Sheet for a thermal conductive substrate, a method for manufacturing the same, a thermal conductive substrate using the sheet and a method for manufacturing the same

a thermal conductive substrate and thermal radiation technology, applied in the field of circuit substrates, can solve the problems of low break down voltage, large noise, and difficult for metal base substrates and ceramic substrates to meet both performance and cost requirements, and achieve excellent thermal radiation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

In the formation of the thermally conductive sheet of the present invention; inorganic filler, thermosetting resin and solvent were mixed and alumina balls were further added into the above mixture so as to obtain a sufficient dispersion. The compositions of the thermally conductive sheet of this Example are shown in Table 1.

TABLE 1Thermosetting resinSolvent having aSheet(includingboiling point ofOther after driedExperimentInorganic Fillerhardener)not more than 150° C.additivesViscosityNo.NameVol. (wt %)NameVol. (wt %)NameVol. (wt %)*1*2*3(Pa · s)1aAl2O360Epoxy36Butyl4———1.5 × 102resincalbitol1bAl2O370Epoxy28acetate2———3.3 × 103resin(BCA)1cAl2O380Epoxy182———2.6 × 104resin1dAl2O390Epoxy9.50.5———8.1 × 104resin1eAl2O395Epoxy4.90.1———1.3 × 105Resin*1: coloring agent *2: coupling agent *3: dispersing agent

Table 1 shows an evaluation of the performance of the thermally conductive sheet when the content of Al2O3 as an inorganic filler is changed. As Al2O3, “AL-33” having a particle diamet...

example 2

In this Example, a thermally conductive substrate in which the thermally conductive sheet was manufactured by the same method as in Example 1 and integrated with a lead frame will be explained. The compositions of the thermally conductive sheet used in this Example will be described hereinafter.(1) Inorganic filler: 90 weight % of Al2O3, “AS-40®” (the product of SHOWA DENKO K.K.) having a spherical shape and an average particle size of 12 μm.(2) Thermosetting resin: 9 weight % of cyanate ester resin, “AroCy M30®” (the product of Asahi-Ciba CO., Ltd.)(3) Solvent having a boiling point of not less than 150° C.: 0.5 weight % of butyl carbitol. (the first grade of chemical reagent of Kanto Chemical CO, Inc.).(4) Other additives: 0.3 weight % of “Carbon Black” (the product of Toyo-carbon CO., Ltd.), and 0.2 wt. % of dispersing agent, “PLYSURF F-208F®” (the product of DAI-ICHI SEIYAKU KOGYO CO., LTD.).

