Non-noxious treatment method for waste electronic lead-containing glass

A technology of harmless treatment and glass, applied in the direction of improving process efficiency, can solve problems such as lead pollution of lead-containing glass, and achieve the effects of short smelting cycle, low industrial cost and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

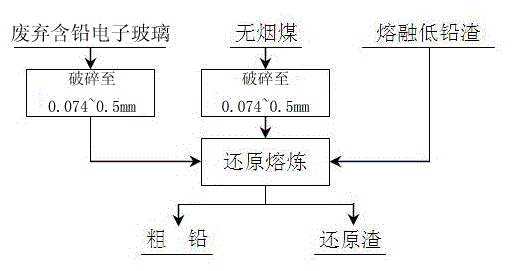

Image

Examples

Embodiment 1

[0031] Break the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, wherein the low-lead slag is 200g, the waste electronic lead-containing glass is 20g, and the amount of anthracite is 200g. 1.5 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1200°C for 1.0h to obtain crude lead and reducing slag.

[0032] After analysis, the crude lead content is 98.26%, the lead content in the reduction slag is 1.47%, and the recovery rate of lead is 92.71%.

Embodiment 2

[0034] Crush the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, wherein the low-lead slag is 200g, the waste electronic lead-containing glass is 40g, and the amount of anthracite is waste 1.2 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1250°C for 0.8h to obtain crude lead and reducing slag.

[0035] After analysis, the crude lead content is 98.55%, the lead content in the reduction slag is 1.35%, and the recovery rate of lead is 93.33%.

Embodiment 3

[0037] Break the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, wherein the low-lead slag is 200g, the waste electronic lead-containing glass is 20g, and the amount of anthracite is 200g. 1.0 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1250°C for 0.5h to obtain crude lead and reducing slag.

[0038] After analysis, the crude lead content is 98.23%, the lead content in the reduction slag is 1.25%, and the recovery rate of lead is 94.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com