Patents

Literature

49results about How to "Less peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum oxide-coated article

InactiveUS6333103B1Improve featuresReduced durabilityPigmenting treatmentRecord information storageX-rayCarbide

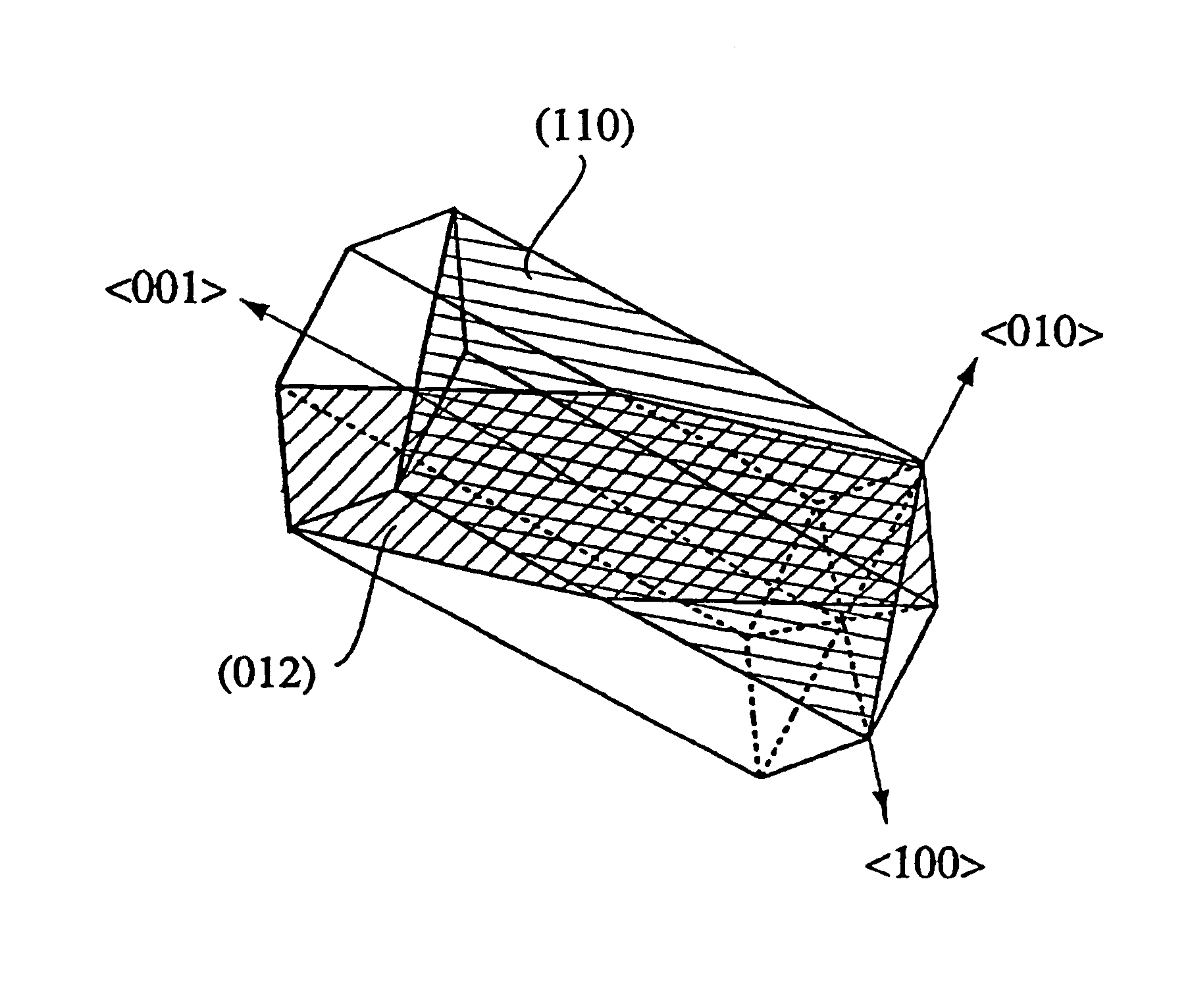

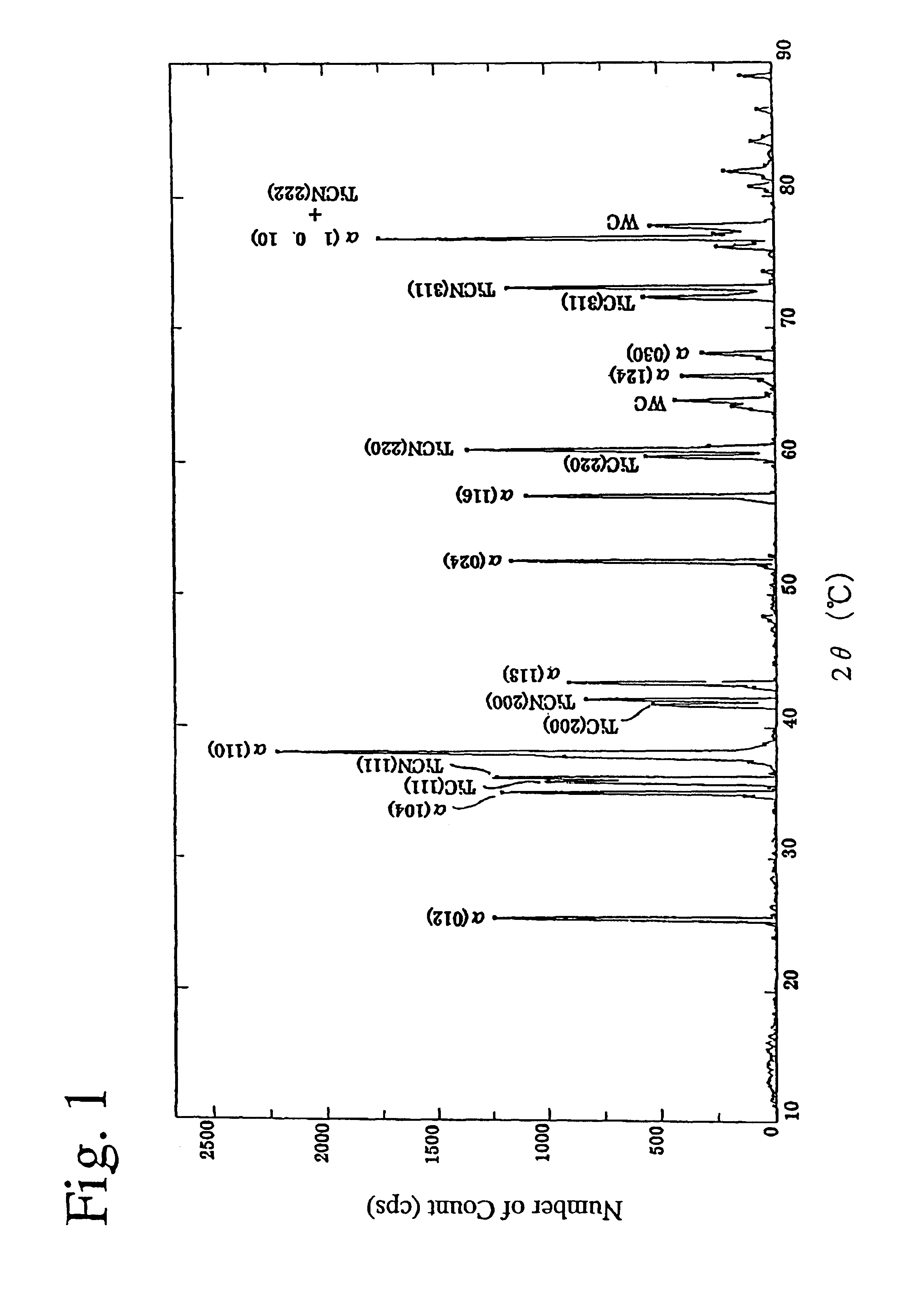

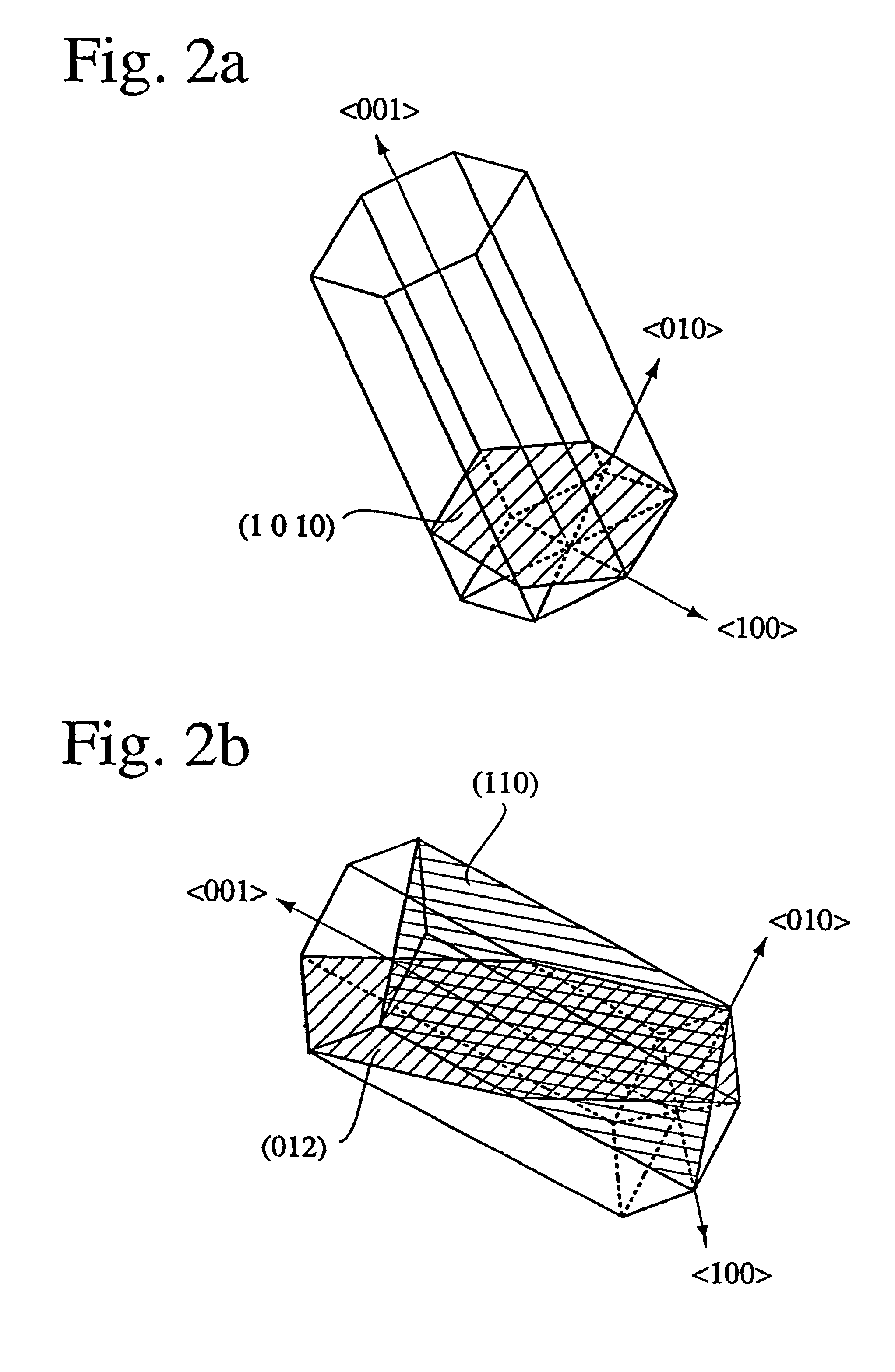

An aluminum oxde-coated article has a first coating layer and a second coating layer formed in this order on a substrate, the first coating layer having a single- or multi-layer structure and being made of at least one selected from the group consisting of carbides, nitrides, carbonitrides, oxides, oxycarbides, oxynitrides and oxycarbonitrides of metals in Groups IVa, Va and VIa of the Periodic Table, and the second coating layer being constituted by at least one alpha-aluminum oxide-based oxide layer, which has an equivalent X-ray diffraction peak ratio PR (1 0 10) of 1.3 or more in a (1 0 10) plane.

