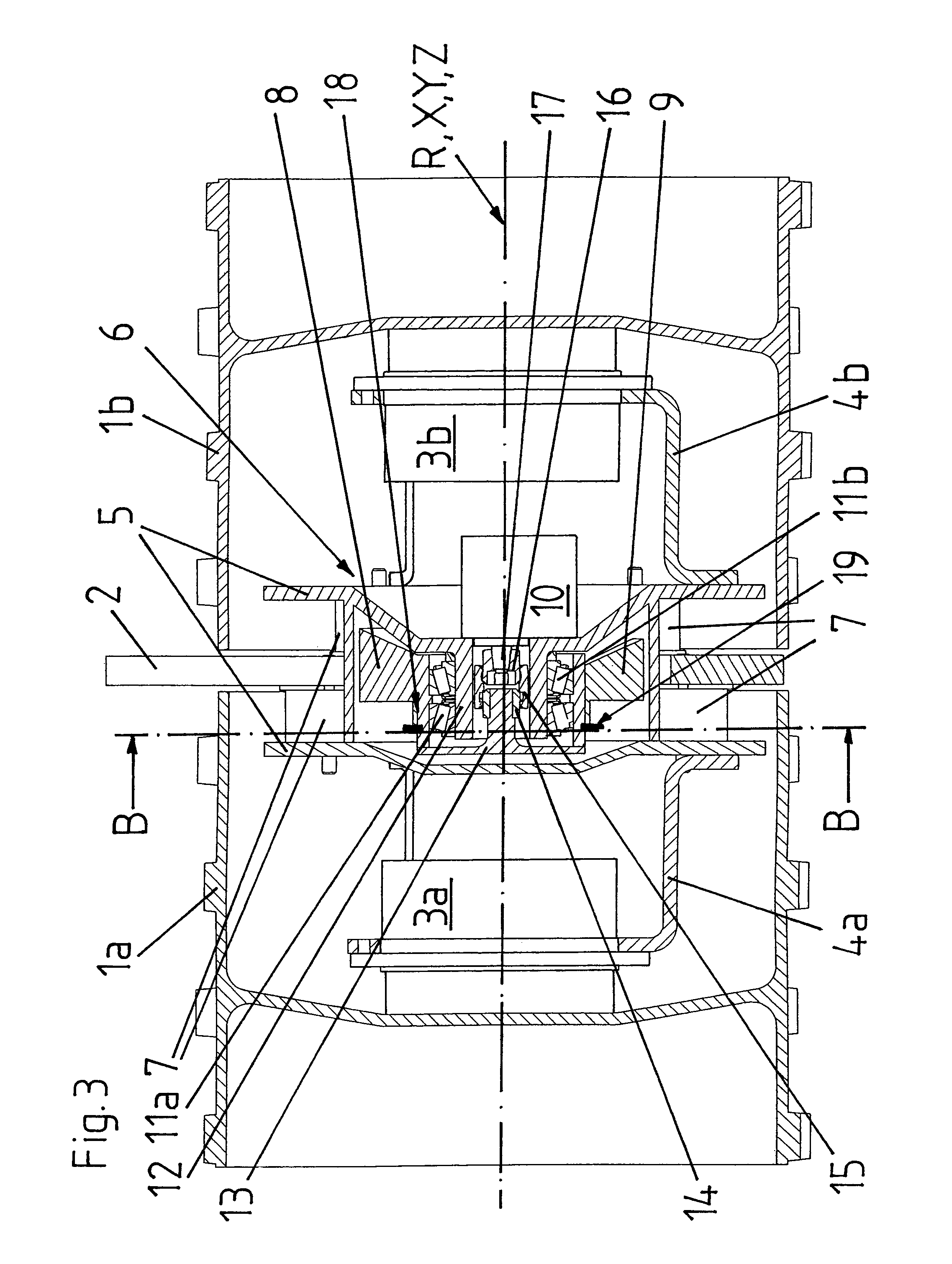

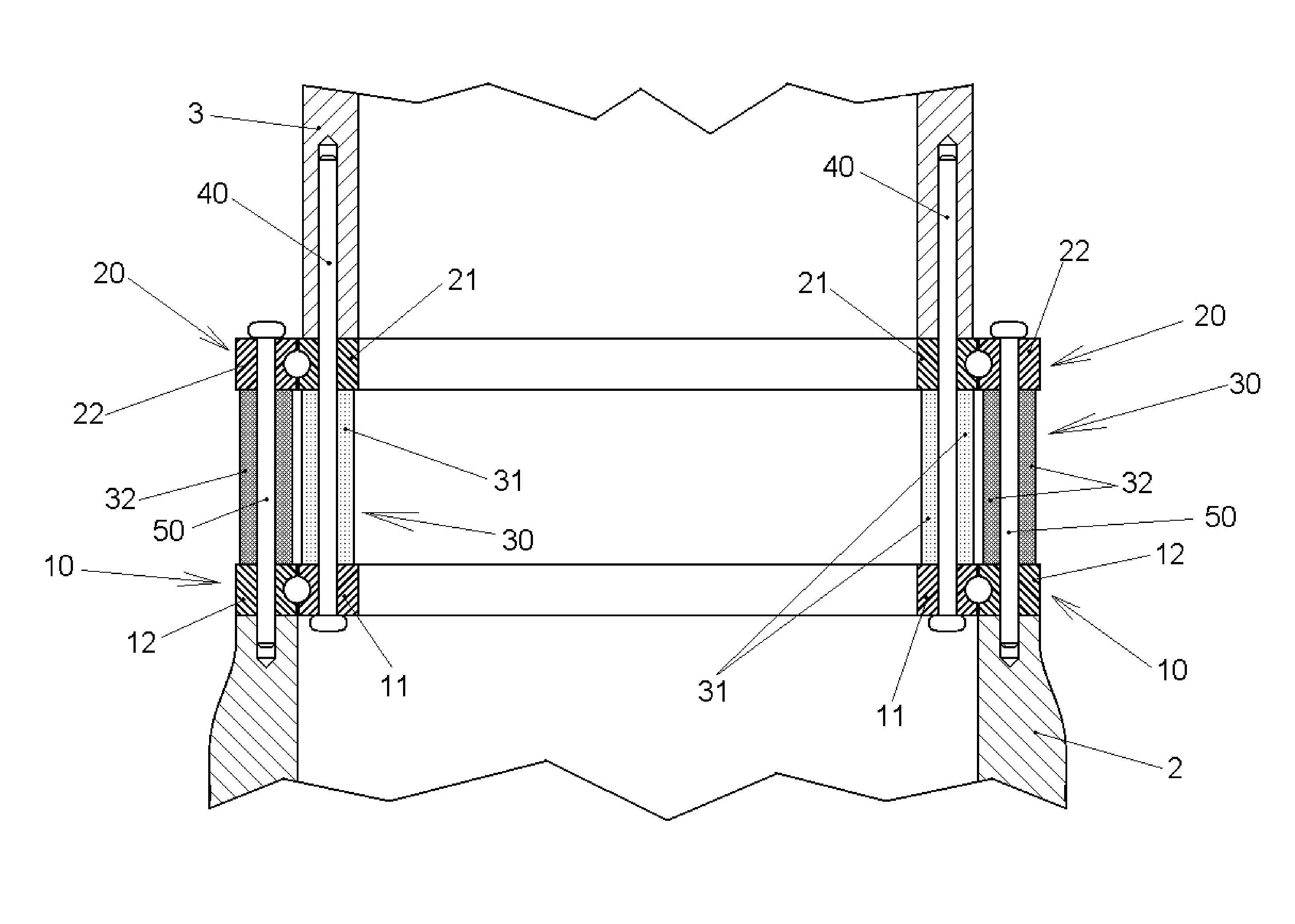

Unbalance type exciter for a soil compaction device

The invention relates to an unbalance type exciter (6) for a soil compaction device. This exciter comprises a carrying structure (5) as well as an unbalance weight (8, 9), which by means of a bearing (11a, 11b) is supported at the carrying structure (5) in rotatable manner around a rotation axis (Y) which in the intended use is stationary with respect to the carrying structure (5), for generating an intermittent exciting force for causing the carrying structure (5) in the intended use to vibrate. The bearing (11a, 11b) of the unbalance weight (8, 9) is arranged at least partially within the space which is circled by the unbalance weight (8, 9) when rotating around the rotation axis (y). Owing to the fact that this space is used for receiving at least part of the bearing of the unbalance weight (8, 9) it becomes possible to provide unbalance type exciters (6) having very small axial overall length.

