Sandwich permanent magnet synchronous motor rotor structure with solid-lamination axial direction compound

A permanent magnet synchronous, rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of low operating efficiency of solid rotor induction motor, poor starting performance of squirrel induction motor, permanent magnet synchronous motor Electric motors are expensive and other problems, to achieve obvious energy-saving effect, high cost performance, and small impact on the power grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

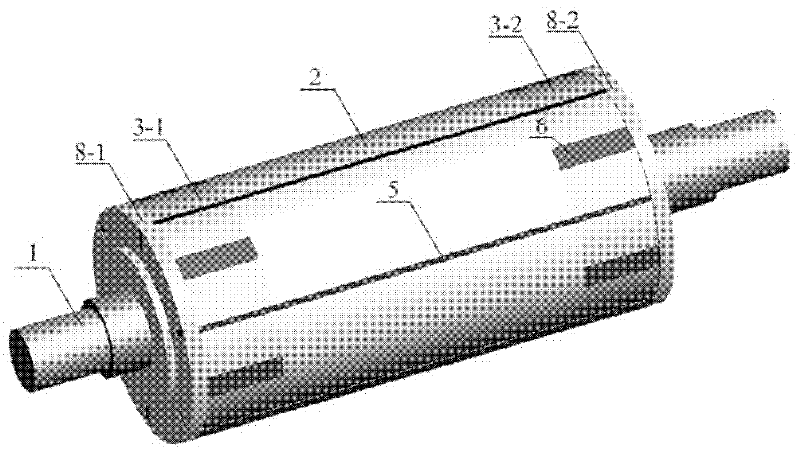

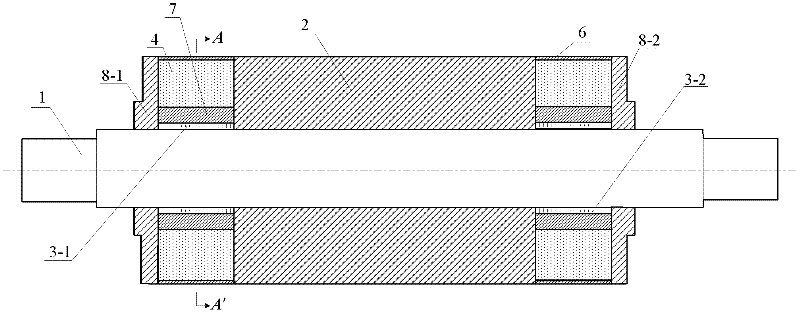

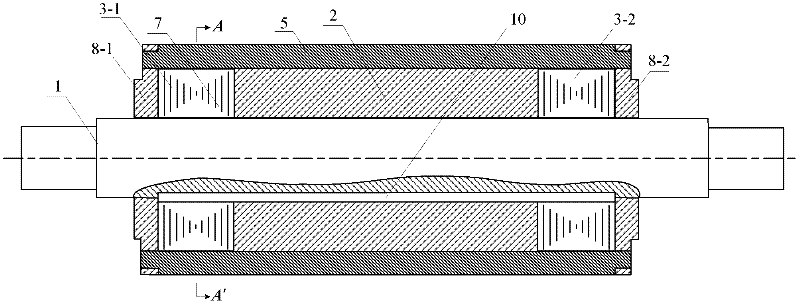

[0025] The rotor structure of the solid-lamination axial composite sandwich permanent magnet synchronous motor, such as figure 1 , 2 , 3. The rotor includes: rotor shaft 1, solid rotor part 2, left laminated rotor part 3-1, right laminated rotor part 3-2, first to Nth permanent magnet poles 4, first to Mth iron-copper alloy starter Cage bars 5, first to Nth aluminum bronze slot wedges 6, first to Nth aluminum spacer magnets 7, and left and right end protection covers 8-1, 8-2.

[0026] The left laminated rotor part 3-1, the solid rotor part 2 and the right laminated rotor part 3-2 are sequentially set on the rotor shaft 1, and are installed on the rotor shaft 1 through the key iron 10. The left laminated rotor part 3-1 and the right laminated rotor part 3-2 are completely symmetrical, such as image 3 .

[0027] The first to Nth aluminum spacer magnets 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com