Dust hood device of torch cutting machine for continuous casting

A technology of dust removal hood and fire cutting machine is applied in the direction of removing smoke and dust, gas flame welding equipment, cleaning methods and utensils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

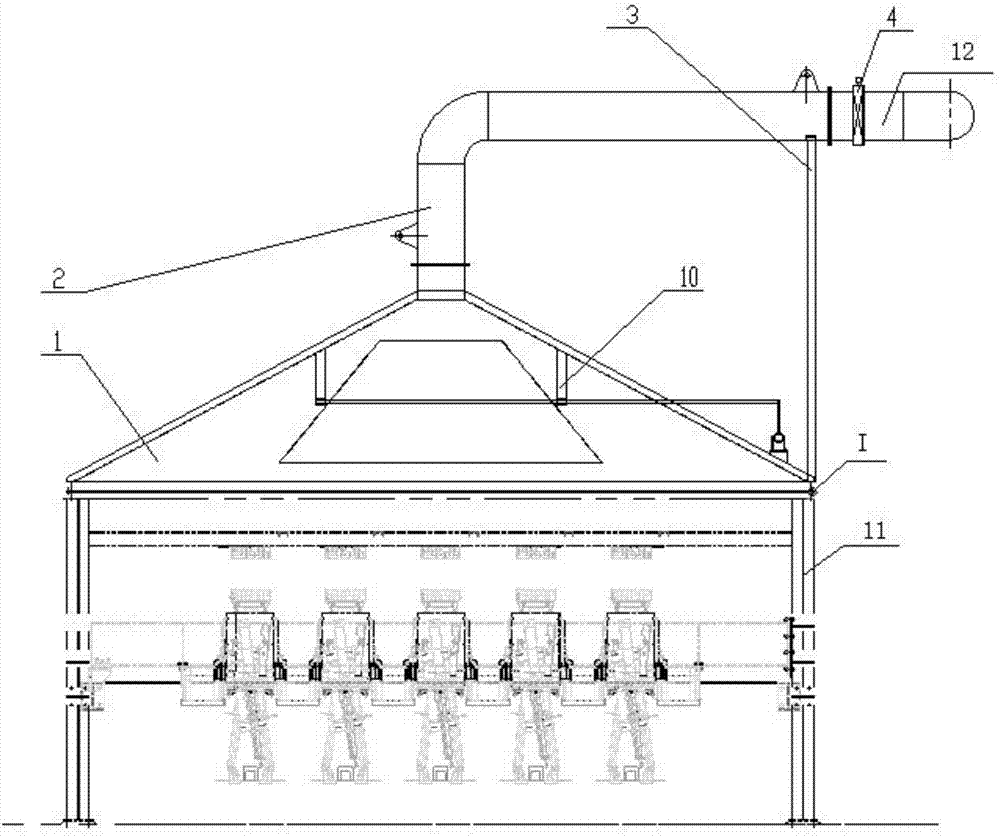

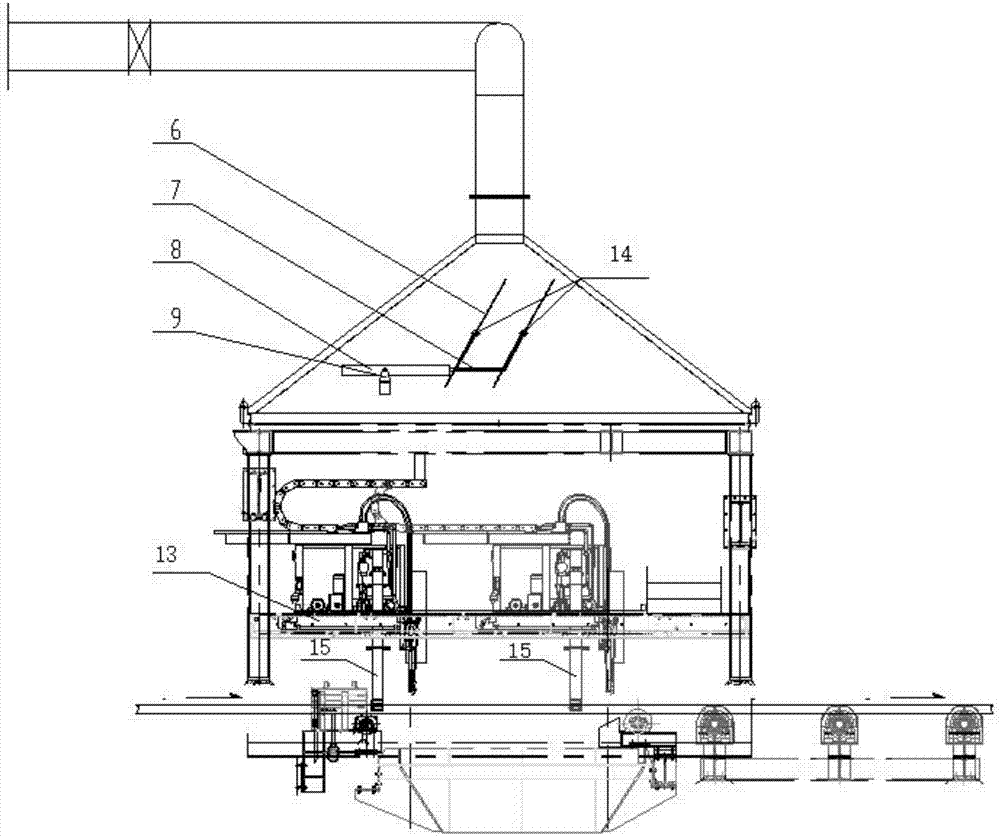

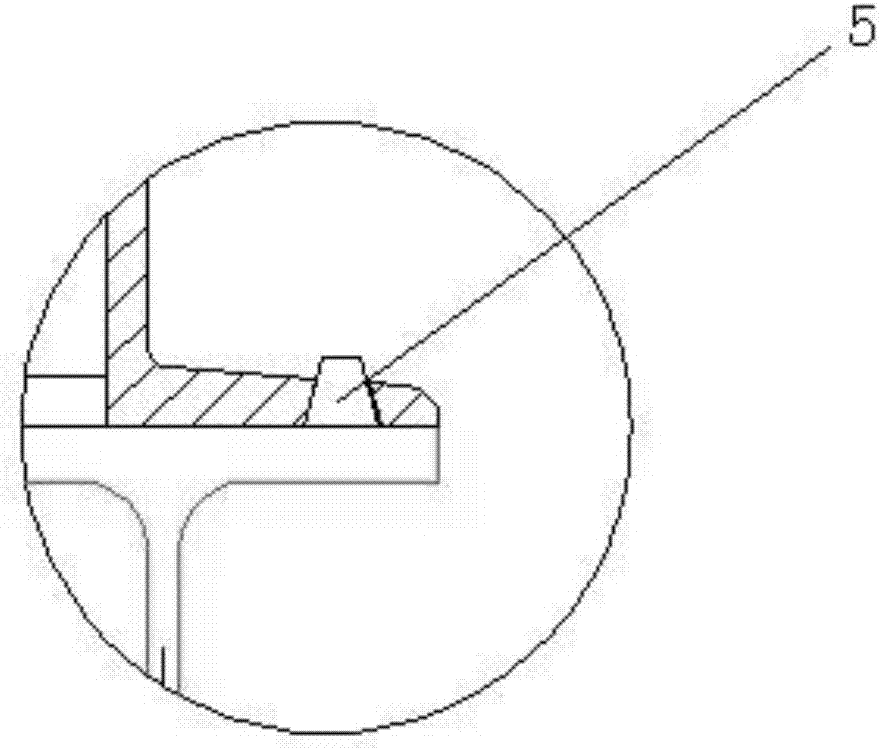

[0019] Such as Figure 1-Figure 4 As shown, the present invention is a dust removal hood device for a continuous casting torch cutter, which includes a dust removal hood 1, a dust removal pipe 2, a pipe support 3, an electric valve 4, a taper pin 5, an airflow guide device, a driving device 8 and a fixed base 9 .

[0020] The dust removal cover 1 is installed above the torch cutter support 11 by the taper pin 5 . The front end of the dust removal pipe 2 is connected to the dust removal cover body 1 through bolts. An electric valve 4 is installed at the end of the dust removal pipe 2. The electric valve 4 is connected to the main dust removal pipe 12 of the workshop. The electric valve 4 is used to close and adjust the dust removal air volume. The valve opening is controlled by hand. Manipulator control and digital display, and interlock with the main dust removal system. The bottom of the pipe support 3 is connected with the dust removal cover body 1, and the top is connecte...

Embodiment 2

[0024] In actual use, the working state of the invention of a continuous casting torch cutter dust removal cover device is as follows:

[0025] The device is installed on the fire cutter support 11, positioned and fixed by the taper pin 5, the action of the driving device 8 is interlocked and synchronized with the cutting action of the fire cutter 13, and the rod end of the driving device 8 is in a retracted state before working.

[0026] First, the electric valve 4 is opened, the dust removal cover 1 is connected to the main dust removal pipeline 12 of the workshop, and the dust removal work starts. Operate the hand operator to adjust the opening value of the electric valve 4 according to the actual situation. When the continuous casting slab reaches the cutting starting point 15 on the left side of the fire cutter 13, the cutting work of the fire cutter 13 starts, and at this time, the electric servo cylinder 8 starts to work synchronously. As the fire cutter 13 moves, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com