Owner:AMMANN SCHWEIZ

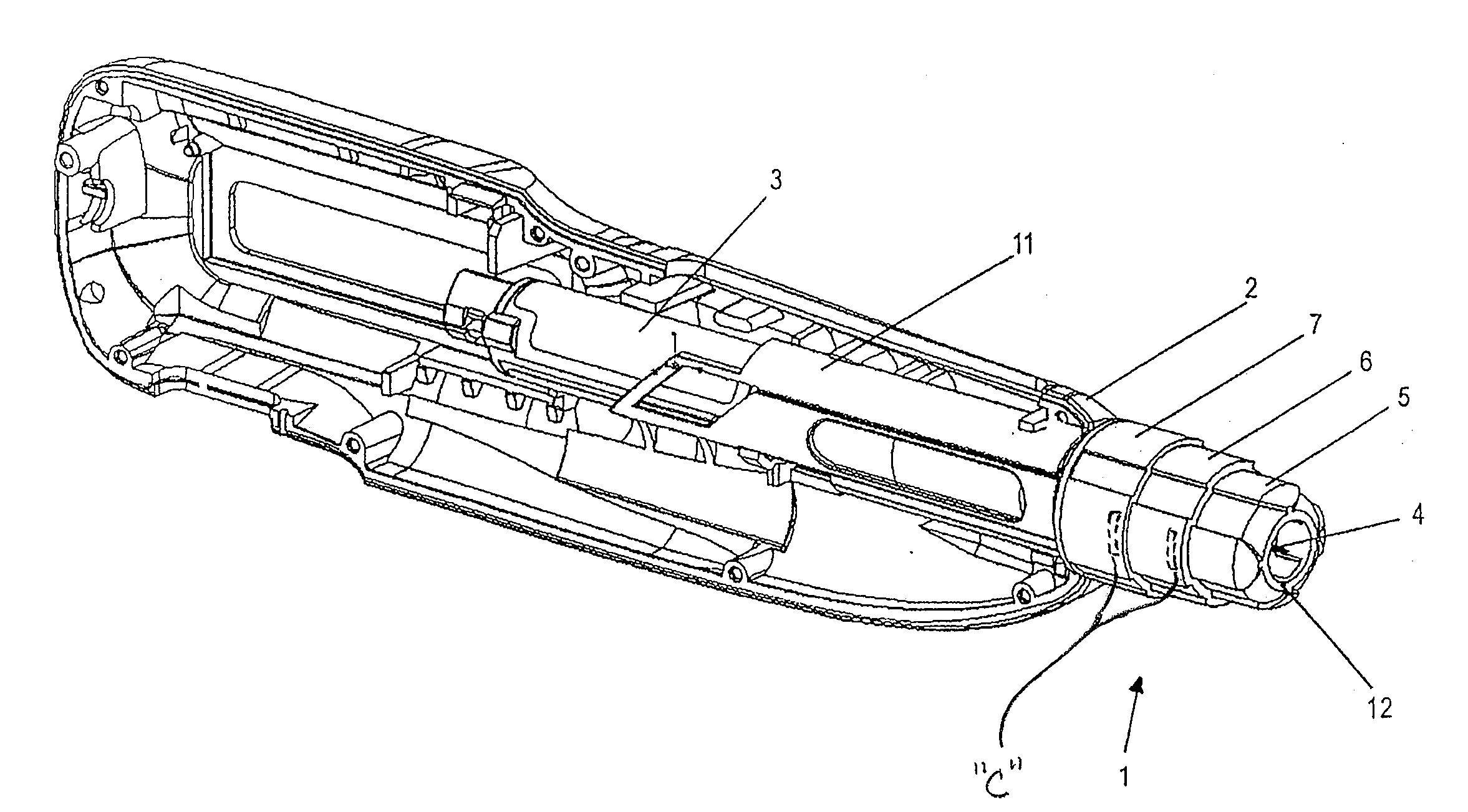

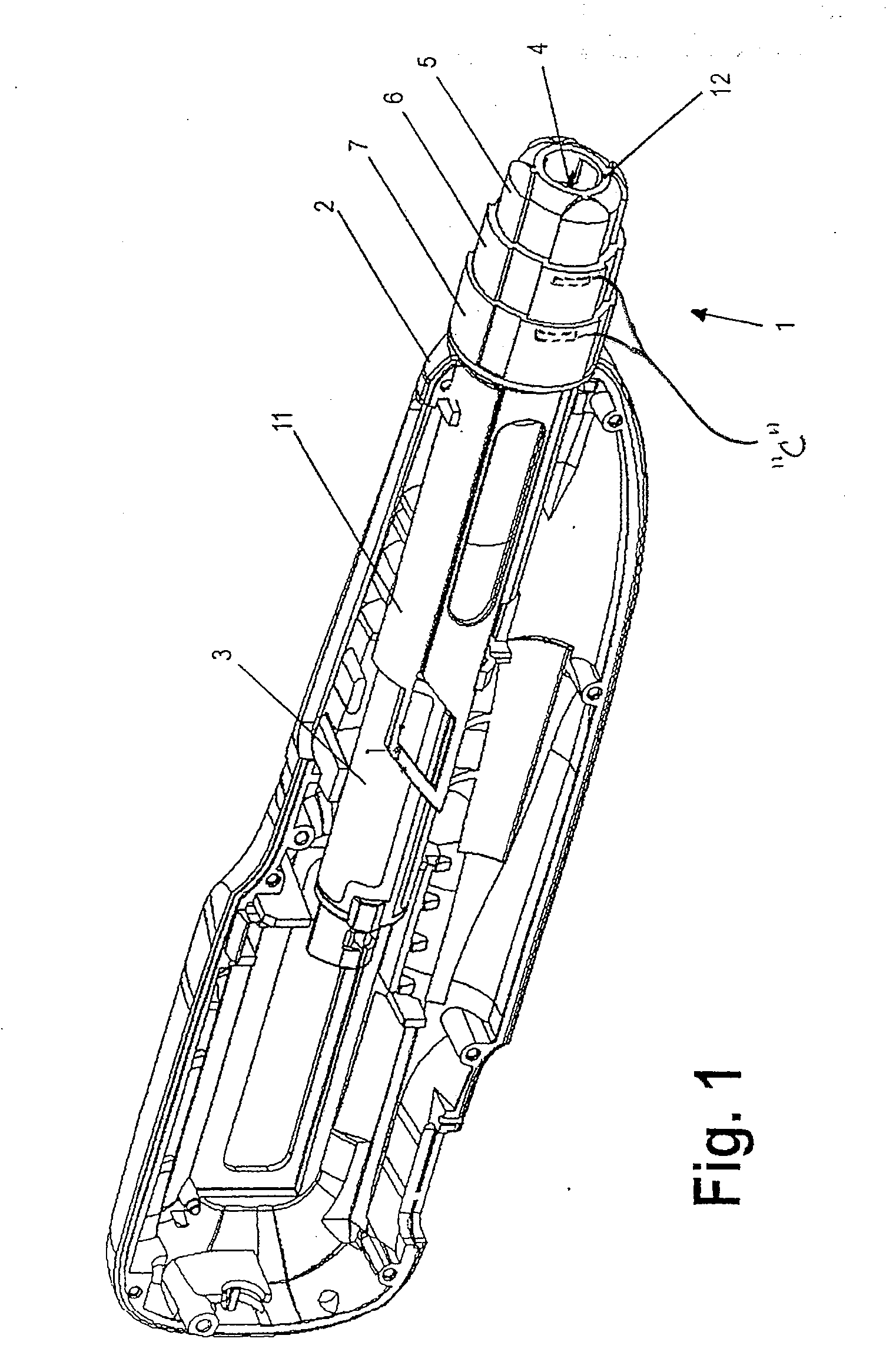

