Direct reduction ironmaking method by electric furnace

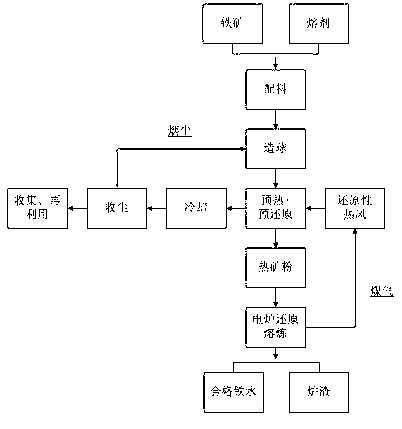

An electric furnace and direct technology, applied in the field of iron and steel metallurgy, can solve the problems of low efficiency, high raw material requirements and high energy consumption, and achieve the effects of shortening the process flow, improving economic benefits and short smelting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The method of electric furnace direct reduction ironmaking in this embodiment is as follows: select an iron ore in Lancang, Yunnan Province as raw material, the chemical composition is shown in Table 1, first crush and batch the iron ore, and pelletize the particle size to 10-20mm iron ore is loaded into the secondary cyclone preheater. Connect the outlet of the secondary cyclone preheater to the inlet of the electric furnace, place coal powder with a carbon content of 70wt% in the electric furnace and heat it. The heating temperature is 1400°C. heater. Pellets obtained by pelletizing pellets. The pellets pass through the first-stage reactor and the second-stage reactor in turn. The temperature of the first-stage reactor is 400°C, and the temperature of the second-stage reactor is 800°C. The residence time of the pellets in each stage of the reactor is 20-30 minutes. The content of CO in the coal gas produced by electric furnace heating coal is 20mol%. ...

Embodiment 2

[0027] Embodiment 2: The method of electric furnace direct reduction ironmaking in this embodiment is: select an iron ore in Lufeng, Yunnan as raw material, the chemical composition is as shown in Table 2, connect the outlet of the five-stage cyclone preheater with the inlet of the electric furnace, and Put coal powder with a carbon content of 80wt% in the electric furnace and heat it. The heating temperature is 1500°C, and the gas with a CO content of 30mol% rises and passes into the multi-stage reactor, and then the iron ore is pelletized to produce Pellets with a particle size of 20-30 mm after the pellets are put into the first-stage reactor of the multi-stage reactor, and are sequentially passed through the multi-stage reactor and gas for suspension fluidization preheating and synchronous pre-reduction, and then the pellets from the multi-stage reactor are The iron ore pellets obtained in the first-stage reactor are sent into the electric furnace, and the gas continues to ...

Embodiment 3

[0029] Embodiment 3: The method of electric furnace direct reduction ironmaking in this embodiment is as follows: select iron ore with iron content of 30wt%, P<1wt%, S<0.1wt% for crushing and batching, and the particle size after pelleting is 10-100wt%. 40mm iron ore is loaded into the fluidized bed. Connect the outlet of the fluidized bed to the inlet of the electric furnace, place pulverized coal with a carbon content of 75wt% in the electric furnace and heat it at a temperature of 1600°C to produce gas with a CO content of 50mol% and pass it into the furnace. first-stage reactor, and then put the iron ore pellets with a particle size of 10-40 mm into the first-stage reactor of the multi-stage reactor, and carry out suspension flow through the multi-stage reactor and gas in turn. State-based preheating and synchronous pre-reduction, and then the iron ore pellets obtained from the multi-stage reactor are sent to the electric furnace, the gas continues to preheat and reduce t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com