Combustion chamber and method for synthesizing ultrafine lanthanum oxide powder through combustion

A combustion chamber, lanthanum salt technology, applied in the field of rare earth oxide powder, can solve the problems of slow gel process, uneven particle size, complex preparation process, etc., to improve the rate and conversion, uniform distribution, good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

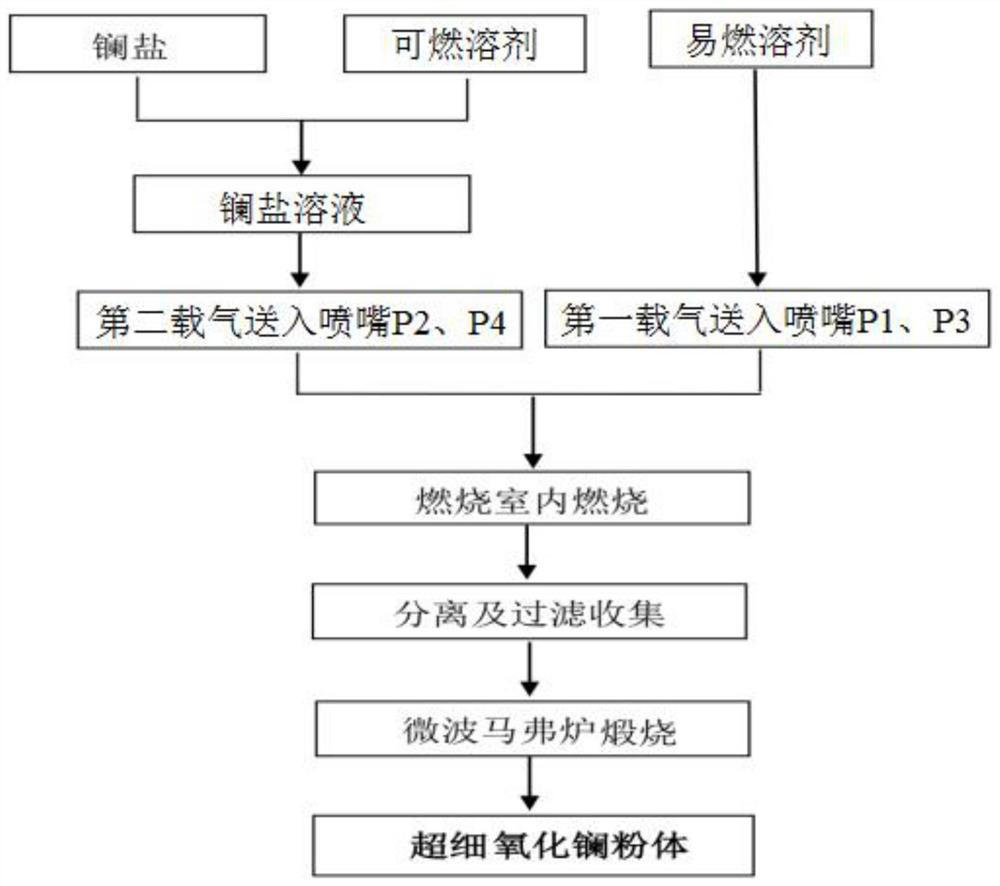

[0044] (1) Add lanthanum nitrate in ethanol, stir at room temperature, obtain clear lanthanum nitrate solution, concentration is 5mol / L;