Owner:HITACHI TOOL ENG LTD

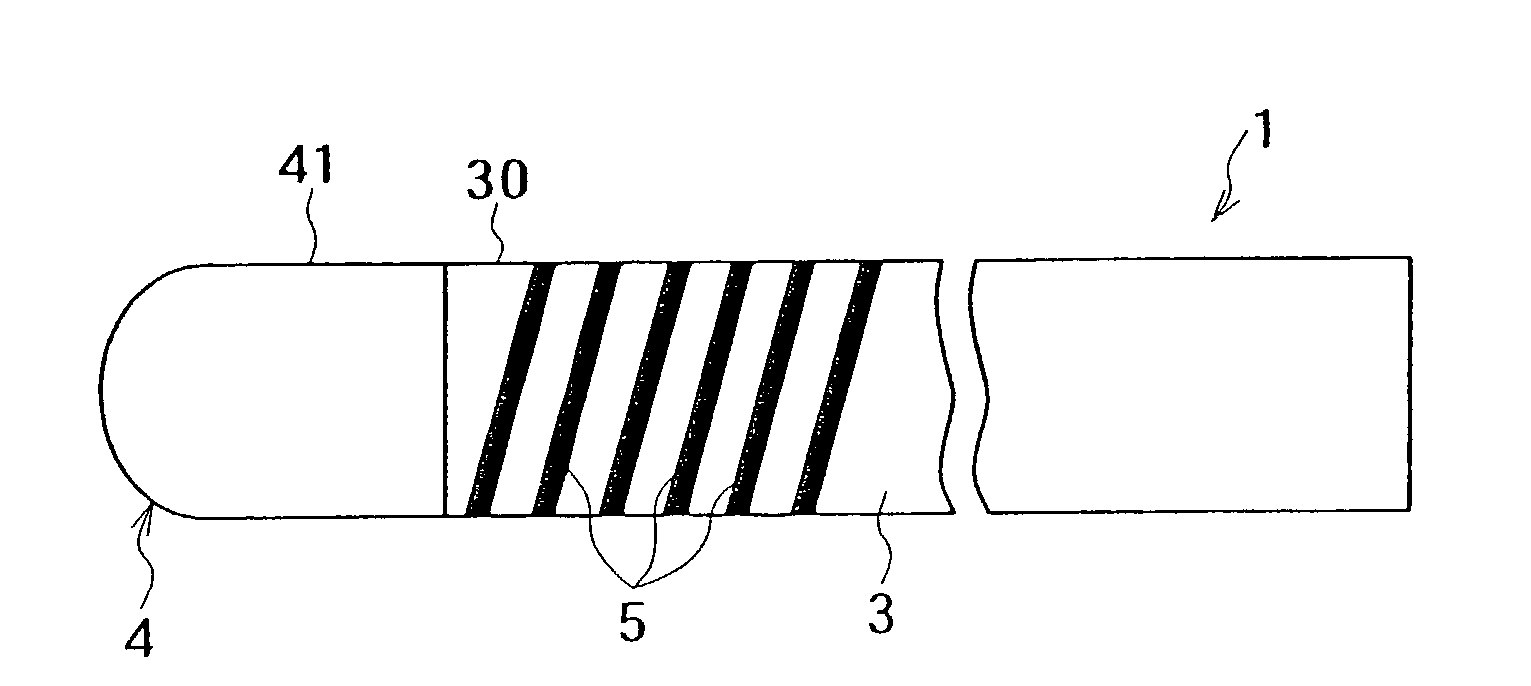

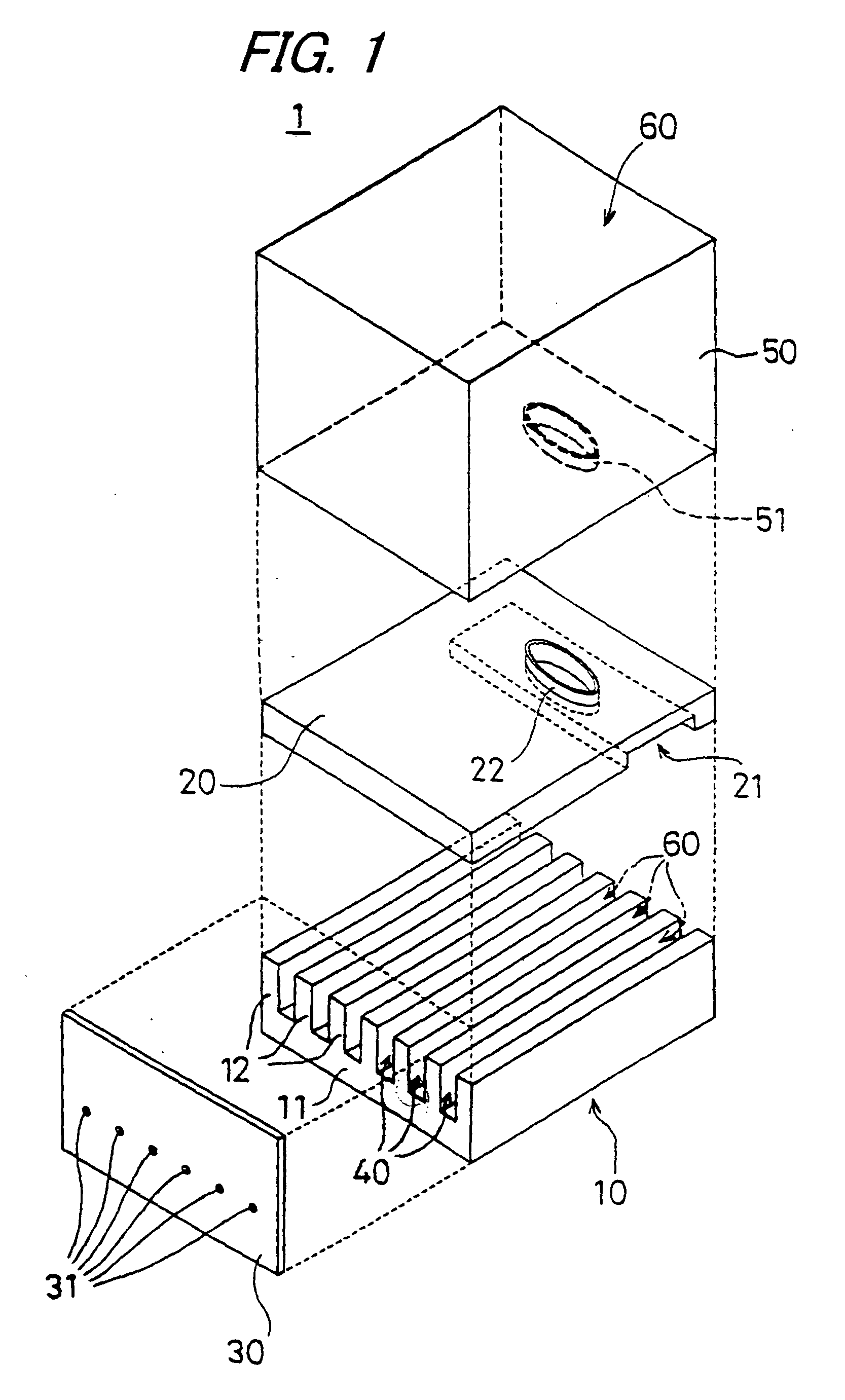

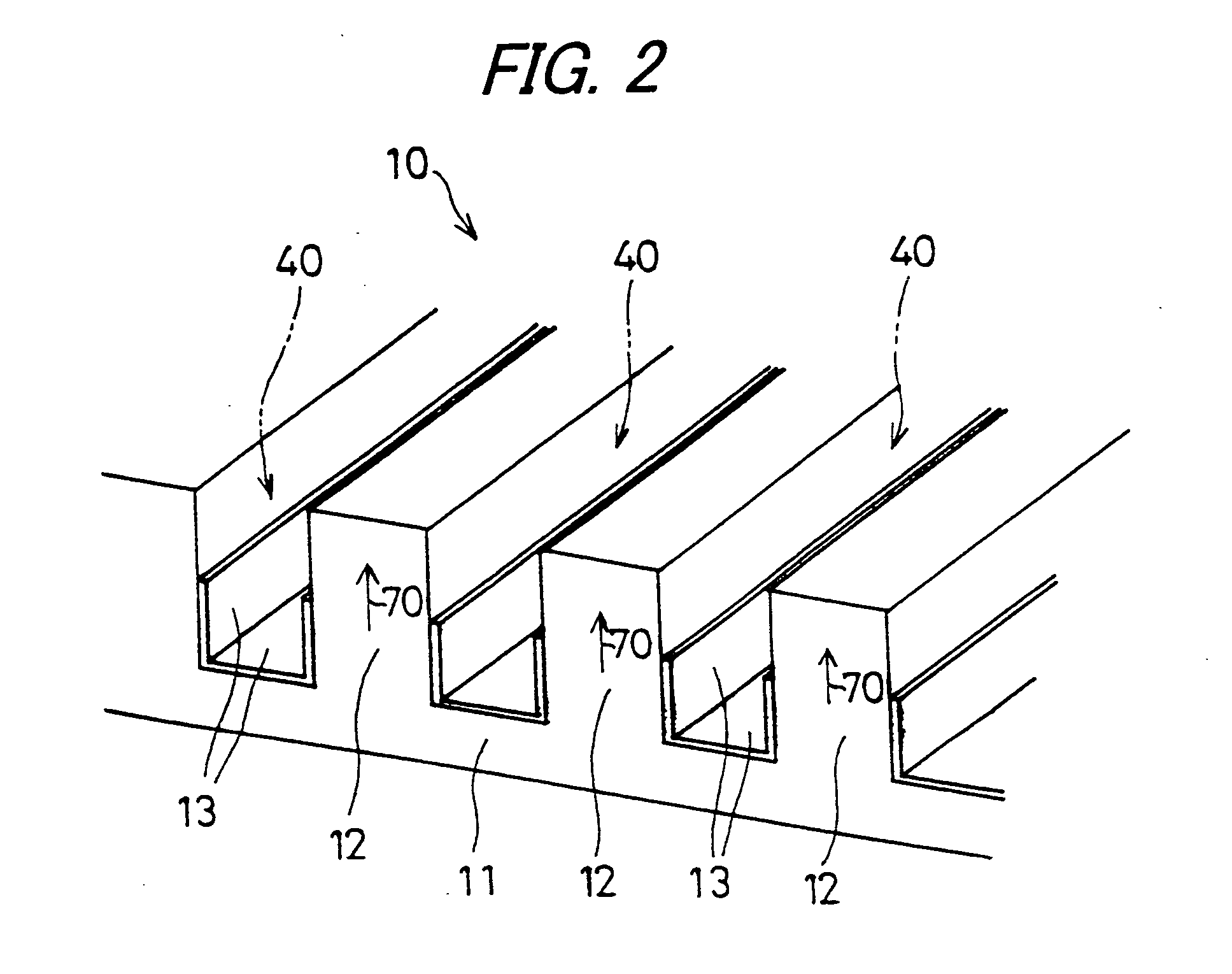

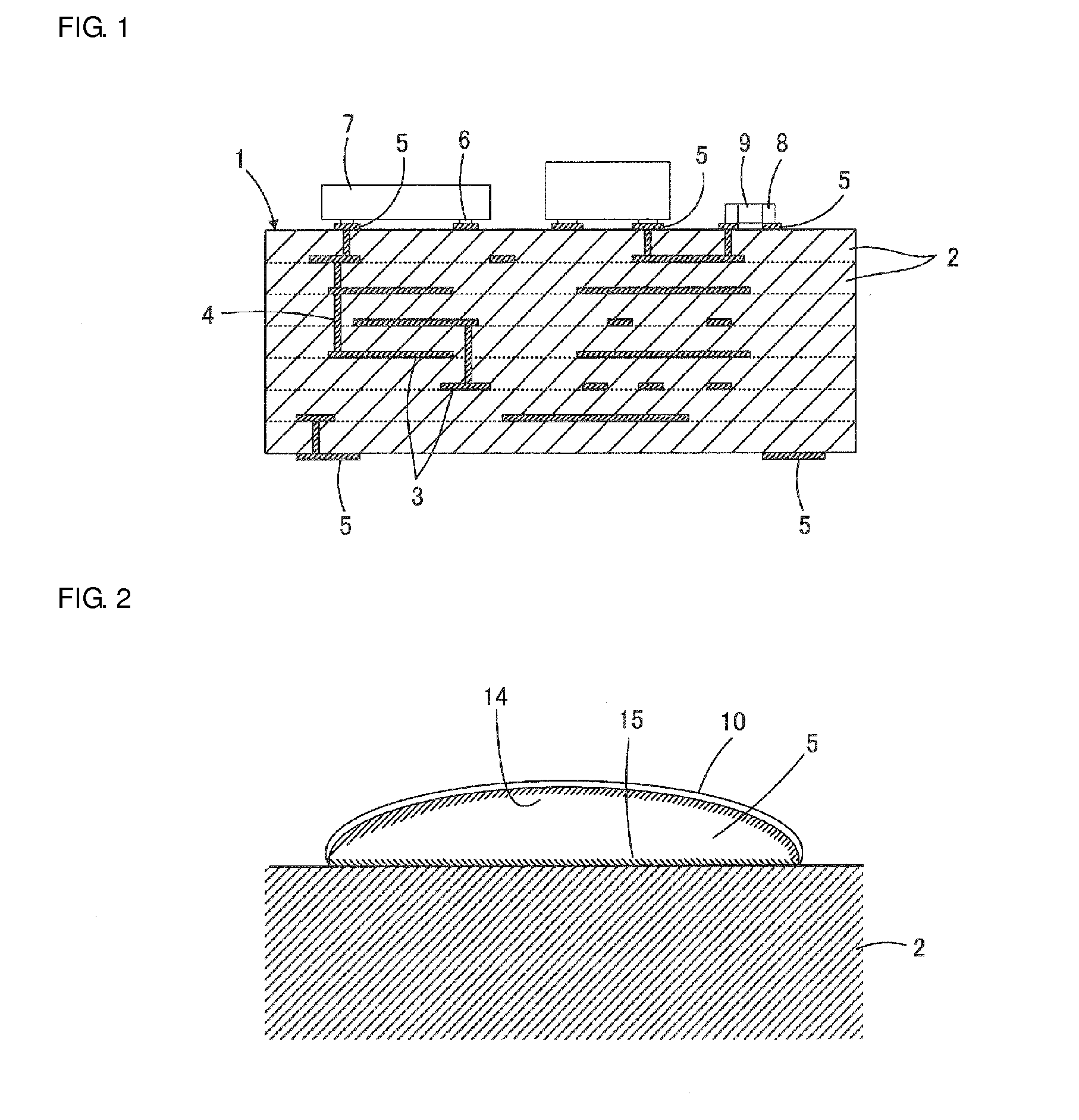

Thermal conductive substrate and semiconductor module using the same

InactiveUS6958535B2Good thermal radiation performanceReduce crackingSemiconductor/solid-state device detailsSolid-state devicesThermal radiationSemiconductor

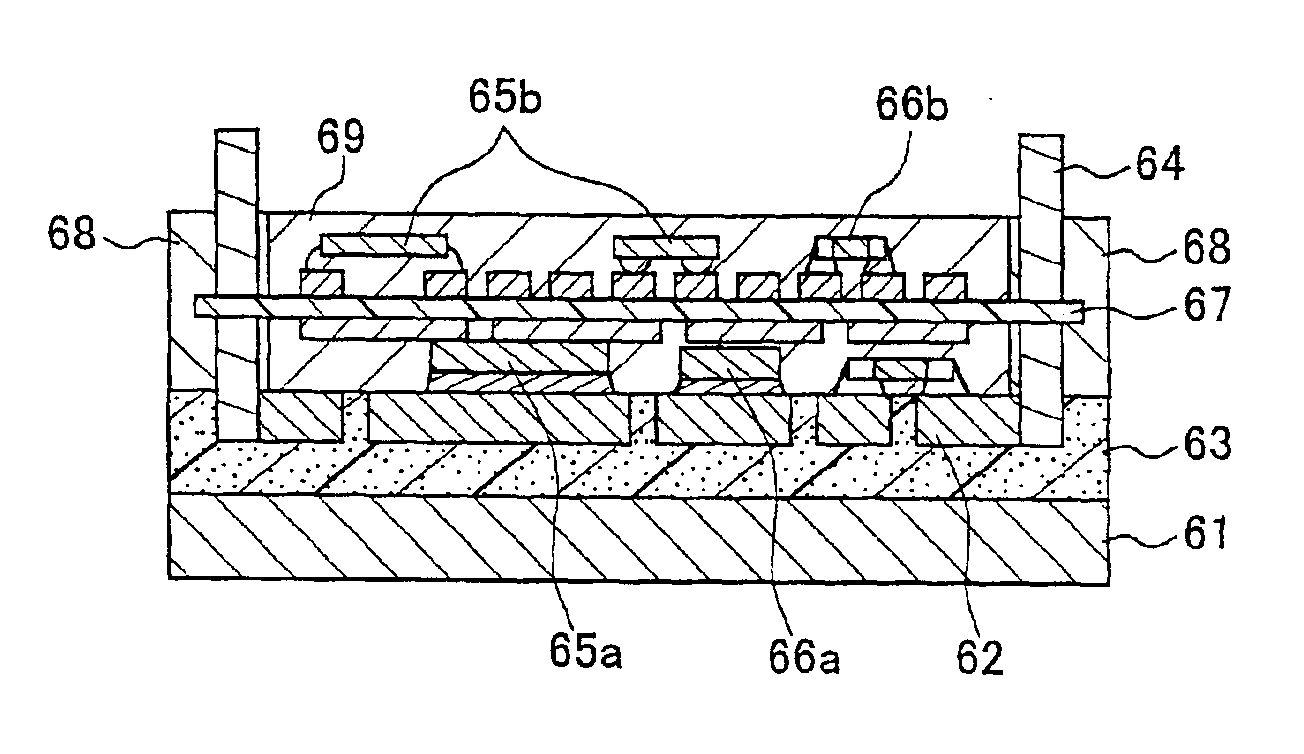

A semiconductor module includes a circuit substrate composed of a wiring pattern, an electrical insulating layer and a thermal radiation board, and in use is fixed to an external thermal radiation member, in which the electrical insulating layer is composed of a thermal conductive mixture containing 70-95 wt % of an inorganic filler and 5-30 wt % of a thermosetting resin. A warping degree of the circuit substrate with respect to the external thermal radiation member is at most 1 / 500 of a length of the substrate, and the circuit substrate warps to protrude toward the thermal radiation board as the temperature rises. Accordingly, the thermal radiation property does not deteriorate even when the temperature rises in use. At a time of fixing the circuit substrate to the external thermal radiation member, the thermal resistance is kept to be a sufficiently low level. The thermal resistance is kept in a low level without sacrificing the contact between a module and the external thermal radiation member even at a high temperature during an operation of the device or the like, and the thermal conductive substrate is resistant to fractures or cracks and thus is highly reliable.

Owner:PANASONIC CORP

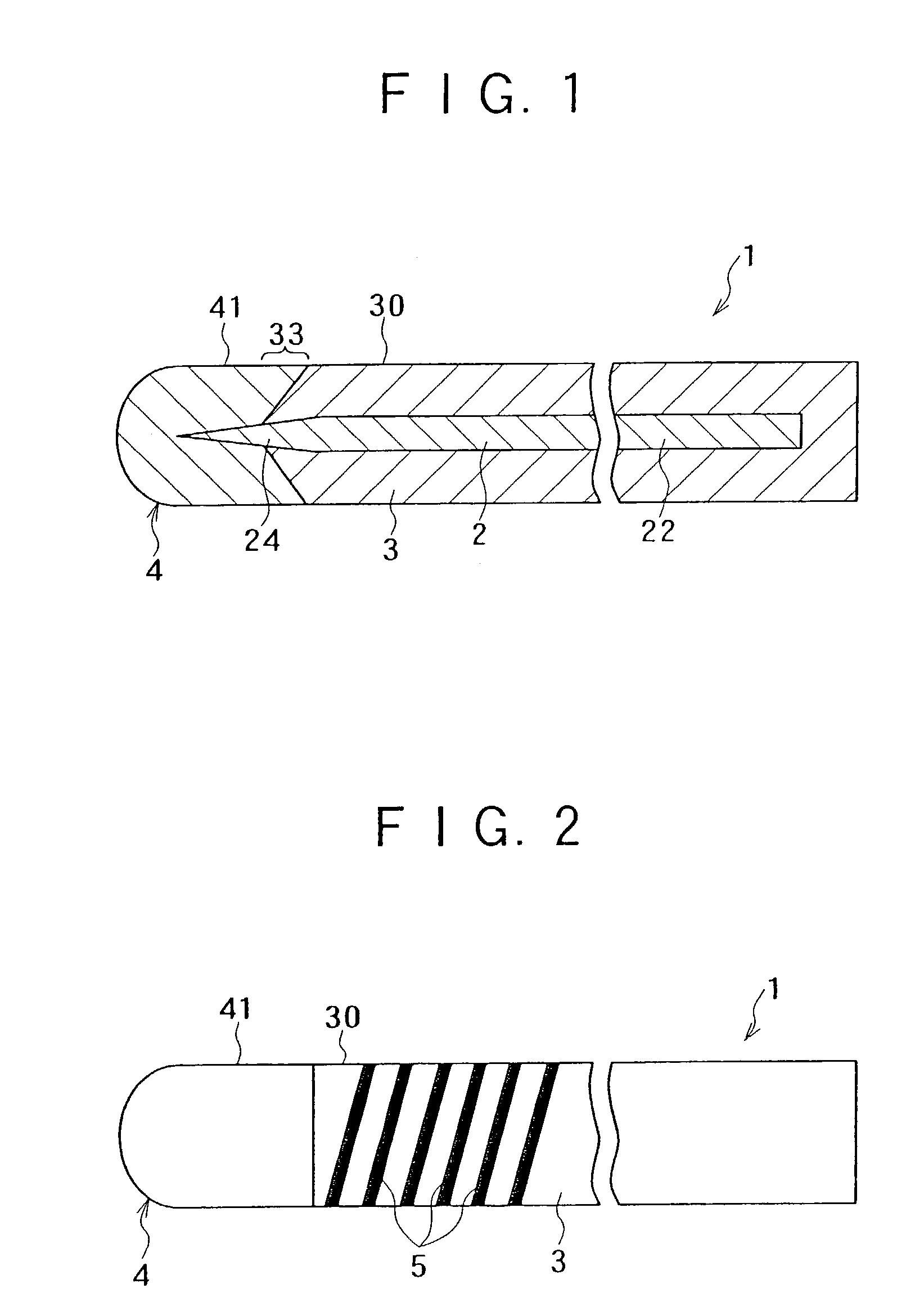

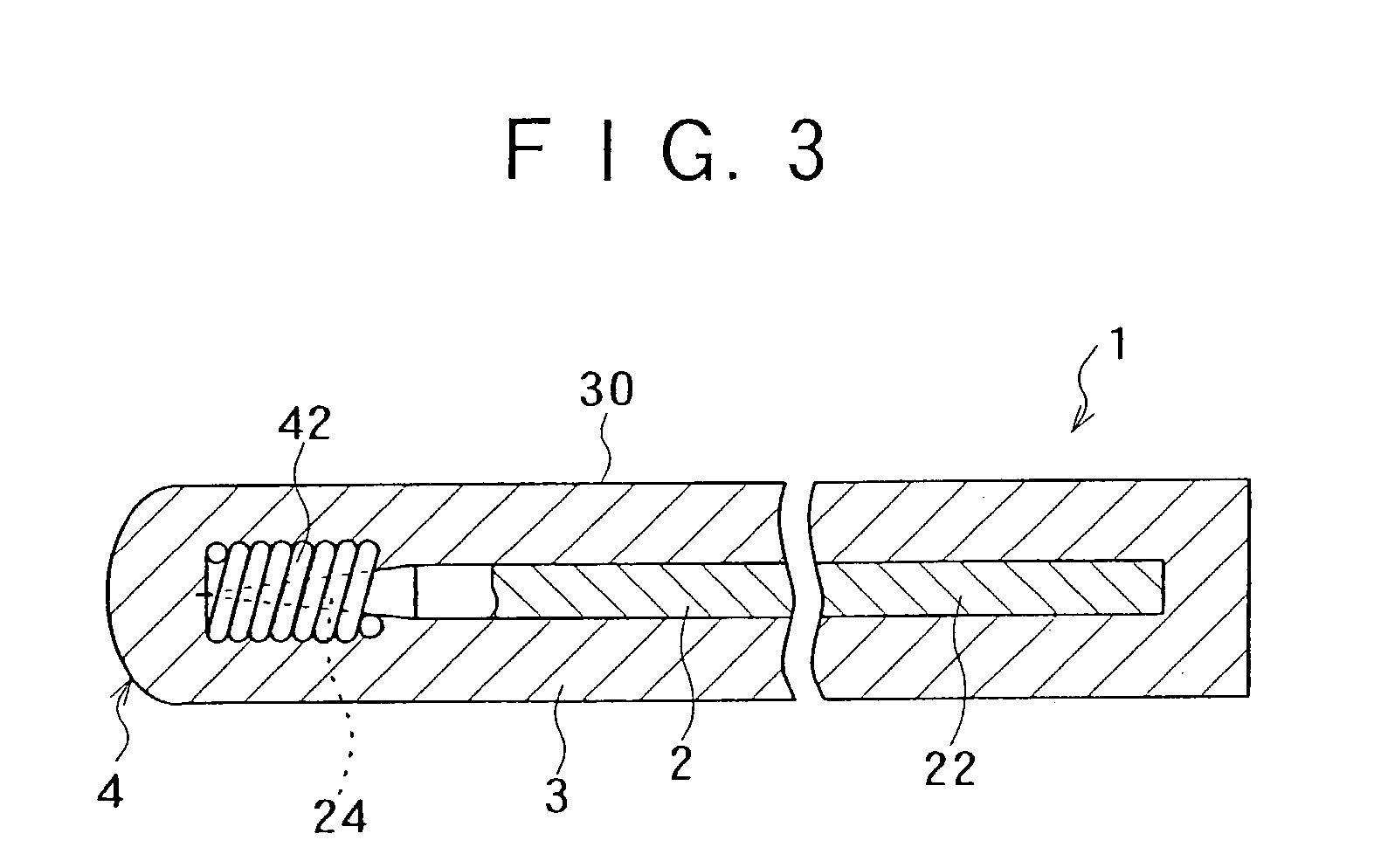

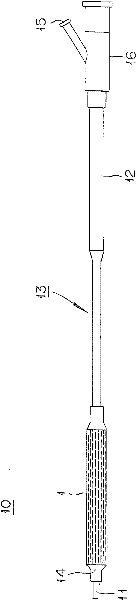

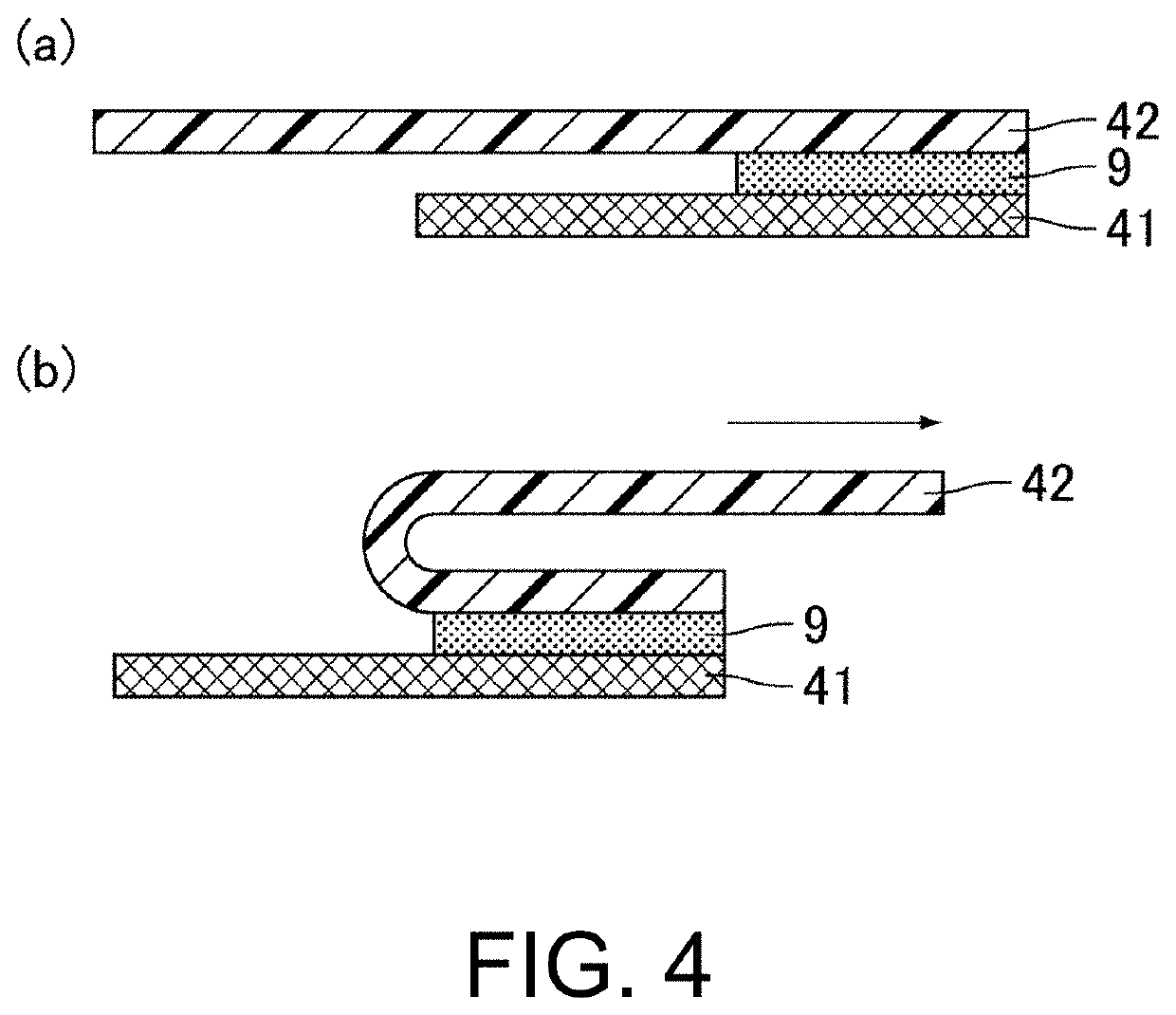

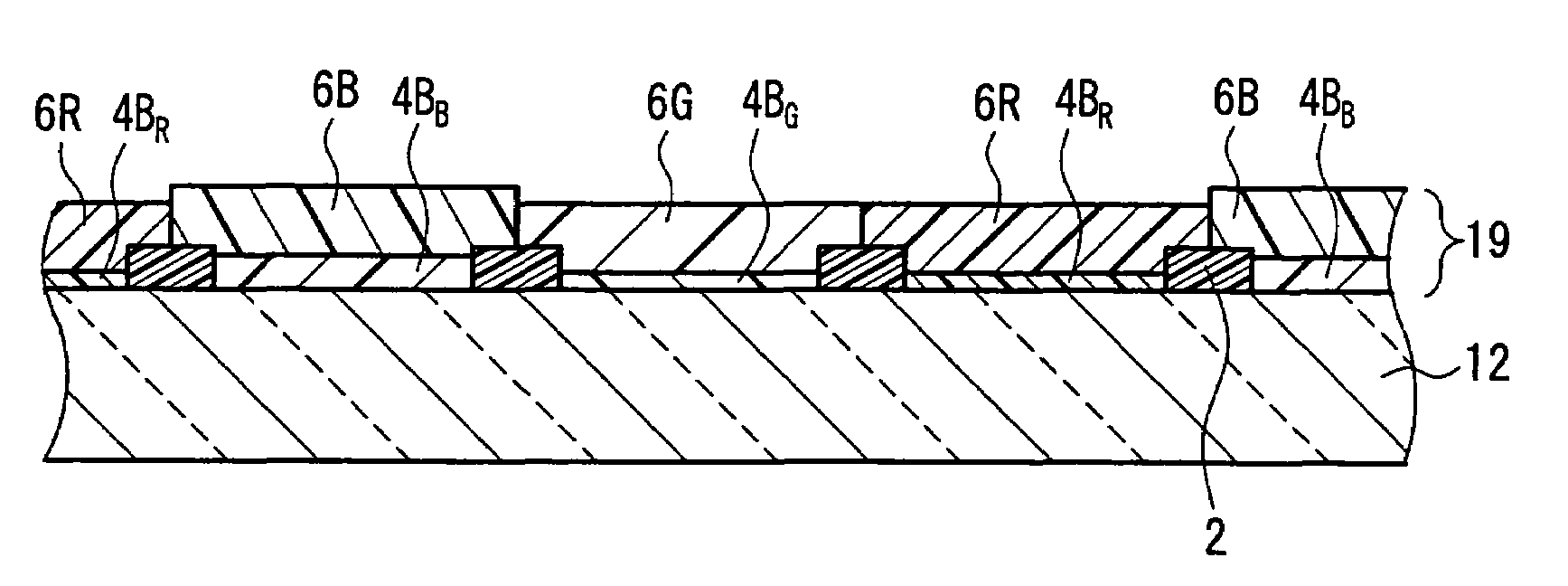

Guide wire

ActiveUS7278973B2Increase awarenessImprove visibilityGuide wiresDiagnostic recording/measuringEngineeringLaser light

A guide wire is configured to have a less lossy marker formed at a desired position and providing a relatively high degree of contrastability under X-ray fluoroscopic guidance or the like. The guide wire includes a linear core member, a resin layer covering a main body portion of the core member, and a contrasting portion covering the distal end portion of the core member. The resin layer contains a color developing agent which develops color by laser light irradiation, and a contrast agent composed of a metal oxide powder. The contrasting portion is made from a resin containing a contrast agent composed of a metal powder and has a contrasting function higher than the resin layer. A visible marker is formed on the outer surface of the resin layer through color development of the color developing agent by irradiating the surface of the resin layer with laser light.

