Permanent magnet brushless direct-current motor with closed windings

A permanent magnet brushless DC and brush DC motor technology, applied to synchronous motors with stationary armatures and rotating magnets, the shape/style/structure of winding conductors, electrical components, etc., can solve the problem of different operating principles that cannot be realized DC motor operating characteristics and other issues to achieve the effect of improving efficiency and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

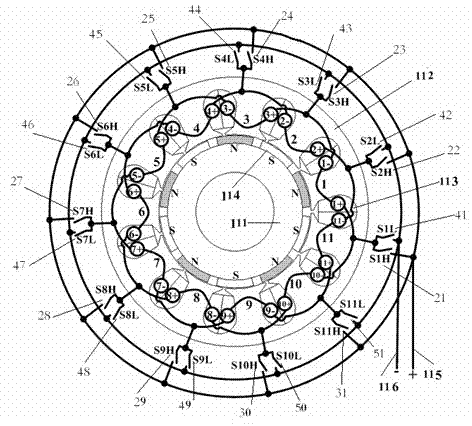

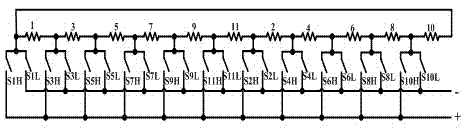

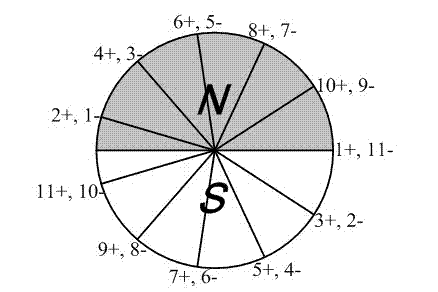

[0015] The closed-winding permanent magnet brushless DC motor includes a rotor and a stator. The armature winding is placed in the coil slot on the stator, and the permanent magnet is placed on the rotor. Adjacent permanent magnets have different polarities. It is characterized in that: in the armature winding Each coil of the armature winding is connected in parallel with a pair of power electronic switches, and the other end of the power electronic switch is respectively connected to the positive and negative poles of the power supply. Each coil in the armature winding skips adjacent coils and is connected in series with the next coil. It is characterized in that all the coils in the armature winding are closed and connected. It is characterized in that each coil in the armature winding is a double-layer winding, the upper layer and the lower layer are respectively placed in adjacent stator coil slots, and the lower layer of each coil is located in the same stator coil slot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com