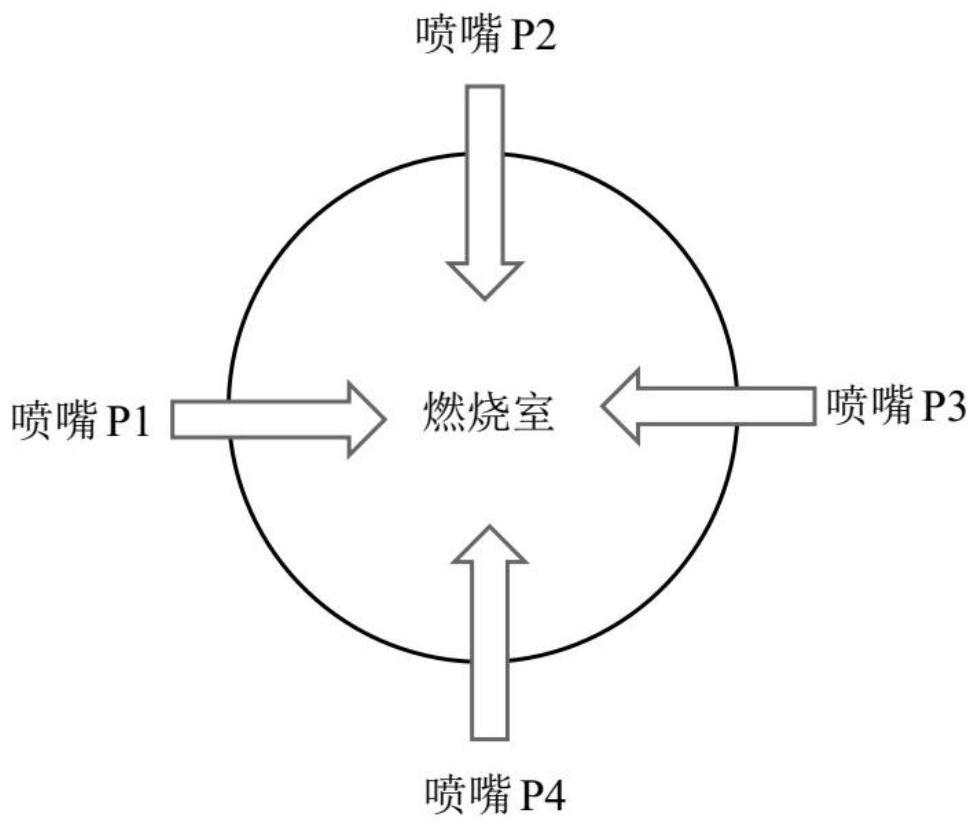

[0045] (2) Prepare the ethanol solvent, send ethanol into the combustion chamber from the nozzles P1 and P3 of the combustion chamber with oxygen as the carrier gas, the feed rate is 20mL / min, and ignite to make the ethanol burn;

[0046] (3) after treating that ethanol burns for 3 minutes, take hydrogen as carrier gas, the lanthanum nitrate solution prepared in the step (2) is sent in the combustion chamber from the nozzle P2 of combustion chamber and P4, and feed rate is 15mL / min, After being ignited, combustion occurs to form lanthanum oxide, and the pressure in the combustion chamber is 0.8 atmospheres at this time;

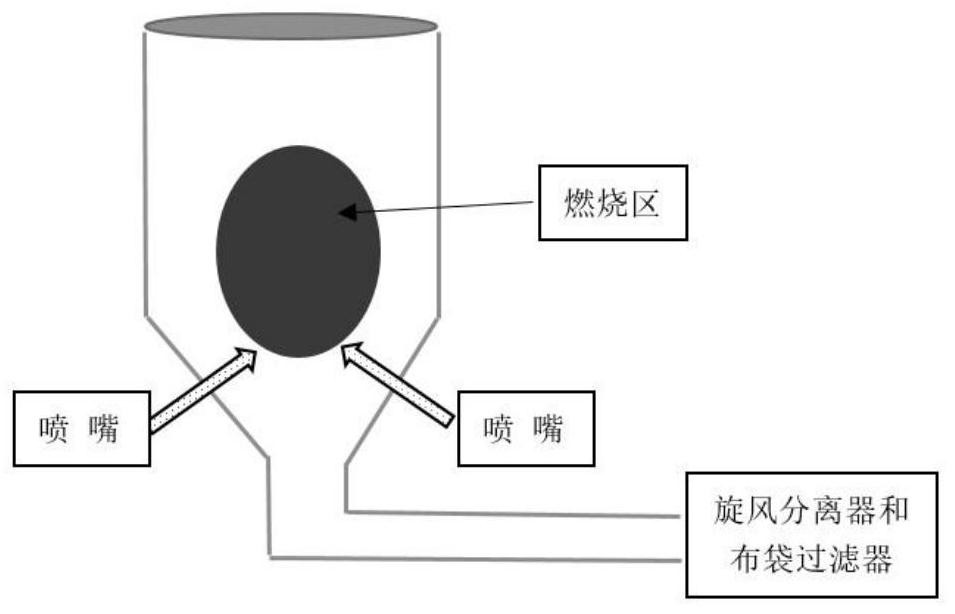

[0047] (3) Catch the combustion product in the combustion chamber with a cyclone separator and a bag filter, after testing, the content of lanthanum oxide in the combustion product is 92%;

[0048] (4) The collected combu...

Embodiment 2

[0052] (1) adding lanthanum chloride to a mixed solvent of ethanol and acetone, stirring at room temperature to obtain a clear lanthanum chloride solution with a concentration of 8mol / L;

[0053] (2) prepare gasoline solvent, take oxygen as carrier gas gasoline is sent in the combustion chamber from nozzle P1 and P3 in the combustion chamber, feeding rate is 20mL / min, and ignition makes it burn;

[0054] (3) after gasoline burns 3 minutes, take air as carrier gas that the lanthanum chloride solution prepared in step (1) is sent in combustion from nozzle P2 and P4 in the combustion chamber, feed rate is 10mL / min, After being ignited, combustion occurs to generate lanthanum oxide, and the pressure in the combustion chamber is 0.7 atmospheres at this time;

[0055] (4) Catch the combustion product produced by the reaction in the combustion chamber with a cyclone separator and a bag filter. After testing, the content of lanthanum oxide in the combustion product is 87%;

[0056] (...

Embodiment 3

[0058] (1) Add lanthanum sulfate in the acetone solvent, stir at room temperature, obtain clear lanthanum sulfate solution, the concentration of rare earth salt is 1mol / L;

[0059] (2) Prepare acetone solvent, load acetone into the nozzles P1 and P3 in the combustion chamber with oxygen, the feed rate is 20mL / min, and ignite to make it burn;

[0060] (3) After acetone was burned for 3 minutes, the lanthanum sulfate solution prepared in step (1) was sent into the combustion chamber from the nozzles P2 and P4 of the combustion chamber with oxygen as the carrier gas, and the feed rate was 5mL / min, which was After ignition, combustion occurs to generate lanthanum oxide powder, and the air pressure in the combustion chamber is 0.9 atmospheres;

[0061] (4) Catch the combustion product produced by the reaction in the combustion chamber with a cyclone separator and a cloth bag filter. After testing, the content of lanthanum oxide in the combustion product is 94%;

[0062] (5) Calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com