Active/passive cold rolling ribbed reinforcing bar producing device

A technology of cold-rolled ribbed steel bar and production device, which is applied in the driving device, roll, metal rolling and other directions of metal rolling mill, can solve the problems of many surface burrs, poor quality and low product strength of ribbed steel bar, and achieves Exquisite appearance, less internal micro-cracks, and various processing specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

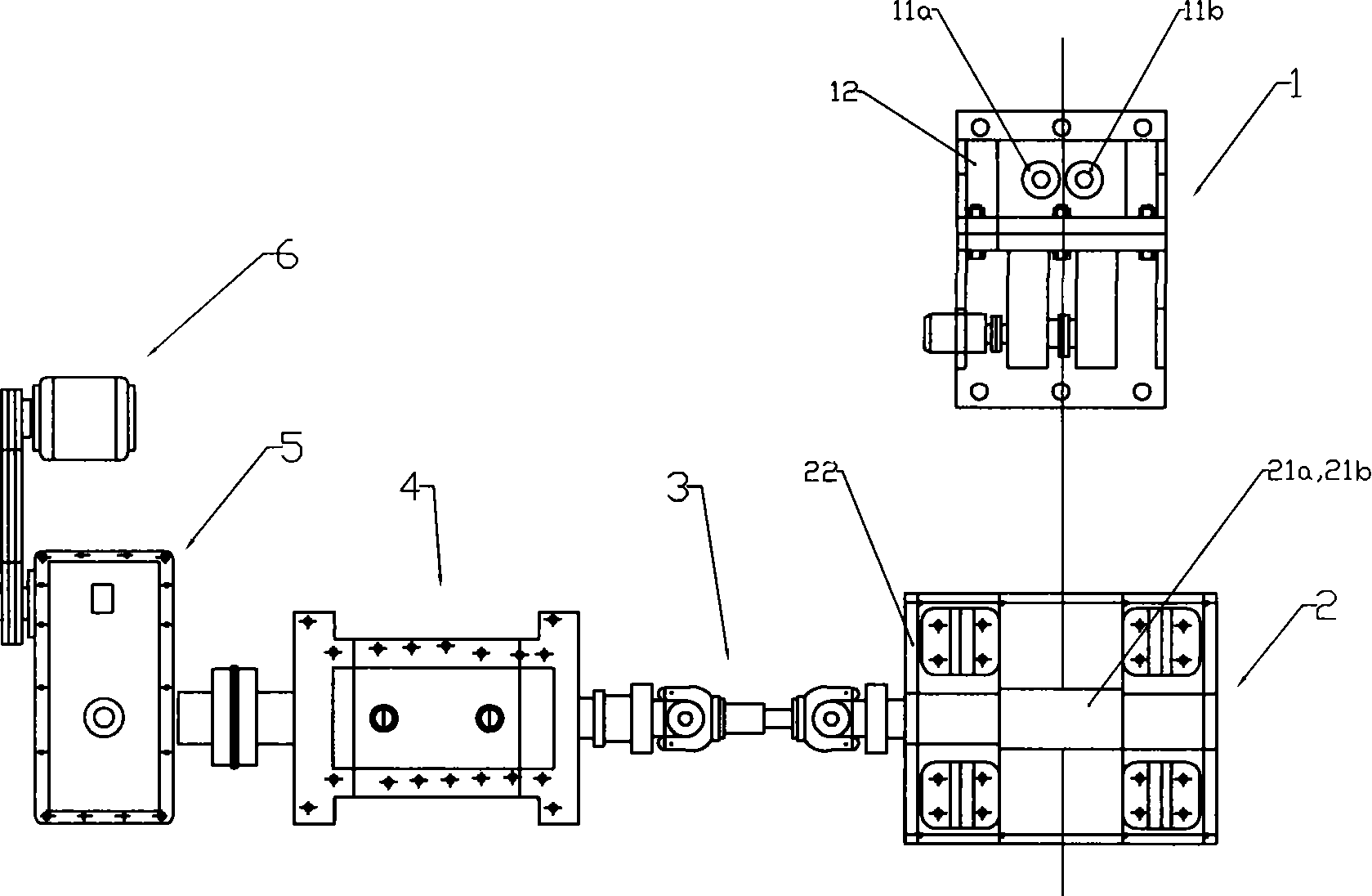

[0019] like figure 1 As shown, it is a schematic diagram of an active and passive cold-rolled ribbed steel bar production device, including a driven rolling mill 1, including a pair of parallel reducing rolls 11a, 11b installed on the stand 12, which adopts direct rolling and is used for To achieve cold extrusion relief for the wire rod, no power unit is required. There is also a driving rolling mill 2 installed downstream of the driven rolling mill 1 .

