Asynchronous starting permanent-magnet synchronous motor and asynchronous motor transformation method

A permanent magnet synchronous and asynchronous starting technology, used in the manufacture of motor generators, synchronous machines, electric components, etc., can solve the problems of reduced motor efficiency, power grid power consumption, and increased use costs, to improve power, save energy, reduce Making use of cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Asynchronous motors are the most common electrical equipment, and squirrel-cage asynchronous motors have the widest range of applications. When the asynchronous motor is working, the rotating magnetic field generated by the stator winding is not synchronized with the rotor winding. The rotor winding needs to absorb part of the electric energy from the power grid to excite and consume the power of the power grid. Larger, and the working temperature rises greatly, the life of the motor is shorter, resulting in an increase in the cost of use. Asynchronous motors waste more energy, which does not conform to the concept of energy conservation and environmental protection.

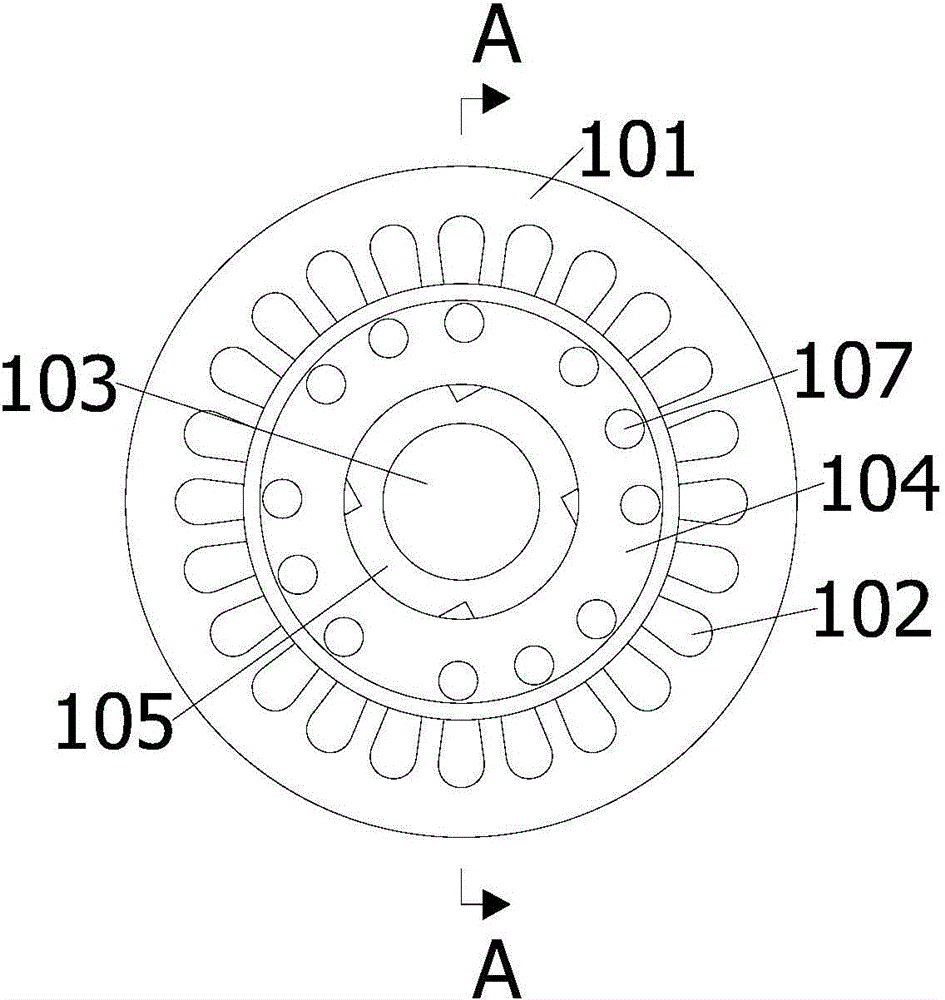

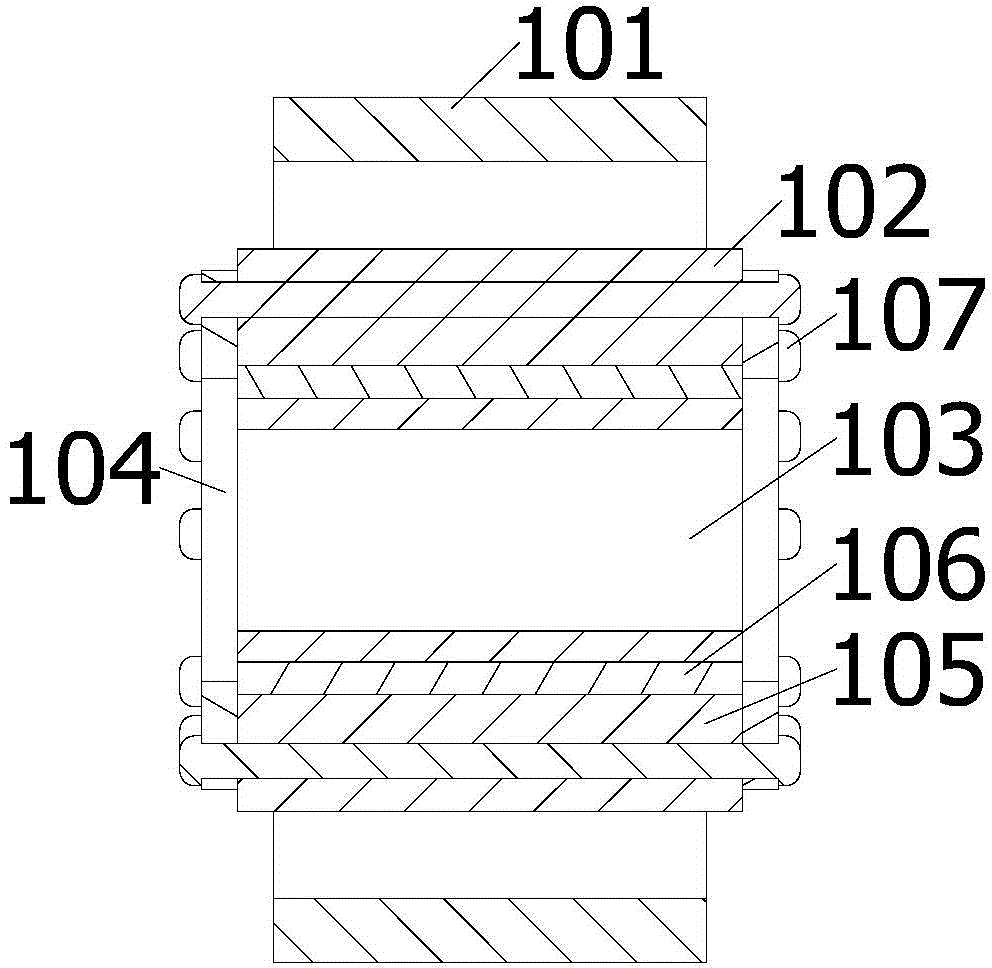

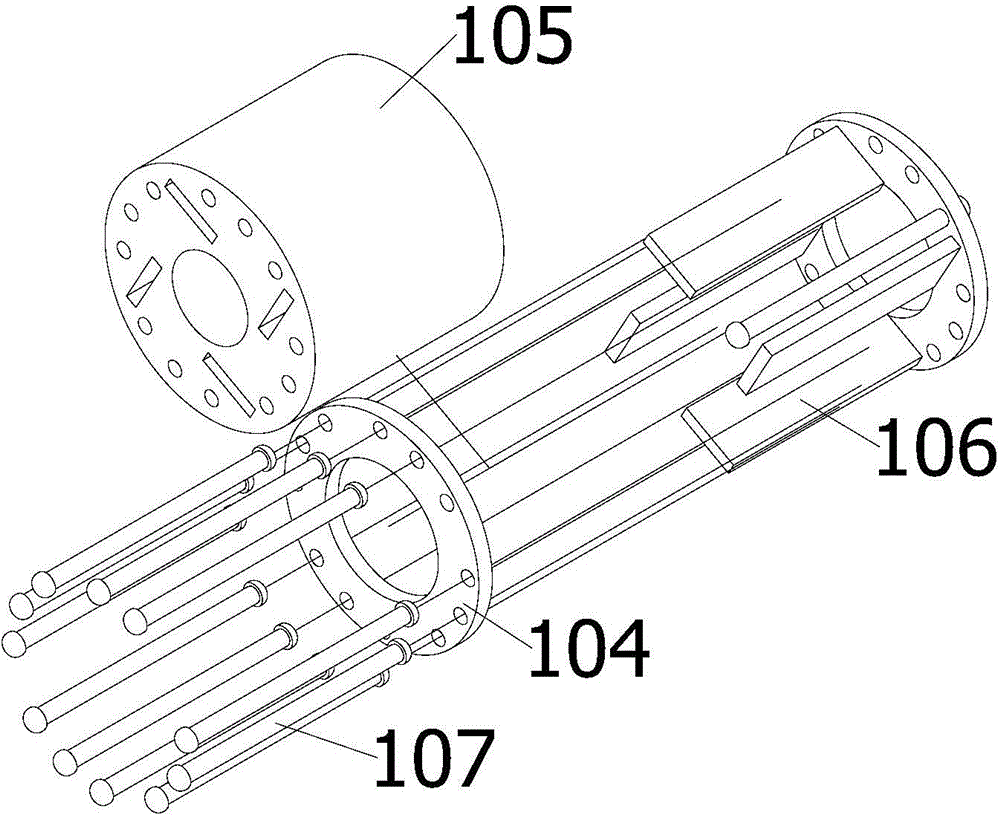

[0047] In order to improve the above problems, the present invention provides an asynchronous starting permanent magnet synchronous motor and asynchronous motor transformation method, which has the characteristics of both asynchronous motor and permanent magnet synchronous motor, and it relies on the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com