Method for low-temperature smelting of high-carbon and low-phosphorus steel in converter

A low-phosphorus steel and low-temperature technology, applied in the manufacture of converters, etc., can solve the problems of difficult synchronization of smelting end points, affecting the efficiency of converter P removal, weakening of molten pool stirring, etc., to shorten the pure oxygen supply time and improve converter production efficiency , Reduce the effect of alloy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

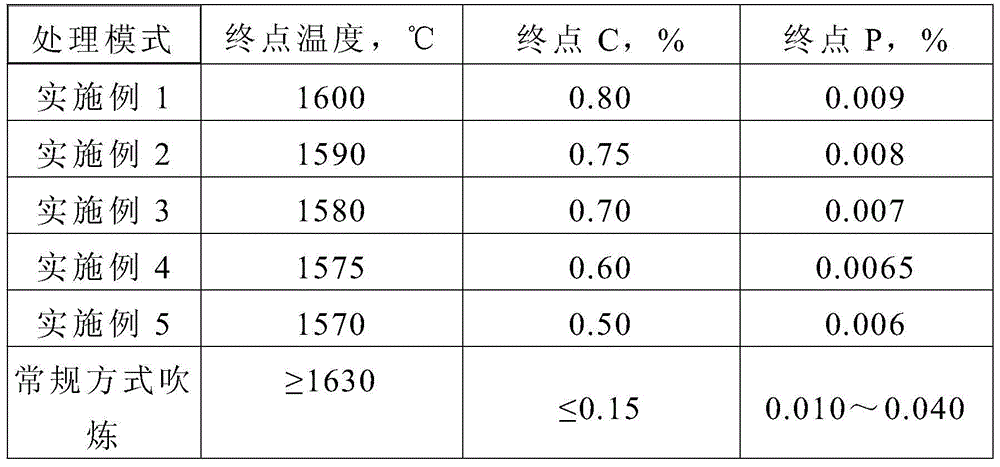

Examples

Embodiment 1

[0031] 1) Control in the early stage of blowing (ie Si, Mn oxidation period). The time limit is 0 to 4 minutes when blowing is started, and the operation is as follows:

[0032] The oxygen lance is ignited, the opening position of the blowing lance is 1200mm, and the flow rate of the oxygen lance is controlled at 30000Nm 3 / h (the flow rate in the early stage of blowing is constant), the gun position is adjusted to 1350mm 1min after the start of blowing, and lime 40Kg / t steel, magnesium ball 10Kg / t steel, light burnt dolomite 7Kg / t steel, ore 5Kg / t steel are added at the same time , The dosage of fluorite is 3Kg / t steel. Add lime 5Kg / t steel, light-burned dolomite 4Kg / t steel, ore 2Kg / t steel at 1.5 minutes of blowing, Si and Mn oxidation period ends at 4 minutes of blowing, and the temperature at the end of the early stage of blowing is 1410 °C.

[0033] 2) Mid-term blowing control. The time limit is 4 to 13 minutes after blowing, and the operation is as follows:

[0034]...

Embodiment 2

[0038] 1) Control in the early stage of blowing (ie Si, Mn oxidation period). The time limit is 0 to 4 minutes when blowing is started, and the operation is as follows:

[0039] The oxygen lance is ignited, the opening position of the blowing lance is 1250mm, and the flow rate of the oxygen lance is controlled at 30500Nm 3 / h (the flow rate in the early stage of blowing is constant), the gun position is adjusted to 1370mm 1min after blowing is started, and lime 42Kg / t steel, magnesium ball 10Kg / t steel, light-burned dolomite 10Kg / t steel, ore 6Kg / t steel are added at the same time , Fluorite dosage 4Kg / t steel. Add lime 6Kg / t steel, light burnt dolomite 5Kg / t steel, and ore 2.2Kg / t steel at 2 minutes of blowing, Si and Mn oxidation period ends at 4 minutes of blowing, and the temperature at the end of the early stage of blowing is 1400 °C.

[0040] 2) Mid-term blowing control. The time limit is 4 to 13 minutes after blowing, and the operation is as follows:

[0041] Oxygen...

Embodiment 3

[0045] 1) Control in the early stage of blowing (ie Si, Mn oxidation period). The time limit is 0 to 4 minutes when blowing is started, and the operation is as follows:

[0046] The oxygen lance is ignited, the opening position of the blowing lance is 1270mm, and the flow rate of the oxygen lance is controlled at 31000Nm 3 / h (the flow rate in the early stage of blowing is constant), the gun position is adjusted to 1400mm 1min after the start of blowing, and at the same time, add lime 43Kg / t steel, magnesium ball 10Kg / t steel, light burnt dolomite 10Kg / t steel, ore 6Kg / t steel , Fluorite dosage 4Kg / t steel. Add lime 6Kg / t steel, light burnt dolomite 5Kg / t steel, and ore 2.5Kg / t steel when blowing starts for 1min50s, Si and Mn oxidation period ends at 4min blowing, and the temperature at the end of the early stage of blowing is 1390°C.

[0047] 2) Mid-term blowing control. The time limit is 4 to 13 minutes after blowing, and the operation is as follows:

[0048] Oxygen lanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com