Owner:TERUMO KK

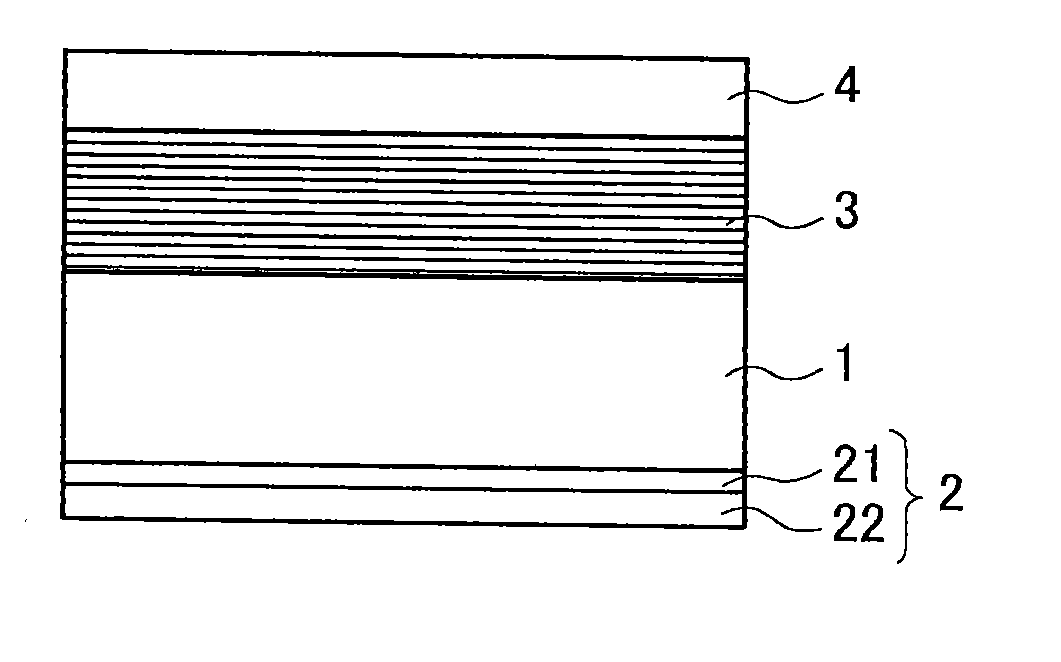

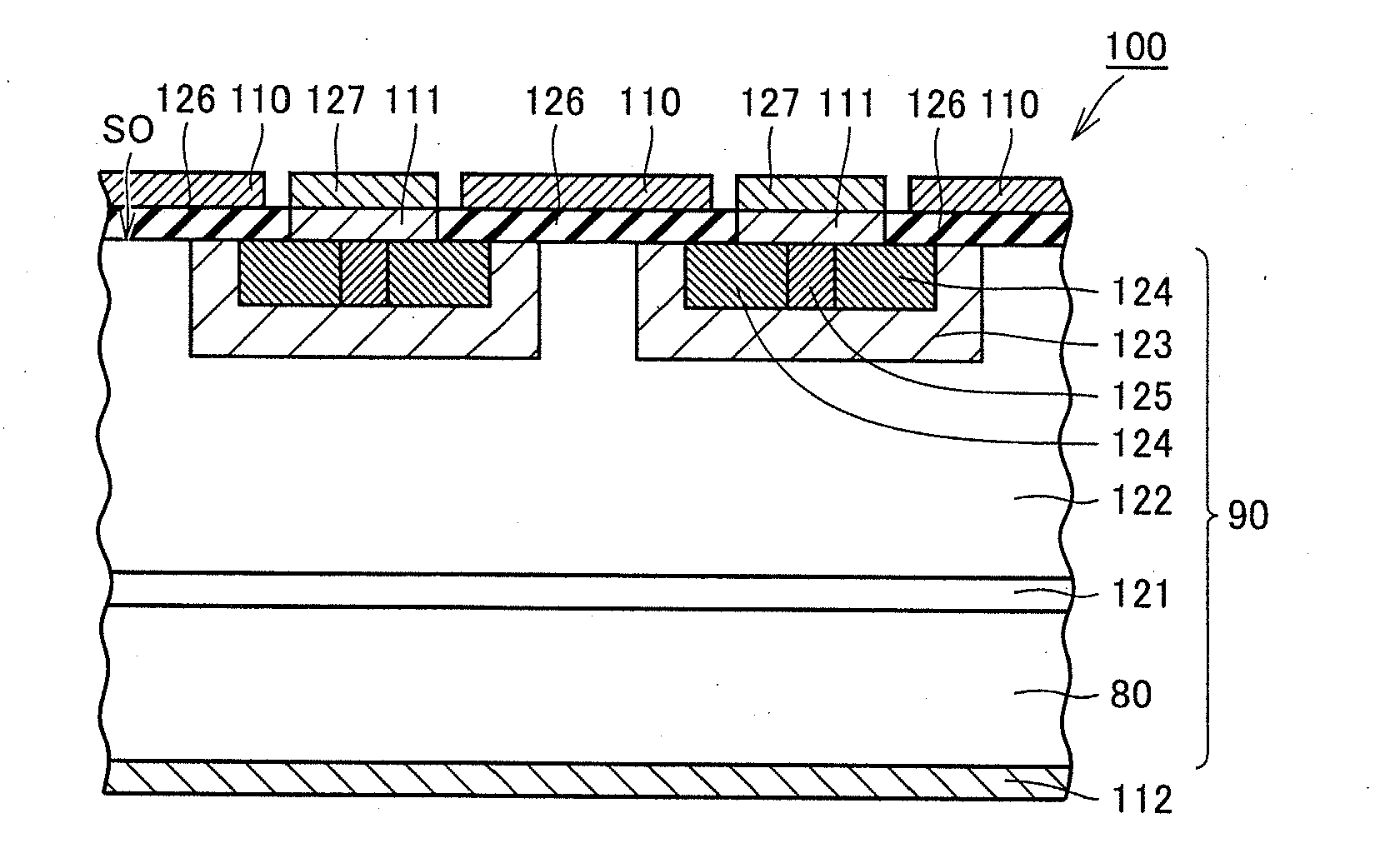

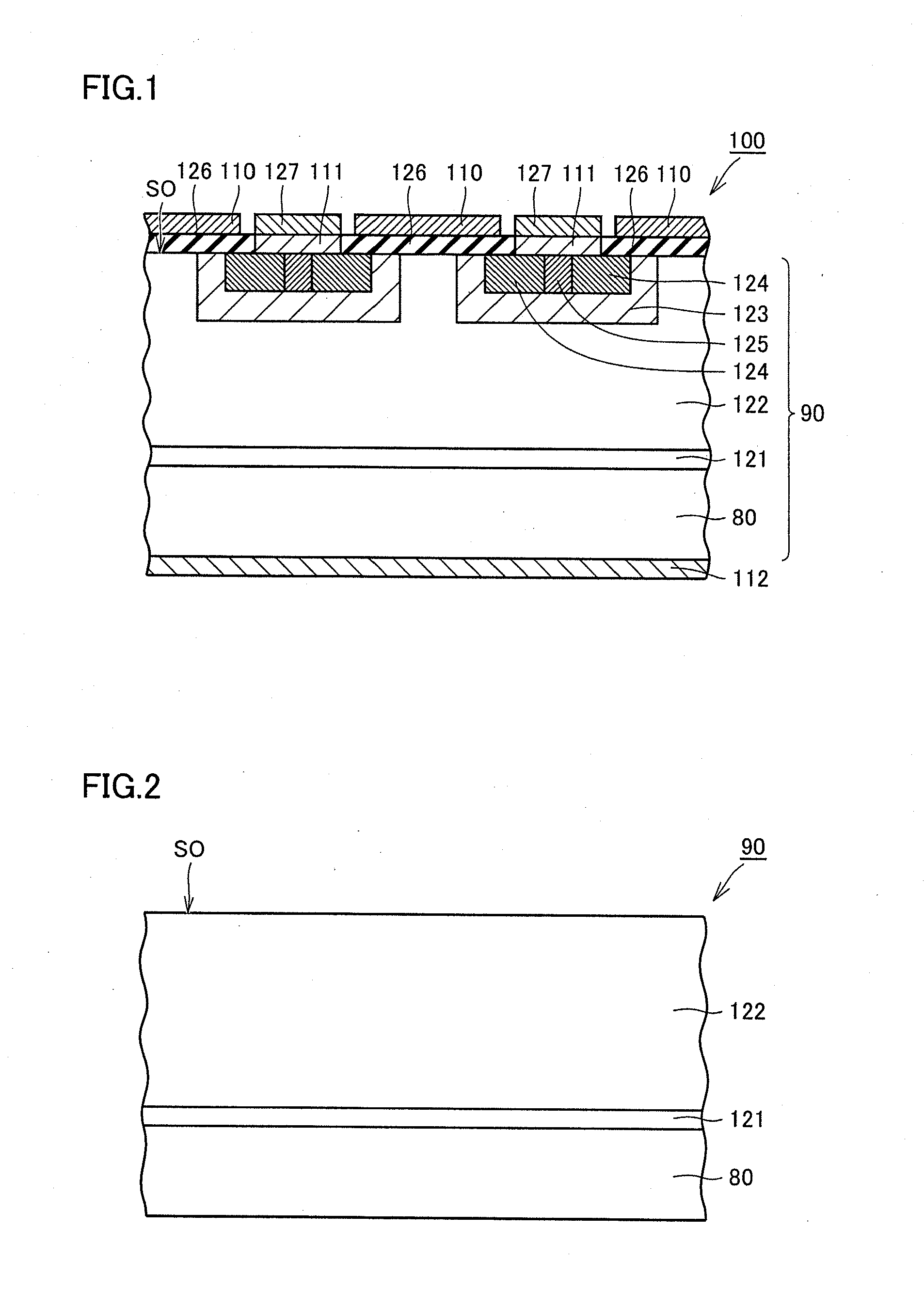

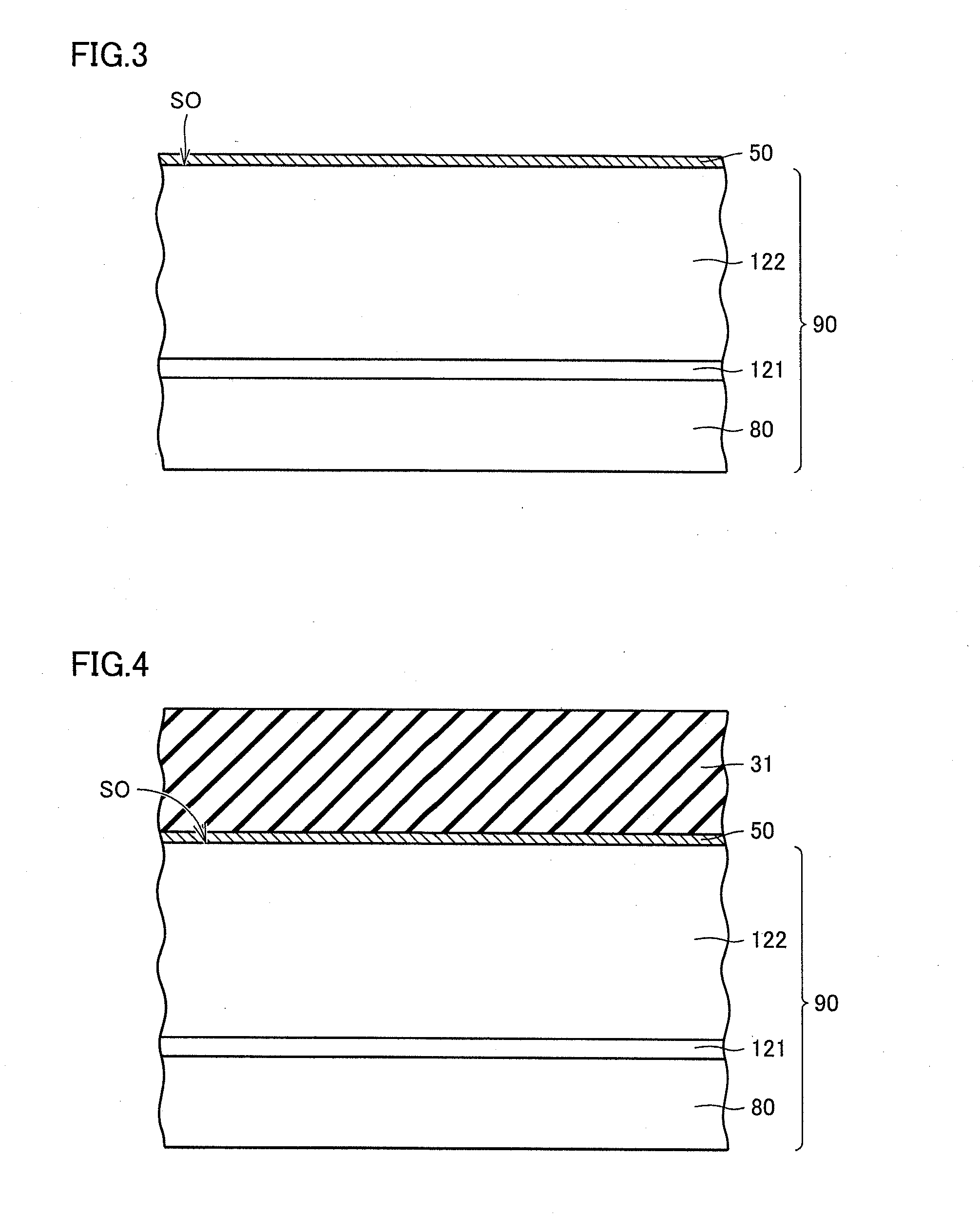

Substrate with conductive film, substrate with multilayer reflective film and reflective mask blank for EUV lithography

ActiveUS20130323630A1Suppress stressReduce resistanceOriginals for photomechanical treatmentElectrical resistance and conductanceLithographic artist

To provide a substrate with a conductive film for an EUV mask blank, which has a conductive film having a low sheet resistance, excellent surface smoothness and excellent contact to an electrostatic chuck, and with which deformation of the substrate by the film stress in an EUV mask blank can be suppressed.A substrate with a conductive film to be used for producing a reflective mask blank for EUV lithography, comprising a conductive film formed on a substrate;wherein the conductive film has at least two layers of a layer (lower layer) formed on the substrate side and a layer (upper layer) formed on the lower layer; andthe lower layer of the conductive film contains chromium (Cr), oxygen (O) and hydrogen (H), and the upper layer of the conductive film contains chromium (Cr), nitrogen (N) and hydrogen (H).

Owner:ASAHI GLASS CO LTD

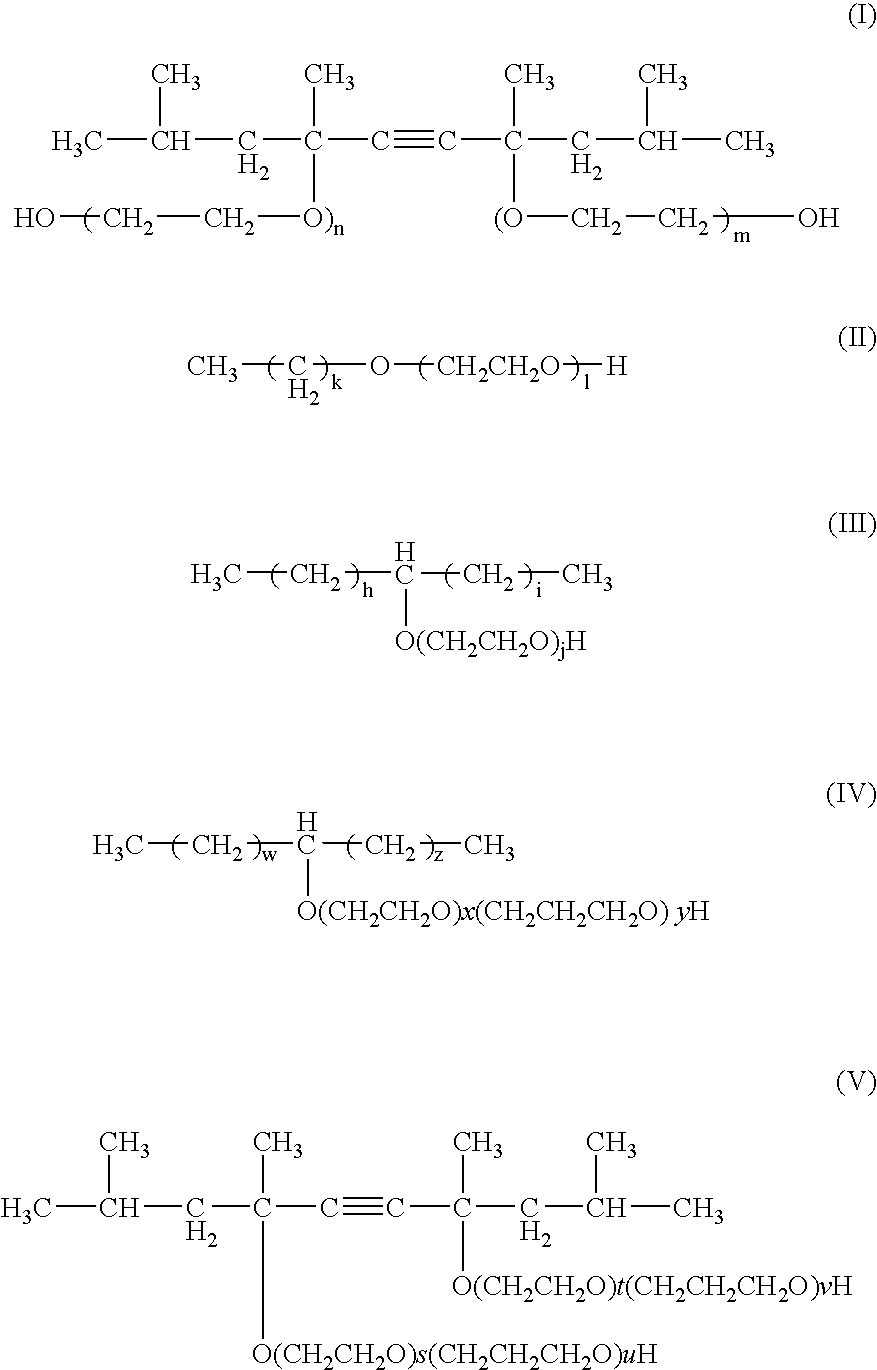

Ink composition, recording method and recording images using the same, as well as ink set and ink head

InactiveUS20040059020A1Excellent in water proofness and scratch resistanceReduce materialDuplicating/marking methodsInksSulfonatePolyester resin

An ink composition is prepared by incorporating water, a colorant and a polyester resin in which a polybasic carboxylic acid ingredient contains an aromatic dicarboxylic acid having a metal sulfonate group. The ink composition is stored in an ink tank of an ink head, the ink composition is supplied from the ink tank into an ink chamber having a discharge port, a voltage is applied to partition wall portions formed of a piezoelectric material, a pressure is applied to the ink composition contained in the ink chamber by the partition wall portions and liquid droplets of the ink composition are discharged from the discharge port and deposited on a recording material thereby recording images.

