A three-phase U-shaped stator tooth external rotor switched reluctance motor and its driving method

The technology of a switched reluctance motor and its driving method is applied in the direction of electrical components, electromechanical devices, starting devices, etc., and can solve the problems of a large number of switching devices in a power converter, complex stator winding connections, and high system costs, and achieve switching Fewer components, suitable for low-speed applications, simple topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

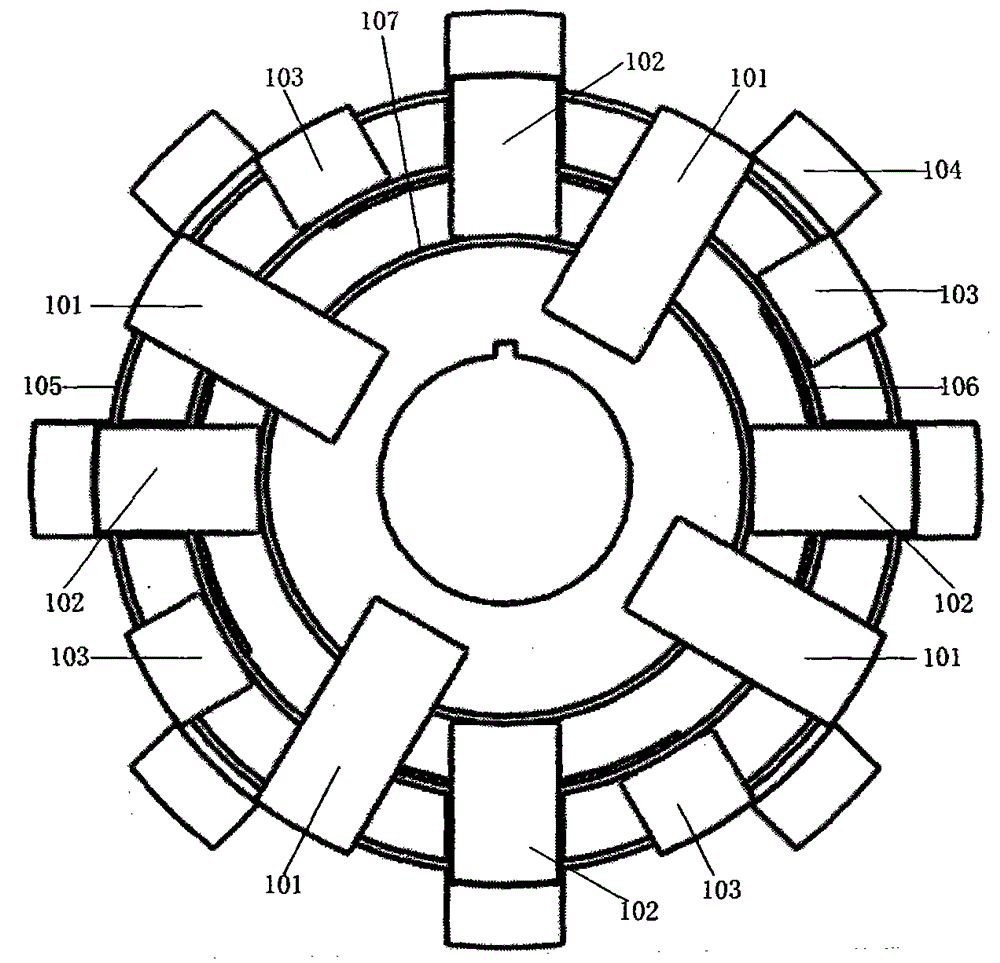

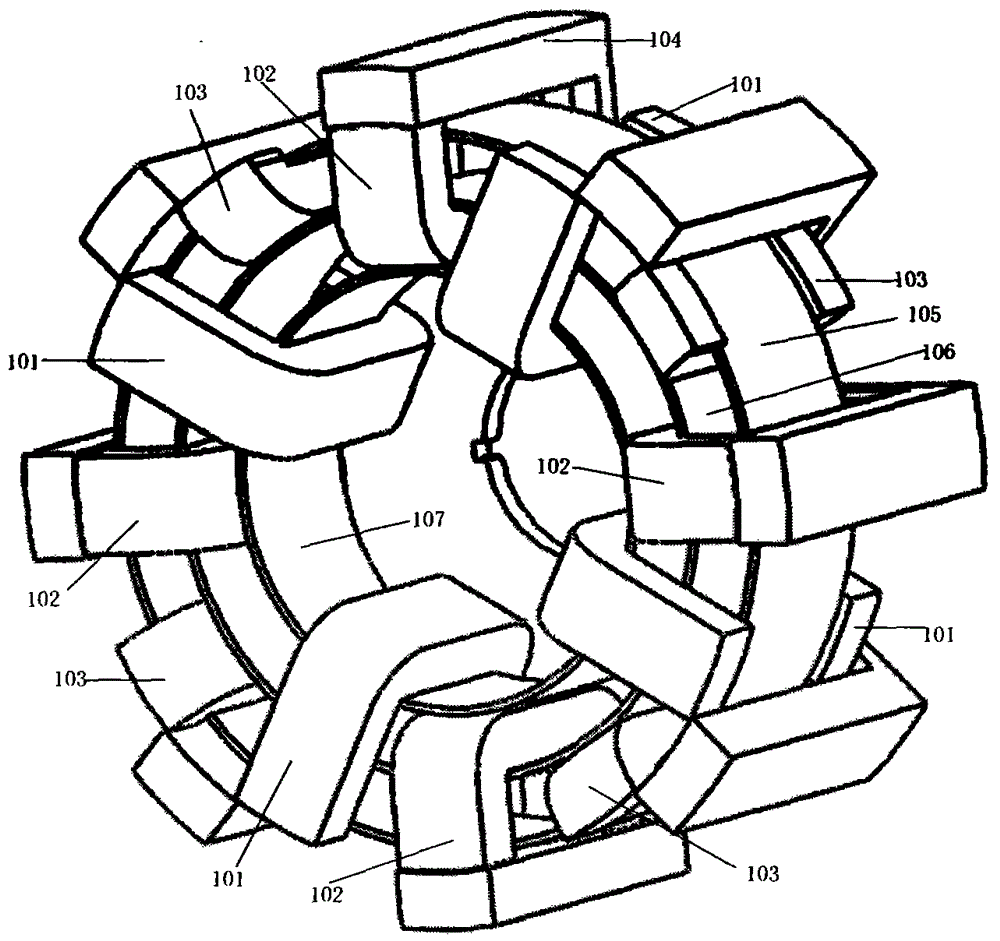

[0026] Such as figure 1 , figure 2As shown, a three-phase U-shaped stator tooth external rotor switched reluctance motor includes a first stator (101), a second stator (102), a third stator (103), a rotor (104) and a first winding ( 105), the second winding (106), the third winding (107), the first stator (101), the second stator (102), and the third stator (103) have 12 in total, using three different sizes U-shaped teeth, 4 of each size stator teeth. The 12 stator teeth are uniformly arranged along the circumference of the motor in order of large, medium and small sizes, and the independent stator teeth are connected to each other by a disc (108) with a rectangular slot made of non-ferromagnetic material. The