Method for preparing industrial silicon by cutting crystal silicon waste through diamond wires

A diamond wire cutting and cutting waste technology, applied in the field of metallurgy, can solve the problems of unreasonable purification and recycling of waste water, hydrogen unfavorable safety production, long smelting cycle, etc., achieve good drop strength and compressive strength, shorten Melting cycle, the effect of facilitating safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

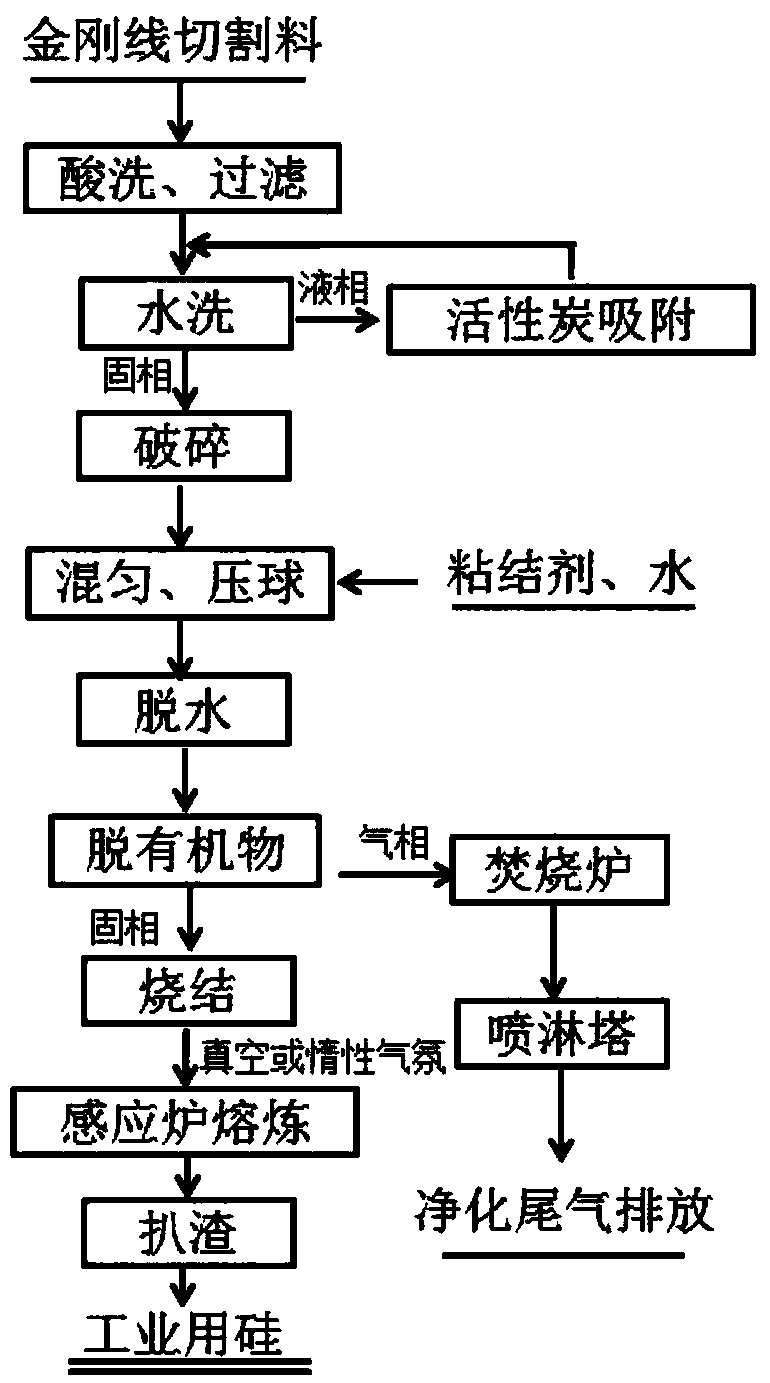

Image

Examples

Embodiment 1

[0033] A method for preparing industrial silicon by diamond wire cutting crystalline silicon waste, comprising the steps of:

[0034] (1) Pickling the crystalline silicon cutting waste to remove impurities and iron, using sulfuric acid to remove iron, time 1h, temperature 80°C, acid concentration 1.5mol / L, liquid-solid ratio 2:1, and then filtered and washed, the iron content was detected to be 0.36%.

[0035] (2) The above crystalline silicon cutting waste is crushed, and after crushing, the particle size of more than 90% of the particles is less than 100 μm. 1 kg of modified water glass consumption, 5 kg of crystalline silicon cutting waste, and 4 kg of water are mixed according to this ratio, and pressed into a ball with a diameter of 25 mm by a high-pressure roller press.

[0036] (3) Low-temperature dehydration at 70°C for 12 hours until the weight of the wet bulb no longer changes.

[0037] (4) Remove organic matter at 300°C for 1 hour. The removed organic matter enter...

Embodiment 2

[0042] A method for preparing industrial silicon by diamond wire cutting crystalline silicon waste, comprising the steps of:

[0043] (1) Pickling the crystalline silicon cutting waste to remove iron impurities, using sulfuric acid to remove iron, time 1.5h, temperature 70°C, acid concentration 1mol / L, liquid-solid ratio 3:1, and then filtered and washed, the iron content was detected to be 0.31%.

[0044] (2) The above crystalline silicon cutting waste is crushed, and after crushing, the particle size of more than 90% of the particles is less than 100 μm. Modified water glass consumption 0.8 kilograms, 5.2 kilograms of crystalline silicon cutting wastes, 4 kilograms of water, carry out mixing according to this proportioning, press into the ball of diameter 20mm with high pressure pair roller press.

[0045] (3) Low-temperature dehydration at 70°C for 12 hours until the weight of the wet bulb no longer changes.

[0046](4) Remove organic matter at 250°C for 1.5 hours. The re...

Embodiment 3

[0051] A method for preparing industrial silicon by diamond wire cutting crystalline silicon waste, comprising the steps of:

[0052] (1) Pickling the crystalline silicon cutting waste to remove iron impurities, using sulfuric acid to remove iron, time 1.5h, temperature 60°C, acid concentration 1mol / L, liquid-solid ratio 5:1, and then filtered and washed, the iron content was detected to be 0.16%.

[0053] (2) The above crystalline silicon cutting waste is crushed, and after crushing, the particle size of more than 90% of the particles is less than 100 μm. Modified water glass consumption is 0.6 kilograms, 5.6 kilograms of crystalline silicon cutting waste materials, 3.8 kilograms of water, carry out mixing according to this proportioning, press into the grain of diameter 2mm with high-pressure pair roller press.

[0054] (3) Perform low-temperature dehydration at 80°C for 10 hours until the weight of the wet bulb no longer changes.

[0055] (4) Remove organic matter at 350°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com