Owner:SHARP KK

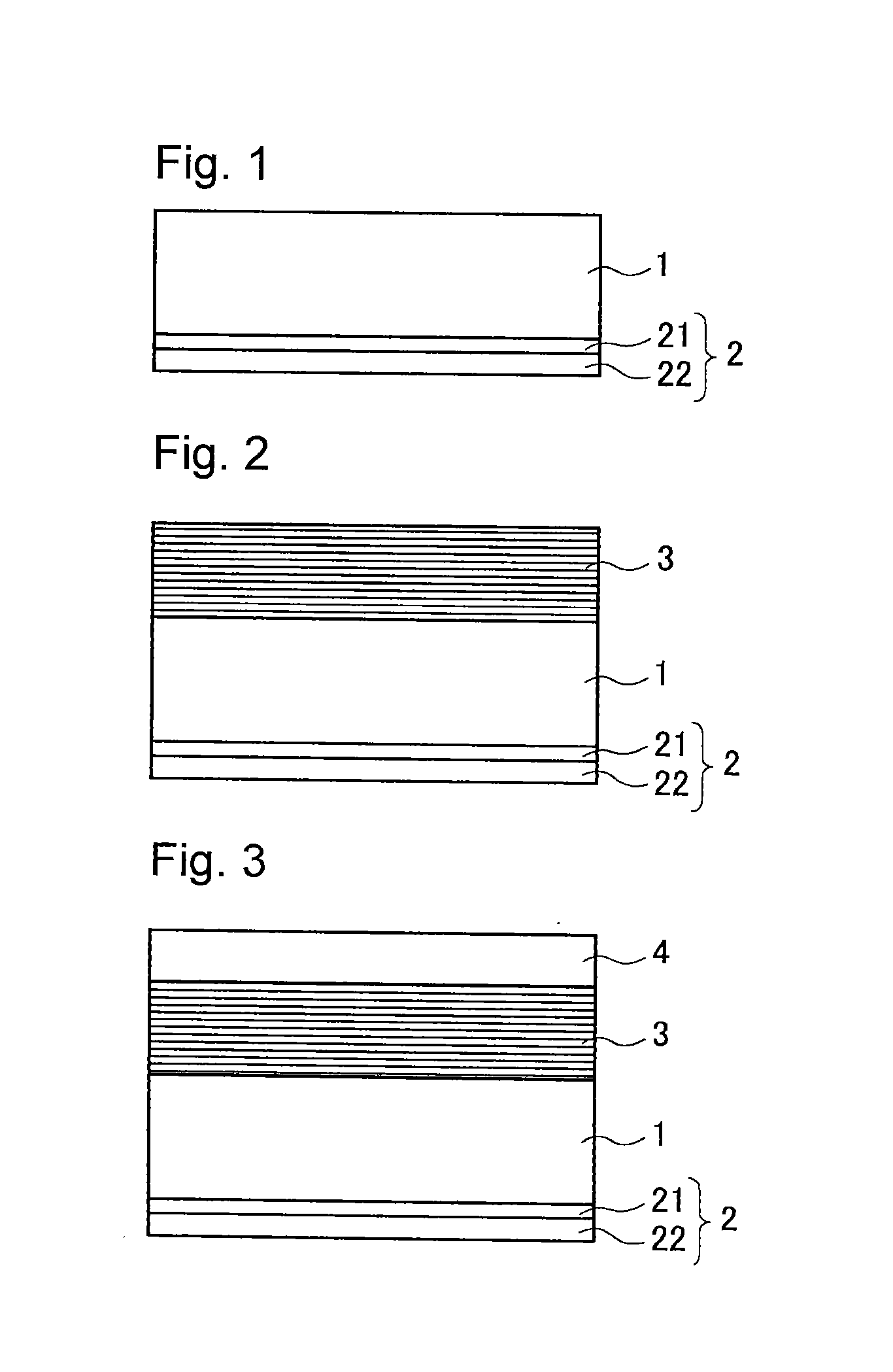

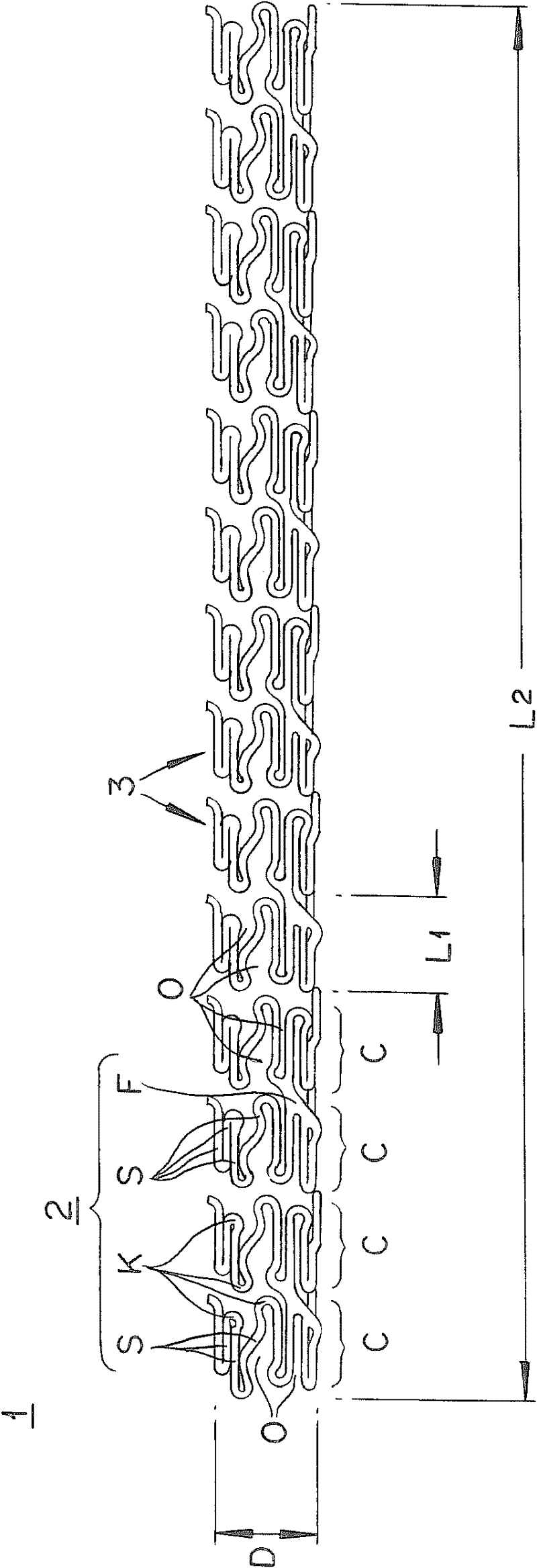

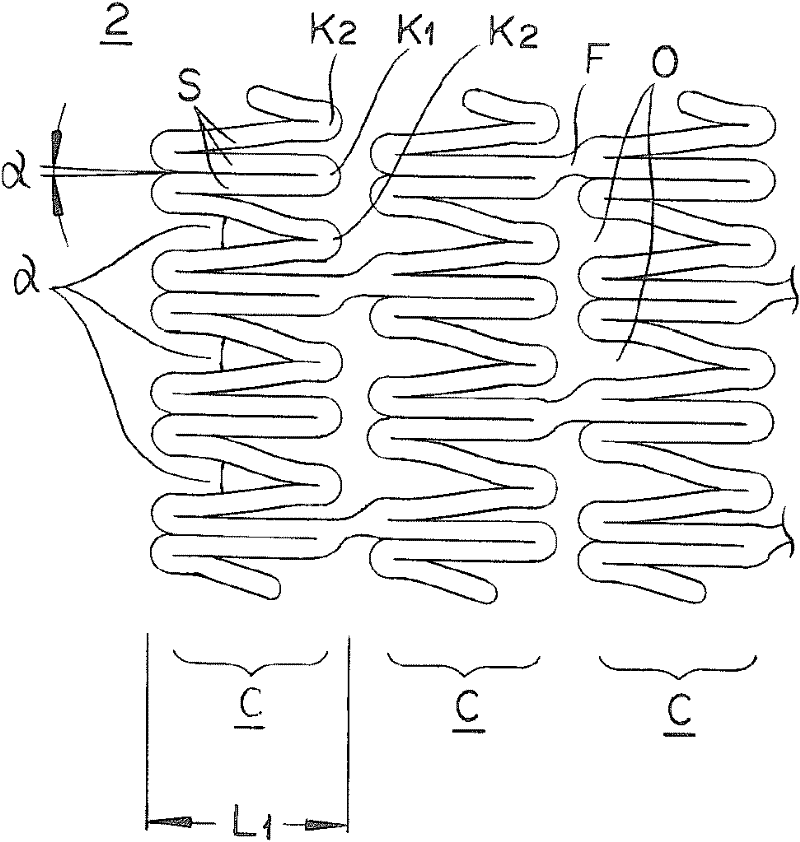

Stent

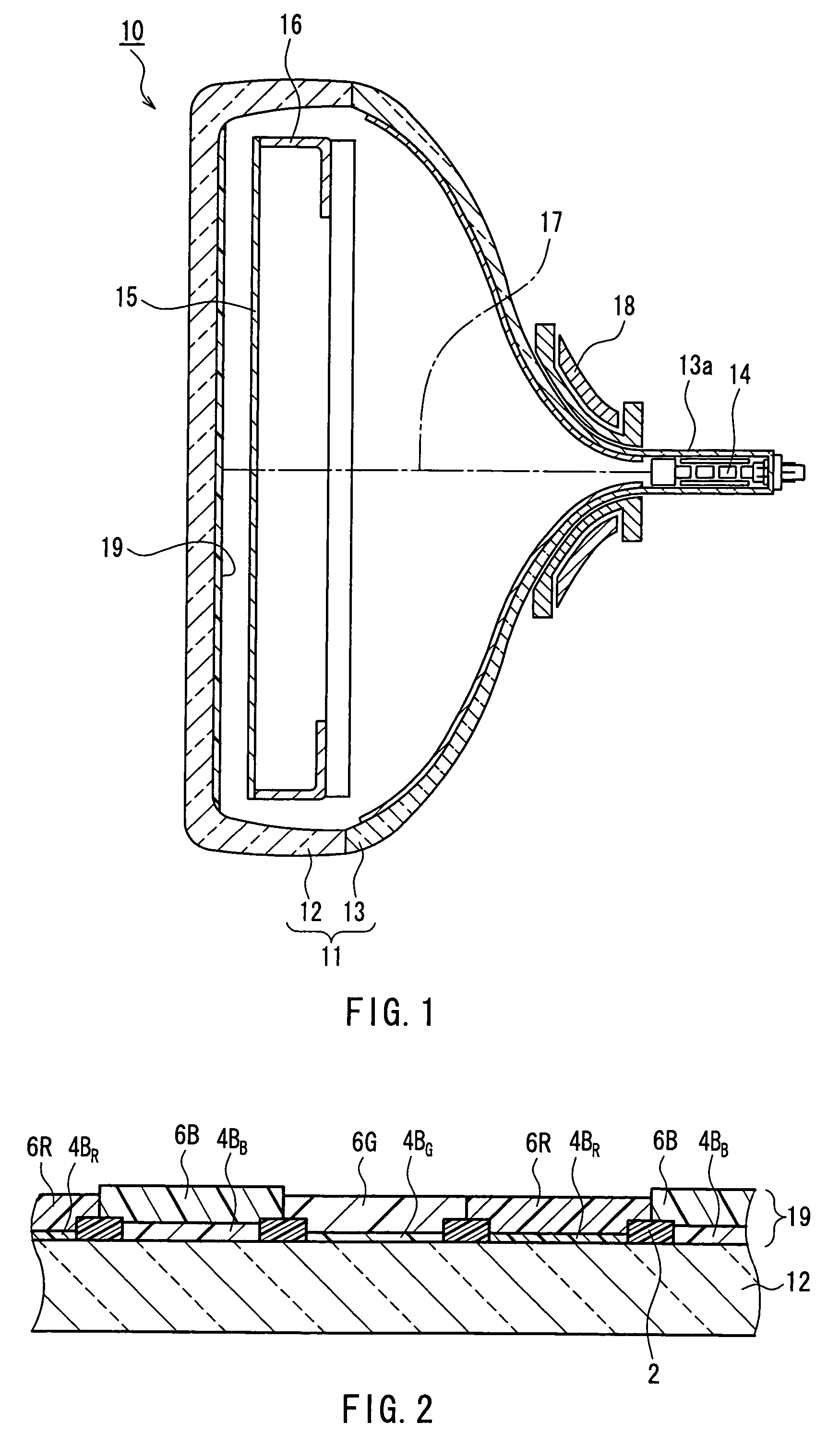

Provided is a stent such that there is minimal occurrence of strain or of stress concentration in a drug coated layer as a consequence of expansion and deformation of the stent in the radial direction thereof, and that as a result, there is no risk of the drug falling off. The aforementioned stent is characterized in that the thickness (B) of the drug coated layer (4) formed by coating the outer surface of a stent body (2) gradually decreases toward a bending section (K), that reduction is made to the strain and stress which occur in the drug coated layer (4) as a consequence of expansion and deformation of the stent (1), and that as a result, the drug is prevented from falling off.

Owner:TERUMO KK

Hot melt adhesive

InactiveUS20140199908A1Improve adhesionAdditional componentSynthetic resin layered productsWoven fabricsPolymer scienceEthylene Homopolymers

The present invention provides hot melt adhesives for disposable products. The hot melt adhesives may be applied at high-speed and at low temperature ranges. The hot melt adhesives also provide excellent adhesion to polyethylene and a nonwoven fabric. The hot melt adhesive comprises (A) a thermoplastic block copolymer, which is a copolymer of a vinyl-based aromatic hydrocarbon with a conjugated diene compound; and (B) a propylene homopolymer having a melting point of 100° C. or lower, which is obtainable by polymerizing propylene using a metallocene catalyst. The disposable products are produced at high-speeds and low temperature with the inventive hot melt, and therefore, the disposal products are produced efficiently and safely, and a nonwoven fabric and a polyethylene film of the disposable products are less likely to peel.

