A vertical roller mill

A vertical roller mill and grinding bowl technology, which is applied to grain processing and other directions, can solve the problems of difficult equipment maintenance and high wear and tear of the mill, and achieve the effects of high adaptability, prevention of useless work, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

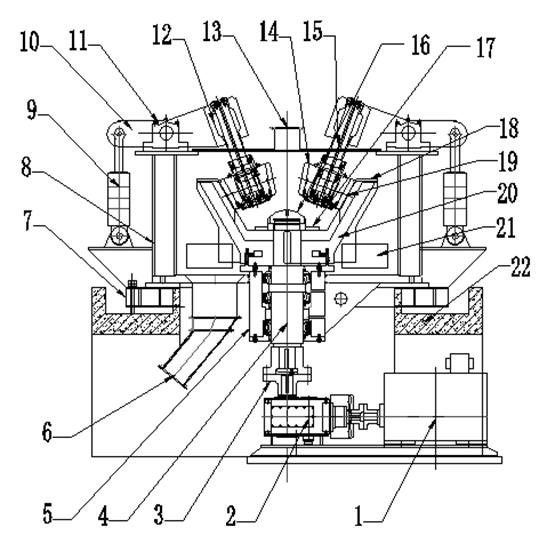

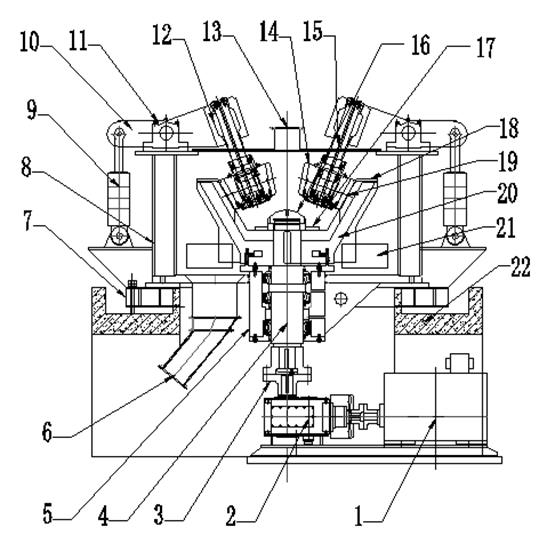

[0029] Accompanying drawing is a kind of specific embodiment of the present invention.

[0030] The vertical roller mill of the present invention includes a vertical main shaft 4 installed on the machine body, the lower end of the main shaft is connected to the reducer 2 and the motor 1 in turn, the upper end of the main shaft is equipped with a grinding bowl 20, and the upper part of the inner side of the bowl contacts several grinding mills. Roller 14, the grinding roller is installed on the grinding roller shaft 15 through bearings, the grinding roller shaft is connected to one end of the rocker arm 10, the middle part of the rocker arm is hinged on the body 8, the other end of the rocker arm is hinged to the upper end of the hydraulic cylinder 9, and the lower end of the hydraulic cylinder is installed on the body On the top of the body, there is a central feed pipe 13 that is aligned downwards with the grinding bowl 20, and the body is provided with a discharge port 6 belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com