Excess/waste heat reutilization structure of little sun heater

A heater and solar technology, applied in applications, household heating, heating methods, etc., to achieve the effect of simple structure, increased manufacturing cost, and sufficient heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

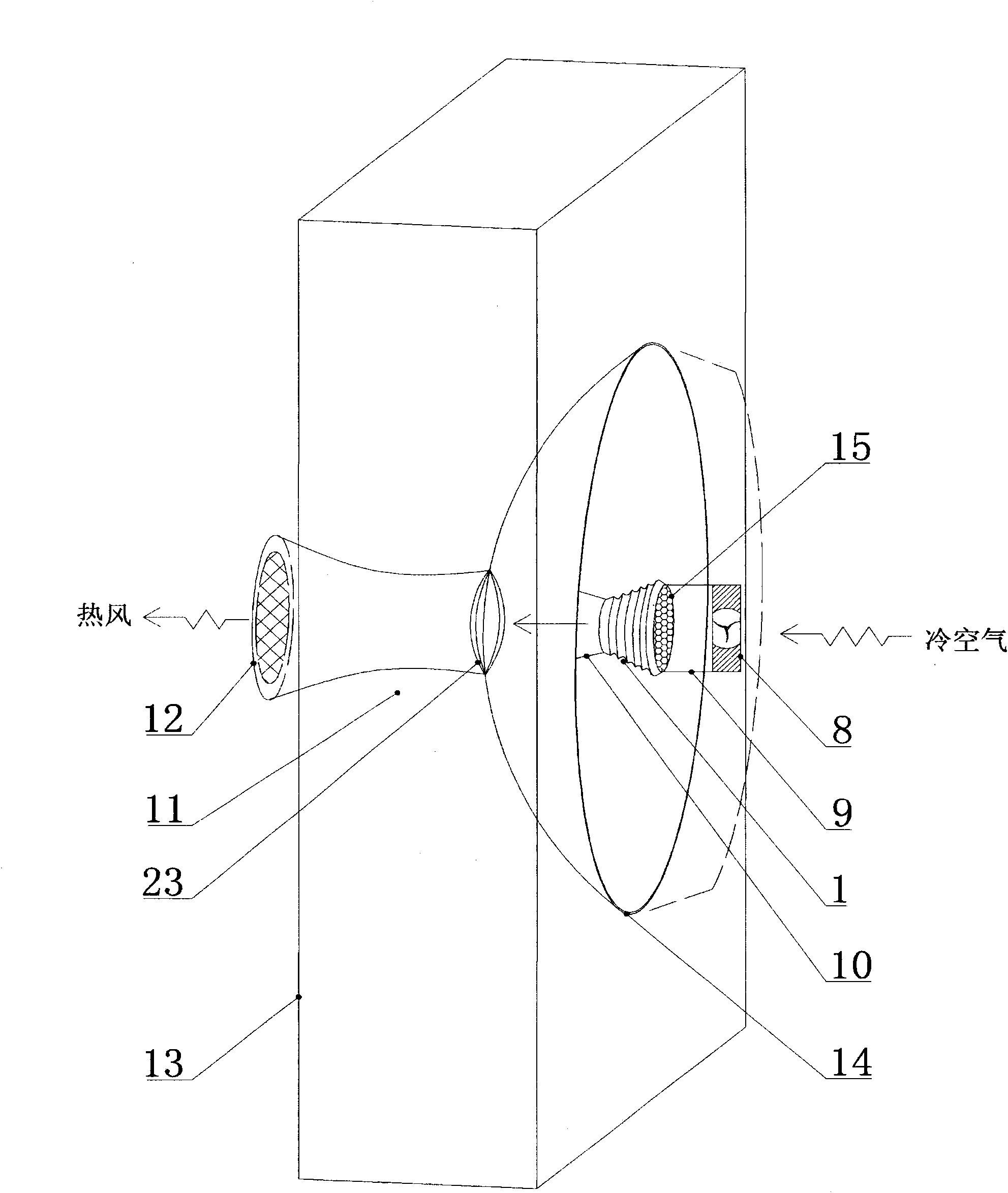

[0042] Such as figure 1 As shown, a reflector 14 is installed on one side of the square or rectangular housing 13, and the central opening 23 is connected to the hollow fixed column 10; the heat source ceramic body 1 and the fan transition pipe 9 that have been inserted into the heat sink or the two ends of the metal honeycomb 15 Connect outwards with blower fan 8 successively.

