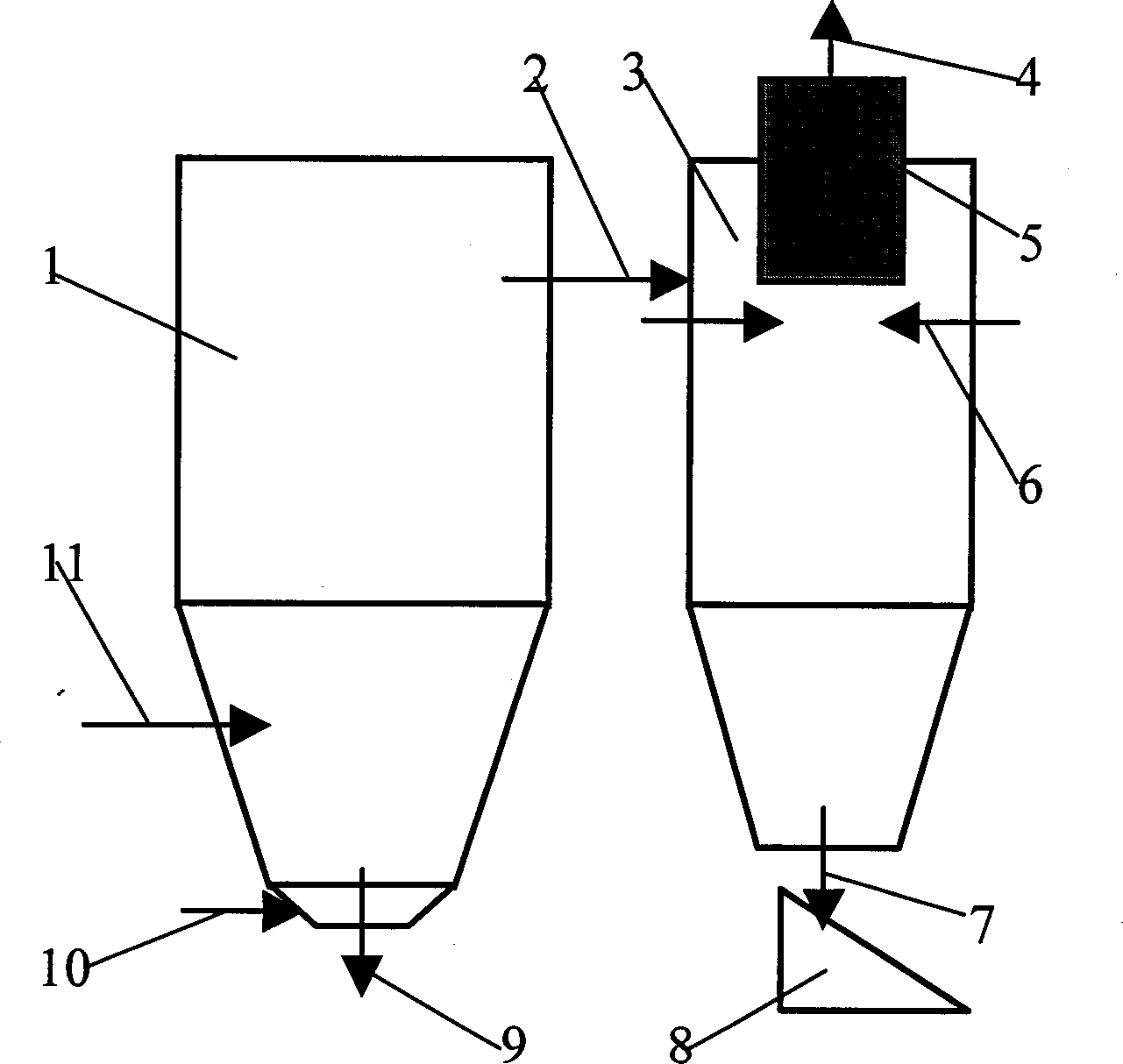

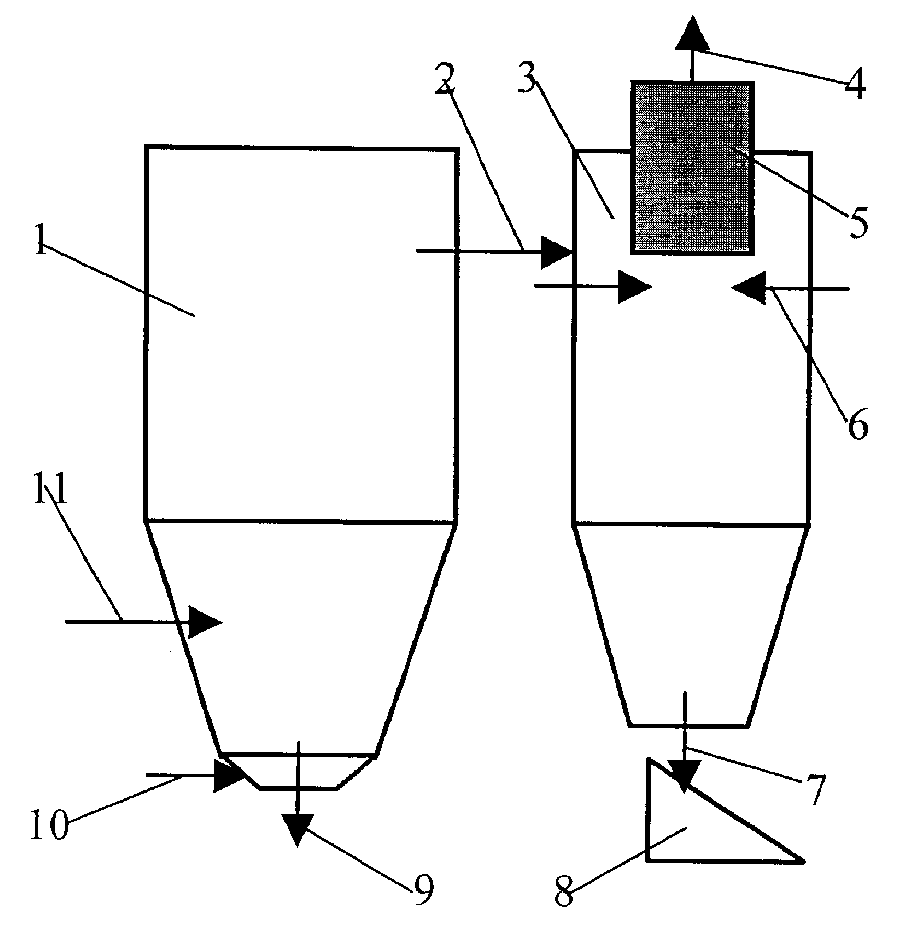

Method for making fluid bed produce high-temp. smoke and its equipment

A high-temperature flue gas and fluidized bed technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve the problem of affecting reliability, affecting the normal fluidization quality of pyrolysis fluidized bed, and affecting safety In order to achieve the effect of low production cost, solve the difficulty of high-temperature flue gas, and prevent coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

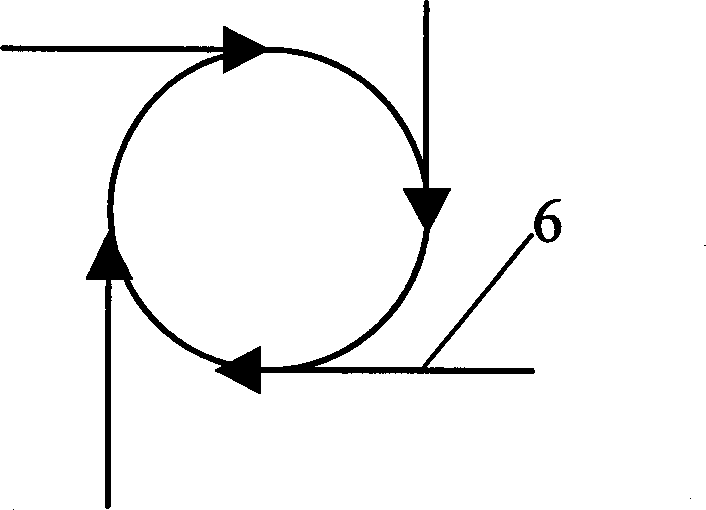

Method used

Image

Examples

Embodiment

[0017] When burning coal whose ash melting point is about 1300°C, the bed temperature of the fluidized bed is controlled at 910°C, the fluidization wind speed is 4.3m / s, the temperature of the flue gas generated by the fluidized bed is 925°C, and the combustible gas content is controlled At 3.7%, the oxygen content is 0.1-0.3%; after the flue gas enters the secondary combustion chamber, the secondary combustion air volume is 2.2m 3 / (kg coal), the temperature of the high-temperature flue gas produced is as high as 1450°C, and the slag discharge temperature is 1450°C, which can continuously discharge slag in liquid state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com