Overcooling freezing method, refrigerator and refrigerator control method

A freezing method and supercooling technology, applied in coolers, household refrigerators, cooling fluid circulation devices, etc., can solve the problems of high cost, high meat juice loss rate, and reduced practicability of refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

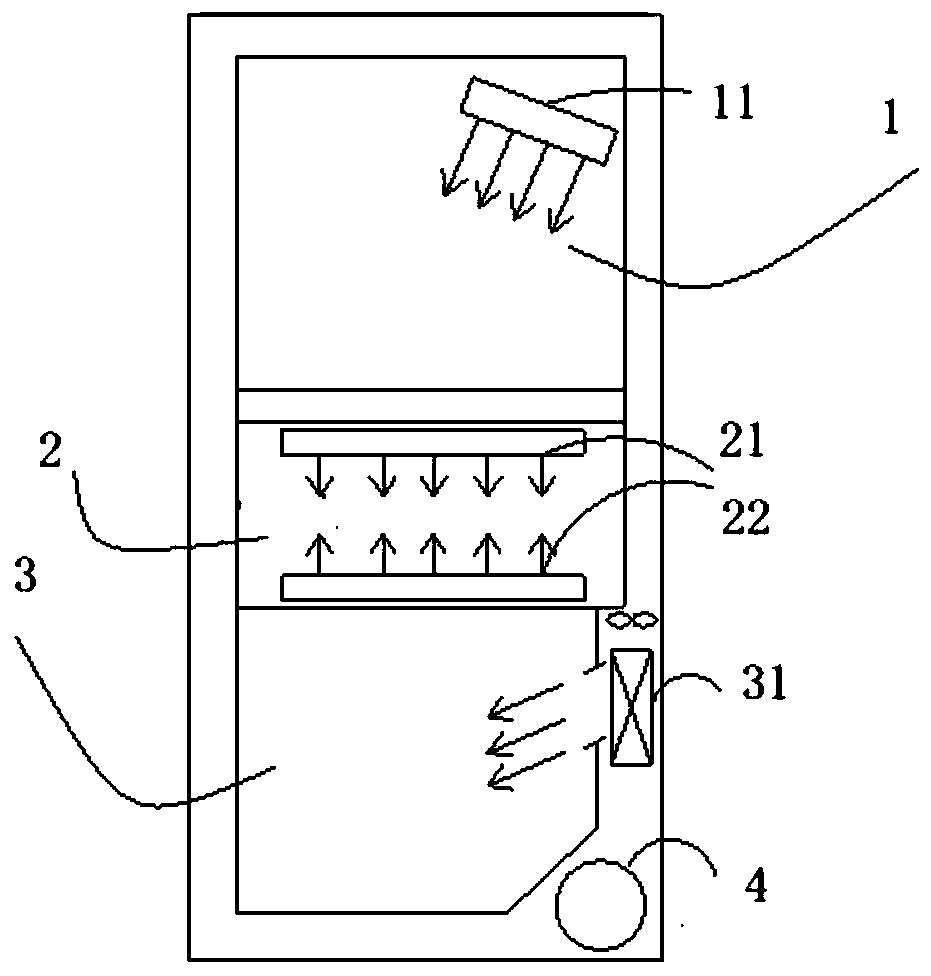

[0044] This embodiment provides a refrigerator such as figure 1 , which are successively provided with a refrigerator compartment 1, a quick freezer compartment 2, and a freezer compartment 3 from top to bottom, wherein the quick freezer compartment 2 is used to supercool and freeze stored items. Using the sequential design of the temperature of the three compartments to decrease step by step, on the one hand, it is not easy to transfer odors, and on the other hand, it also saves energy.

[0045] In order to achieve better freezing quality of the quick freezing chamber 2, a first direct-cooling evaporator 21 is provided at the top, and a second direct-cooling evaporator 22 is provided at the bottom. In the different processes of supercooling and freezing, direct cooling evaporators in different positions are used to cool down the stored items in the quick freezing chamber.

[0046] The refrigerator compartment 1 is equipped with a fan 11 for air cooling, and the freezer compa...

