Wound rotor self-starting permasyn motor

A permanent magnet synchronous, wound rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problem of motor starting difficulties, low starting torque, Problems such as poor pull-in synchronization ability, etc., to achieve the effect of improving pull-in synchronization ability, reducing motor slip, and improving starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed structure of the wound rotor self-starting permanent magnet synchronous motor of the present invention is described in conjunction with the embodiments.

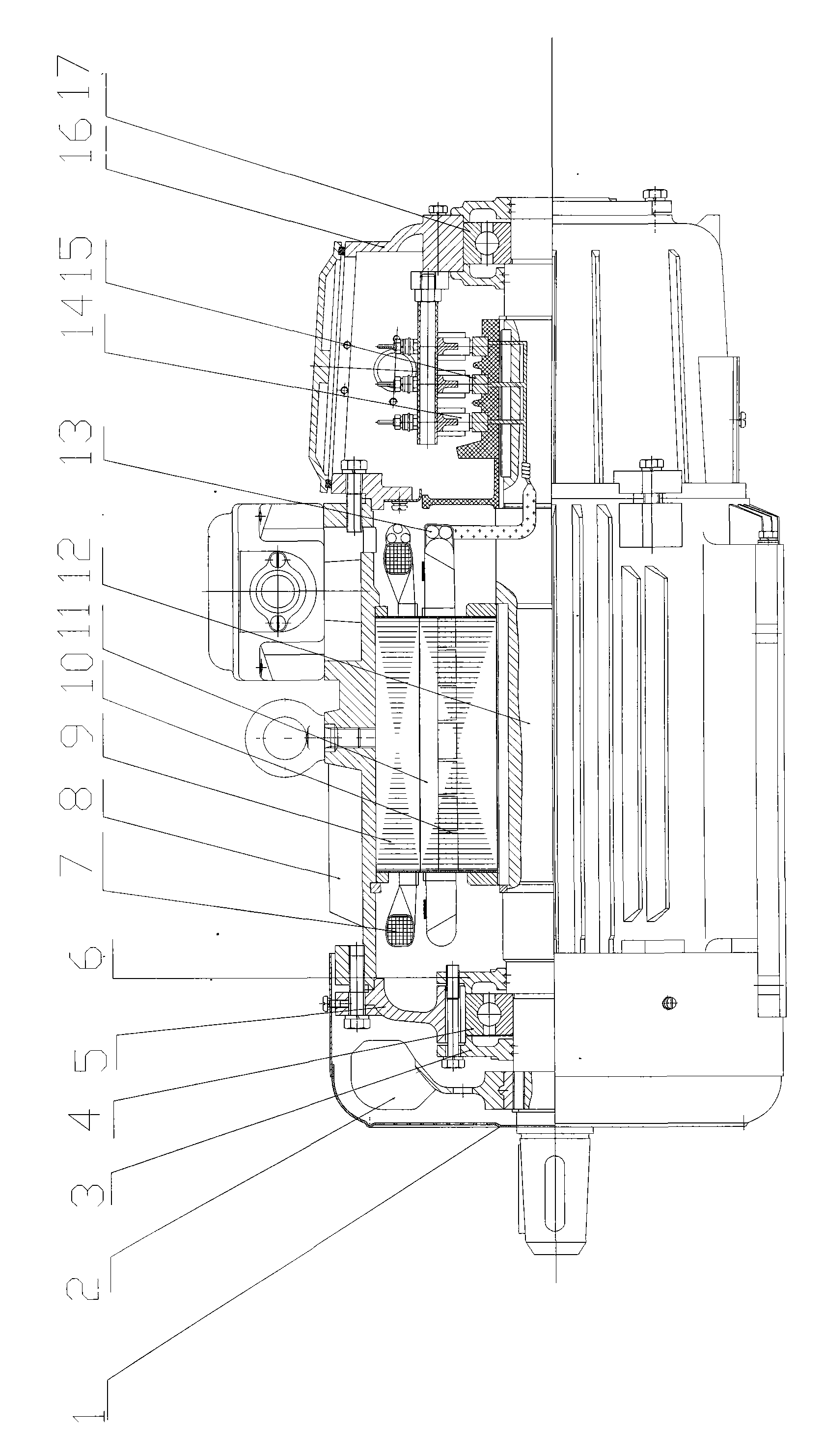

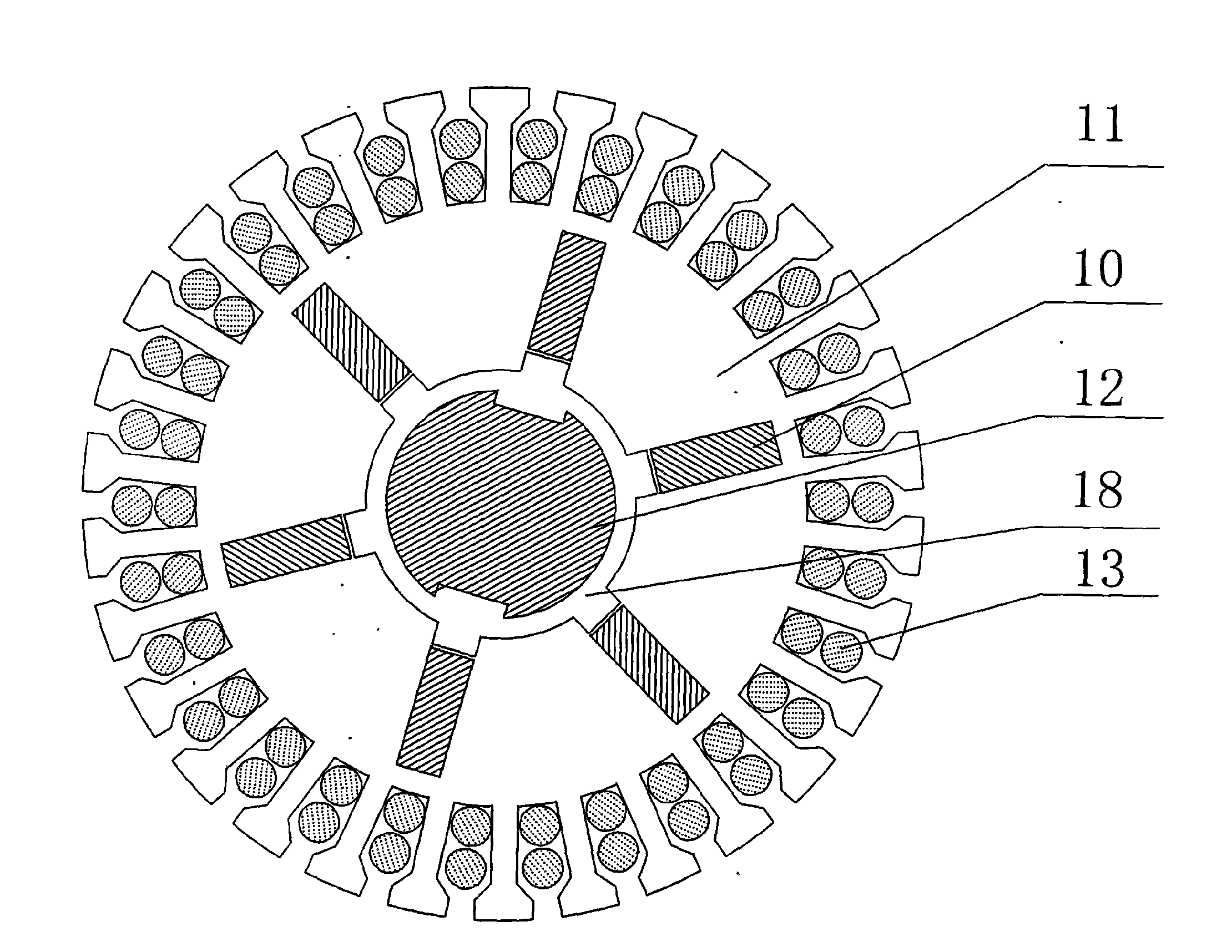

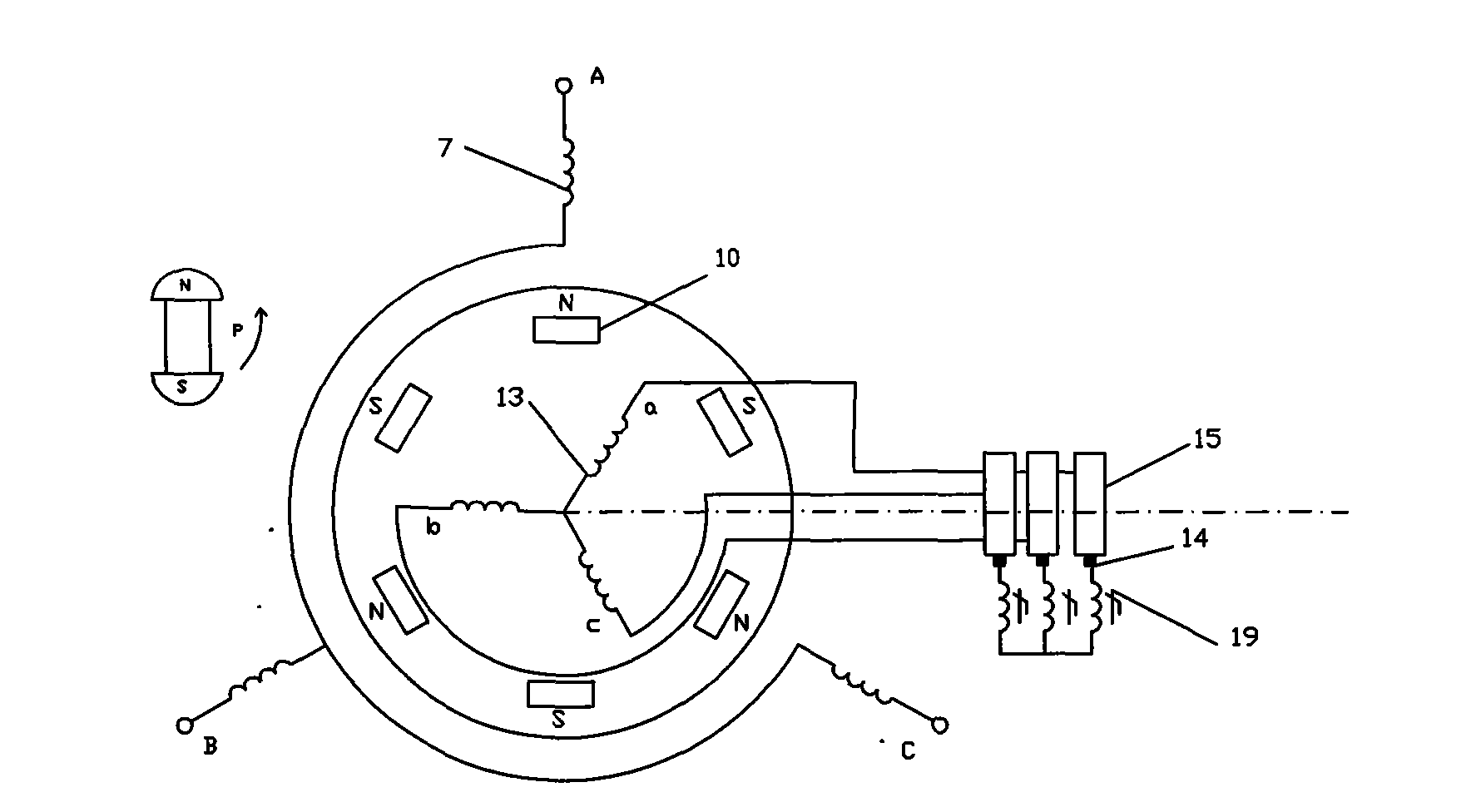

[0020] The device as figure 1 , 2 As shown, it includes fan cover 1, fan 2, bearing front end cover 3, front bearing 4, motor front end cover 5, bearing rear end cover 6, stator winding 7, housing 8, stator core 9, permanent magnet 10, rotor core 11 , rotating shaft 12, rotor winding 13, brush 14, slip ring 15, motor rear end cover 16, rear bearing 17 and magnetic isolation bridge 18.

[0021] The fan 2 of this device is connected with the rotating shaft 12 through the front bearing 4, the fan cover 1 is added on the fan 2, the bearing front end cover 3 and the bearing rear end cover 4 are installed on the front bearing 4, the motor front end cover 5 is above the front bearing 4, and the stator core 9 is fixed on the shell 8, the stator core 9 is provided with a stator slot, and the stator winding 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com