Apparatus and method for controlling internal combustion engine

一种控制设备、内燃机的技术,应用在机械设备、内燃机测试、内燃活塞发动机等方向,能够解决不能提高发动机起动性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

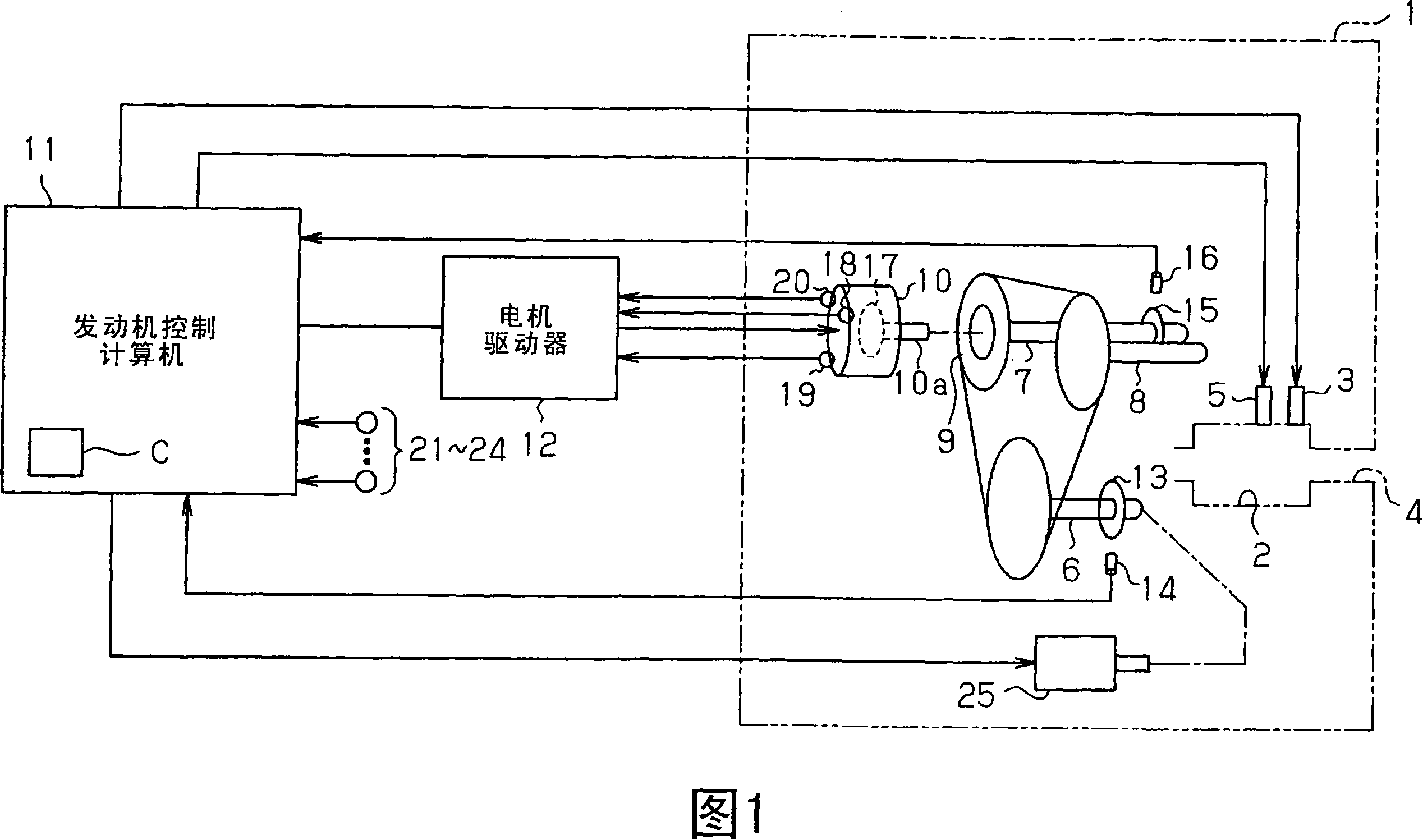

