Heat dissipating and cooling system as well as heat dissipating and cooling method aimed at high-temperature heat source equipment

A high-temperature heat source, heat insulation and cooling technology, applied in heat exchange equipment, lighting and heating equipment, heating methods, etc., can solve the problems of unable to meet the thermal comfort needs of workers, unable to ensure uniform distribution of temperature field, and harsh thermal environment. Achieve significant economic value and social value, meet thermal comfort requirements, and improve the effect of thermal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

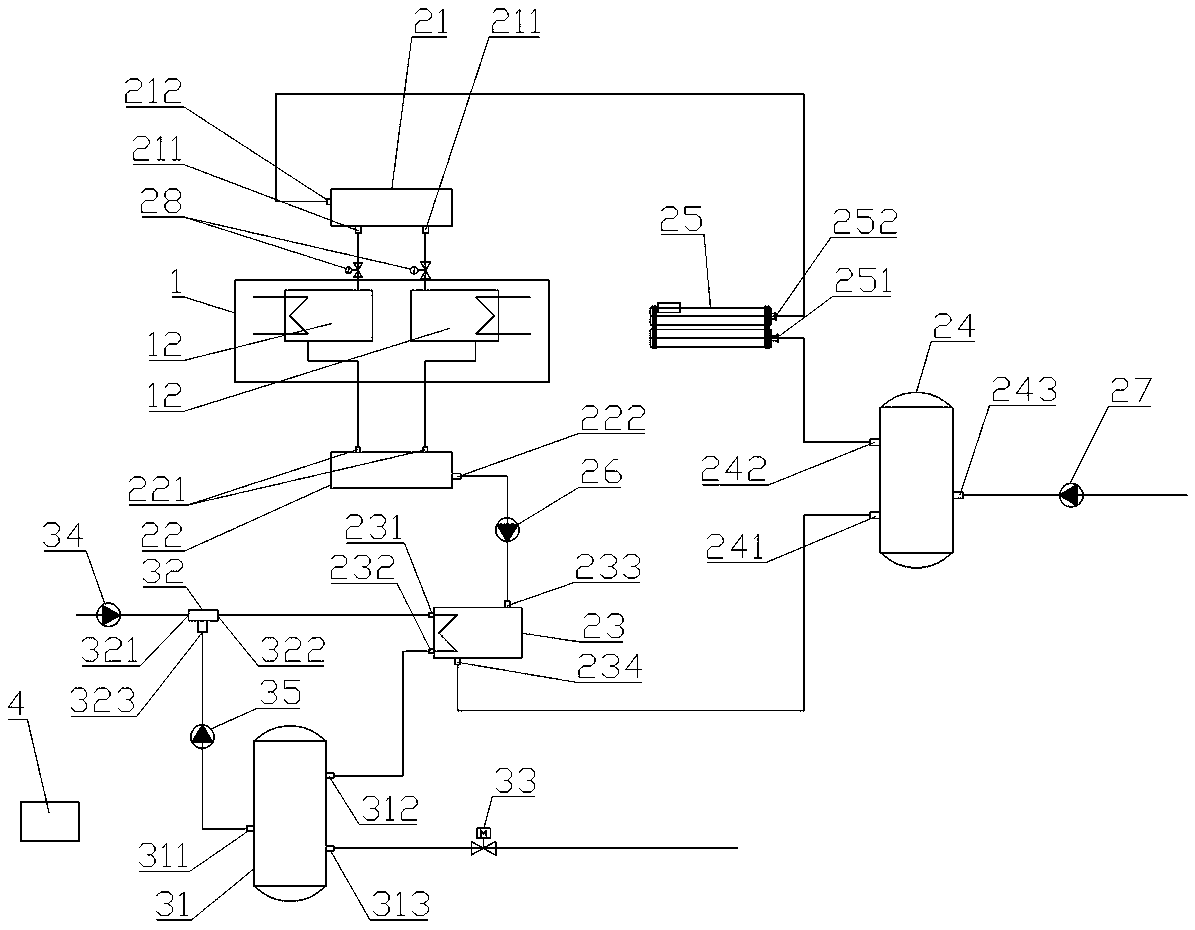

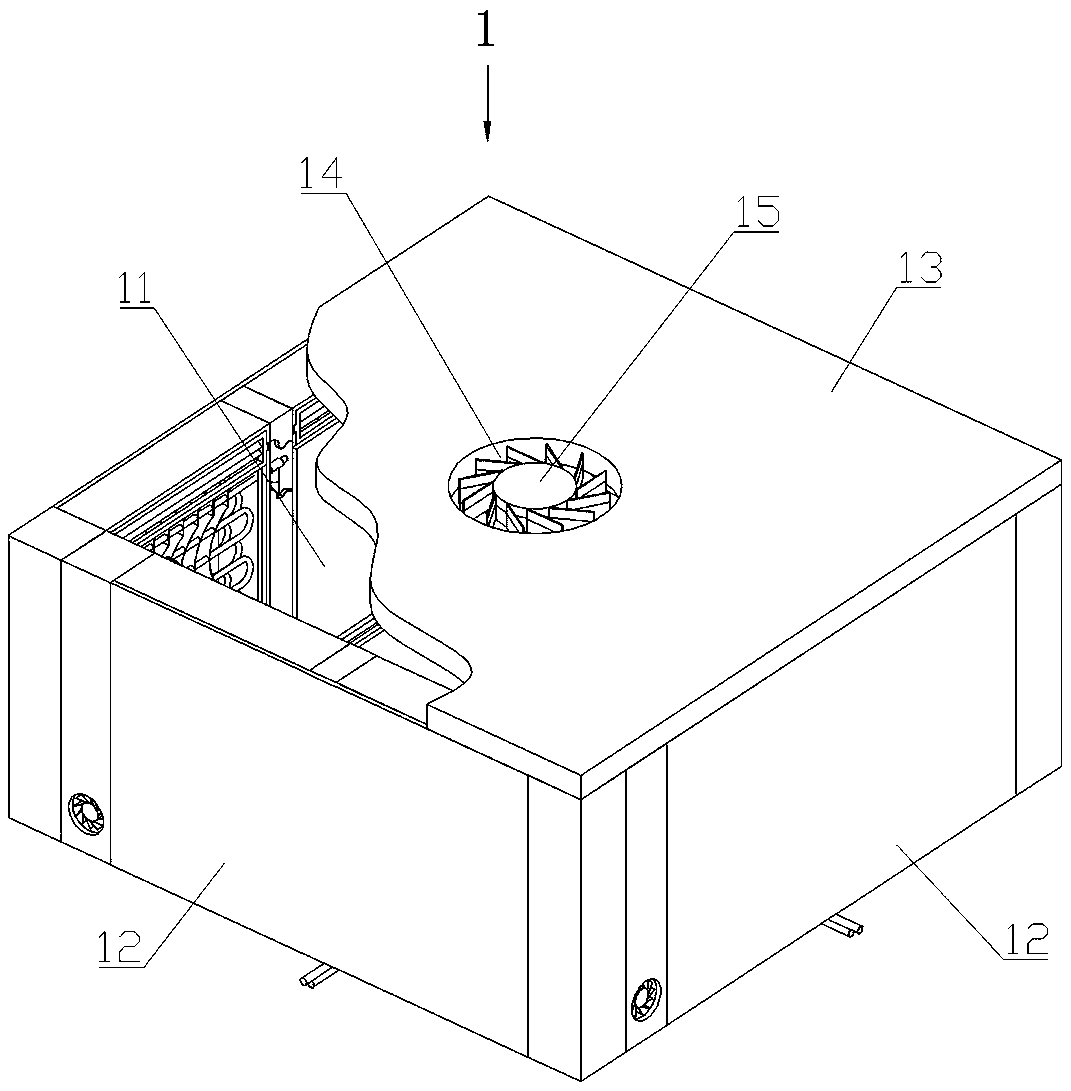

[0054] Such as Figure 1-7 As shown, the heat dissipation and cooling system for high-temperature heat source equipment includes a heat insulation and cooling cover 1, a water cooling circulation device and a waste heat utilization device.