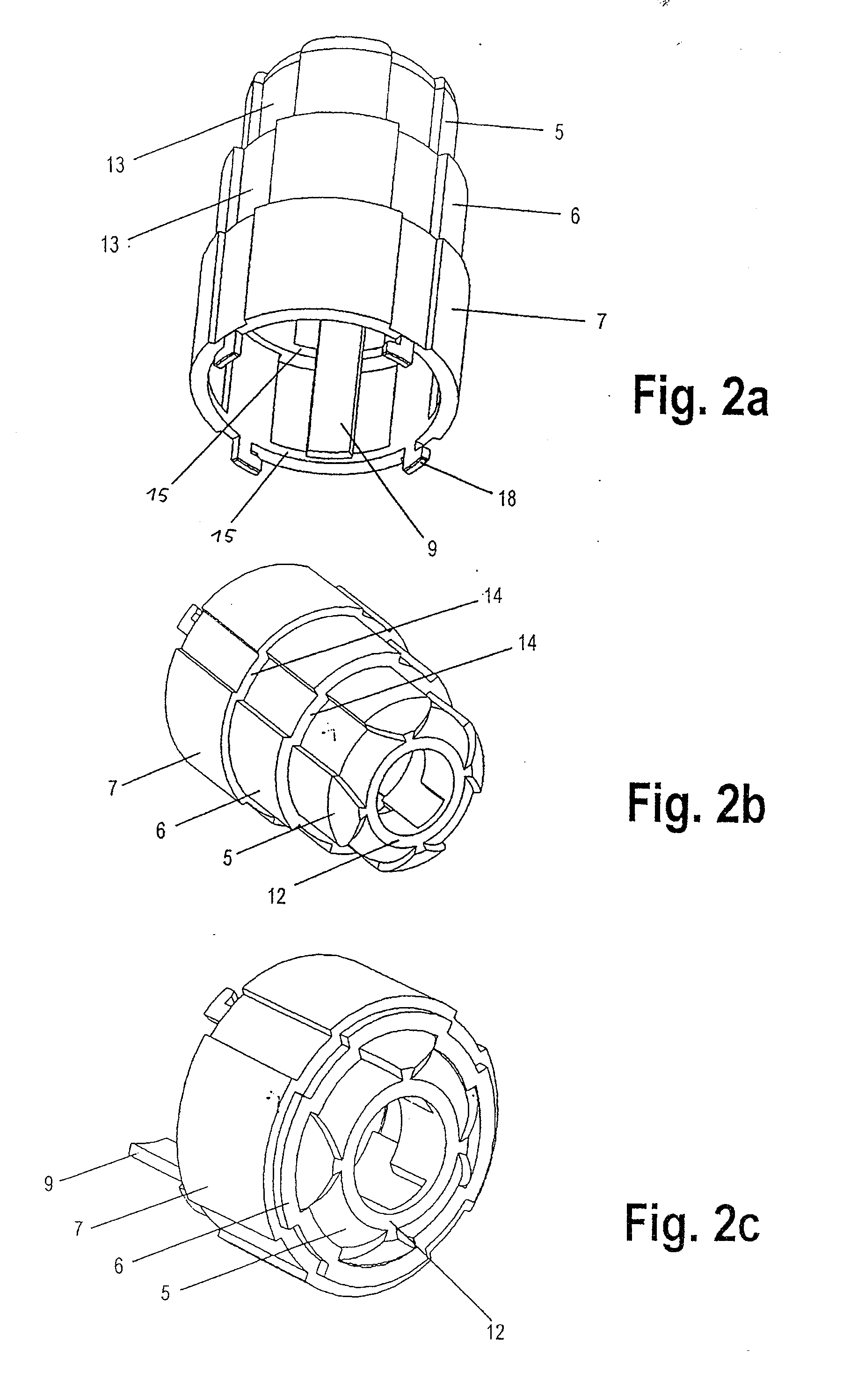

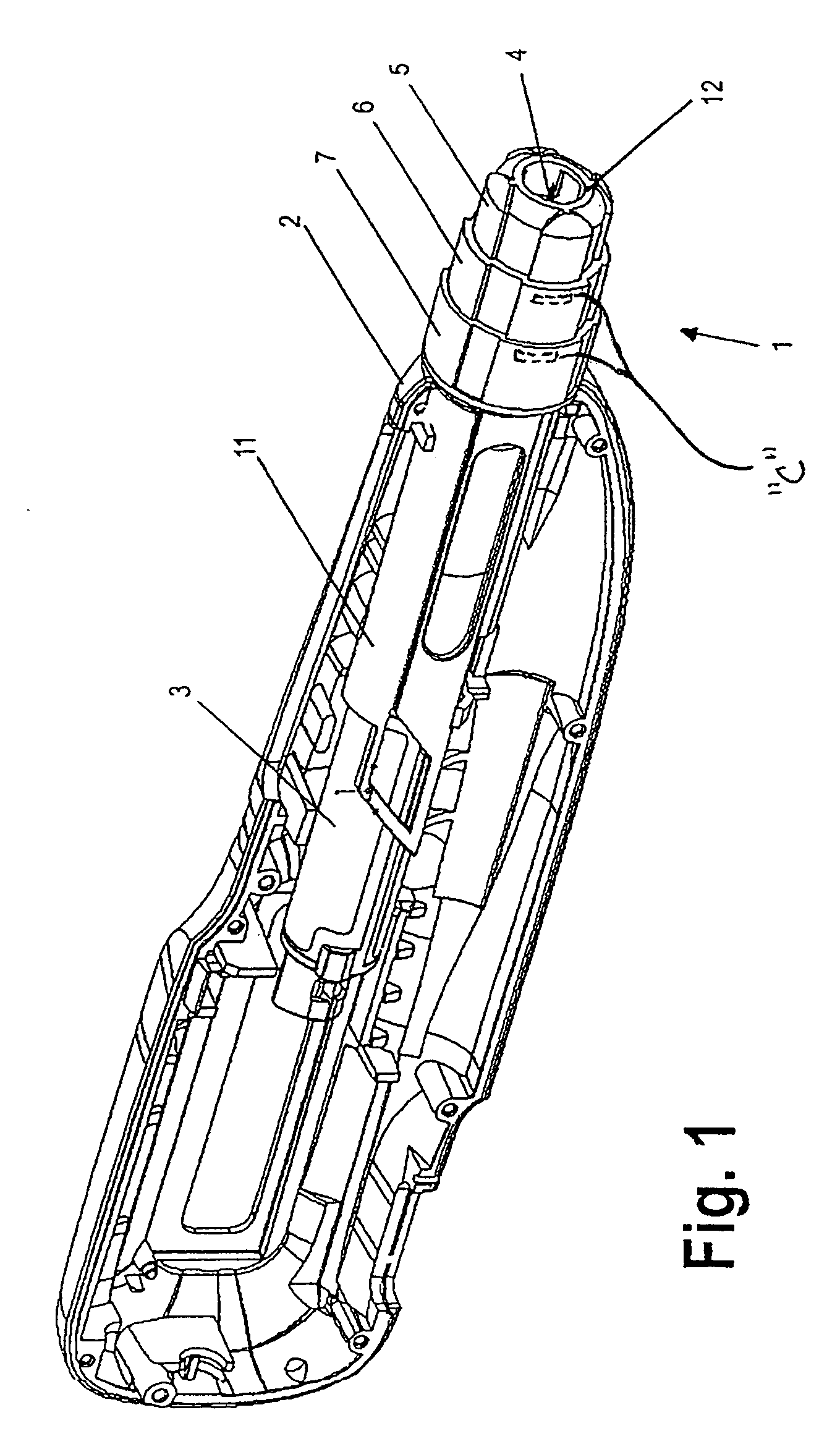

Variable-length needle covering device of an injection device

InactiveUS20070293824A1Simple operationSecure operationAutomatic syringesMedical devicesInjections needleVariable length

