Tool arrangement

A technology for arranging structures and tools, applied in milling cutters, reamers, forming cutters, etc., can solve the problems of insufficient connection and insufficient use of thread tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

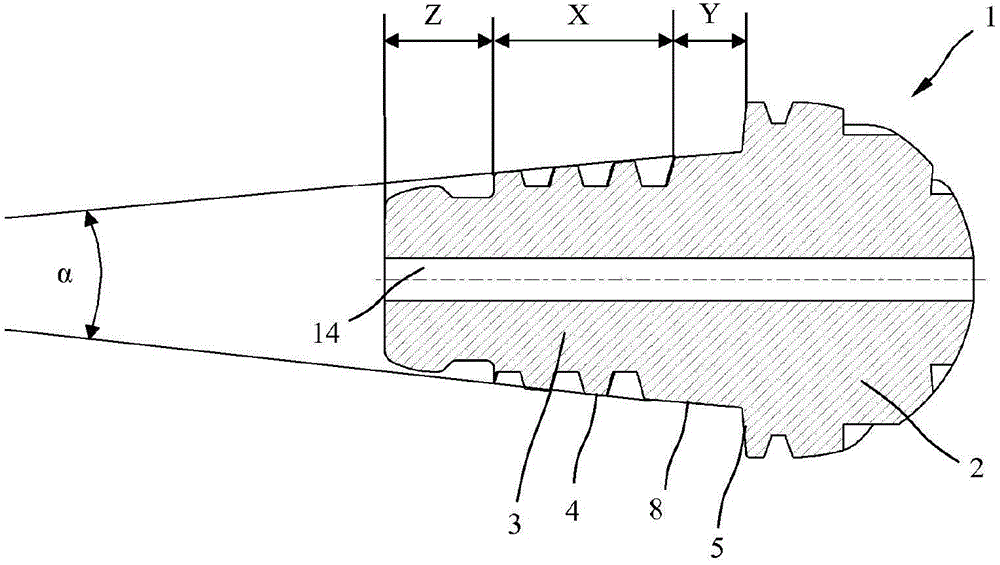

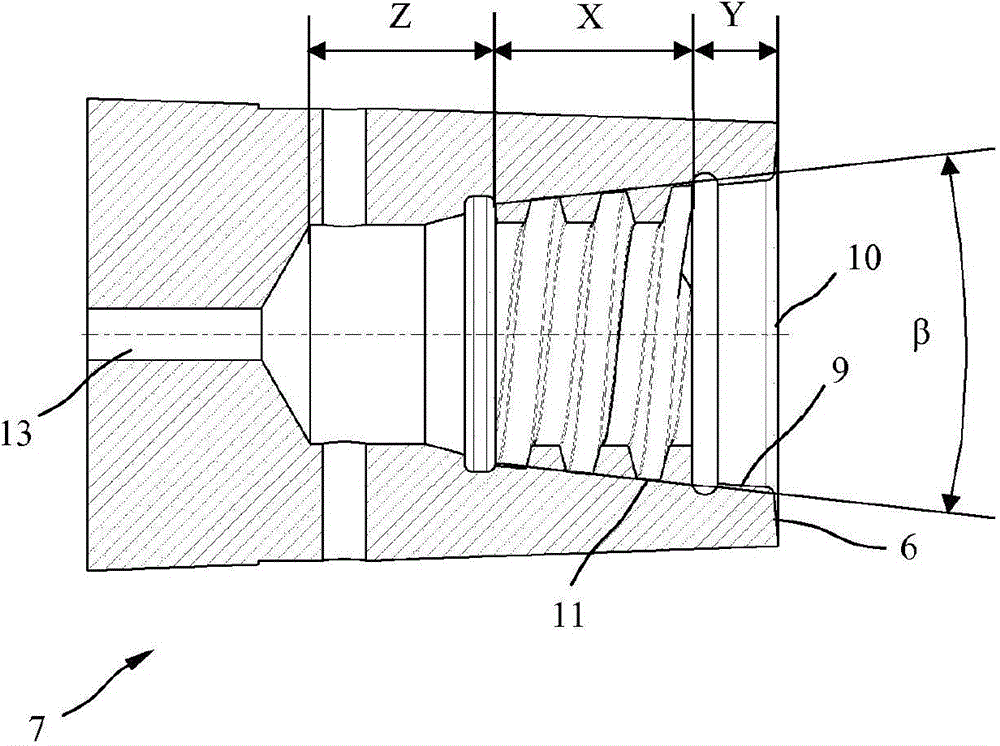

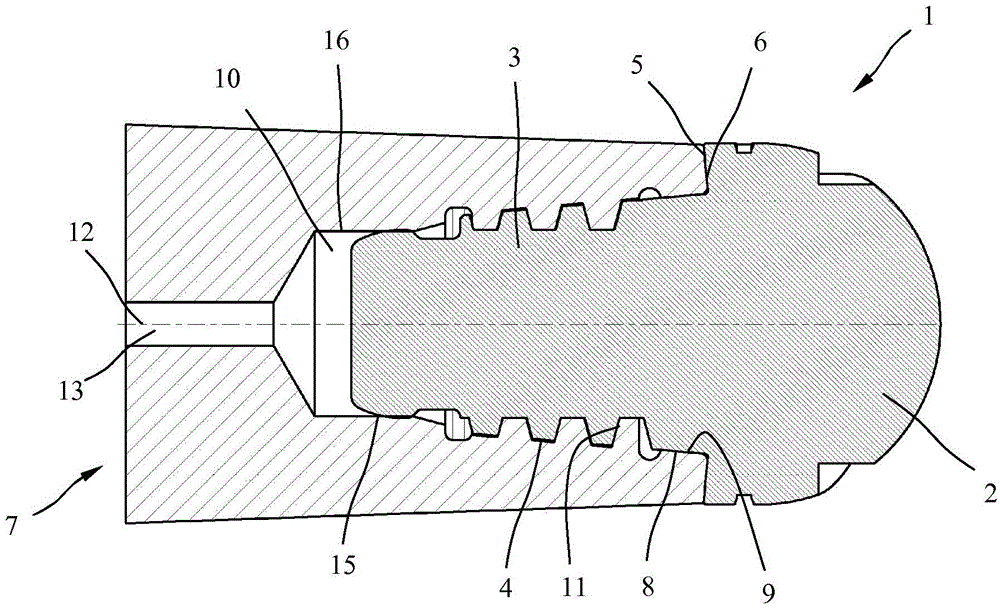

[0021] exist figure 1 A sectional view of the screw-in tool 1 is shown in the tool arrangement. The screw-in tool 1 has a tool head 2 , here designed as a ball-nose milling cutter, and a tool shank 3 tapering conically towards the rear. In the exemplary embodiment shown here, the tool shank 3 is divided into a thread region X with an external thread 4, a first outer bearing point Y arranged between the tool head 2 and the external thread 4, and a second external support point Y on the free end of the tool shank 3. Two internal support parts Z. However, the tool holder 3 can also be designed without an additional outer bearing point Y and / or without an inner bearing point Z.

[0022] The external thread 4 in the thread point X tapers conically at a cone angle α. The first outer bearing point Y has a first conical contact surface 5 and a second conical contact surface 8 for abutting against a correspondingly conical bearing surface 6 on the front side of the tool receptacle 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com