Owner:HENKEL KGAA

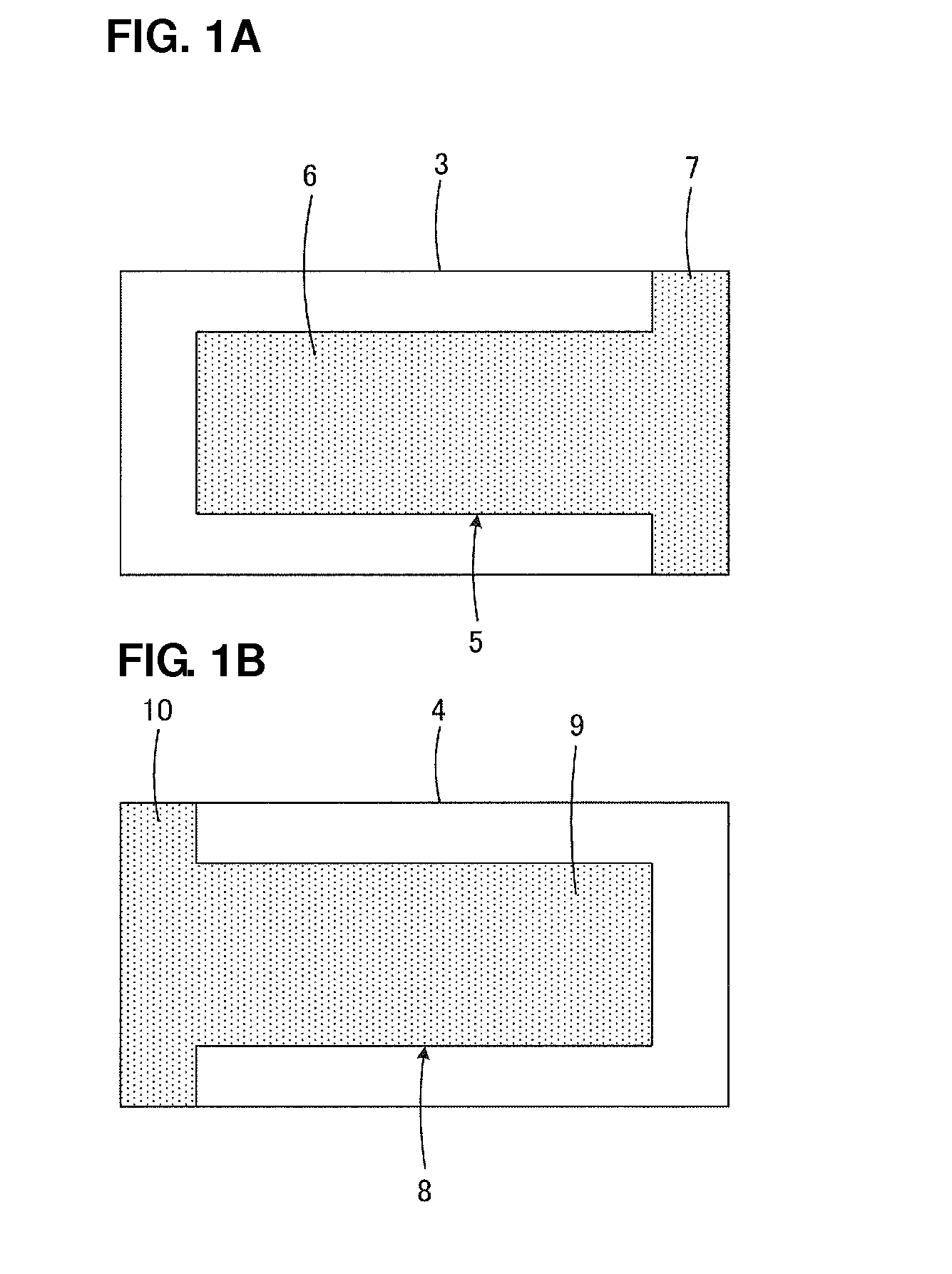

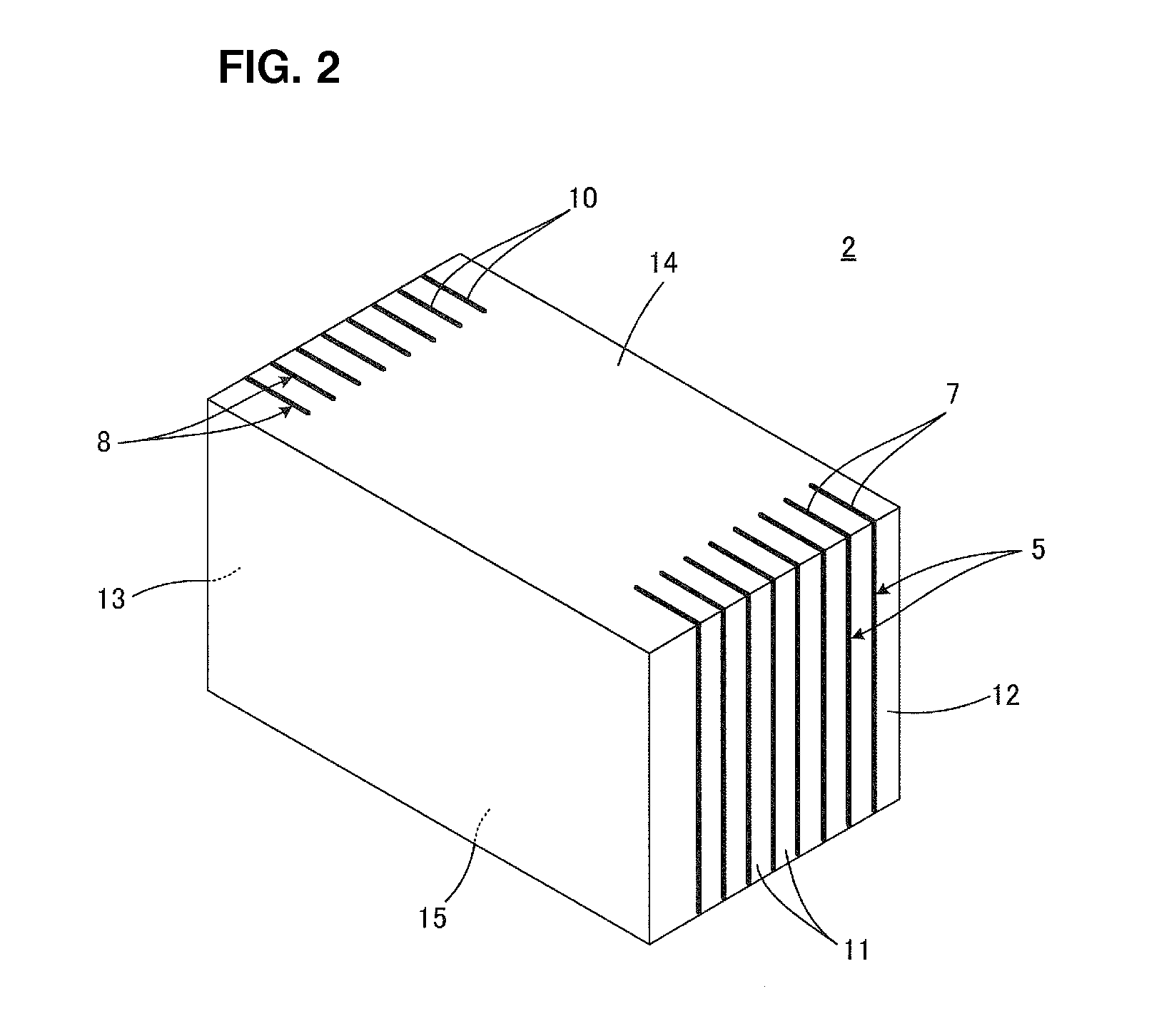

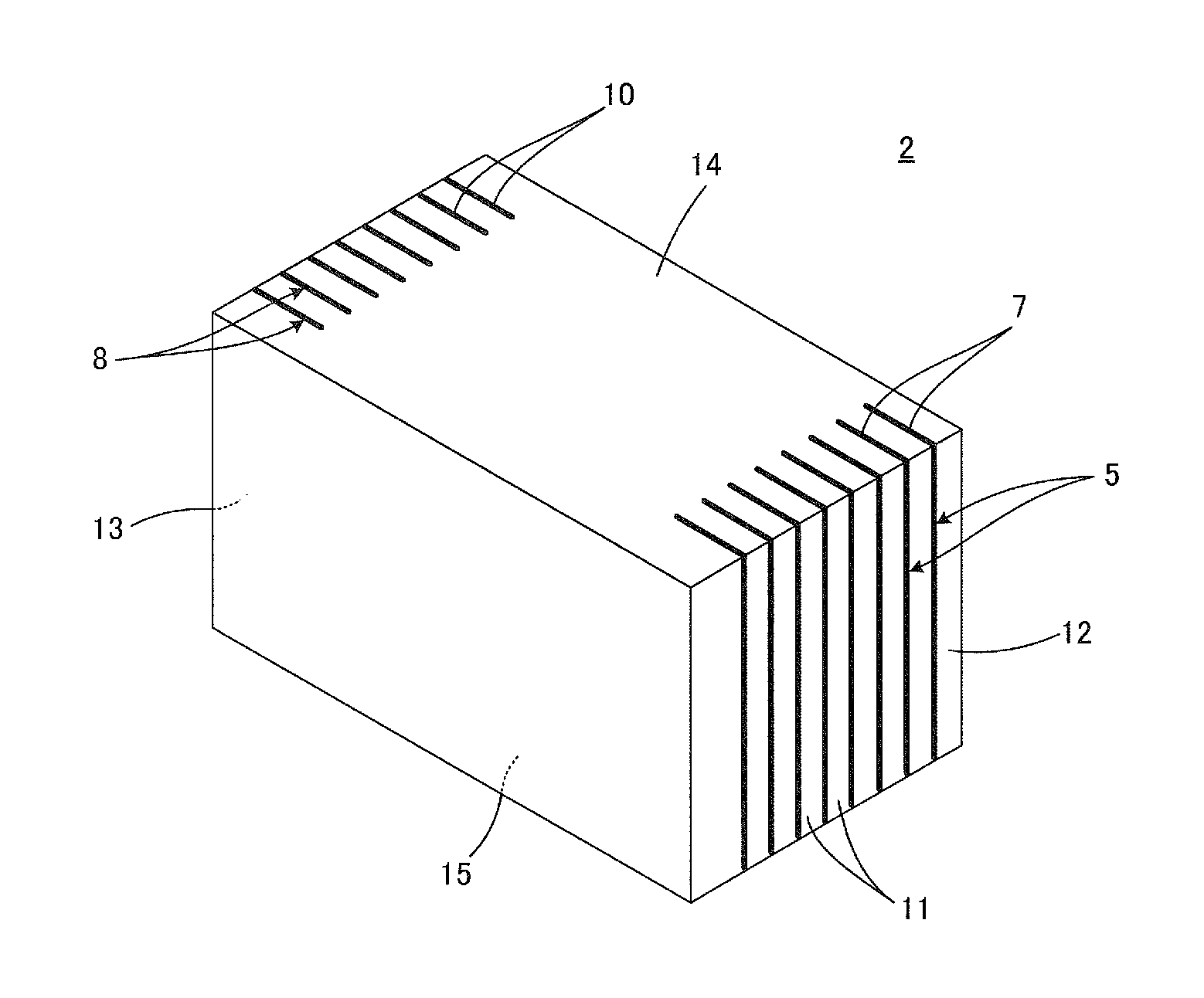

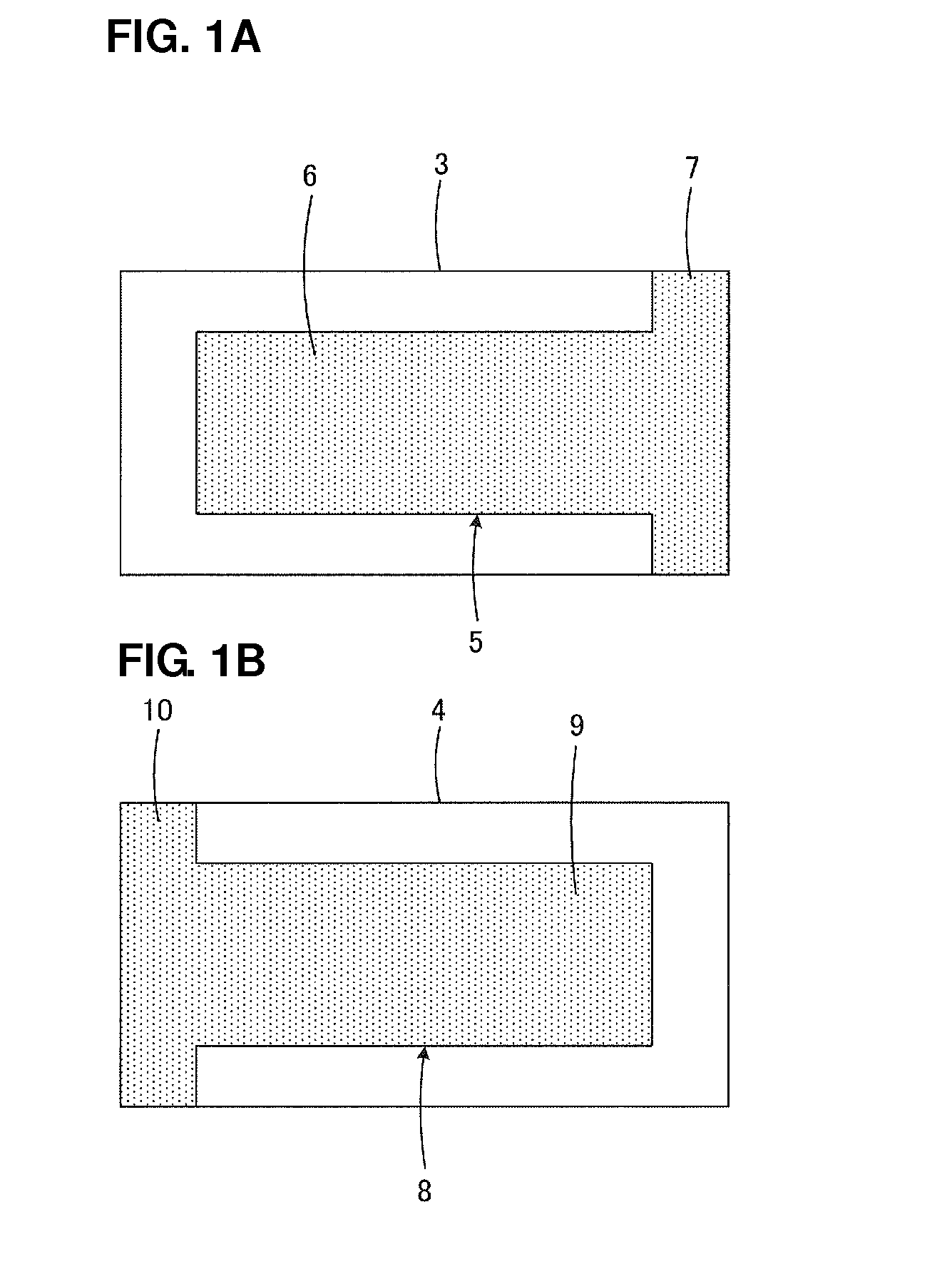

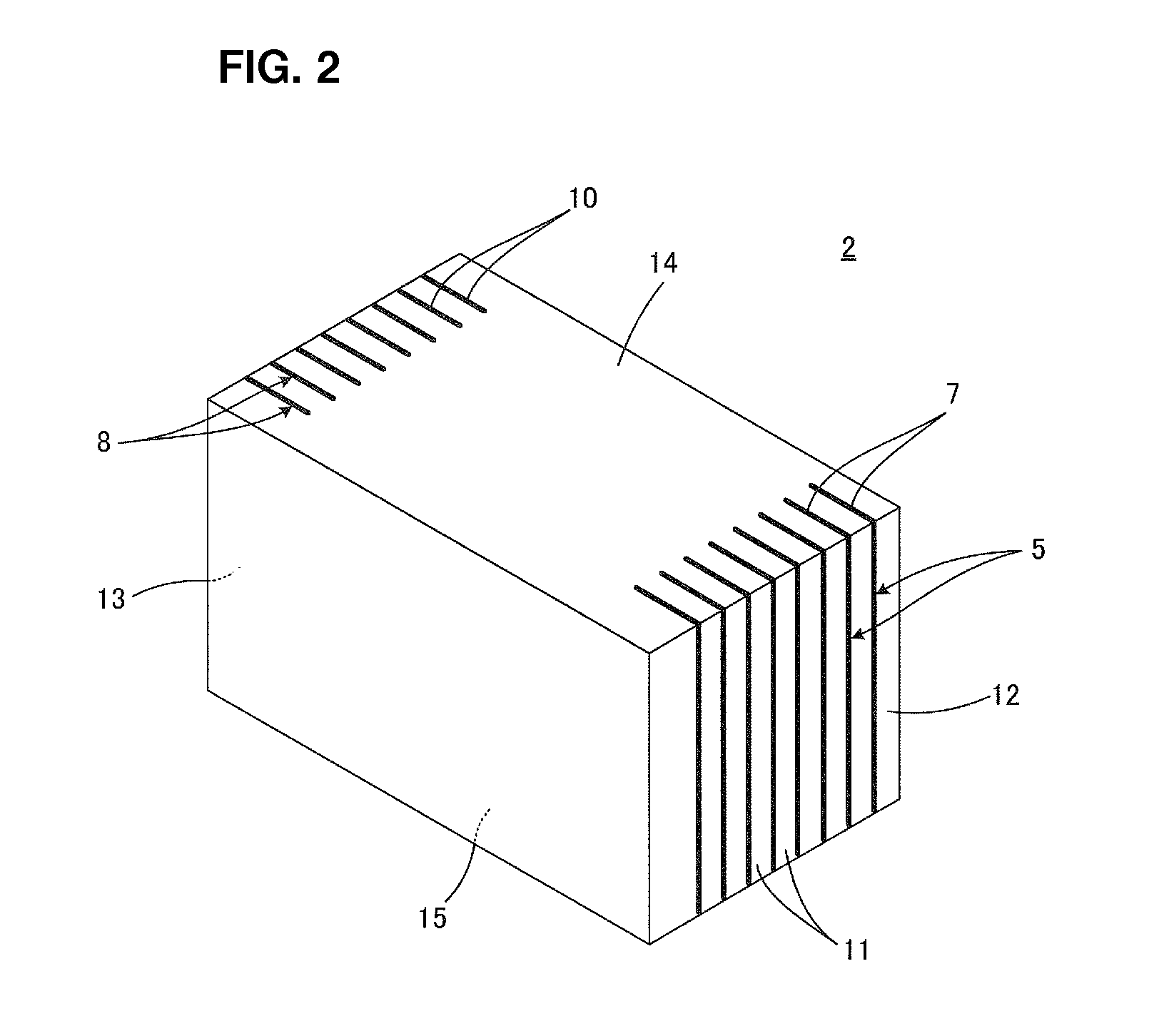

Laminate type ceramic electronic component and manufacturing method therefor

ActiveUS20120039014A1High hardnessImprove anchoring abilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorElectronic component

In a laminate type ceramic electronic component, when an external electrode for a laminated ceramic capacitor is formed directly by plating onto a surface of a component main body, the film that is directly plated may have a low fixing strength with respect to the component main body. As the external electrode, a first plating layer composed of a Ni—P plating film with a P content rate of about 9 weight % or more is first formed such that a plating deposition deposited with the exposed ends of respective internal electrodes as starting points is grown on at least an end surface of a component main body. Then, a second plating layer composed of a Ni plating film containing substantially no P is formed on the first plating layer. Preferably, the first plating layer is formed by electroless plating, whereas the second plating layer is formed by electrolytic plating.

Owner:MURATA MFG CO LTD

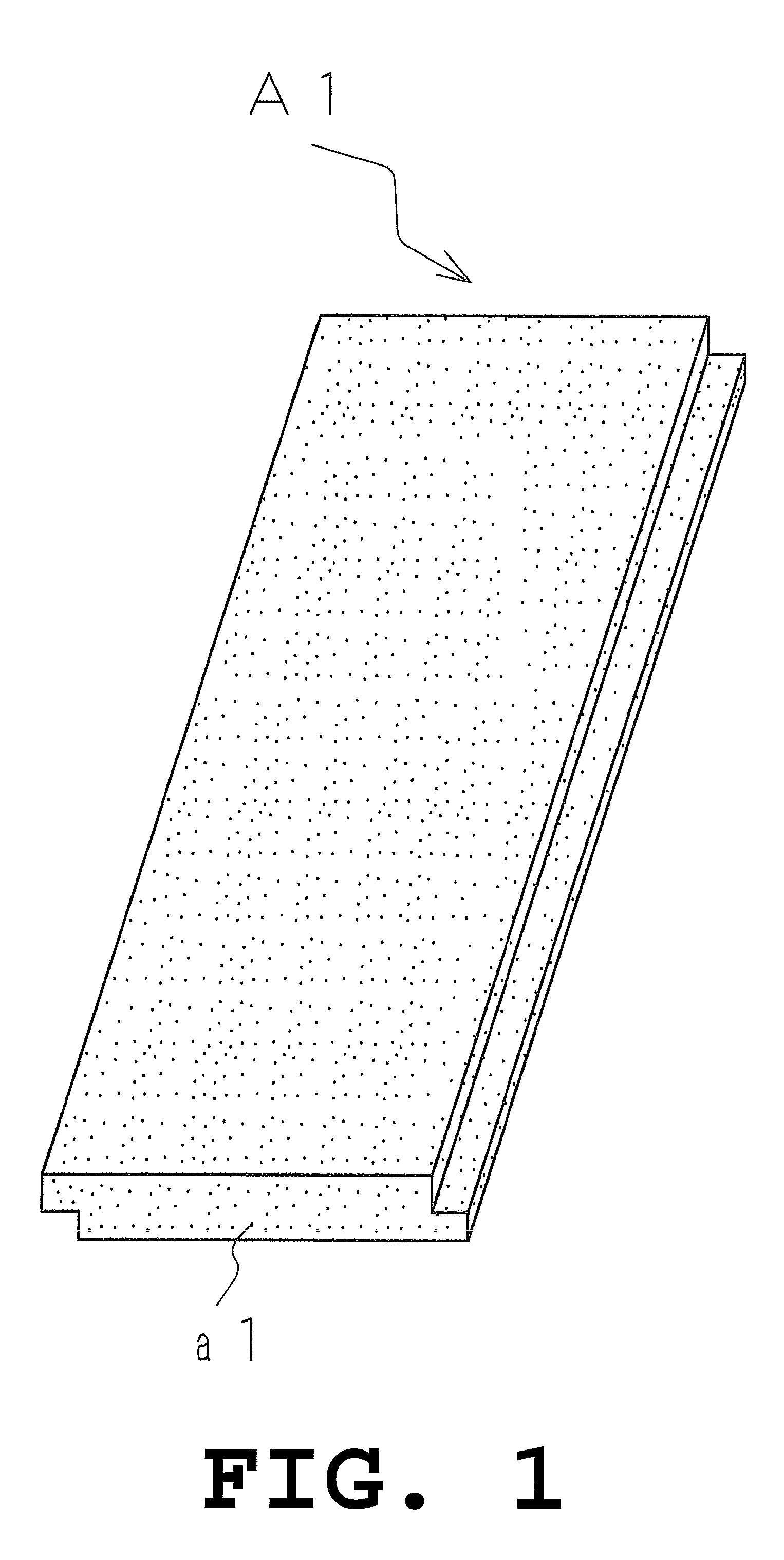

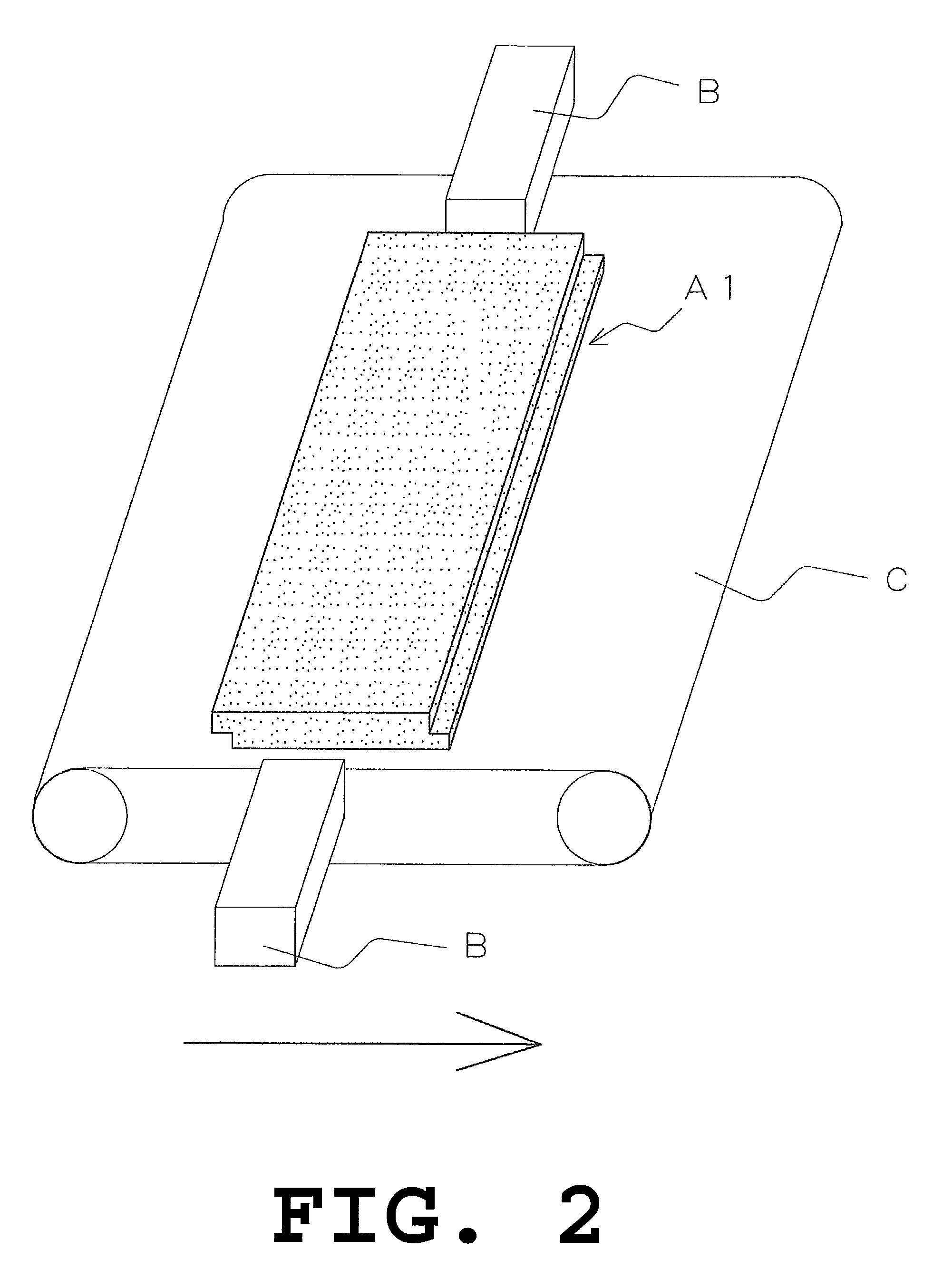

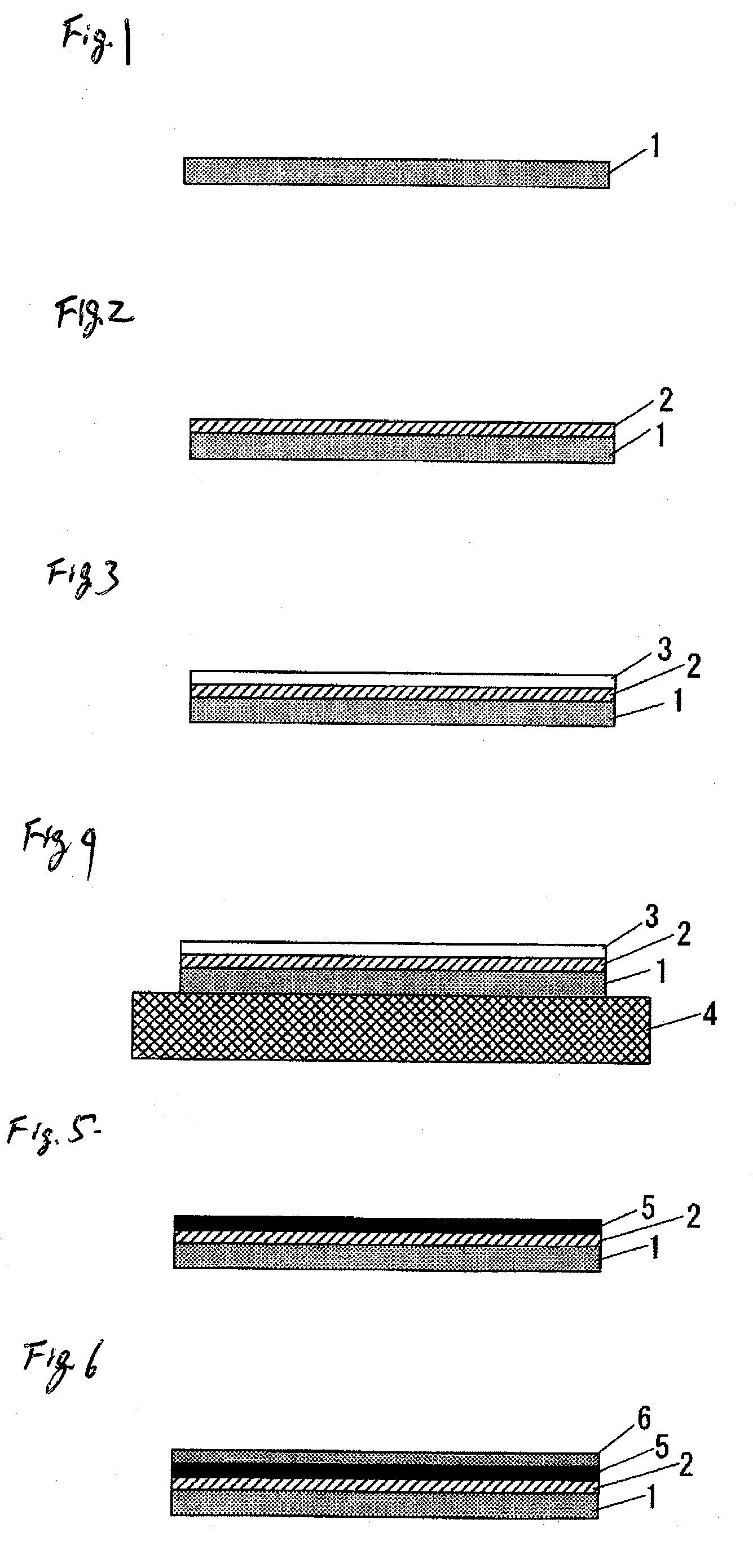

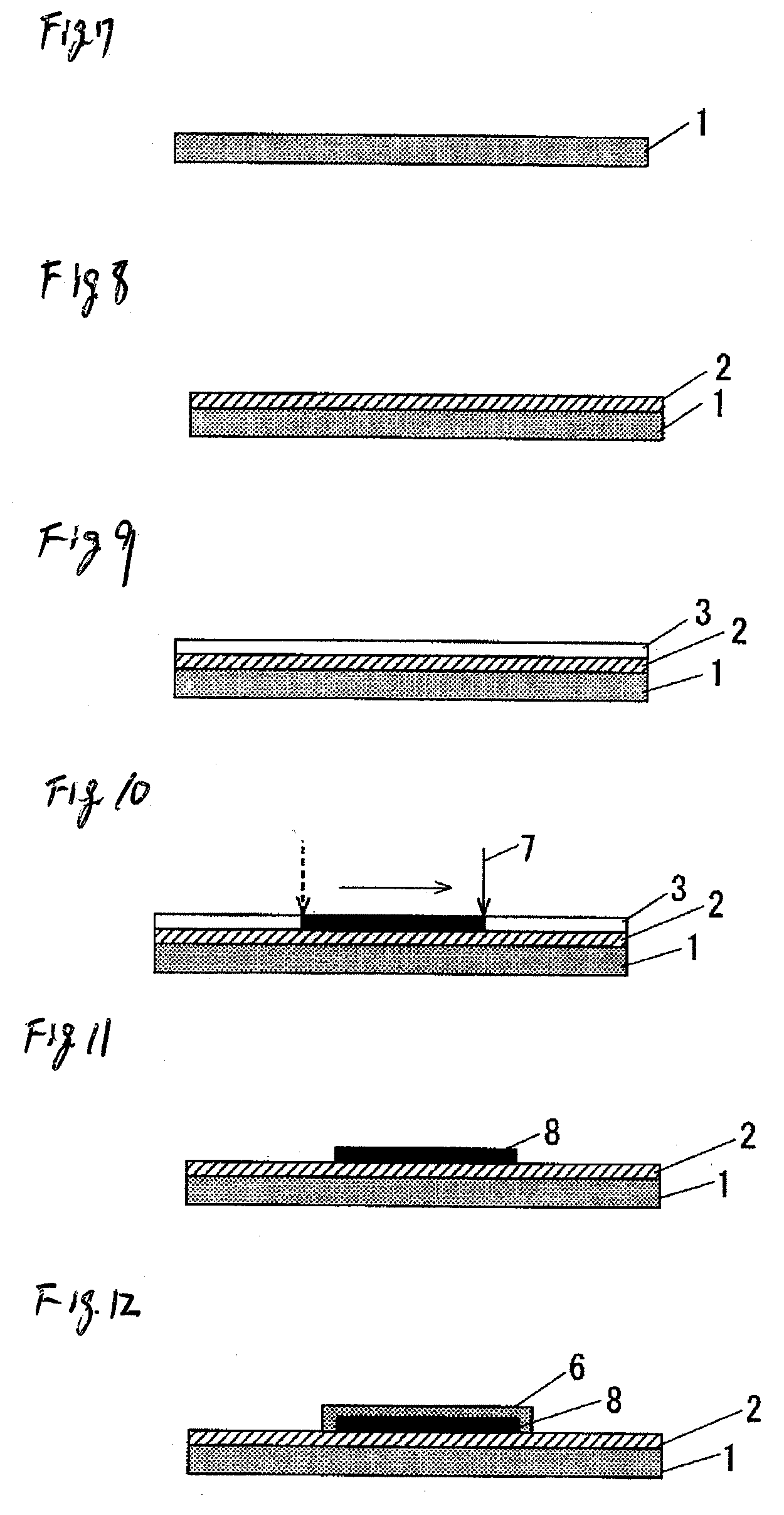

Building material and method for manufacturing thereof

The present invention provides a building material in which a coating is applied to a front surface and a side surface is sufficiently adhered to a sealing and method for manufacturing thereof. In a building material in which a coating is applied to a front surface, a coating film on a side surface is removed or reduced by laser irradiation. The part of the side surface in which the coating film has been removed or reduced by laser irradiation has a width of at least 5 mm from a front surface side toward a rear surface side of the building material, or extends over the entire side surface from the front surface side toward the rear surface side of the building material, or is formed more than a part in which coating film is formed.