The invention relates to a needle covering device of an injection device, the injection device including a casing comprising a reservoir, in particular an ampoule, for a product fluid to be administered, and an injection needle for injecting the product fluid from the reservoir, wherein the device surrounds the injection needle in an extended position and exposes the injection needle in a retracted position. The device comprises a passage for the injection needle, a front section via which the device is placed on an injection point, and another section which is nearer to the casing than the front section is, at least in the extended position. The sections can be moved axially relative to the casing and relative to each other, such that the device is variable in its length, the front section being guided in a straight line on the casing.

Owner:TECPHARMA LICENSING AG

Propulsion unit

ActiveUS20140356199A1Small amount of heatSmall amountPropulsion based emission reductionPropulsive transmission driveWater flowPropeller

A propulsion unit is disclosed, which can include a casing, a shaft, a propeller, an annular housing and a rim drive electric motor. The casing can be rotatably supported at a hull of a vessel. The shaft can be rotatably supported with bearings within a lower portion of the casing. A propeller can be attached to an outer end of the shaft protruding from the lower portion of the casing. The annular housing can surround an outer perimeter of the propeller and can form a duct for water flowing through the interior of the annular housing. The rim drive electric motor can include a rotor rim provided on an outer perimeter of the propeller and a stator provided within the annular housing. Oil lubricated roller bearings can be used on the shaft within the casing. The axial length of the propulsion unit can be short.

Owner:ABB (SCHWEIZ) AG

Joining system head, joining system, and method of feeding and joining elements

A joining method head is proposed for fixation to a movable frame, in particular to a robot, having a holding means for an element to be joined to a part, a joining drive means to move the holding means along a joining direction for joining, and a feeding means for feeding elements to the joining method head. Here a control means to control the joining drive means is arranged at the joining method head spatially distanced from the holding means and the joining drive means, so that the holding means and the joining drive means form a joining tool of small dimensions, and means are provided to pass on the elements fed to a transfer station of the feeding means in each instance to the holding means from in front.

