Composite metallurgical refining agent

A compound refining agent and metal technology, which is applied in the field of metallurgical refining agents, can solve the problems of unsatisfactory effect, small control range, and slow speed of synthetic slag formation, so as to achieve good effect of inclusion denaturation, improve internal quality, and low steelmaking cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

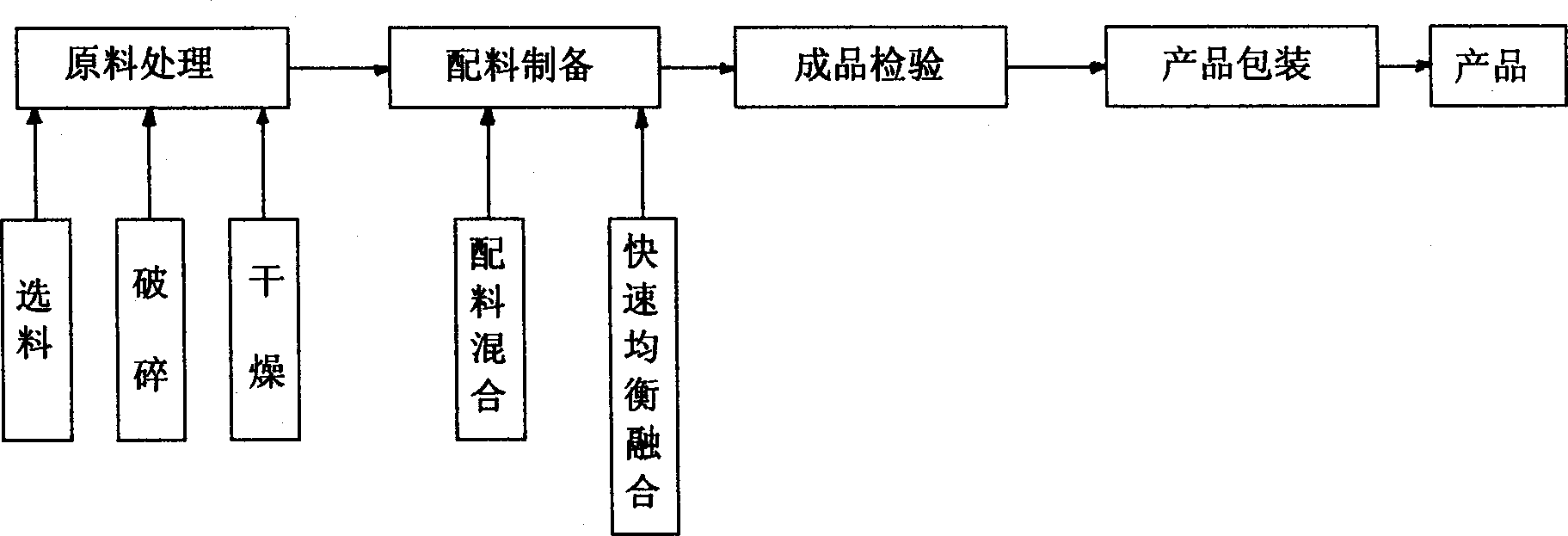

Method used

Image

Examples

Embodiment 2

[0022] Each component is a solid particle of 10-40mm in size, and its powder is less than 10%. Embodiment 2: metallurgical composite refining agent (II) component: silicon-barium alloy+silicon-barium slag 45%

[0024] Limestone 10%

[0025] Aluminum 5%

[0026] Rare earth alloys and oxides 10%

Embodiment 3

[0028] Fluorite 50% Example 3: Metallurgical composite refining agent III component: silicon-barium alloy + silicon-barium slag 20%

[0029] Calcium silicon alloy + calcium calcium slag 40%

[0031] Limestone 10%

[0032] Aluminum 5%

[0033] Rare earth alloys and oxides 10% Example 4: Metallurgical composite refining agent (IV) Component: silicon-calcium alloy+silicon-calcium slag 30%

[0034] Silicon-aluminum-barium-calcium alloy + silicon-aluminum-barium-calcium slag 30%

[0035] Calcium carbide 15%

[0036] Limestone 10%

[0037] Aluminum 5%

[0038] Rare earth alloys and oxides 10% Example 5: Metallurgical composite refining agent (V) Component: silicon-calcium alloy+silicon-calcium slag 40%

[0039] Silicon-aluminum-barium-calcium alloy + silicon-aluminum-barium-calcium slag 20%

[0040] Calcium carbide 15%

[0041] Limestone 10%

[0042] Fluorite 5%

Embodiment 6

[0043] Rare earth alloys and oxides 10% Example 6: (metallurgical composite refining) (VI) component: silicon-calcium alloy+silicon-calcium slag 50%

[0044] Calcium carbide 15%

[0045] Limestone 5%

[0046] Magnesium + magnesium slag 20%

[0047] Silicon-barium alloy and silicon-barium slag 10% Embodiment 7: metallurgical composite refining agent (VII) component: silicon-barium alloy+silicon-barium slag

[0048] Calcium silicon alloy + calcium calcium slag 30%

[0049] Calcium carbide 15%

[0050] Aluminum 5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com