[0055] The heat insulation and cooling cover 1 is in the shape of a hollow prism, and there is an equipment placement cavity 11 inside, which is constructed by a side wall composed of a heat insulation cooling wall 12 and a top wall composed of a heat insulation board 13 . The top wall is provided with an air outlet 14 connecting the inside and outside of the heat insulation and cooling cover 1 , and an exhaust fan 15 is installed on the air outlet 14 .

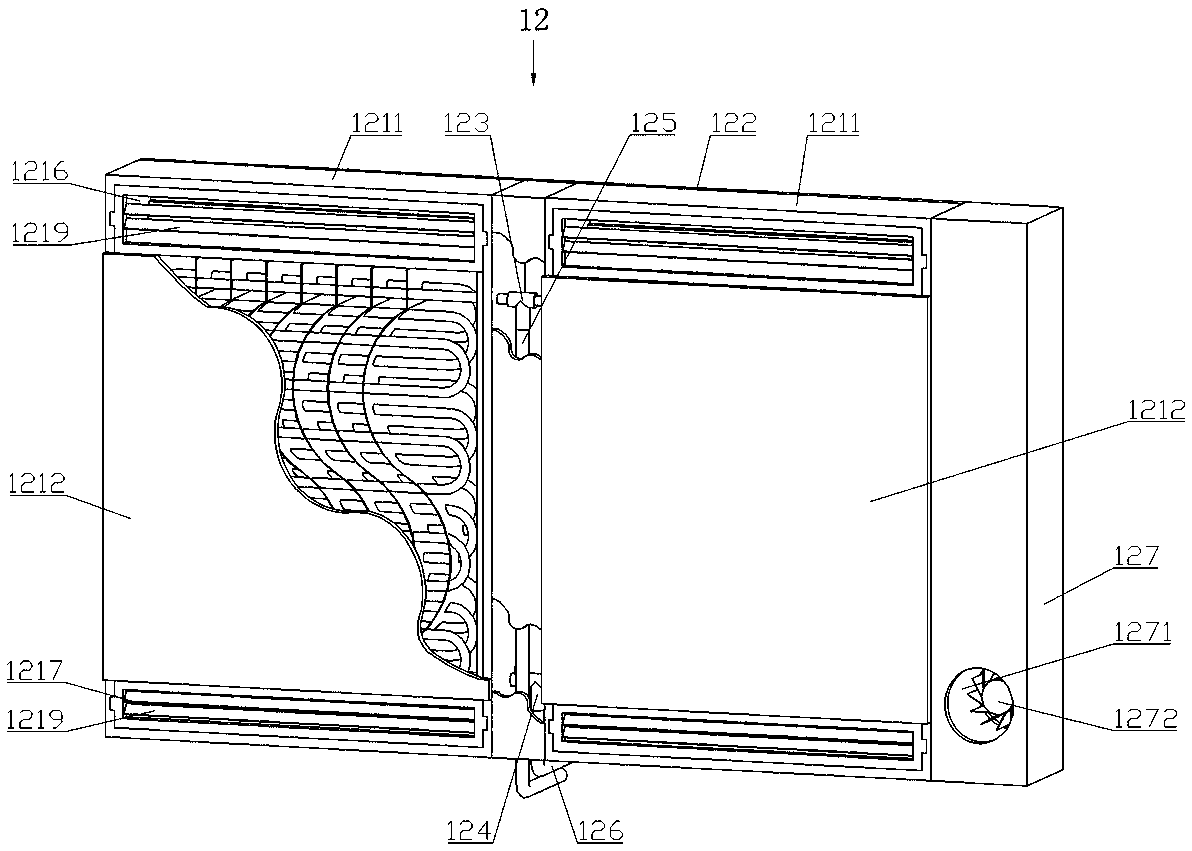

[0056] The heat insulating and cooling wall 12 includes a wall unit 121 , a backboard 122 , a tee joint A123 , a tee joint B124 , an input pipe 126 , an output pipe 125 and an air inlet chamber 127 .

[0057] The wall unit 121 includes a heat insulating shell 1211 , a radiation metal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com