Owner:NEWFREY

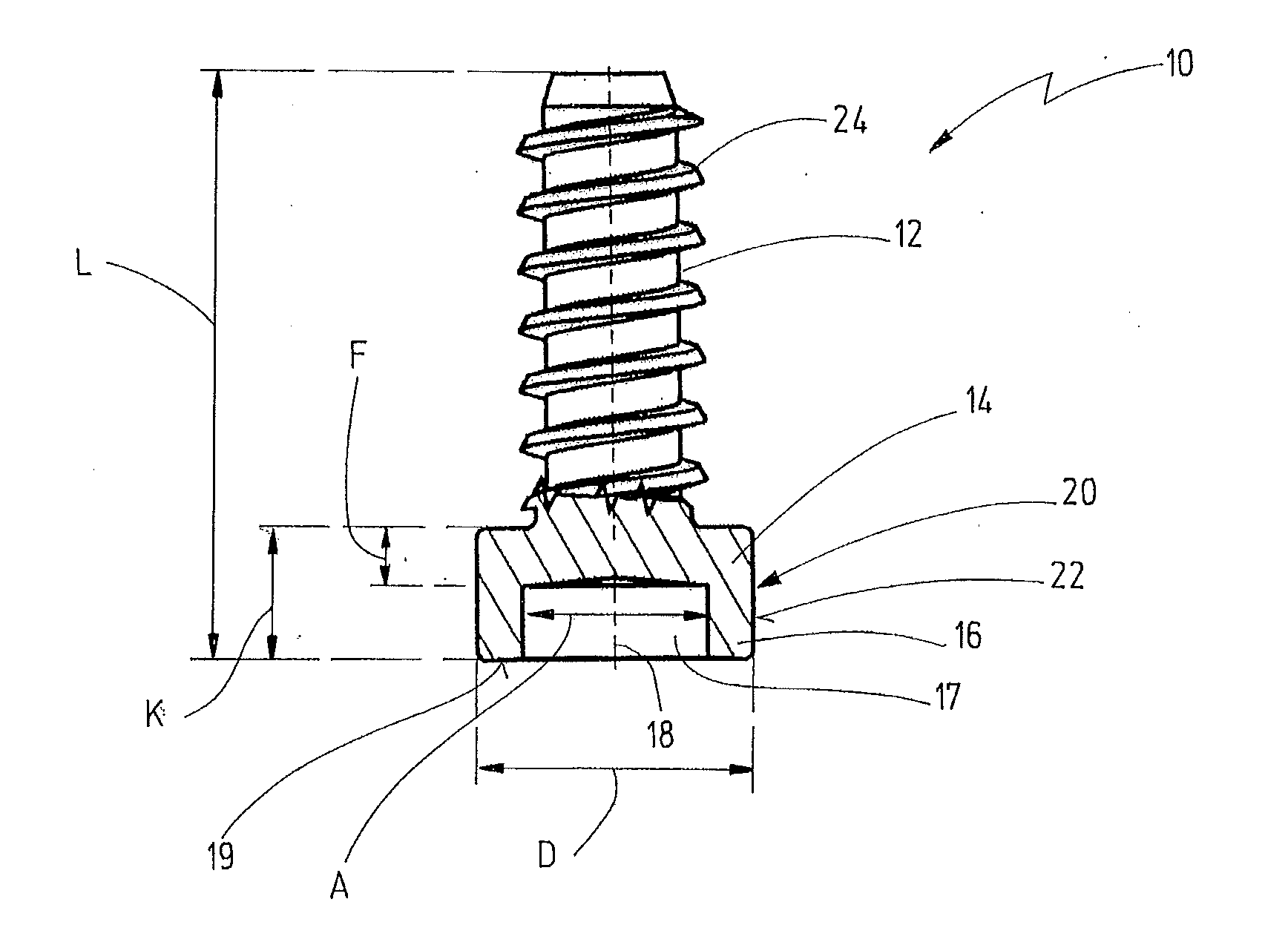

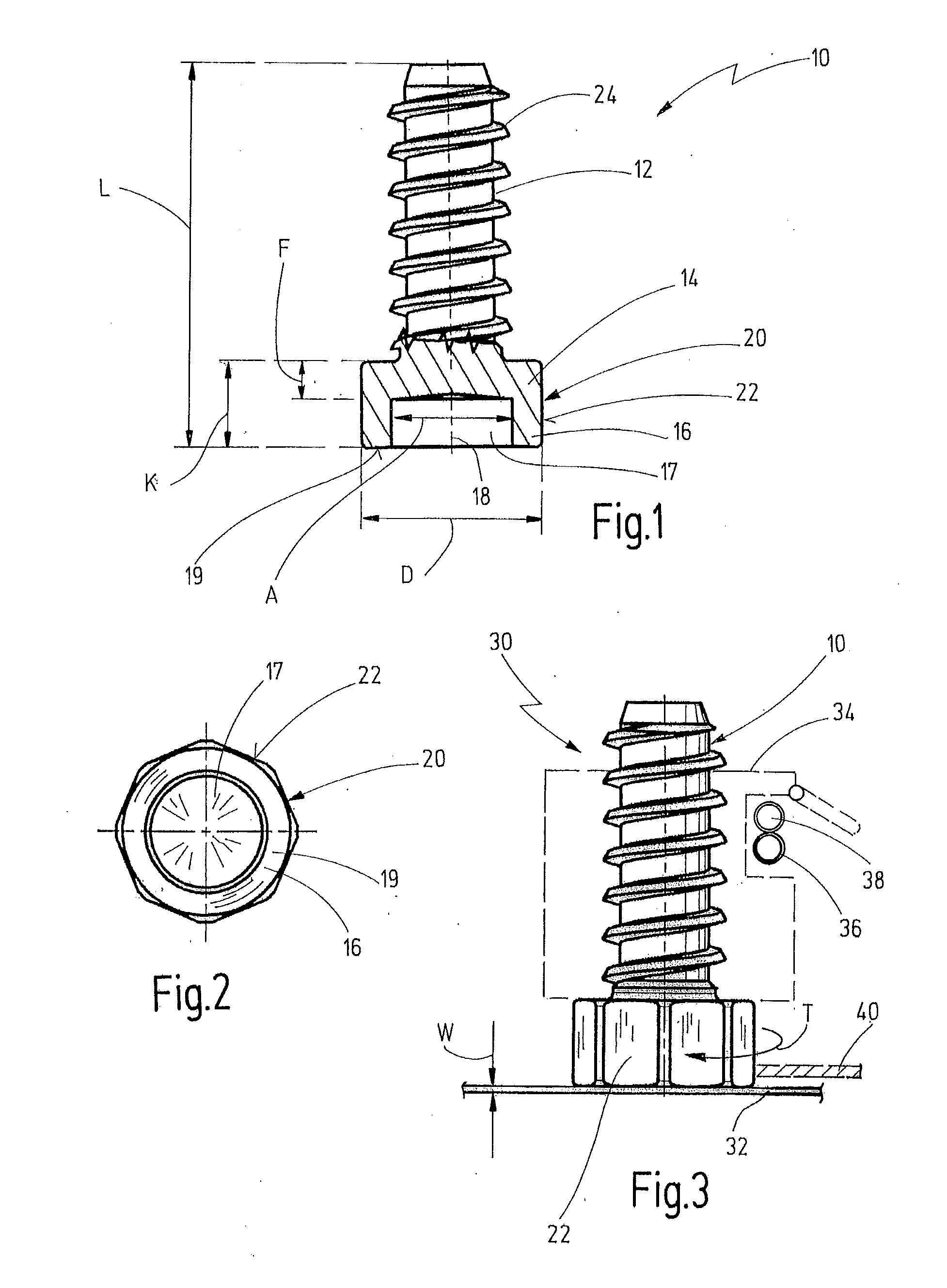

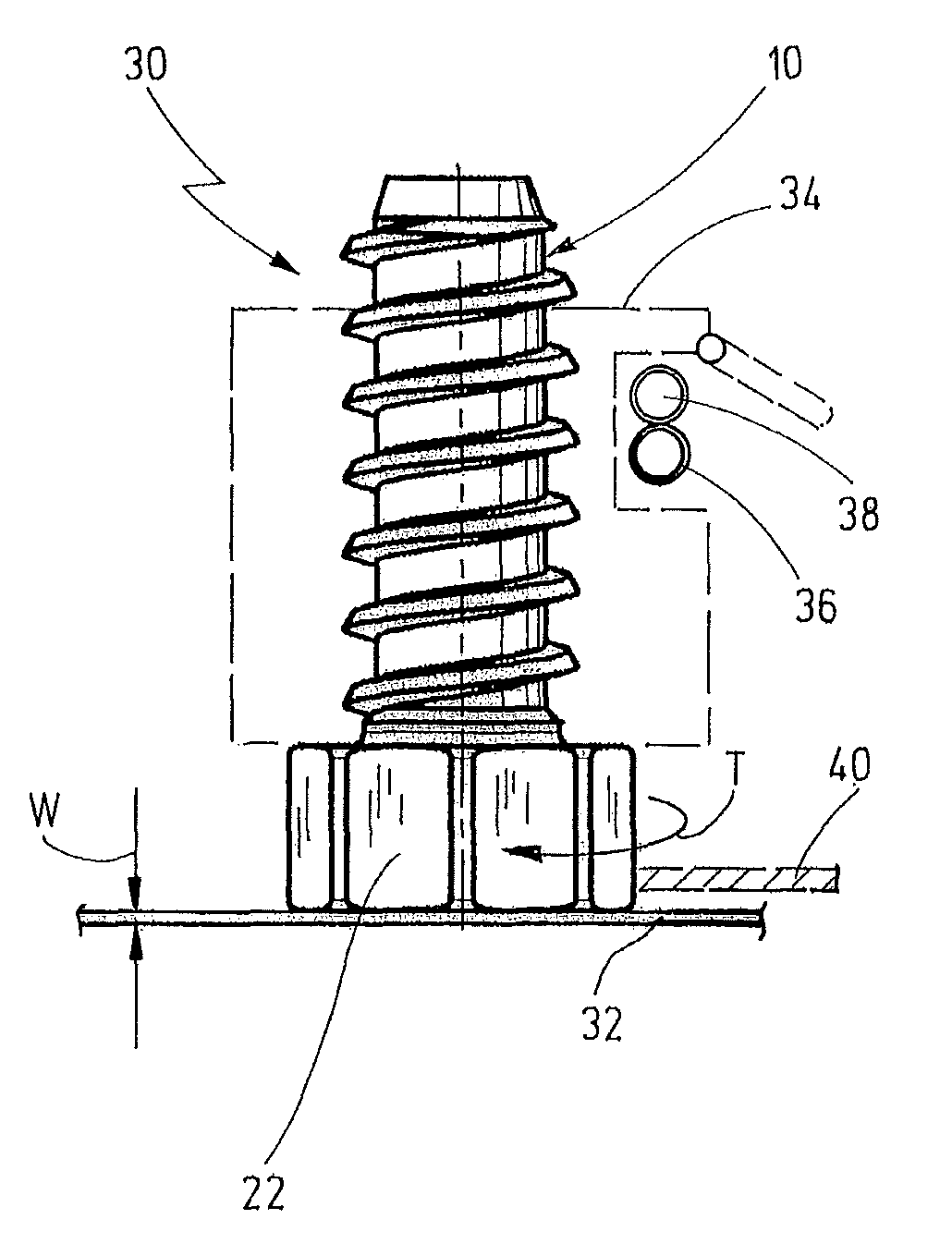

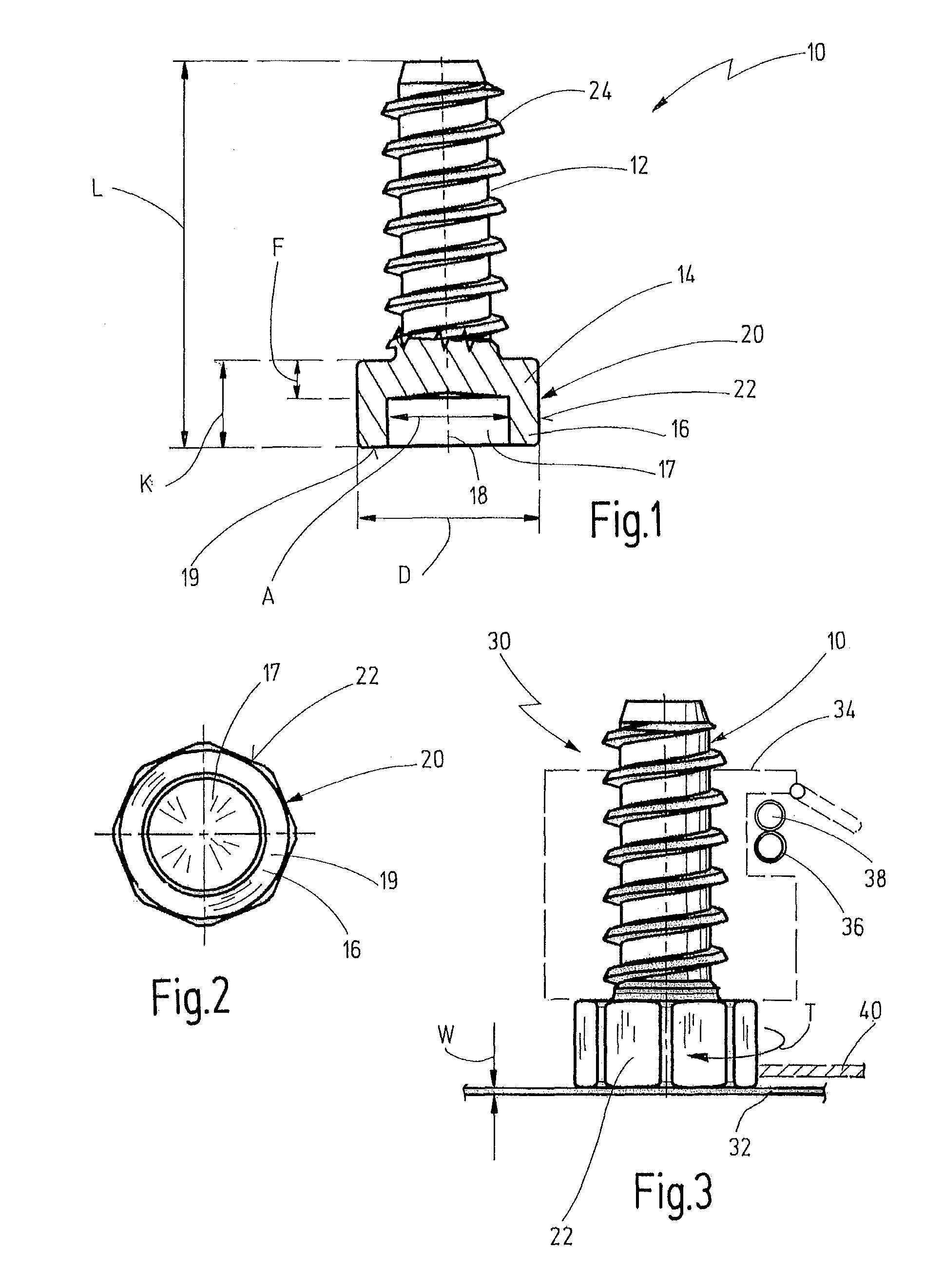

Stud for stud welding

A welding stud includes a shank and a head flange, which projects radially relative to the shank and whose outer circumference is of polygonal design in order to be able to apply a test torque (T) to the stud by means of a tool. The flange includes an annular section (16) whose front facing and radially extending annular surface is designed as a welding surface. The annular section directly adjoins the flange, and the annular section and the flange form a head section which has a uniform outside diameter (D) throughout, and wherein the polygonal shape of the flange extends over the annular section up to its front annular surface.

Owner:NEWFREY

Mechanical seal

Owner:EAGLE INDS

Unbalance type exciter for a soil compaction device

The invention relates to an unbalance type exciter (6) for a soil compaction device. This exciter comprises a carrying structure (5) as well as an unbalance weight (8, 9), which by means of a bearing (11a, 11b) is supported at the carrying structure (5) in rotatable manner around a rotation axis (Y) which in the intended use is stationary with respect to the carrying structure (5), for generating an intermittent exciting force for causing the carrying structure (5) in the intended use to vibrate. The bearing (11a, 11b) of the unbalance weight (8, 9) is arranged at least partially within the space which is circled by the unbalance weight (8, 9) when rotating around the rotation axis (y). Owing to the fact that this space is used for receiving at least part of the bearing of the unbalance weight (8, 9) it becomes possible to provide unbalance type exciters (6) having very small axial overall length.

Owner:AMMANN SCHWEIZ

Valve timing control apparatus

ActiveUS8327813B2Easy to assembleSmall axial lengthMachines/enginesNon-mechanical valveEngineeringCam

