Motor rotor

A technology of motor rotor and rotor body, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of increased cost, smaller surface area, reduced magnetic flux density of motor rotor 2, etc., to increase torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A motor rotor according to a preferred embodiment of the present invention will be described below with reference to related drawings.

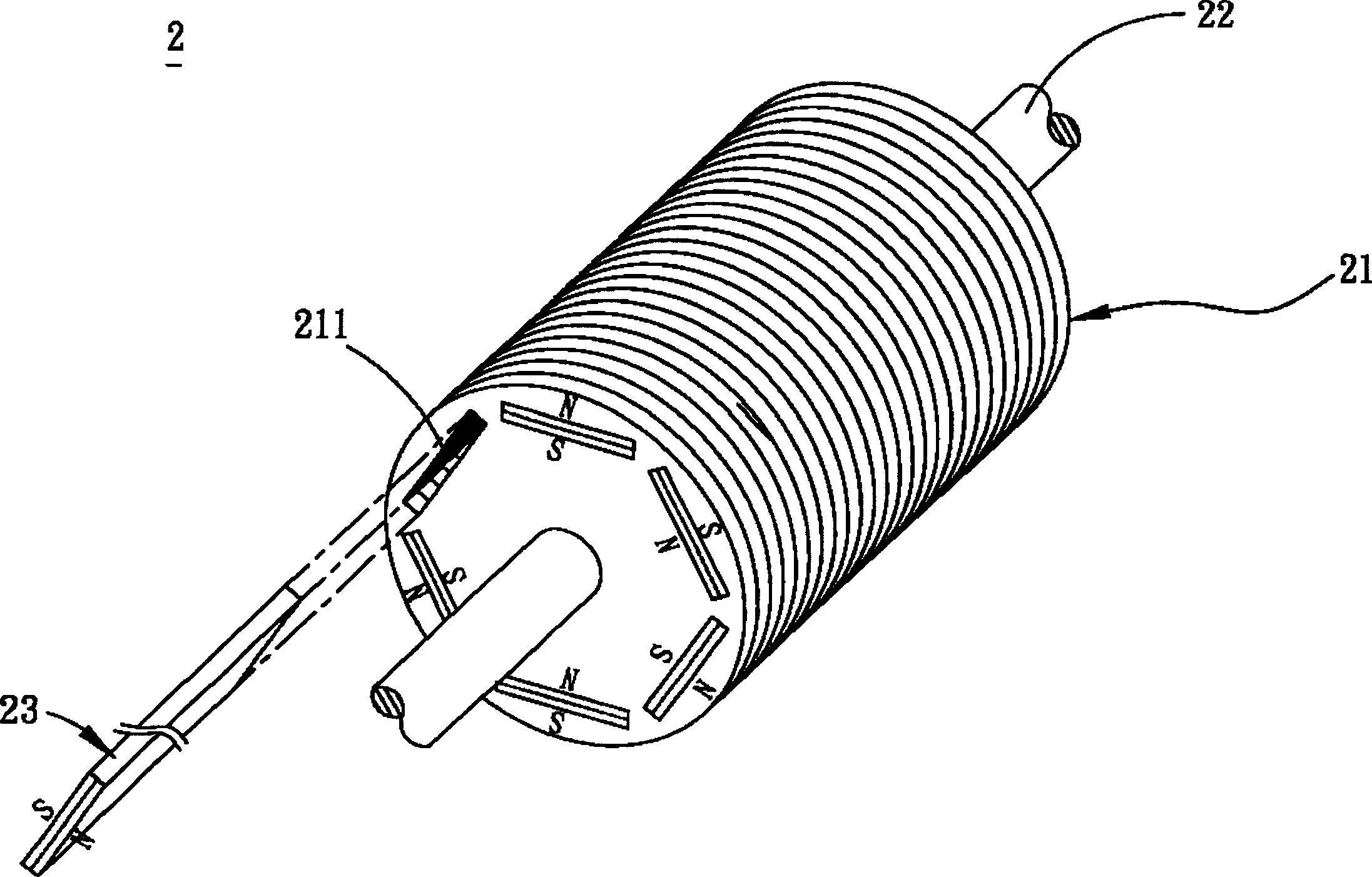

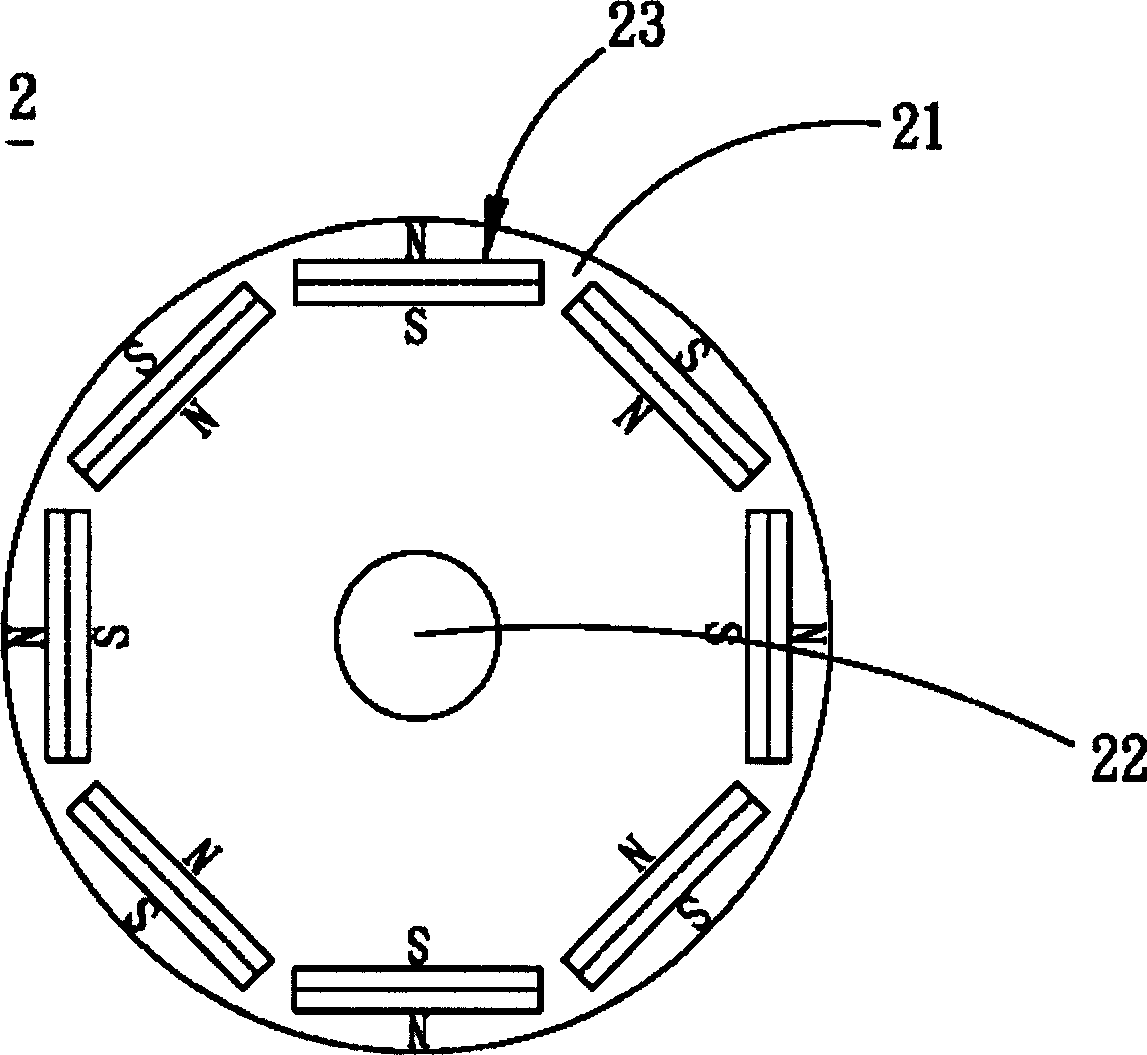

[0029] see Figure 4 as well as Figure 5 As shown in FIG. 1 , are respectively a three-dimensional schematic view and a front view of a motor rotor in a preferred embodiment of the present invention. The motor rotor 3 of this embodiment is a motor inner rotor, which includes a rotor body 31 , a rotating shaft 32 and a plurality of magnetic elements 33 .

[0030] The rotor body 31 of this embodiment has a through hole 311 and a plurality of accommodating portions 312 . The through hole 311 is arranged at the axis of the rotor body 31, and the accommodating portions 312 are arranged radially toward the outer circumference of the rotor body 31 from the rotation axis 32, and these accommodating portions 312 are radially centered on the axis. The rotor body 31 is arranged at equal intervals for accommodating the magnetic elements 33 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com