position between them is fixed and fixed on the casing (112) of the motor; the disk (108) is connected to the motor shaft (109) through the bearing (110); the first winding (105), the second winding (106) , The third winding (107) is three annular coils of different...

Embodiment 2

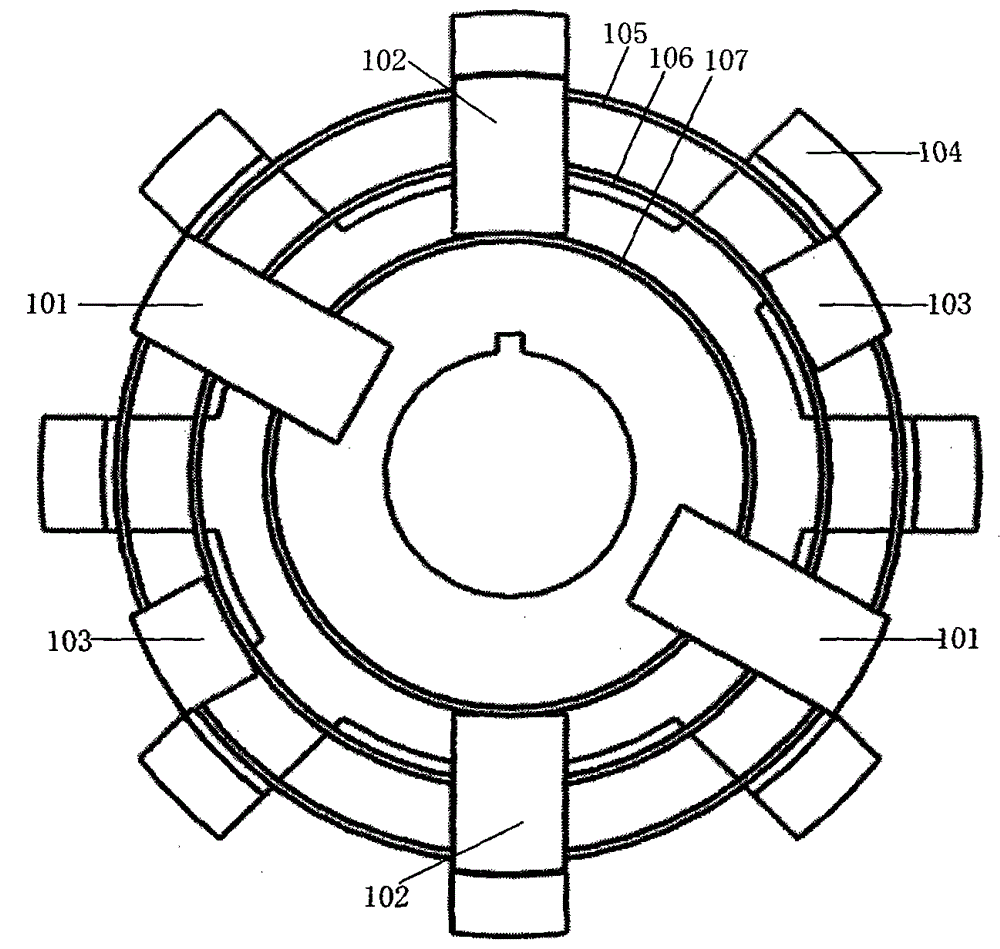

[0029] Such as image 3 , Figure 4 As shown, a three-phase U-shaped stator tooth external rotor switched reluctance motor includes a first stator (101), a second stator (102), a third stator (103), a rotor (104) and a first winding ( 105), the second winding (106), the third winding (107), the first stator (101), the second stator (102), and the third stator (103) have 6 total, using three different sizes U-shaped teeth, 2 of each size stator teeth. The six stator teeth are uniformly arranged along the circumference of the motor in order of large, medium and small sizes, and the mutually independent stator teeth are connected to each other by a disc (108) with a rectangular slot made of non-ferromagnetic material. The position between them is fixed and fixed on the casing (112) of the motor; the disk (108) is connected to the motor shaft (109) through the bearing (110); the first winding (105), the second winding (106) , The third winding (107) is three annular coils of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com