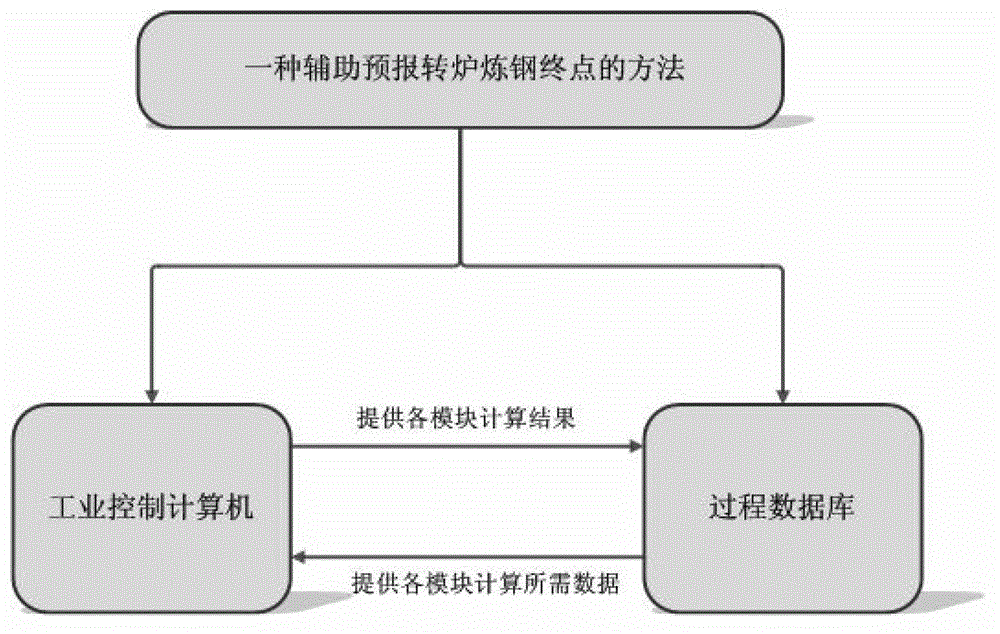

An auxiliary method for predicting the end point of converter steelmaking

A converter steelmaking and converter smelting technology, applied in the field of iron and steel metallurgy, can solve the problems of inability to install sub-guns, high equipment investment costs, limited hit rate at the end point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

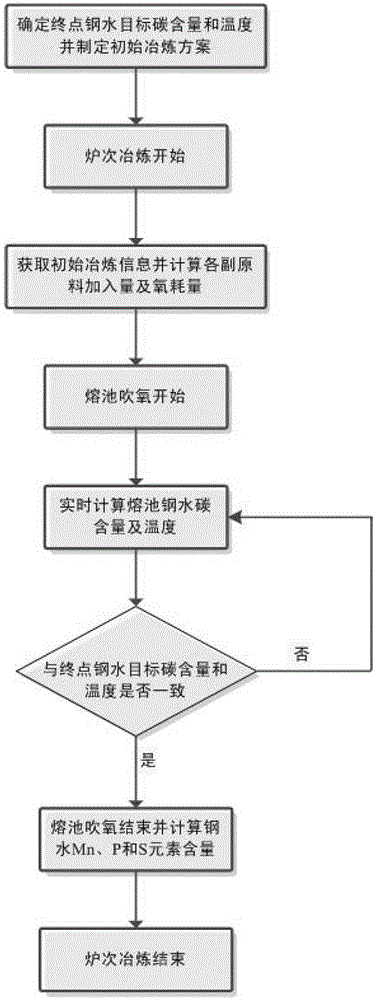

[0041] The present invention will be further elaborated below with specific implementation cases. In the specific implementation process, the calculation process of each operating module of the industrial control computer involved in the present invention includes the following steps:

[0042] (1) Before the start of smelting a furnace of molten steel, determine the target carbon content and temperature of the end-point molten steel according to the steel type in the smelting plan, and formulate an initial smelting plan;

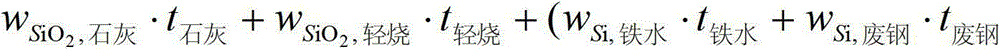

[0043] (2) At the beginning of the smelting furnace, the process database system collects and records the metal material loading information of the furnace (hot metal, scrap steel, pig iron loading, composition and temperature data, etc.), and the industrial control computer provides these data according to the process database system , use the secondary raw material calculation module to calculate the amount of each secondary raw material added in the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com