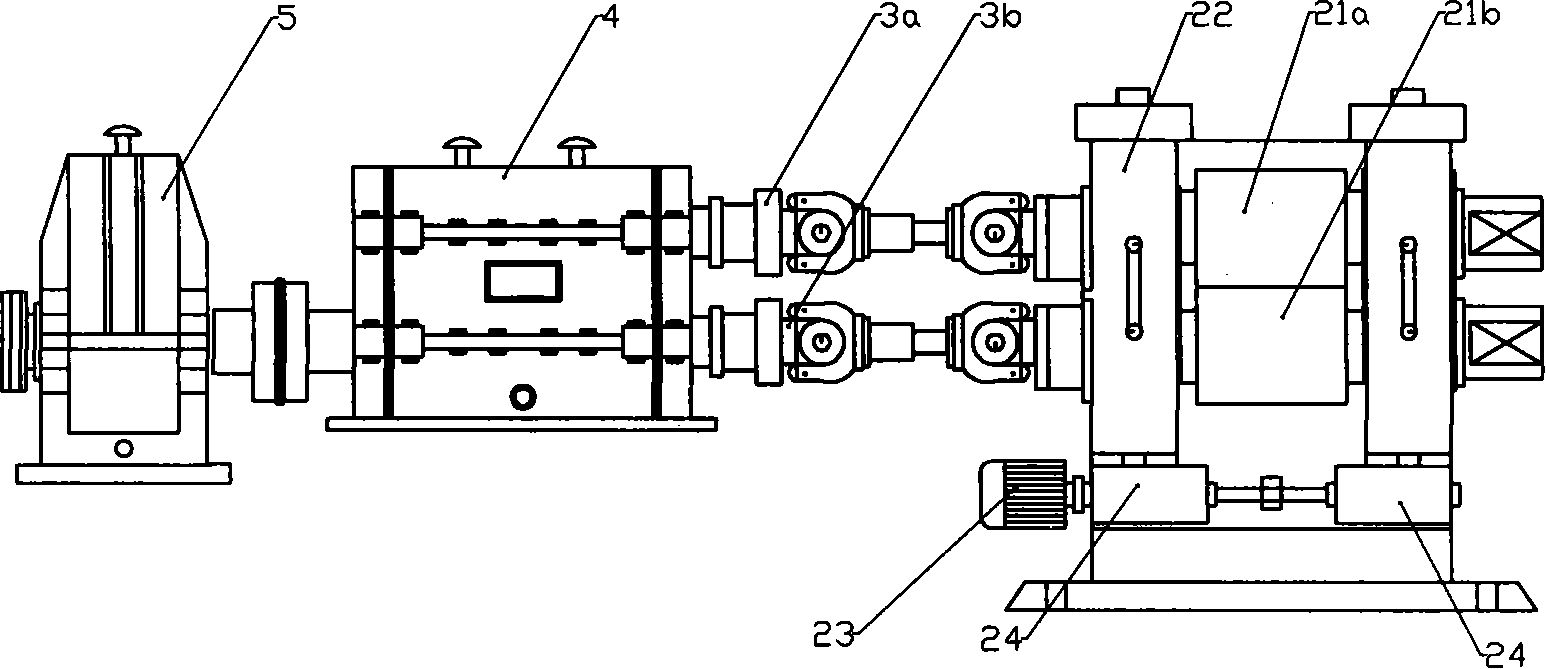

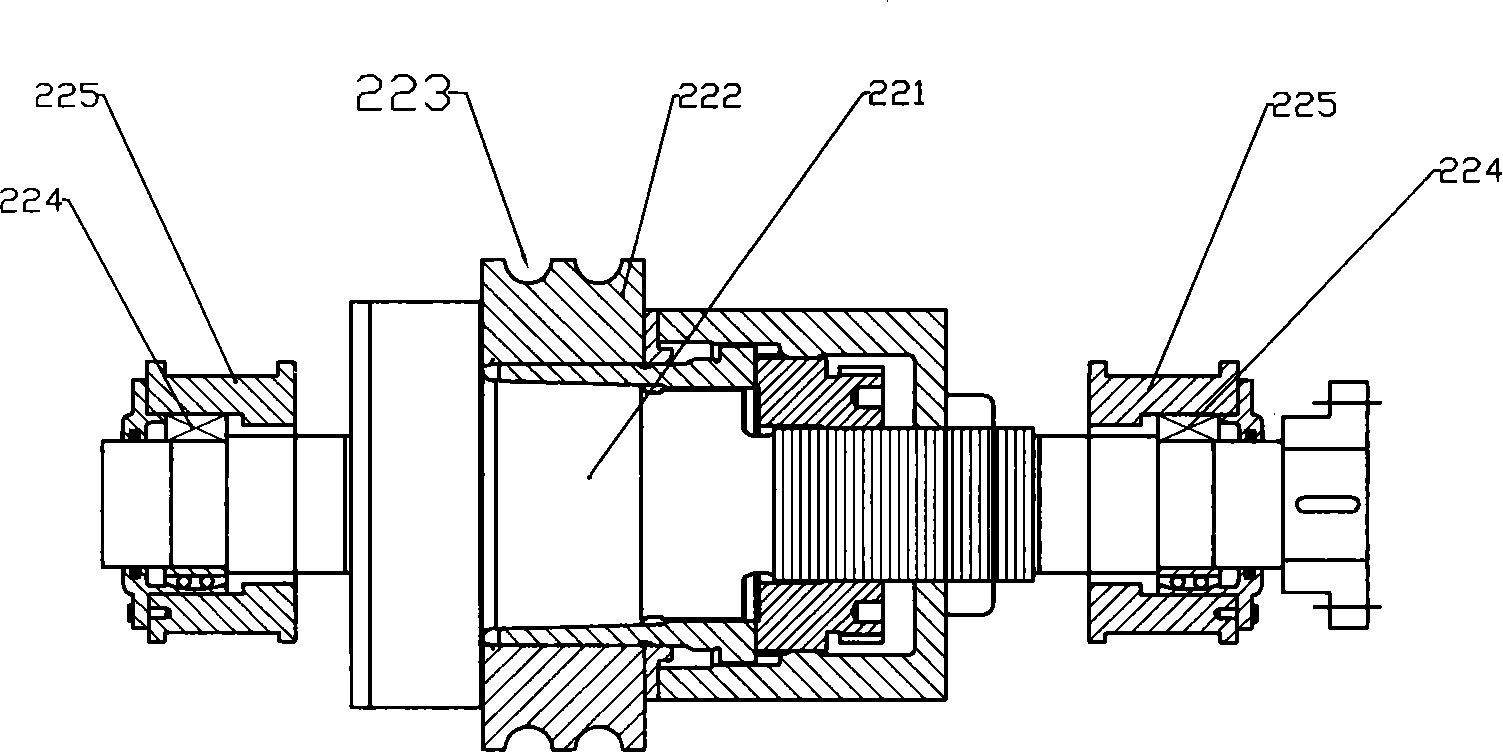

[0020] combine figure 2 As shown, the active rolling mill 2 includes a pair of parallel profiled rolls 21a, 21b installed on a stand 22, and patterns for rolling ribs are provided on the profiled rolls. The main motor 6 realizes deceleration output by the reducer 5 through the pulley and the belt, the reducer 5 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com