Owner:NICHIHA CORP

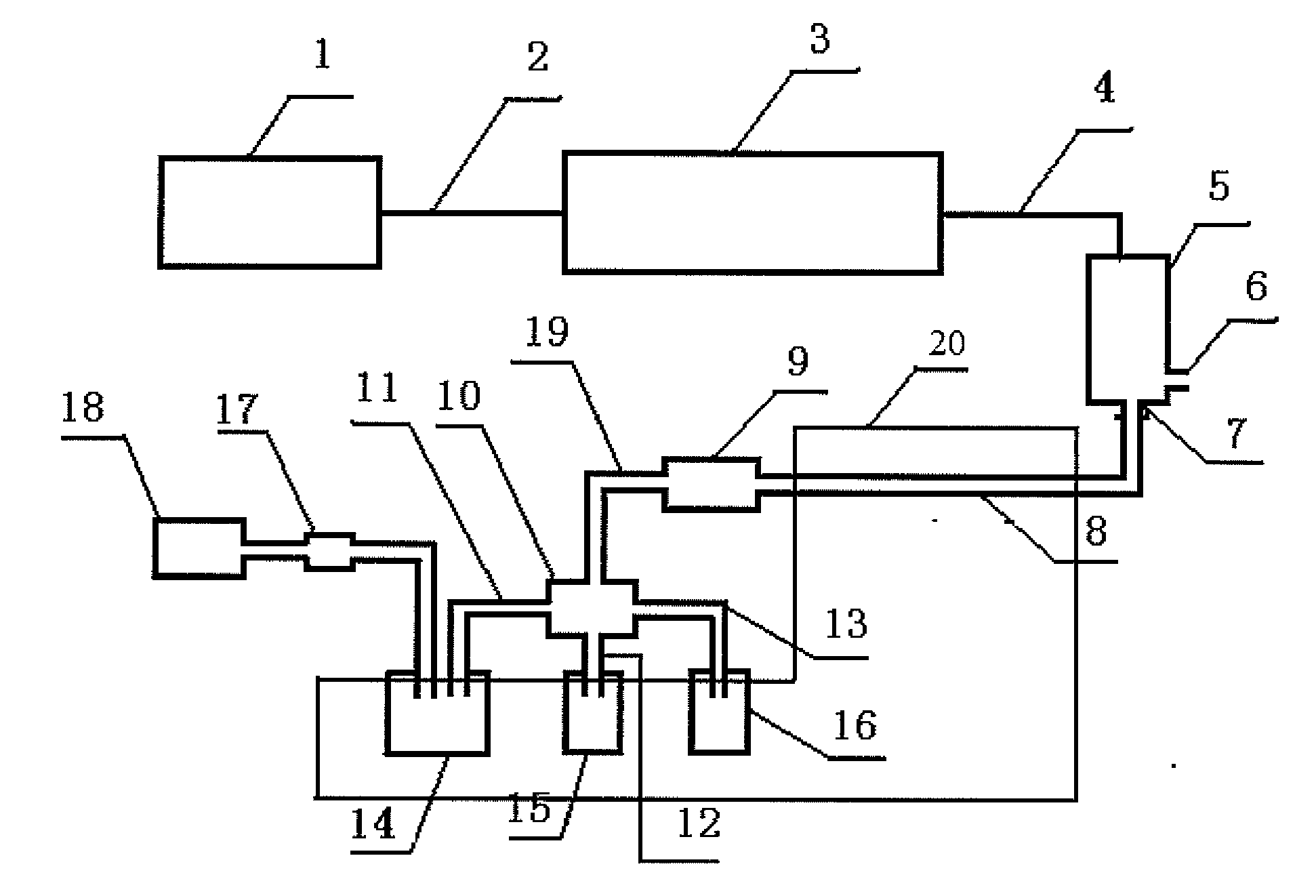

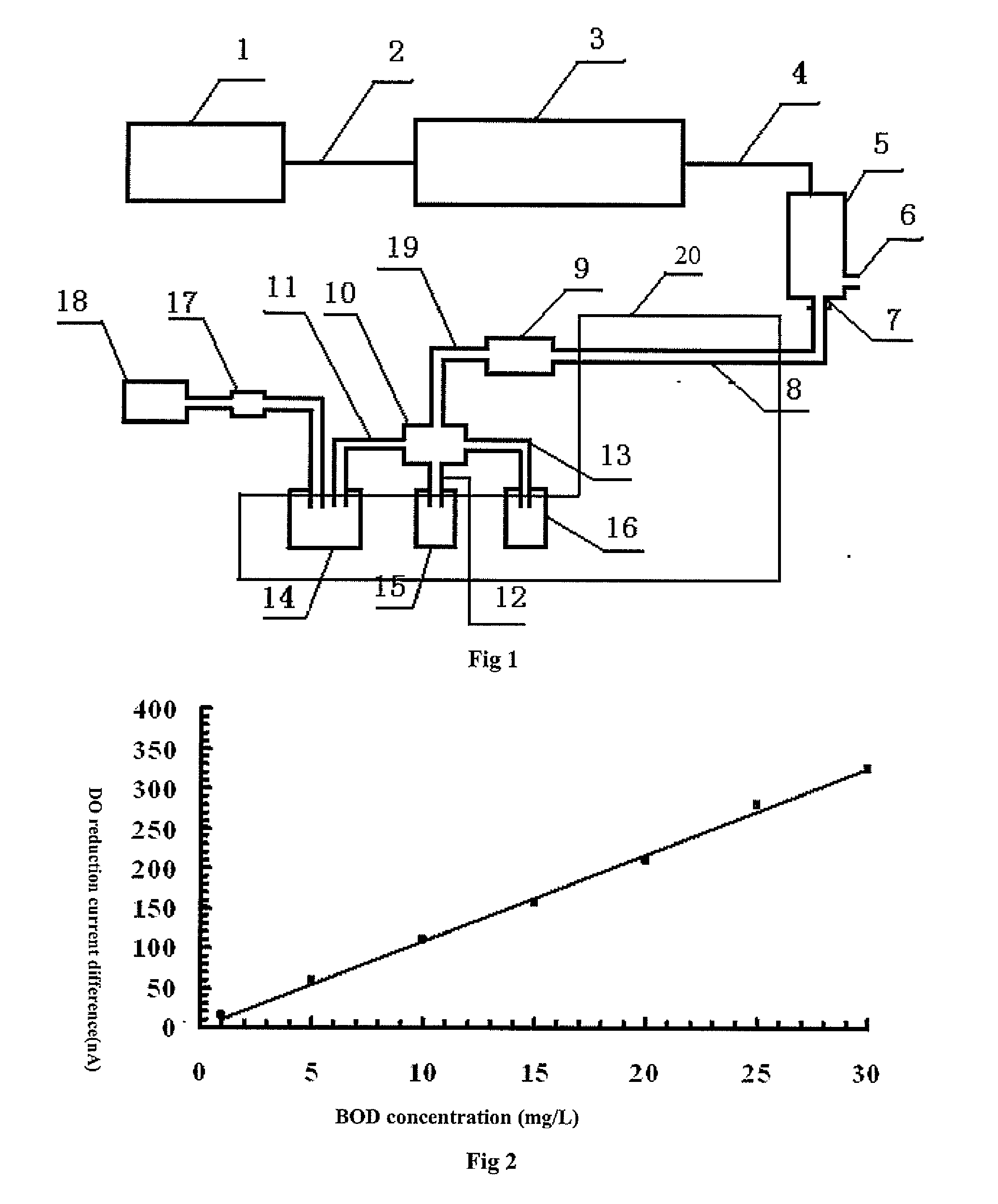

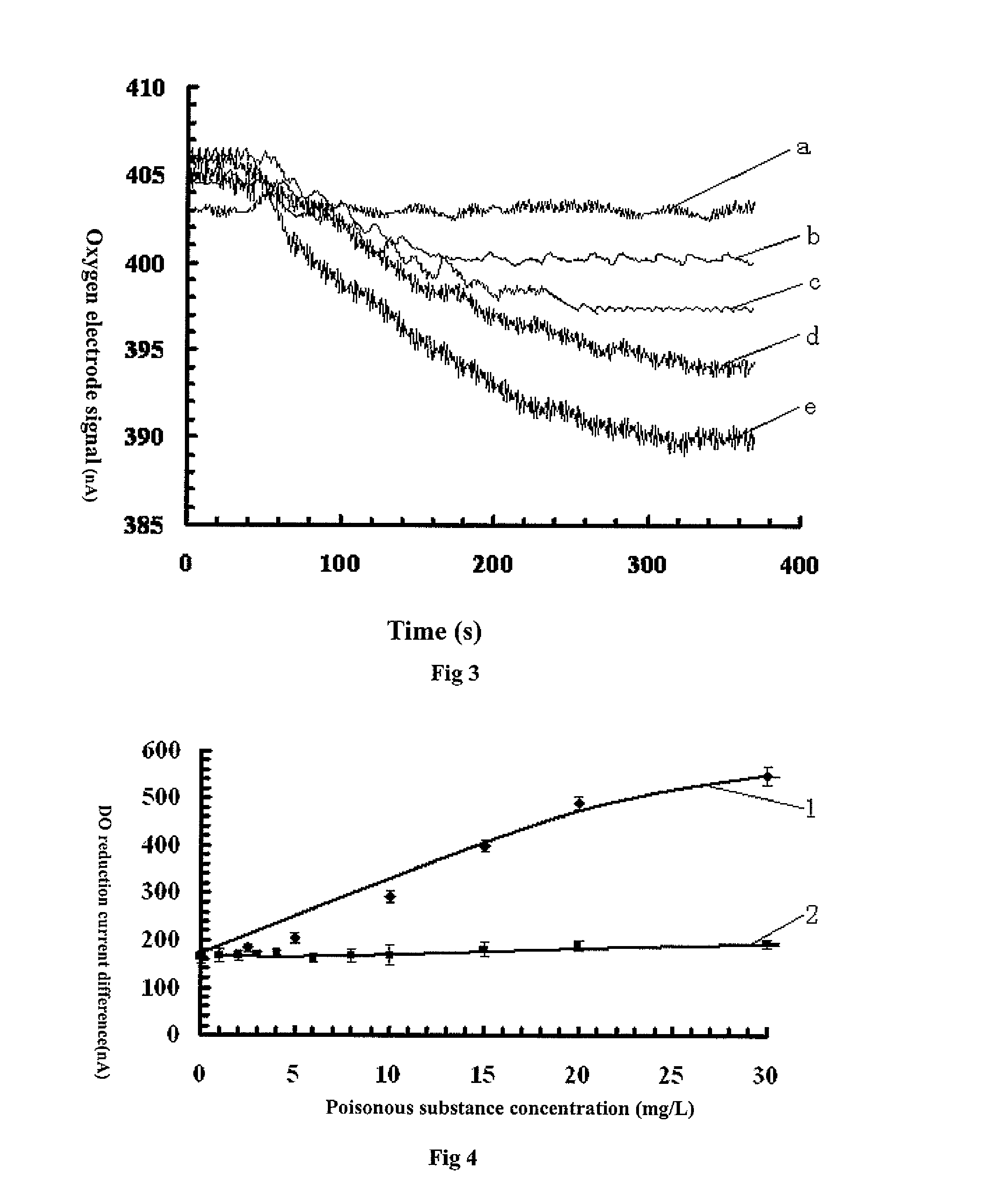

Method for detecting biochemical oxygen demand

ActiveUS20140326617A1AdaptableAdaptive strongMicrobiological testing/measurementVolume/mass flow measurementIndustrial waste waterSludge

The present invention provides a method for detecting biochemical oxygen demand. Active sludge, surface water, domestic waste water, or industrial waste water comprising microorganism is taken as a water sample with microorganism in the method provided by the present invention. The water sample with microorganism is cultivated to obtain a microorganism film. The blank water sample and the target water sample are made to pass through the microorganism film respectively. The dissolved oxygen reduction current values of the blank water sample and the target water sample are detected. The difference value between the dissolved oxygen reduction current value of the target water sample and that of the blank water sample is obtained. On the basis of the difference value and the predetermined standard curve, the biochemical oxygen demand of the target water sample is acquired. The method provided by the present invention adopts active sludge, surface water, domestic waste water, or industrial waste water comprising microorganism as the water sample with microorganism. The environmental adaptability of the prepared microorganism film is strong, so that one or more of tap water, well water, atmospheric water, or ground water may serve as medium to maintain the physiological activity with no need of providing a buffer solution system.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for manufacturing silicon carbide semiconductor device

InactiveUS20130045593A1Increase stickinessOccurrence of peel off from the silicon carbide substrate can be suppressedTransistorSemiconductor/solid-state device manufacturingIon beamImpurity ions

A silicon carbide substrate having a surface is prepared. A coating film made of a first material is formed directly on the surface of the silicon carbide substrate. A mask layer made of a second material is formed on the coating film. The first material is higher in adhesiveness with silicon carbide than the second material. A first opening is formed in the mask layer. First impurity ions for providing a first conductivity type are implanted into the silicon carbide substrate by using ion beams passing through the first opening in the mask layer and through the coating film.