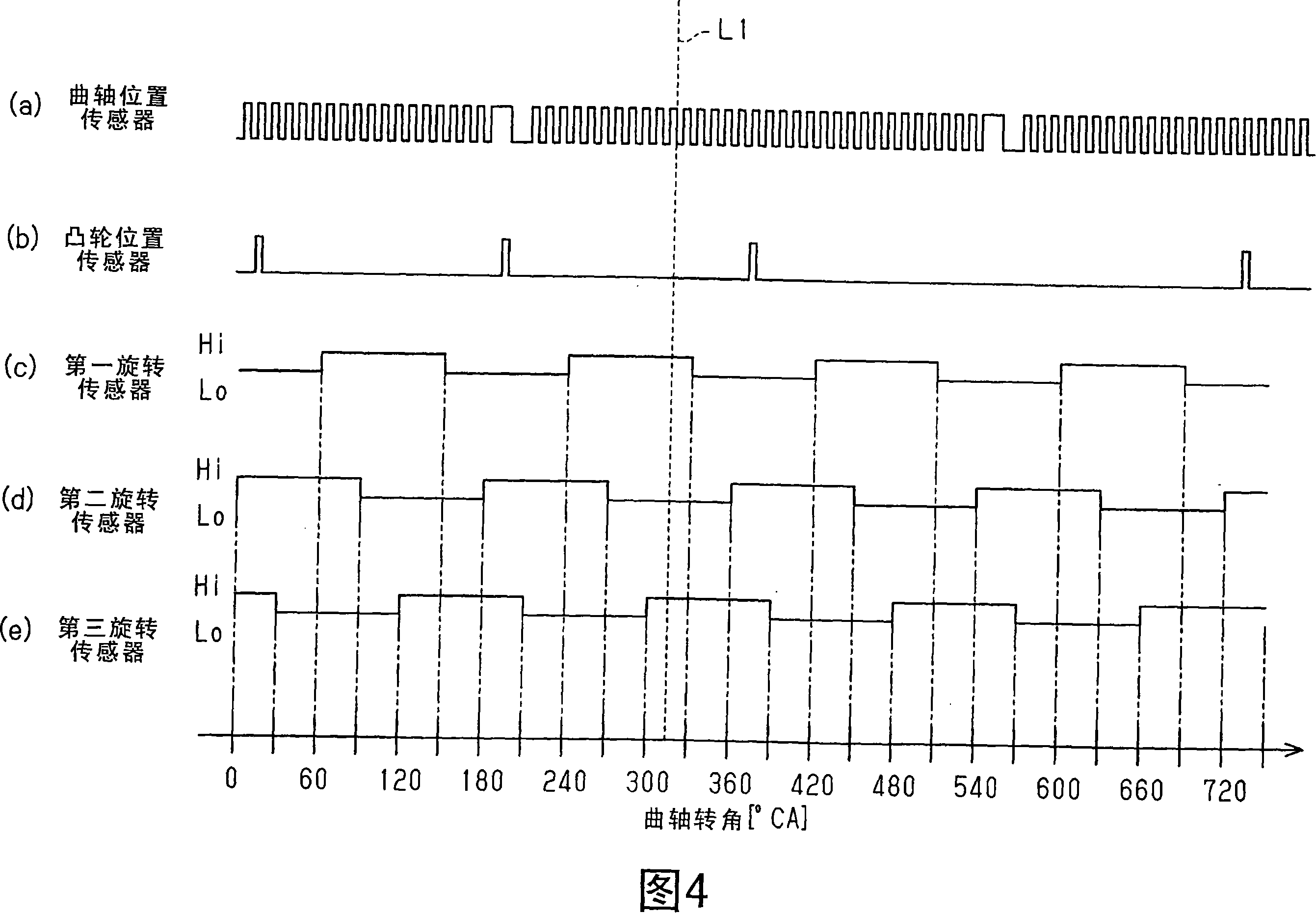

[0036] An automotive multi-cylinder engine 1 according to a preferred embodiment of the present invention will now be described with reference to FIGS. 1 to 22 .

