Biogas anaerobic fermentation tank waste heat utilization and temperature increasing system

An anaerobic fermentation tank, waste heat technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, gas production bioreactor, etc. Scaling, heat transfer efficiency attenuation and other problems, to achieve the effect of easy promotion, uniform and stable temperature, and ensure heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below.

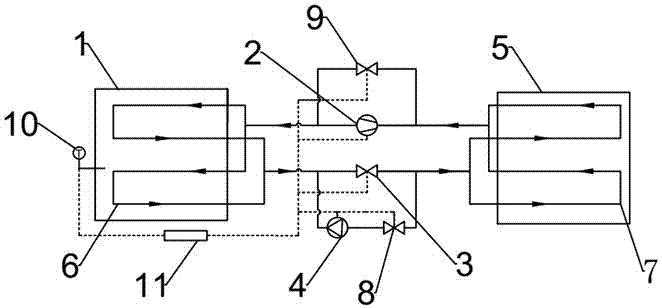

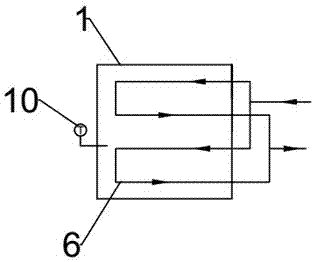

[0031] Implementing the waste heat utilization and warming system of the biogas anaerobic fermentation tank provided by the present invention is mainly to further overcome the high viscosity of the biogas slurry and the fouling of the heating coil after a period of use, resulting in a sharp decline in heat exchange efficiency The problem of high-efficiency utilization of waste heat from biogas residue and biogas slurry. For this reason, the present invention adopts the direct expansion heat pump system with the integrated radiation end of the concrete embedded coil, that is, the integrated radiation end of the concrete embedded coil replaces the traditional heating coil; at the same time, the biogas residue is used as the low-level heat source to use The heat pump technology increases the temperature of the anaerobic fermentation tank. The system only needs to include the anaerobic ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com