Owner:SUMITOMO ELECTRIC IND LTD

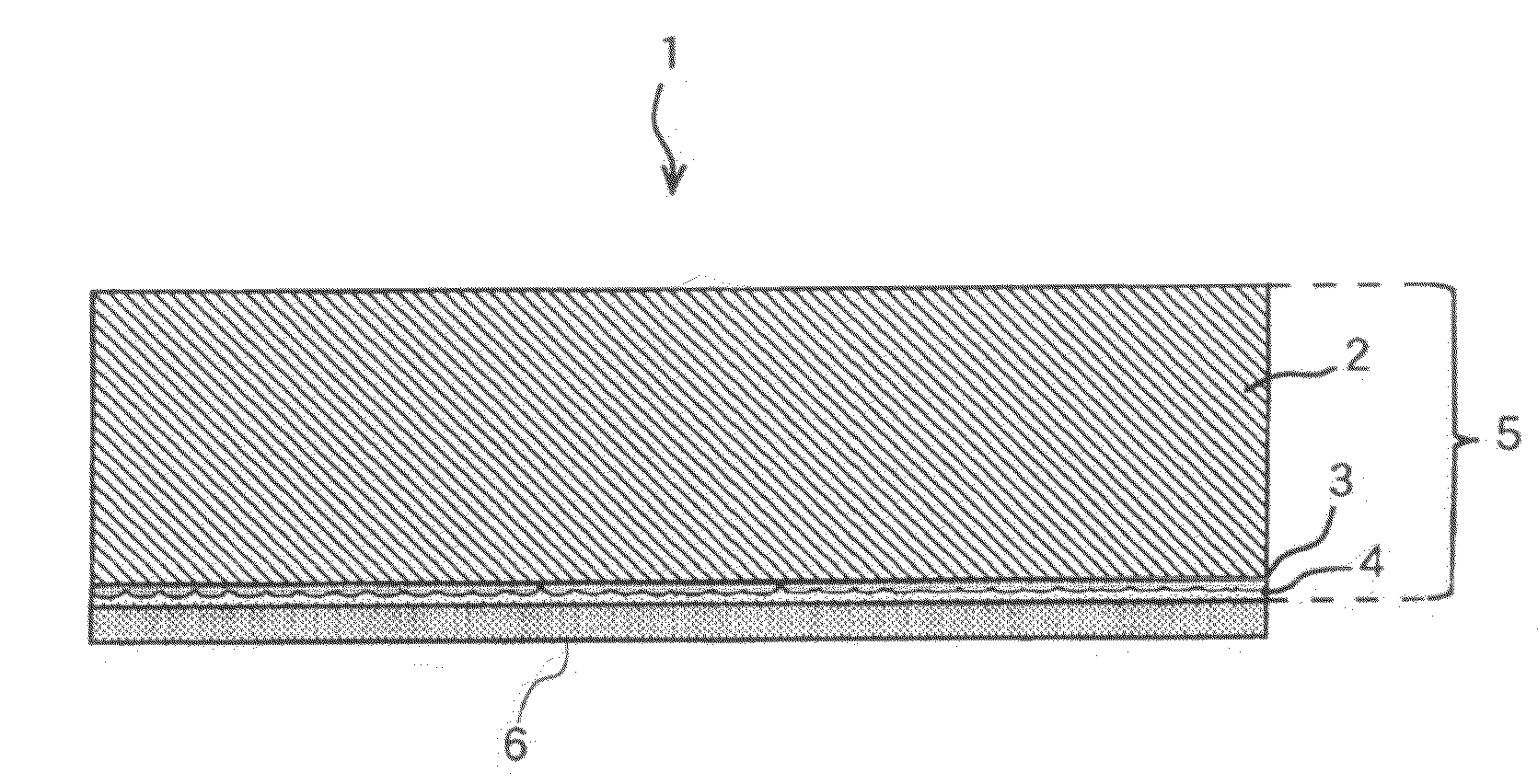

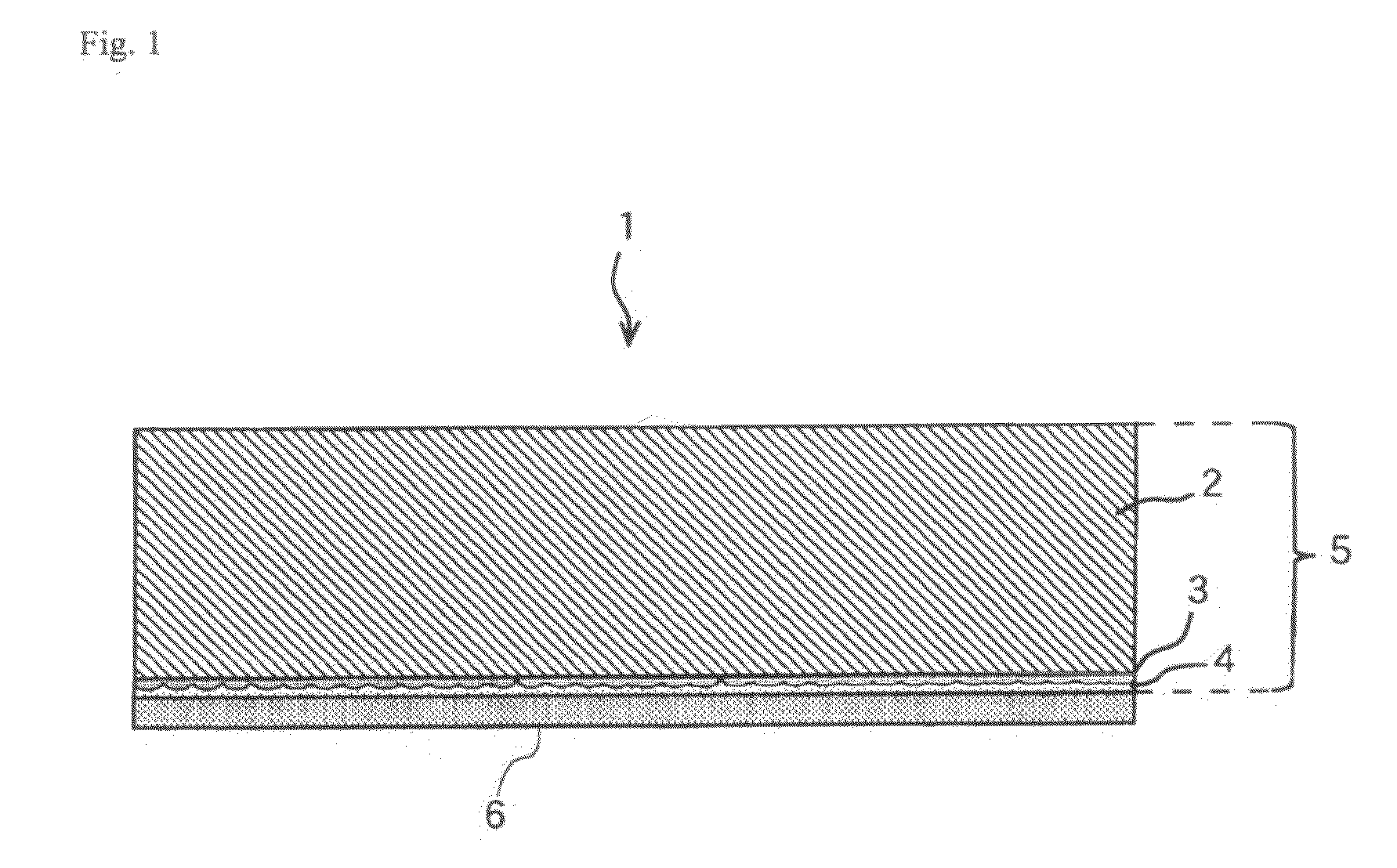

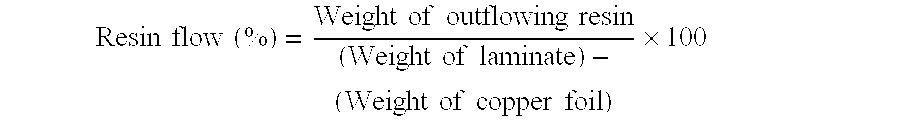

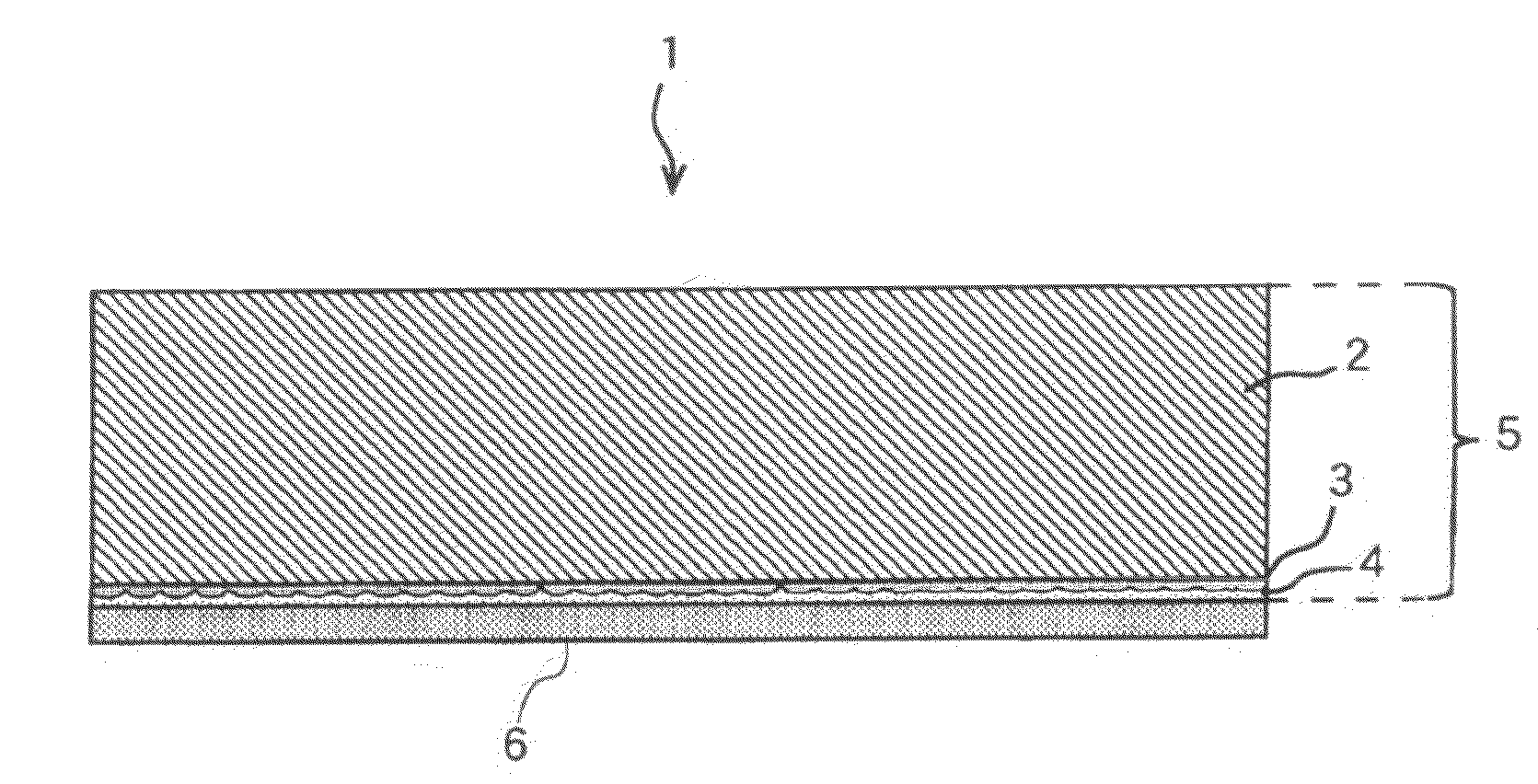

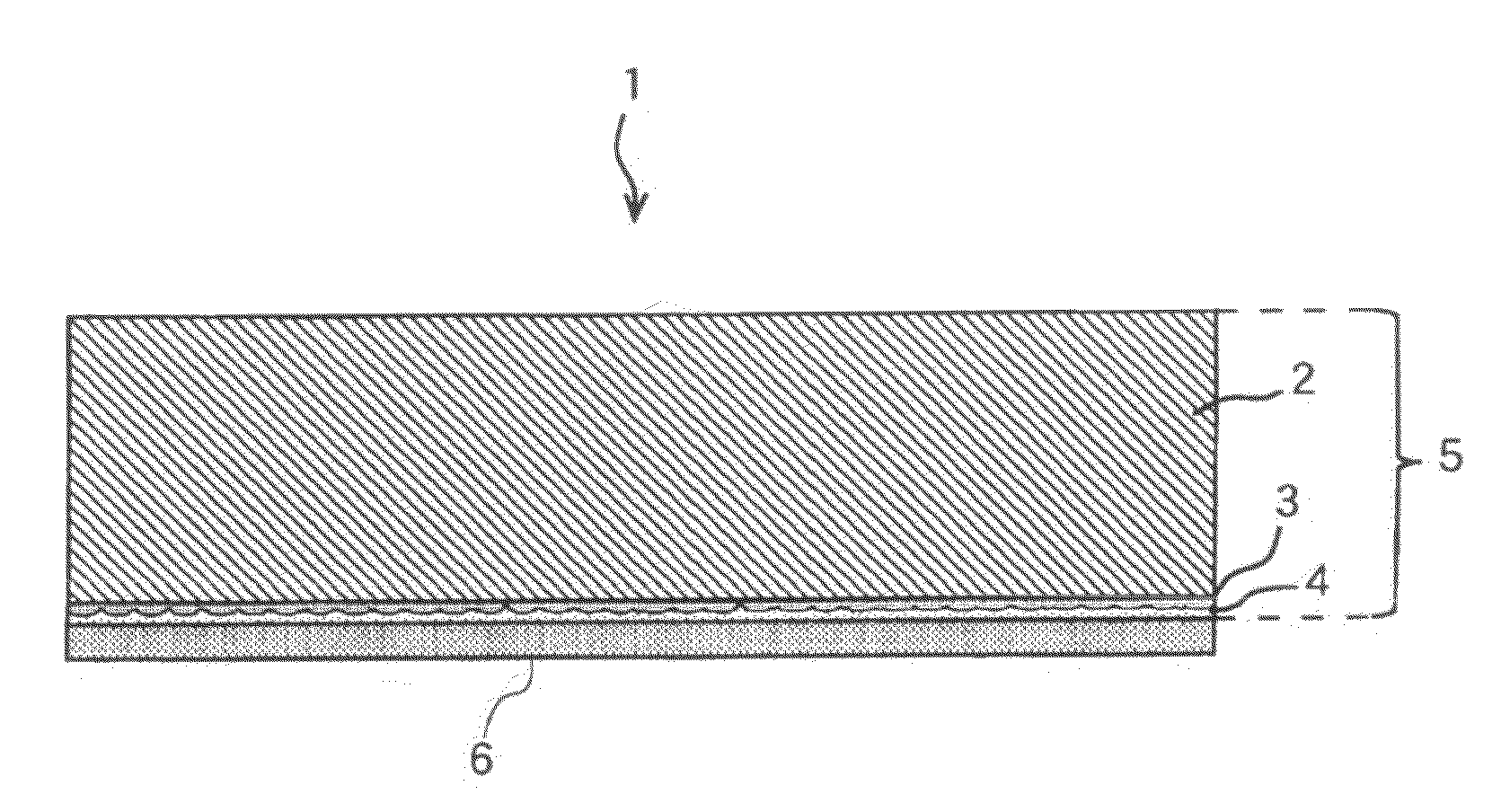

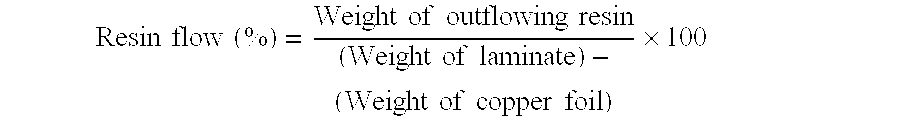

Surface-treated copper foil, manufacturing method of the surface-treated copper foil, and surface-treated copper foil coated with very thin primer resin layer

InactiveUS20090029186A1Less peel lossGood solder blisterPretreated surfacesRecord information storageChromium freeChemical treatment

It is an object of the present invention to provide a surface-treated copper foil comprising an electrodeposited copper foil with a chromium-free rust-proofing layer which exhibits good performance in peel strength and resistance to peel loss after chemical treatment as a printed wiring board. To achieve this object, a surface-treated copper foil comprising an rust-proofing layer and a silane coupling agent layer formed on the bonding surface of an electrodeposited copper foil to an insulating resin substrate, wherein the rust-proofing layer comprises a nickel layer having a thickness by weight of 5 to 40 mg / m2 and a tin layer having a thickness by weight of 5 to 40 mg / m2 stacked in this order, and the rust-proofing layer is provided with the silane coupling layer on the surface is applied. Also a surface-treated copper foil coated with a very thin primer resin layer, comprising the surface-treated copper foil according to the present invention (without roughening treatment), and a very thin primer resin layer having a thickness by calculation of 0.5 to 5-micron meter provided on the bonding surface of the surface-treated copper foil to the insulating resin substrate is applied.

