High-temperature-resistant austenitic stainless steel for furnace pipe

An austenitic stainless steel, high temperature resistant technology, applied in furnaces, electric furnaces, furnace types, etc., can solve the problems of not meeting the high temperature creep resistance and oxidation resistance requirements of high temperature furnace, and shortening the smelting time. The effect of cycle and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

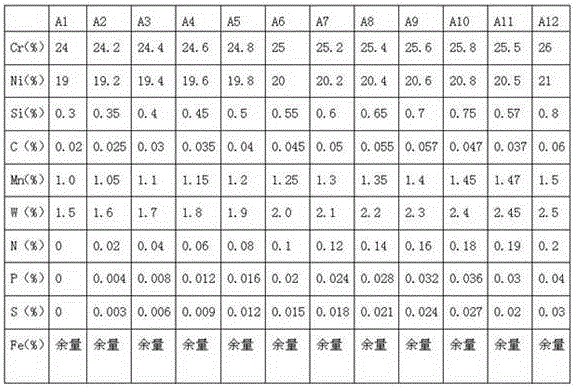

Image

Examples

Embodiment

[0044] 1. Consteel electric furnace smelting stainless steel mother liquor, the mother liquor tapping composition is composed of: C: 1.9%, Si: 0.3%, P: 0.005%, Cr: 1.25%, W: 4.1, Ni: 30%, and the balance is Fe; the tapping temperature is 1595°C.

[0045] 2. The Consteel mother liquor with qualified composition and the high-carbon ferrochrome steel liquid in the intermediate frequency furnace are successively tapped into the duckbill ladle and mixed, and then mixed into the AOD furnace for oxygen blowing decarburization and nitrogen blowing. Deoxidation and composition adjustment, the tapping temperature is 1570°C; after the composition is qualified, it is blended into the LF furnace for refining and microalloying, and the composition of the stainless steel melt is finally adjusted according to mass percentage: C: 0.025%, Cr: 24.5%, Si: 0.45%, Ni: 20.1%, Mn: 1.5%, W: 2.01, N: 0.08%, P: 0.018%, S: 0.0005%, and the balance is Fe; the molten stainless steel is continuously cast in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com