Preparation method of aluminum-titanium-boracium mater alloy

An intermediate alloy, aluminum titanium boron technology, applied in the field of metallurgy, can solve the problems of low production efficiency, high reaction temperature, not very ideal, etc., and achieve the effect of good product quality, simple operation and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

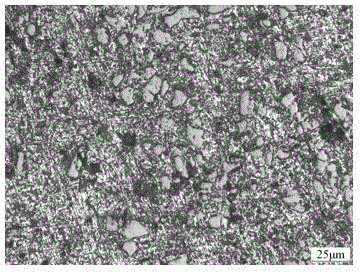

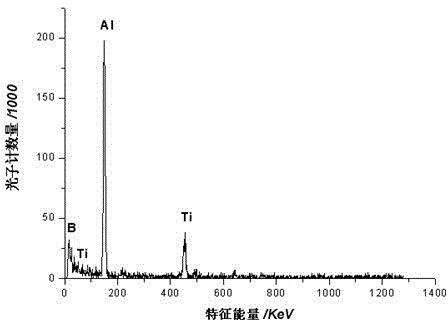

Image

Examples

Embodiment 1

[0024] 1. Weigh raw materials: Al powder is industrial grade, sulfate is anhydrous calcium sulfate (CaSO 4 ), sulfate can not only provide heat, but also has a slagging effect, TiO 2 and B powder are analytically pure, and the slagging agent is selected as CaF 2 ; Raw material mass percentage is as follows:

[0025] Al CaSO 4 TiO 2 B CaF 2 60 30 5.5 0.5 4

[0026] 2. Mixing: Put the raw materials into the mixer and mix evenly, the number of times is 3 times;

[0027] 3. Loading: put the mixed raw materials into the mold cavity, and slightly compact the raw materials;

[0028] 4. Ignition: Sprinkle the igniting agent on the raw material and ignite it with a torch;

[0029] 5. Cooling: After the metal flowing into the forming mold from the reaction mold is cooled naturally, the Al-Ti-B alloy is taken out.

Embodiment 2

[0031] 1. Weigh raw materials: Al powder is industrial grade, sulfate is anhydrous calcium sulfate (CaSO 4 ), sulfate can not only provide heat, but also has a slagging effect, TiO 2 and B powder are analytically pure, and the slagging agent is selected as CaF 2 ; Raw material mass percentage is as follows:

[0032] Al CaSO 4 TiO 2 B CaF 2 50 35 8 2 5

[0033] 2. Mixing: Put the raw materials into the mixer and mix evenly, the number of times is 3 times;

[0034] 3. Loading: put the mixed raw materials into the cavity of the mold, and slightly compact the raw materials;

[0035] 4. Ignition: Sprinkle the igniting agent on the raw material and ignite it with a torch;

[0036] 5. Cooling: After the metal flowing into the forming mold from the reaction mold is cooled naturally, the Al-Ti-B alloy is taken out.

Embodiment 3

[0038] 1. Weigh raw materials: Al powder is industrial grade, sulfate is anhydrous calcium sulfate (CaSO 4 ), sulfate can not only provide heat, but also has a slagging effect, TiO 2 and B powder are analytically pure, and the slagging agent is selected as CaF 2 ; Raw material mass percentage is as follows:

[0039] Al CaSO 4 TiO 2 B CaF 2 70 25.8 1 0.2 3

[0040] 2. Mixing: Put the raw materials into the mixer and mix evenly, the number of times is 3 times;

[0041] 3. Loading: put the mixed raw materials into the cavity of the mold, and slightly compact the raw materials;

[0042] 4. Ignition: Sprinkle the igniting agent on the raw material and ignite it with a torch;

[0043] 5. Cooling: After the metal flowing into the forming mold from the reaction mold is cooled naturally, the Al-Ti-B alloy is taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com