An assist spring is fixed at its one end to a vane rotor and at its other end to a spring hook provided at an outside of a housing 18. A signal plate is fixed to the vane rotor on a side of the spring hook. A cam angle sensor is provided at an outer peripheral side of the signal plate for detecting a rotational angle of the signal plate. The assist spring and the spring hook are arranged in an area, which is inside of an outer periphery of the signal plate in a radial direction, so that the cam angle sensor may not misidentify the assist spring and the spring hook and thereby exactly detects the rotational angle of the signal plate.

Owner:DENSO CORP

Variable-length needle covering device of an injection device

InactiveUS7326185B2Operational securityEasy to operateAutomatic syringesMedical devicesInjection pointVariable length

The invention relates to a needle covering device of an injection device, the injection device including a casing comprising a reservoir, in particular an ampoule, for a product fluid to be administered, and an injection needle for injecting the product fluid from the reservoir, wherein the device surrounds the injection needle in an extended position and exposes the injection needle in a retracted position. The device comprises a passage for the injection needle, a front section via which the device is placed on an injection point, and another section which is nearer to the casing than the front section is, at least in the extended position. The sections can be moved axially relative to the casing and relative to each other, such that the device is variable in its length, the front section being guided in a straight line on the casing.

Owner:TECPHARMA LICENSING AG

Flow controller

ActiveUS9651953B2Reduced space requirementsReduced space required for installationOperating means/releasing devices for valvesLighting and heating apparatusEngineeringHeating system

A flow controller for a heating system with a housing, which has an inlet connection for a heating medium, an outlet connection for the heating medium, and a preadjustment connection, with a rate regulating module, and with a handle, which acts together with a movably disposed structural element of the rate regulating module to preadjust the flow. To change the preadjustment of the flow via the handle, an effective cross section of a first flow-through