[0037] As shown in FIG. 1 , an engine 1 has combustion chambers 2 (only one is shown) into which fuel is injected by a fuel injection valve 3 in each combustion chamber 2 . Furthermore, air is introduced into each combustion chamber 2 from an intake passage 4 . The air-fuel mixture in each combustion chamber 2 is ignited by a spark plug 5 . When such an air-fuel mixture is ignited so that the air-fuel mixture burns, the combustion energy drives the engine 1 , in other words, rotates the crankshaft 6 . A starter 25 is connected to the crankshaft 6 . When the engine 1 is started (the engine 1 is cranked), the starter 25 forcibly rotates the crankshaft 6 .

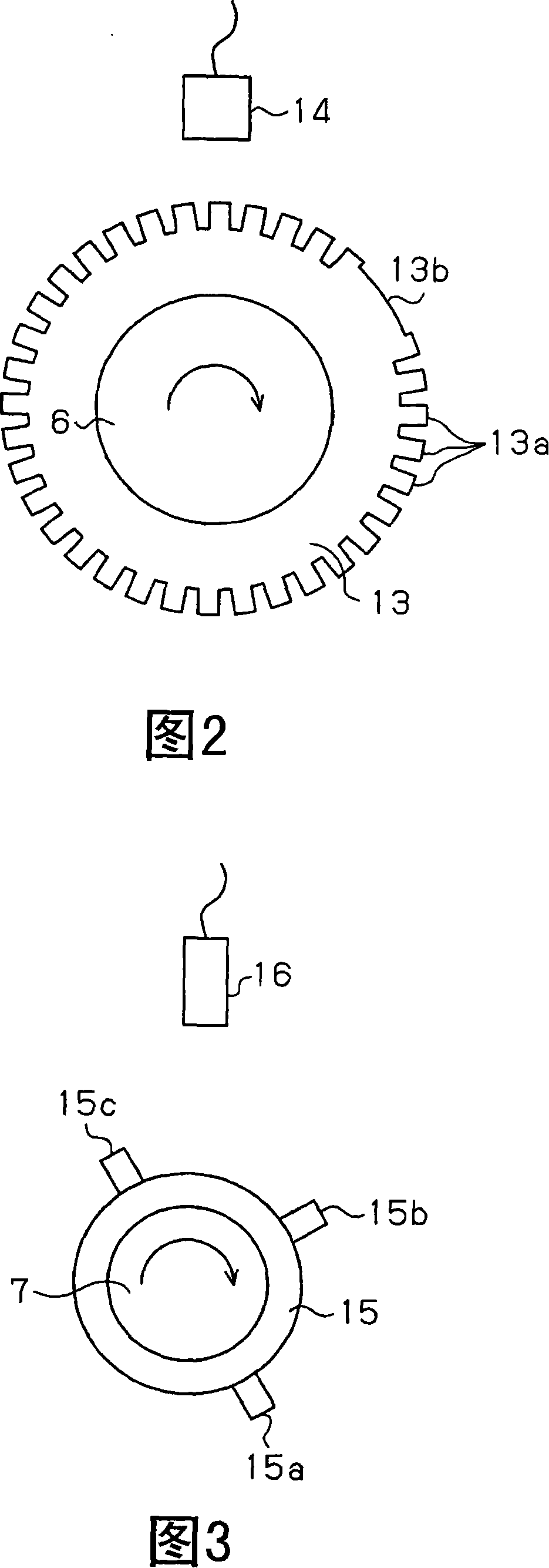

[0038] The rotation of the crankshaft 6 is transmitted to an intake camshaft 7 and an exhaust camshaft 8 . The rotation transmitted from the crankshaft 6 is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com