Embodiment 2

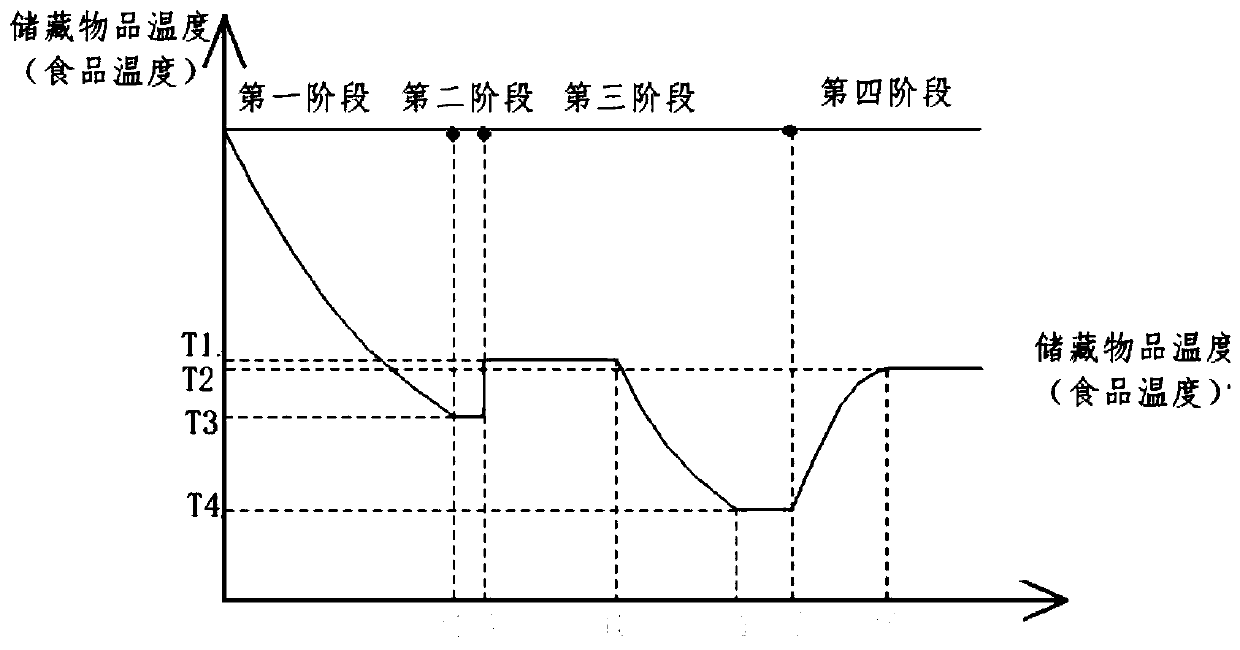

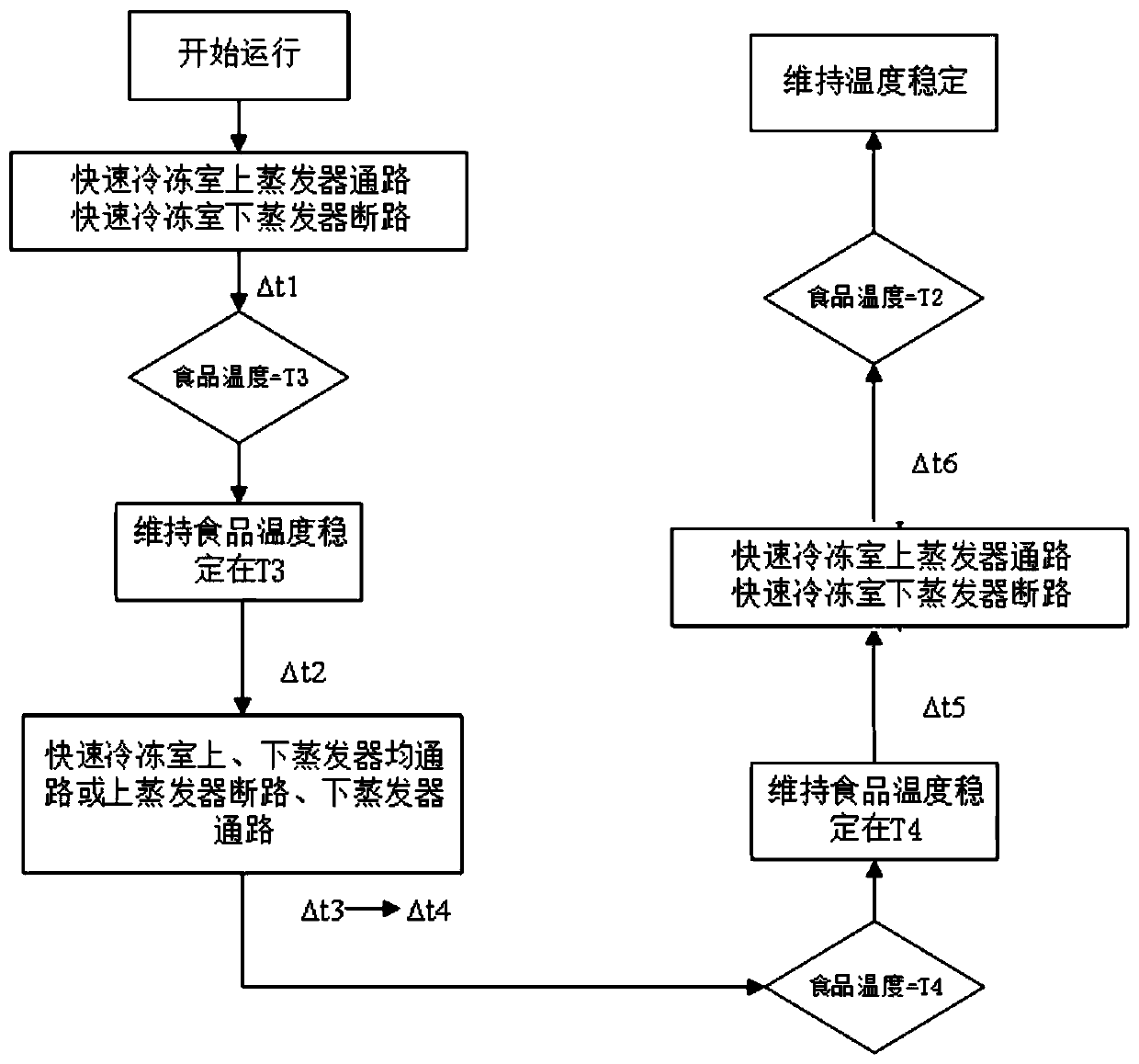

[0052] Taking the above-mentioned refrigerator and the food stored therein as examples, an embodiment of a supercooling freezing method and a refrigerator and a refrigerator control method is provided, including the following stages and supercooling and freezing operations:

[0053] In the pre-cooling stage, the refrigeration system is started, and the first evaporator is used to cool down the fast freezing chamber, so that the temperature of the fast freezing chamber is lowered. After time t1, the temperature of the stored items is reduced to the third temperature T3 below the freezing point T1, but the stored items are not Freezing: This step can make the food that needs to be overcooled and frozen quickly enter the low temperature zone required for the supercooling process from the normal temperature state, and the food does not freeze. This cooling measure can not only ensure that the food can enter the supercooling process in the subsequent results, but also improve the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com