opening for the heating medium can be adjusted and to regulate the preadjusted flow of the heating medium, a sleeve of the rate regulating module and a cup of the rate regulating module are disposed axially movable to one another. The inflow to the rate regulating module occurs on an outer side via the first flow-through opening which is provided on the sleeve and upstream of the second flow-through opening.

Owner:IMI HYDRONIC ENG INT SA

Pitch system for a wind turbine rotor

ActiveUS9567973B2Increase stiffnessSimple and cost-effectiveRolling contact bearingsWind motor controlBlade pitchWind force

A pitch system for a wind turbine rotor, comprising a first bearing and a second bearing, each provided with an outer race, an inner race, and at least one row of rolling elements, the first and second bearings being adapted to be arranged between a hub and a blade root portion or extender, to allow rotation of the blade with respect to the hub, wherein the first bearing is adapted to be arranged nearer to the hub than the second bearing in the axial direction, the pitch system further comprising an intermediate body arranged between the first bearing and the second bearing in the axial direction, said intermediate body comprising at least a blade-side part extending between the race of the first bearing that is associated with the blade and the race of the second bearing that is associated with the blade.

Owner:GE RENEWABLE TECH WIND BV

Stud for stud welding

A welding stud includes a shank and a head flange, which projects radially relative to the shank and whose outer circumference is of polygonal design in order to be able to apply a test torque (T) to the stud by means of a tool. The flange includes an annular section (16) whose front facing and radially extending annular surface is designed as a welding surface. The annular section directly adjoins the flange, and the annular section and the flange form a head section which has a uniform outside diameter (D) throughout, and wherein the polygonal shape of the flange extends over the annular section up to its front annular surface.

Owner:NEWFREY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com