[0043] The air duct 11 behind the reflector is connected with the central hole 23 and the rear air duct is connected front and back, and the mouth of the air duct has a safety net 12 . There are wire teeth or screw hole platform connections between each accessory. As shown by the wavy arrow, the cold air is sucked by the fan 8, heated by the cooling fins and blown out from the air supply pipe 11 at the back. Fan transition pipe 9 is a non-essential accessory in this example, if removed then the heat insulation measures must be done well between the fan and the ceramic body.

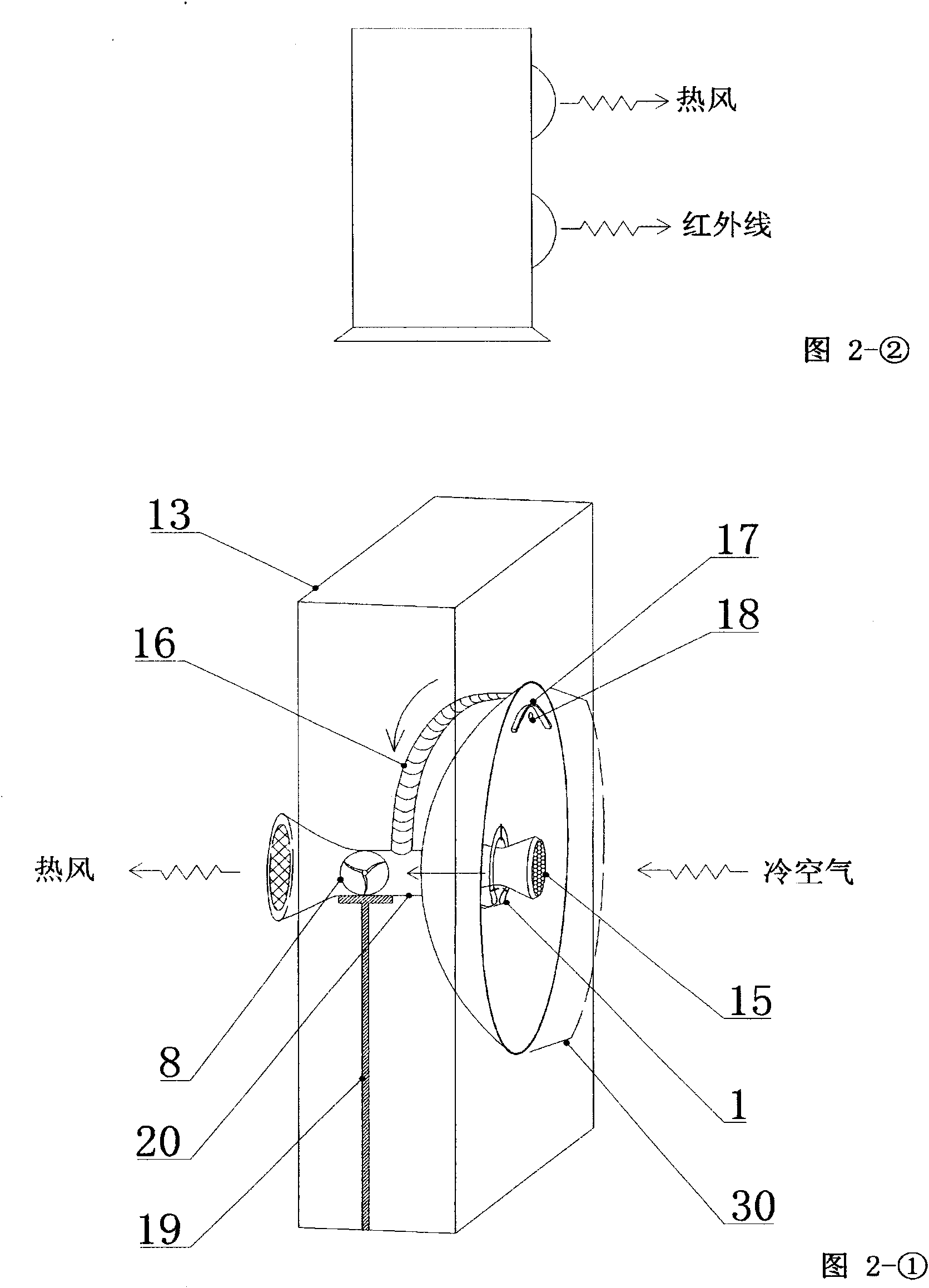

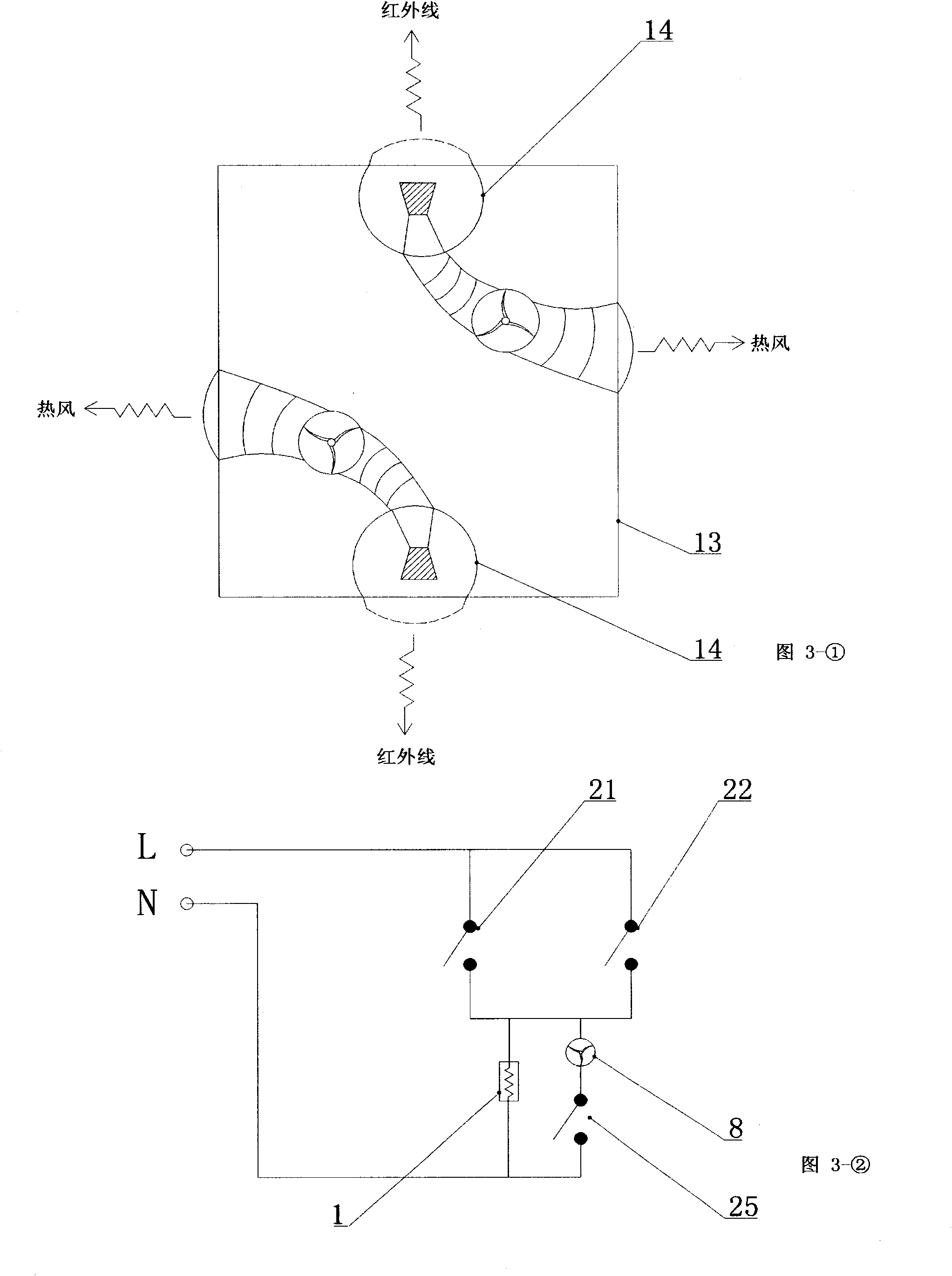

[0044] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com