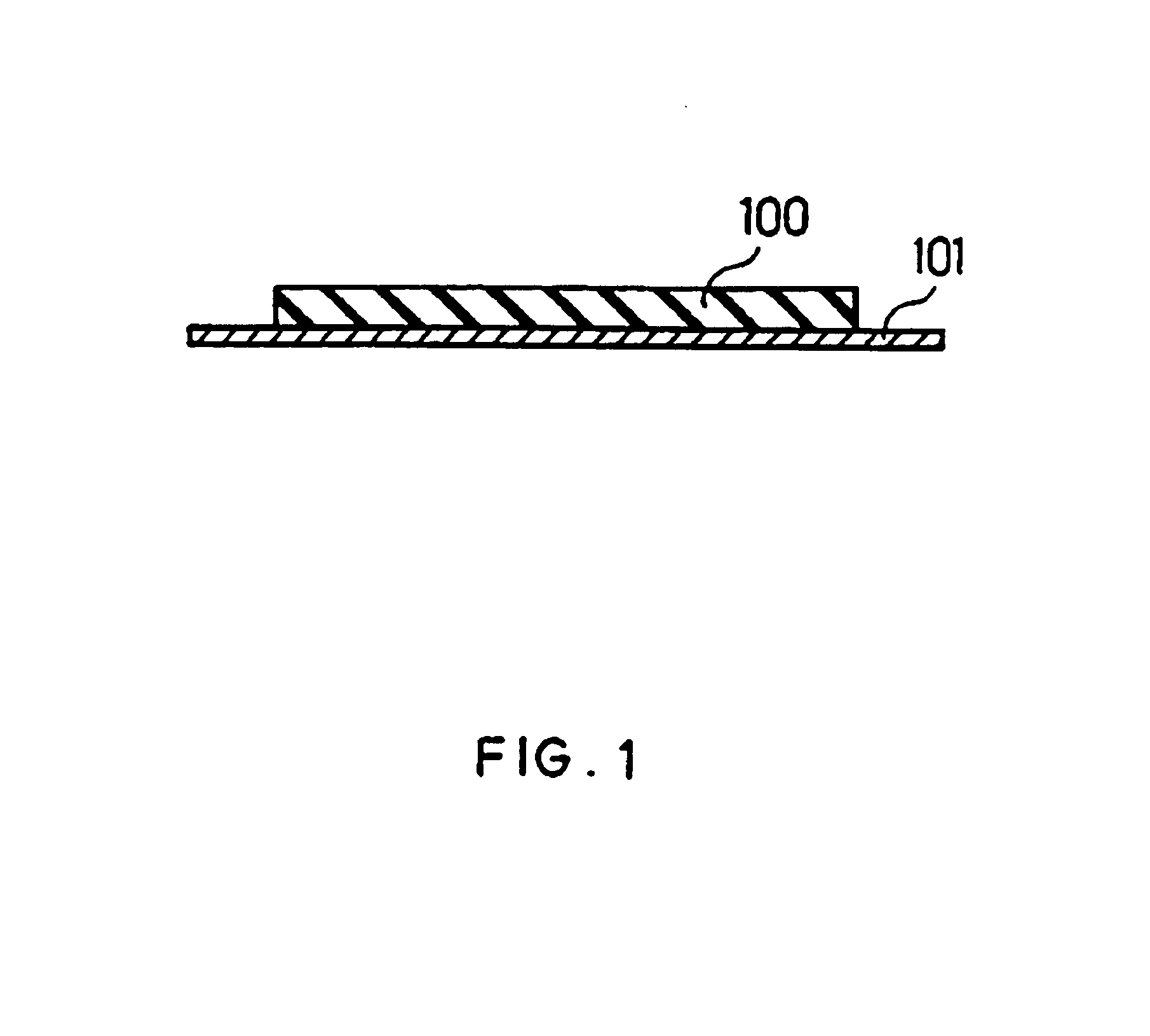

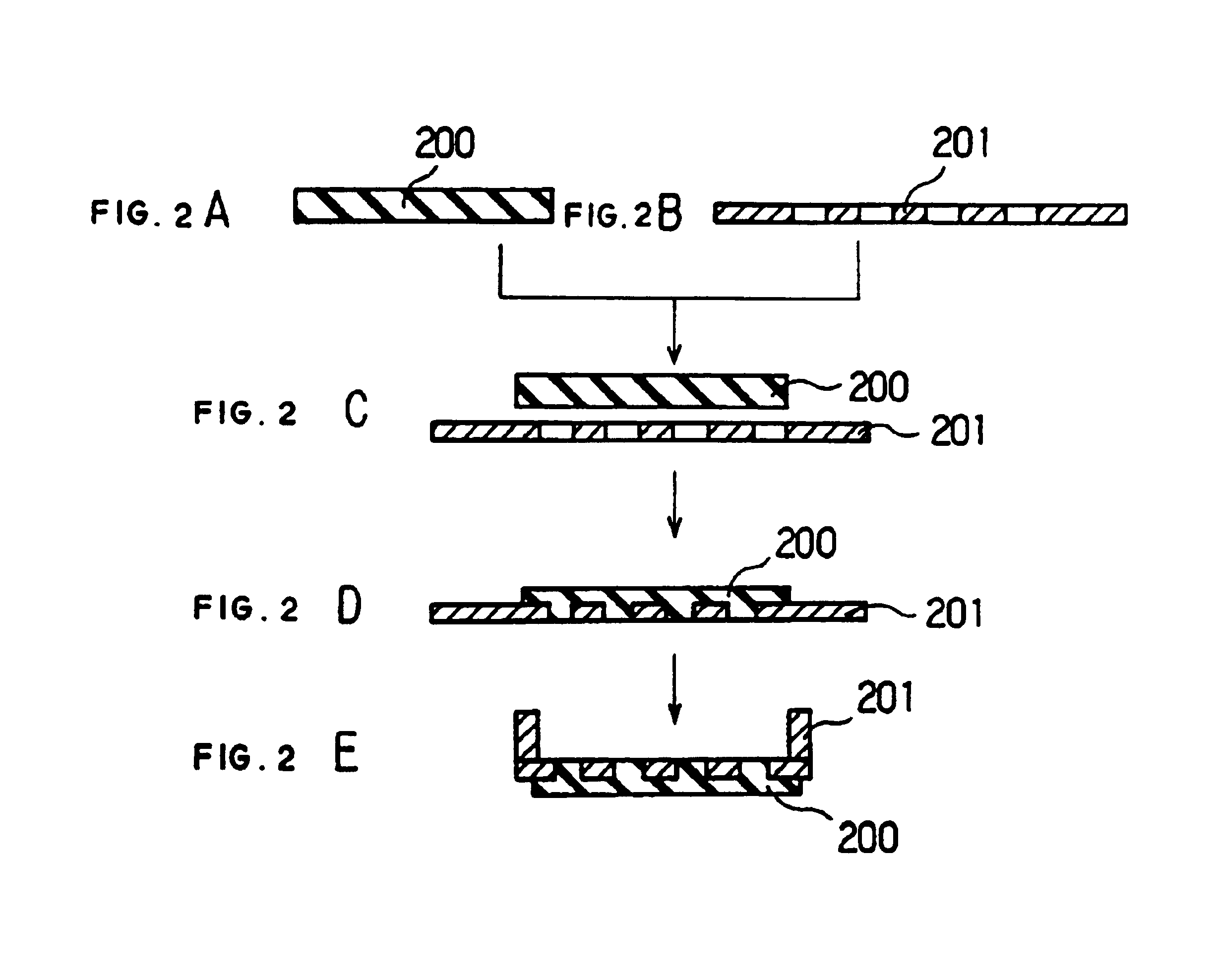

A thermally conductive sheet (a thickness was 770 μm) comprising the above mentioned com...

example 3

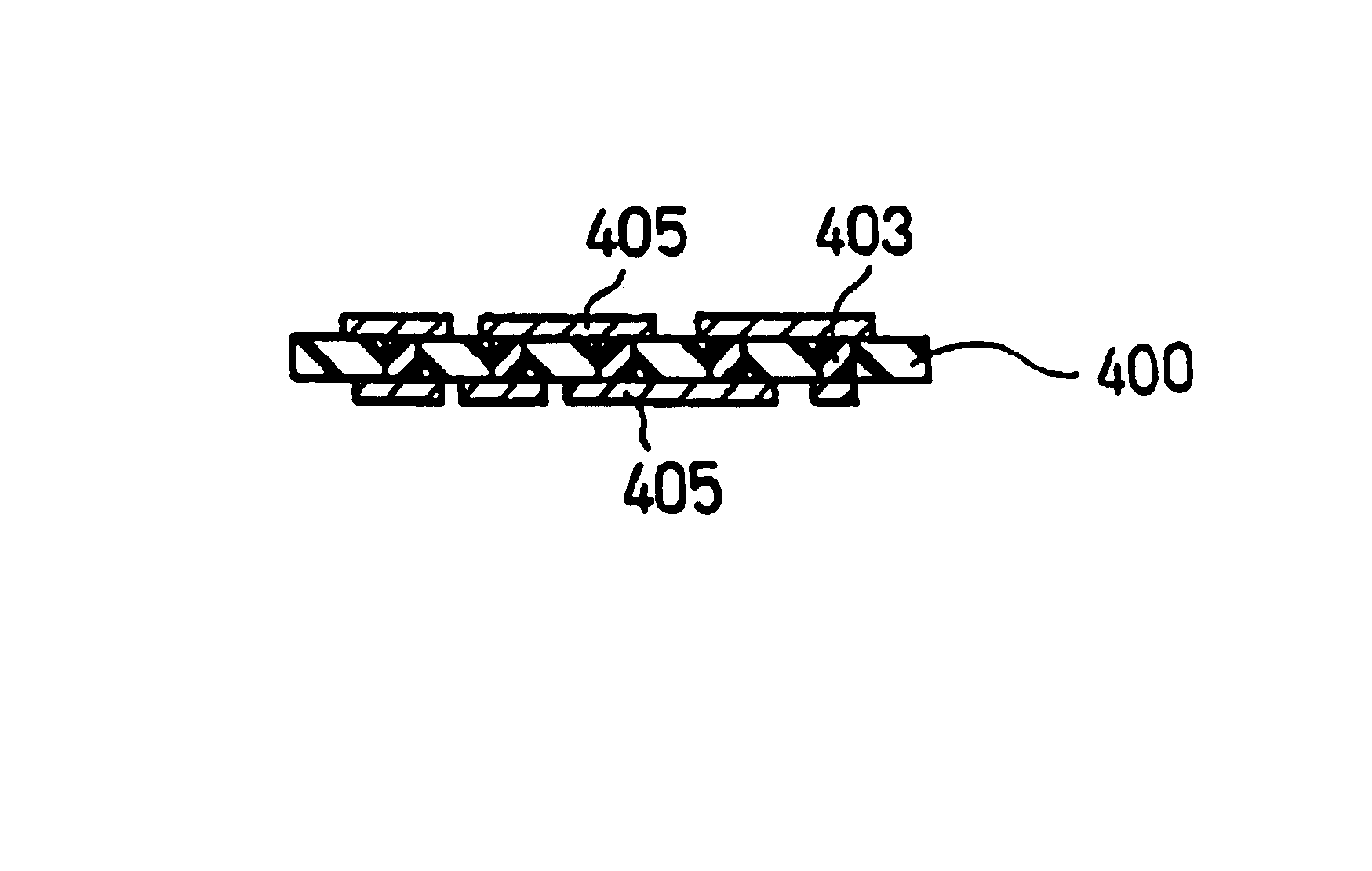

In this Example, a thermally conductive substrate will be explained, where the thermally conductive sheet was manufactured by the same method as in Example 1 and both sides of the sheet had metallic foil wiring layers and conductive resin composition was filled between the layers to electrically connect the layers. The compositions of the thermally conductive sheet used in this Example will be described hereinafter.(1) Inorganic filler: 90 weight % of Al2O3, “AS-40®” (the product of SHOWA DENKO K.K.) having a spherical shape and an average particle size of 12 μm.(2) Thermosetting resin: 9 weight % of “NRV-1010®” (the product of Japan REC CO., Ltd.), a mixture comprising 60 weight parts of brominated multifunctional epoxy resin as a main agent, 39.5 weight parts of bisphenol A nobolak resin as a hardener, and 0.5 weight parts of imidazol as a hardening accelerator.(3) Solvent having a boiling point of not less than 150° C.: 0.5 weight % of butyl carbitol (the first grade chemical rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com