Owner:MITSUI MINING & SMELTING CO LTD

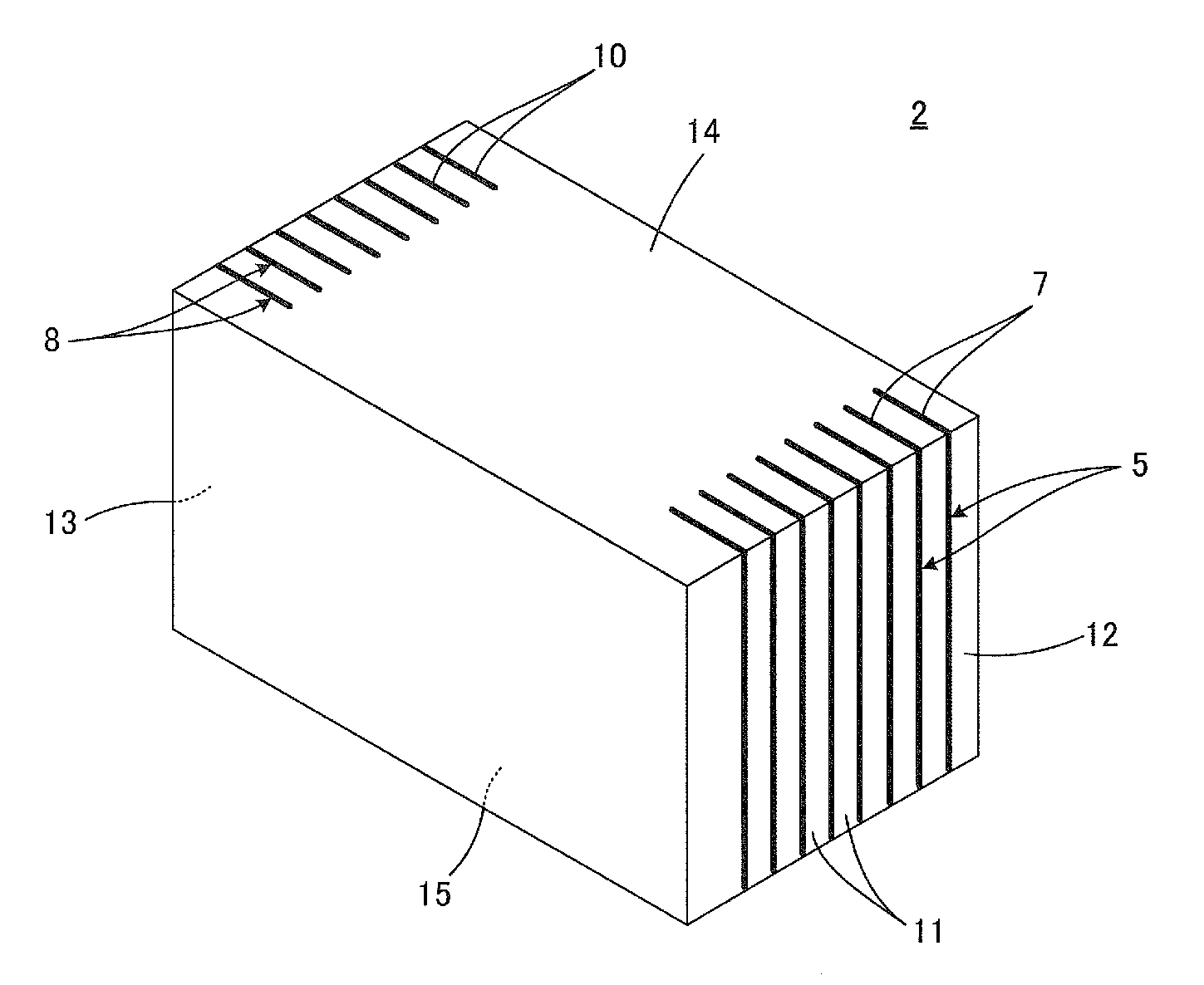

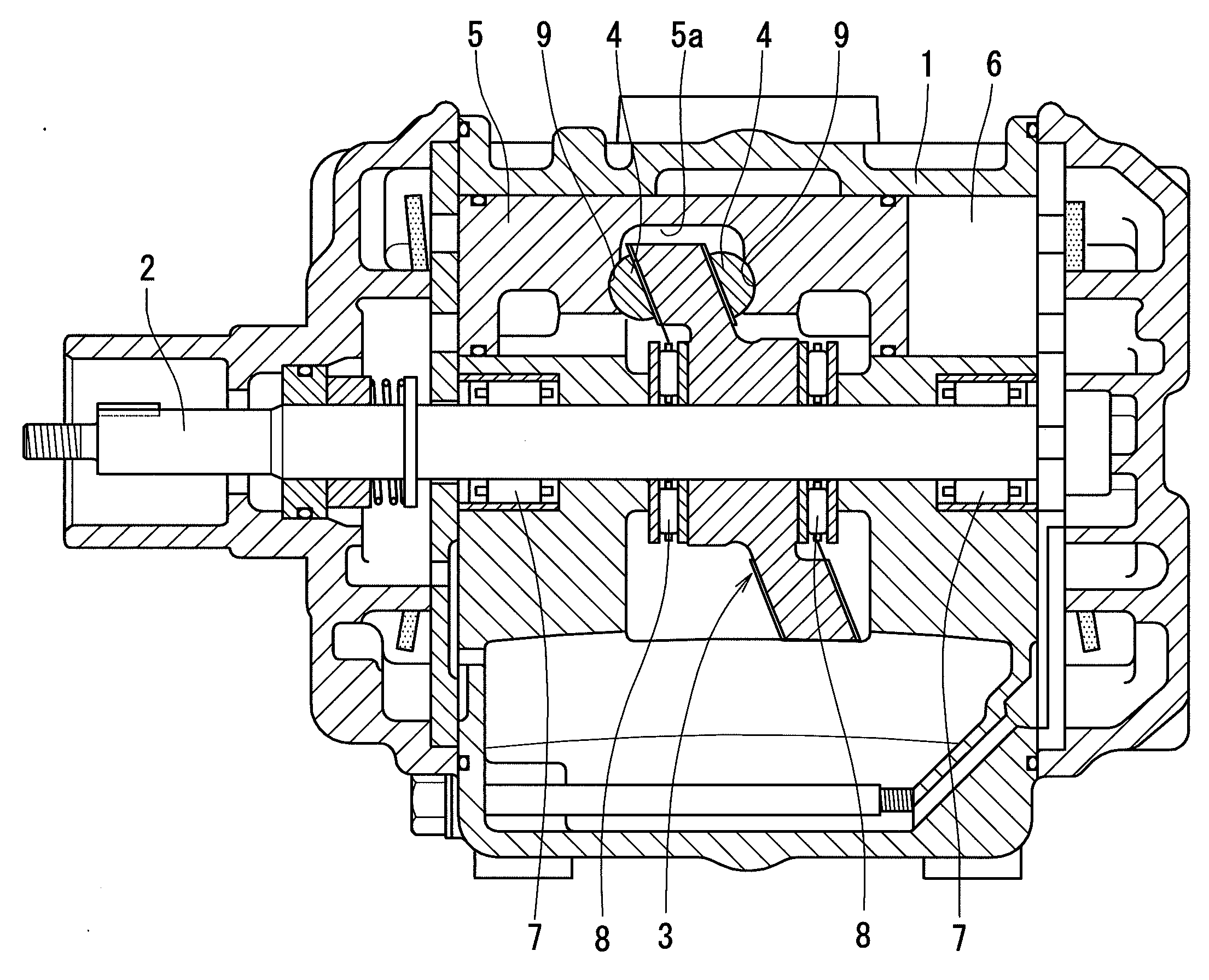

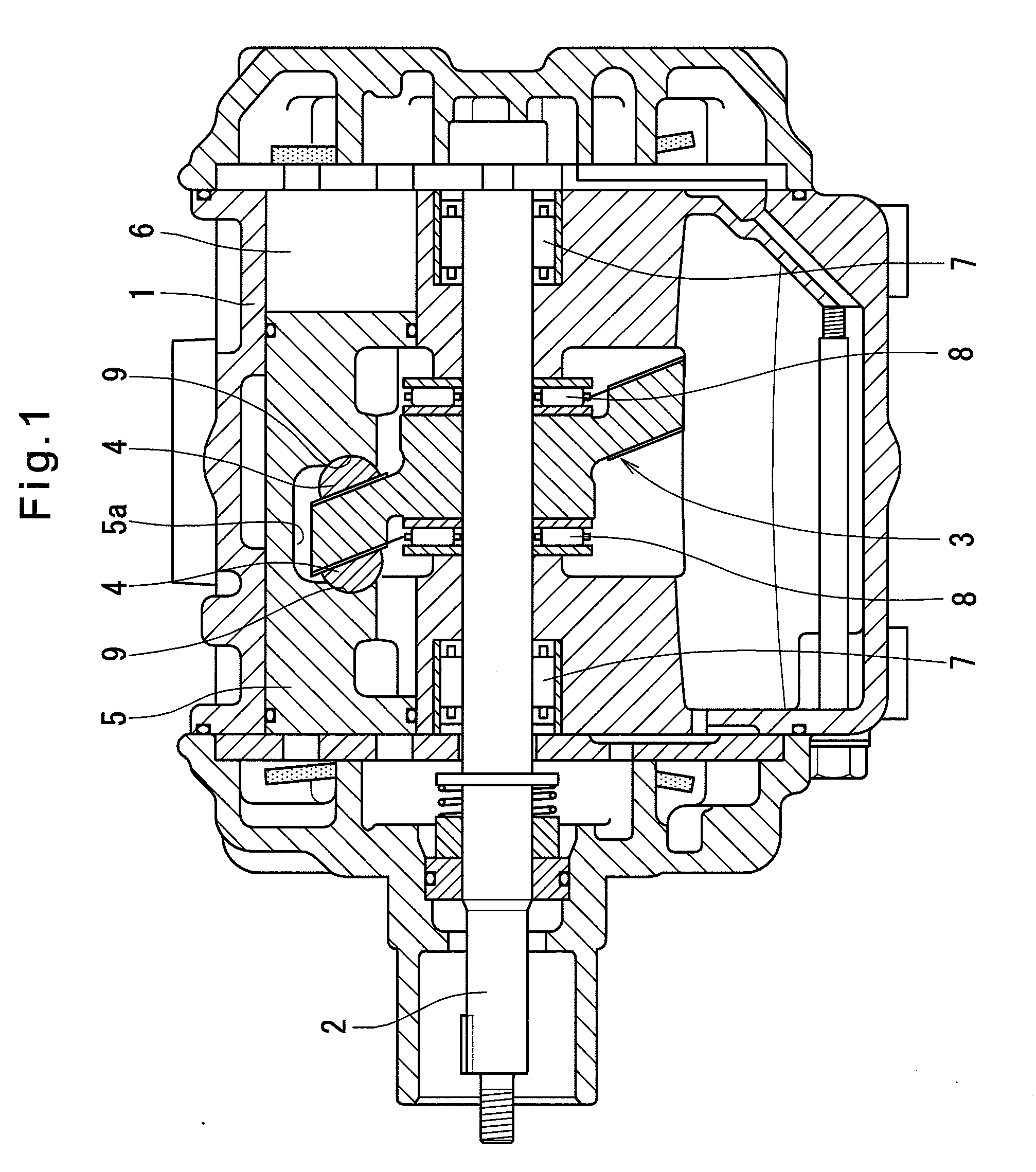

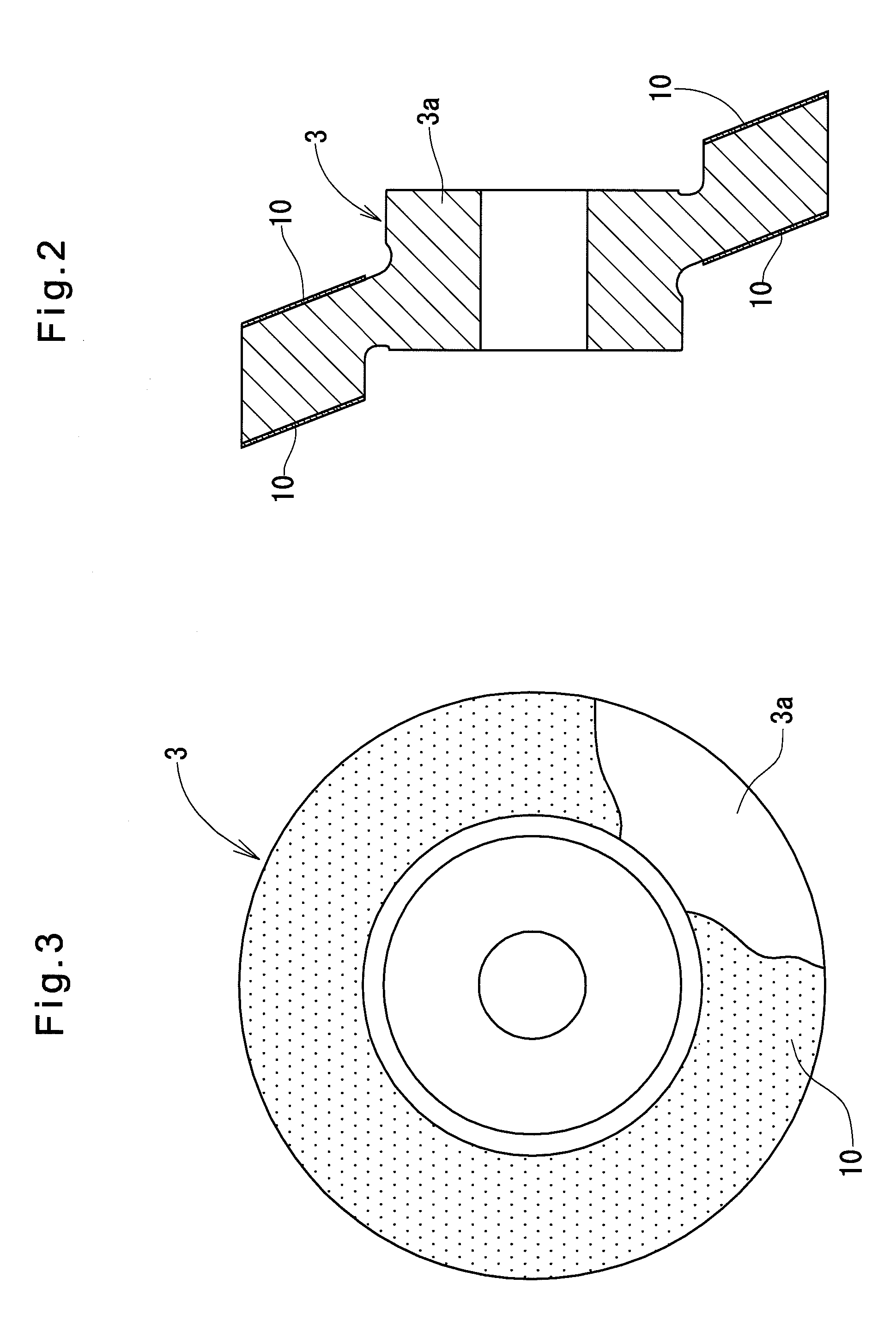

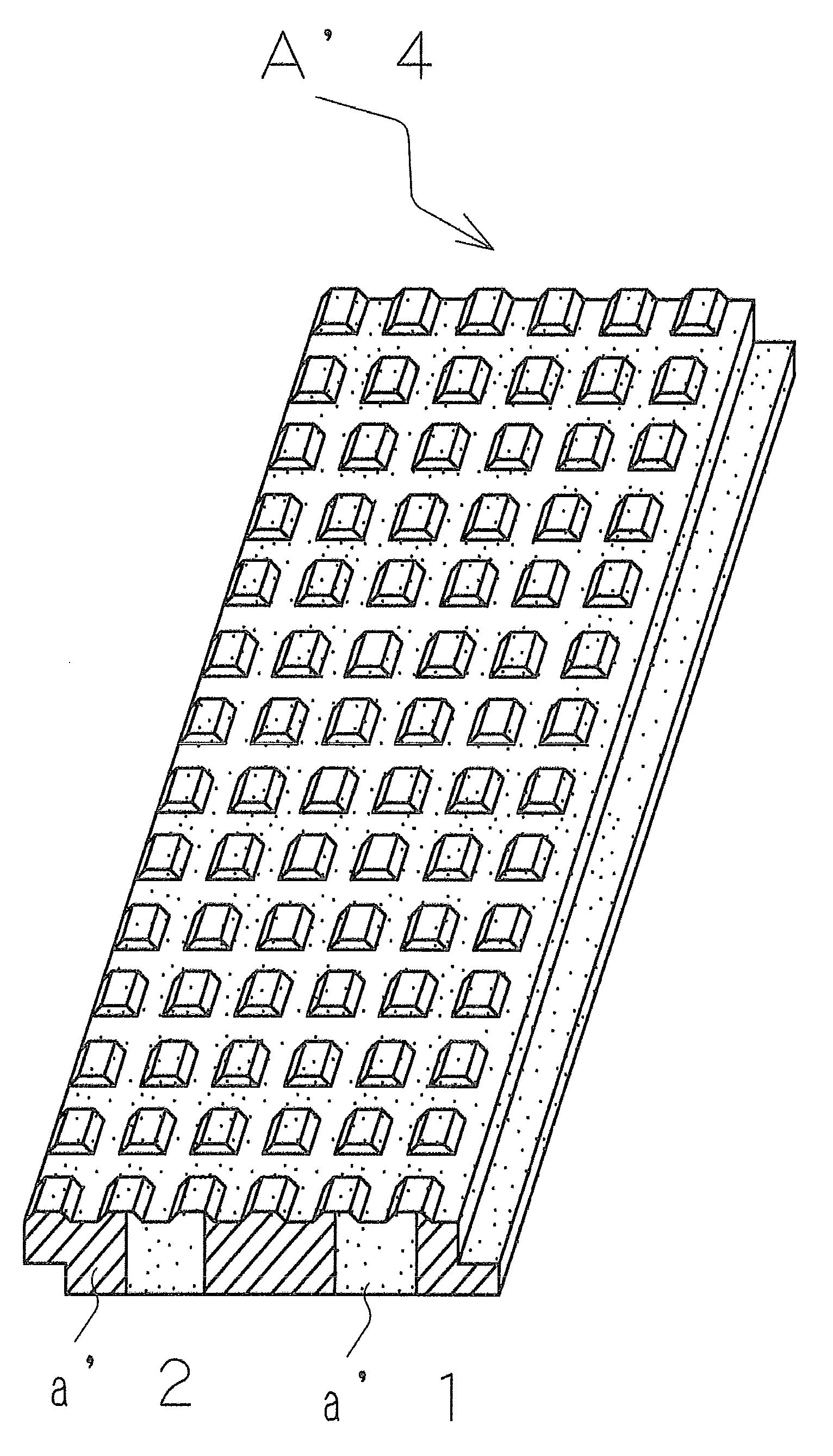

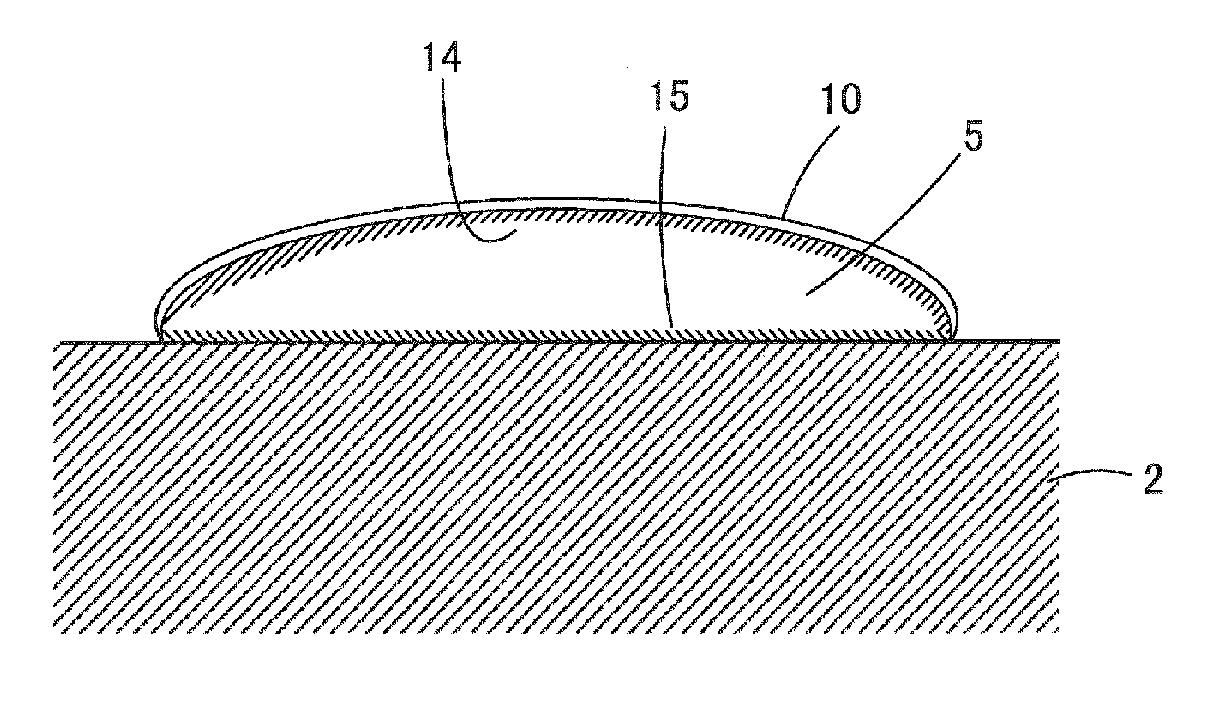

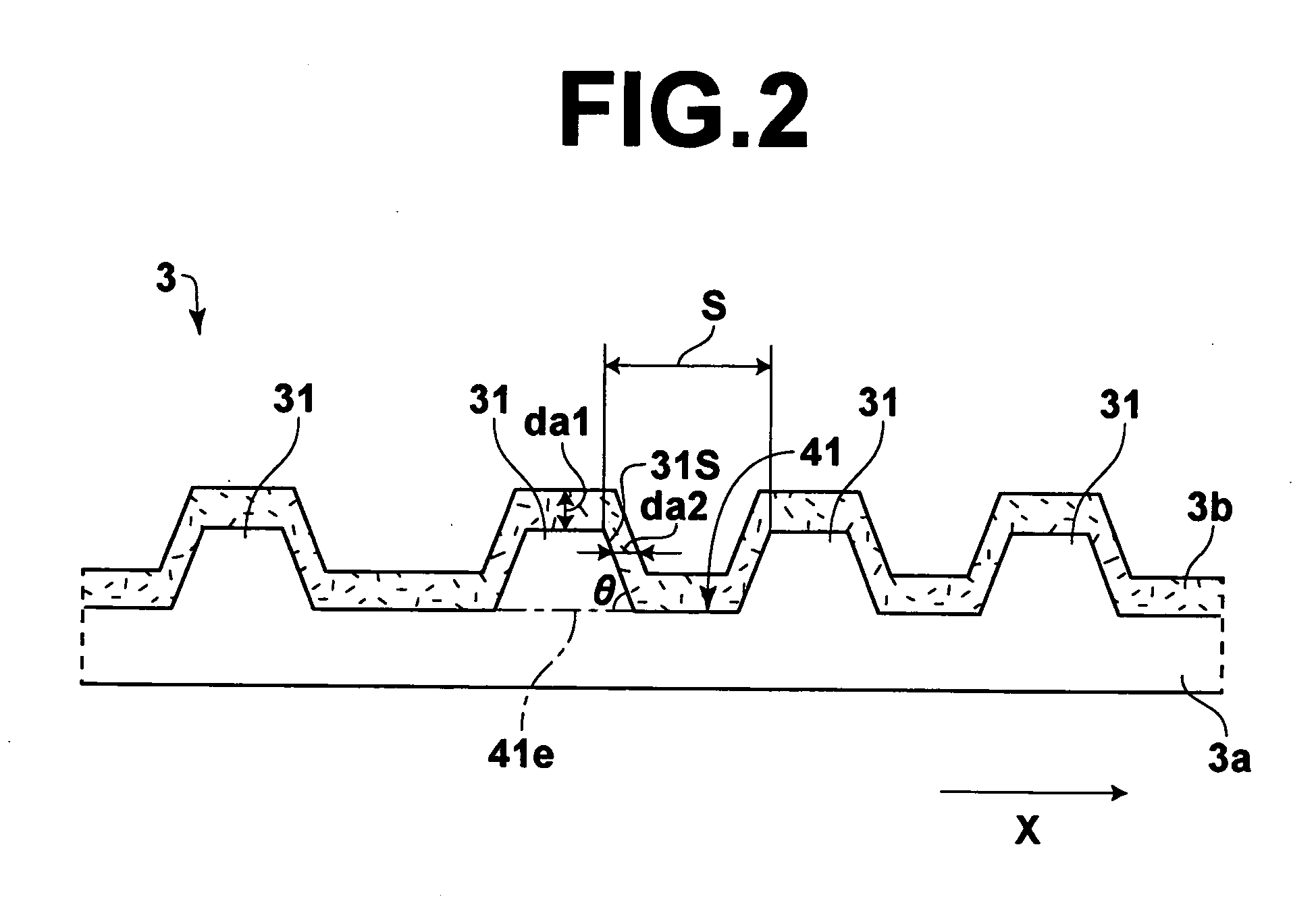

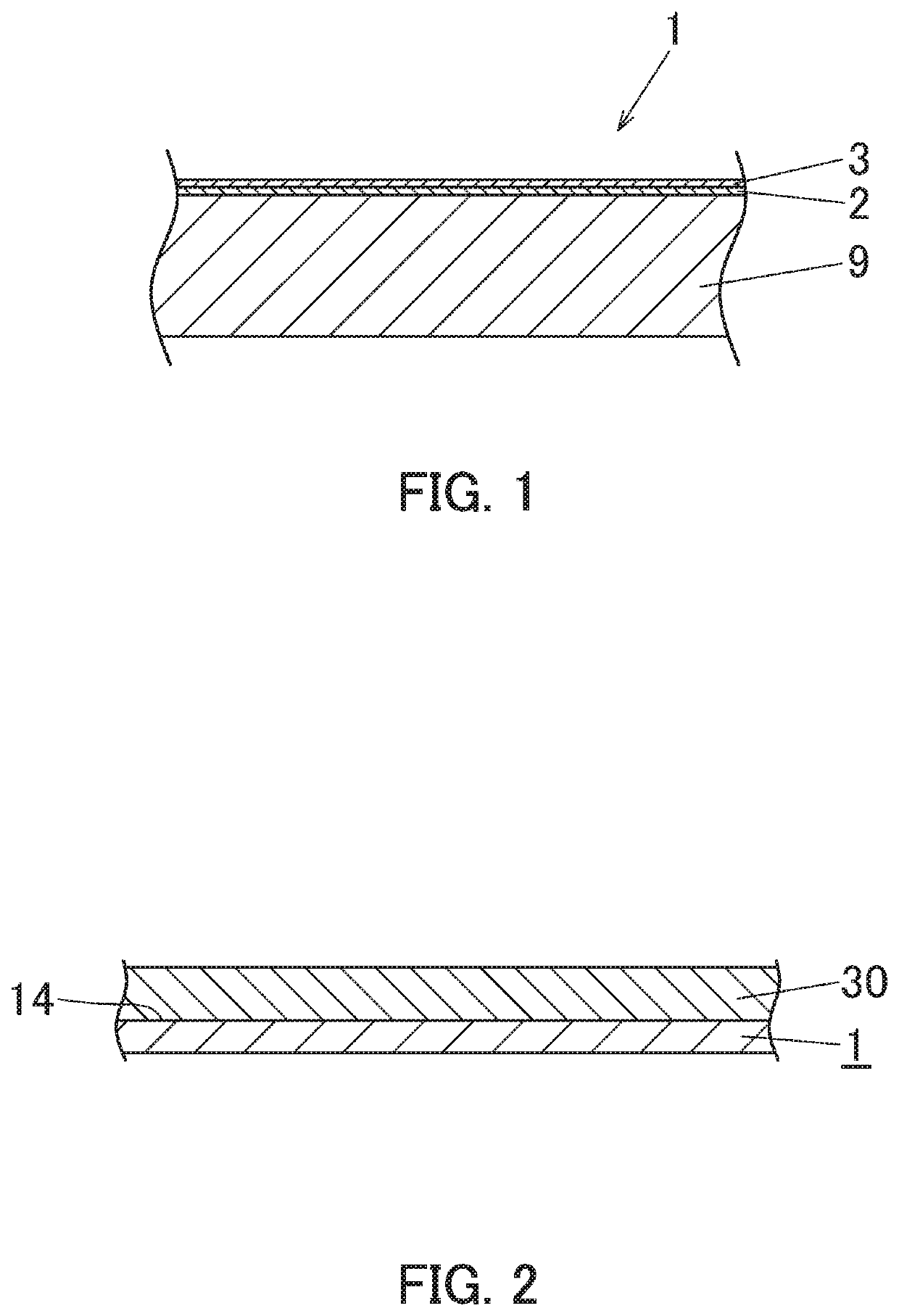

Swash plate of a swash plate type compressor and the swash plate type compressor

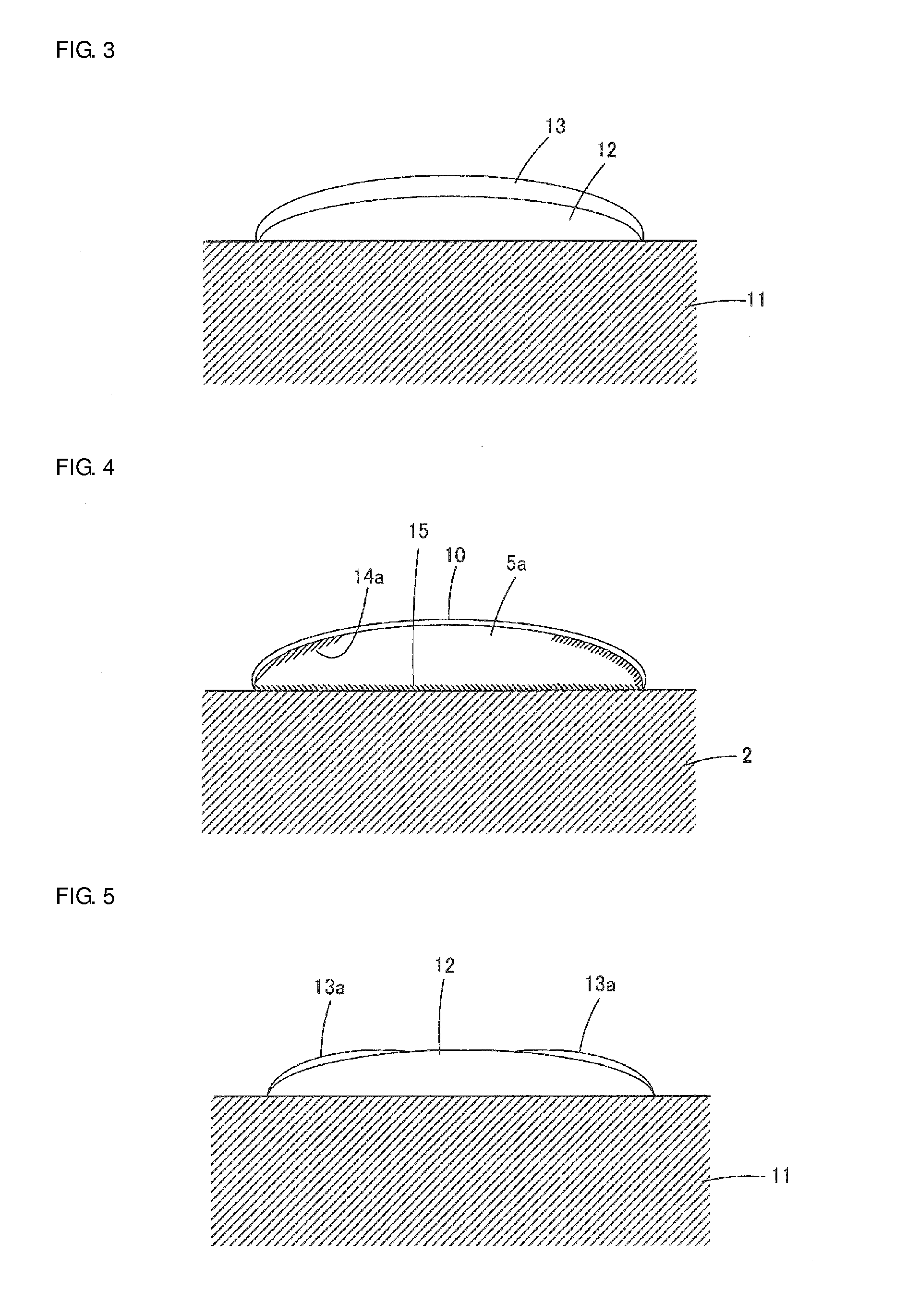

InactiveUS20100316517A1Less peelingGood surface smoothnessPositive displacement pump componentsEngine componentsCircular discSpray coating

The object of the present invention is to provide a swash plate which fulfils the basic properties required for a swash plate, which are stable boundary lubricating state by lubricating oil, without forming a metal spray coating layer comprising a copper type or aluminum type material on the surface of the substrate 3a forming the swash plate 3 of the swash plate type compressor as an intermediate layer.The substrate 3a of the swash plate 3 comprises a disk-shaped steel sheet formed by pressing a rolled steel sheet into a disk shape, and both surfaces of the disk-shaped steel sheet is ground. Thus, resin coating layers 10 containing fluororesin, which has superior seizure resistance, can be strongly fixed to the substrate without the need to form a metal spray coating layer on the surface of the substrate. This improves the durability of the swash plate type compressor using carbon dioxide gas as a refrigerant.

Owner:NTN CORP

Building material and method for manufacturing thereof

Owner:NICHIHA CORP

Glass ceramic substrate and method for producing the same

ActiveUS20140022699A1Enhanced resistance to peelingEasy to useFixed capacitor dielectricPrinted circuit aspectsMetal powderGlass-ceramic

A first paste film containing a metal powder and non-vitreous inorganic oxide is formed on a glass ceramic green sheet, and a second paste film containing a metal powder is formed on the first paste film to cover at least the edge portion of the first paste film. Then the glass ceramic green sheet and the first and second paste films are fired. As a result, a surface electrode is obtained, and then a plating layer is formed on the surface electrode. The second paste film contains less non-vitreous inorganic oxide than the first paste film and the abundance ratio of the non-vitreous inorganic oxide in the surface electrode is lower in a region bordering the plating layer than in a region bordering the glass ceramic layer at least in an edge portion of the surface electrode.

Owner:MURATA MFG CO LTD

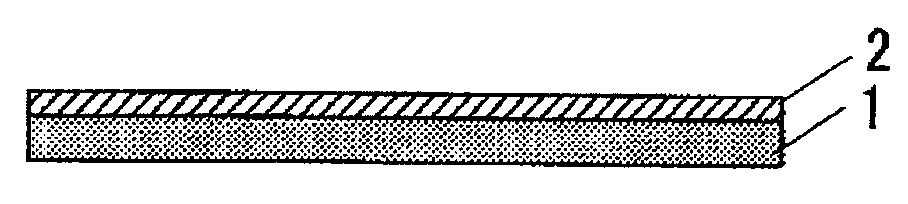

Method of forming thin metal film and thin metal film manufactured by the forming method

InactiveUS20080311414A1Improve conductivityImprove adhesionRadiation applicationsPretreated surfacesThin metalMetal particle

An under-layer 2 comprising a coupling agent having a metal element to be transformed to an oxide is disposed on the surface of an inorganic oxide substrate 1, and a liquid containing micro-fine metal particles dispersed therein is coated on the under-layer 2 to form a micro-fine metal particle layer 3. Then, temperature is elevated to a metallizing temperature of the micro-fine metal particles, to form a thin metal film layer 5.

Owner:PANASONIC CORP

Surface-treated copper foil, manufacturing method of the surface-treated copper foil, and surface-treated copper foil coated with very thin primer resin layer

InactiveUS8187723B2Good solder blisterImprove adhesionPretreated surfacesRecord information storageChromium freeChemical treatment

Owner:MITSUI MINING & SMELTING CO LTD

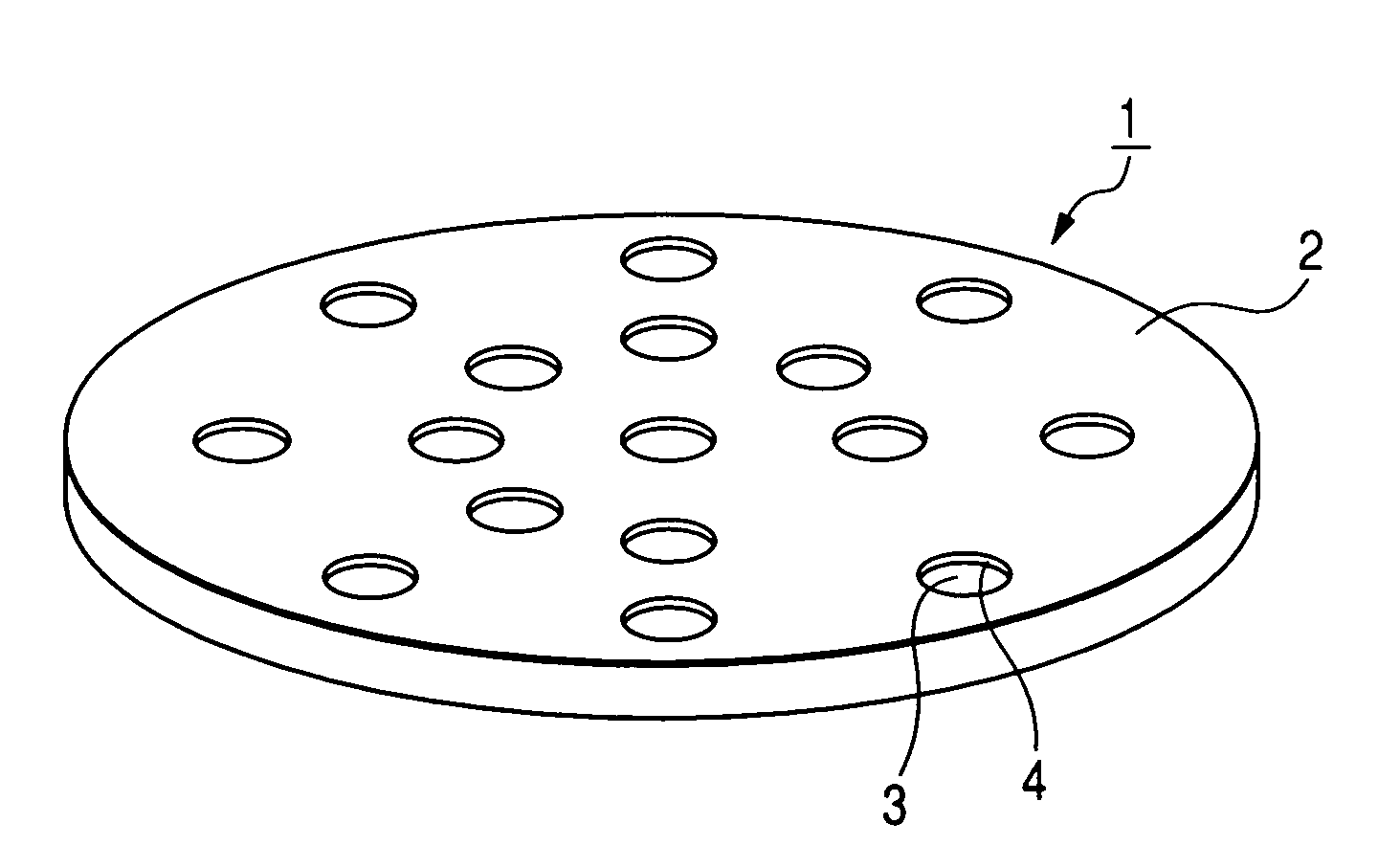

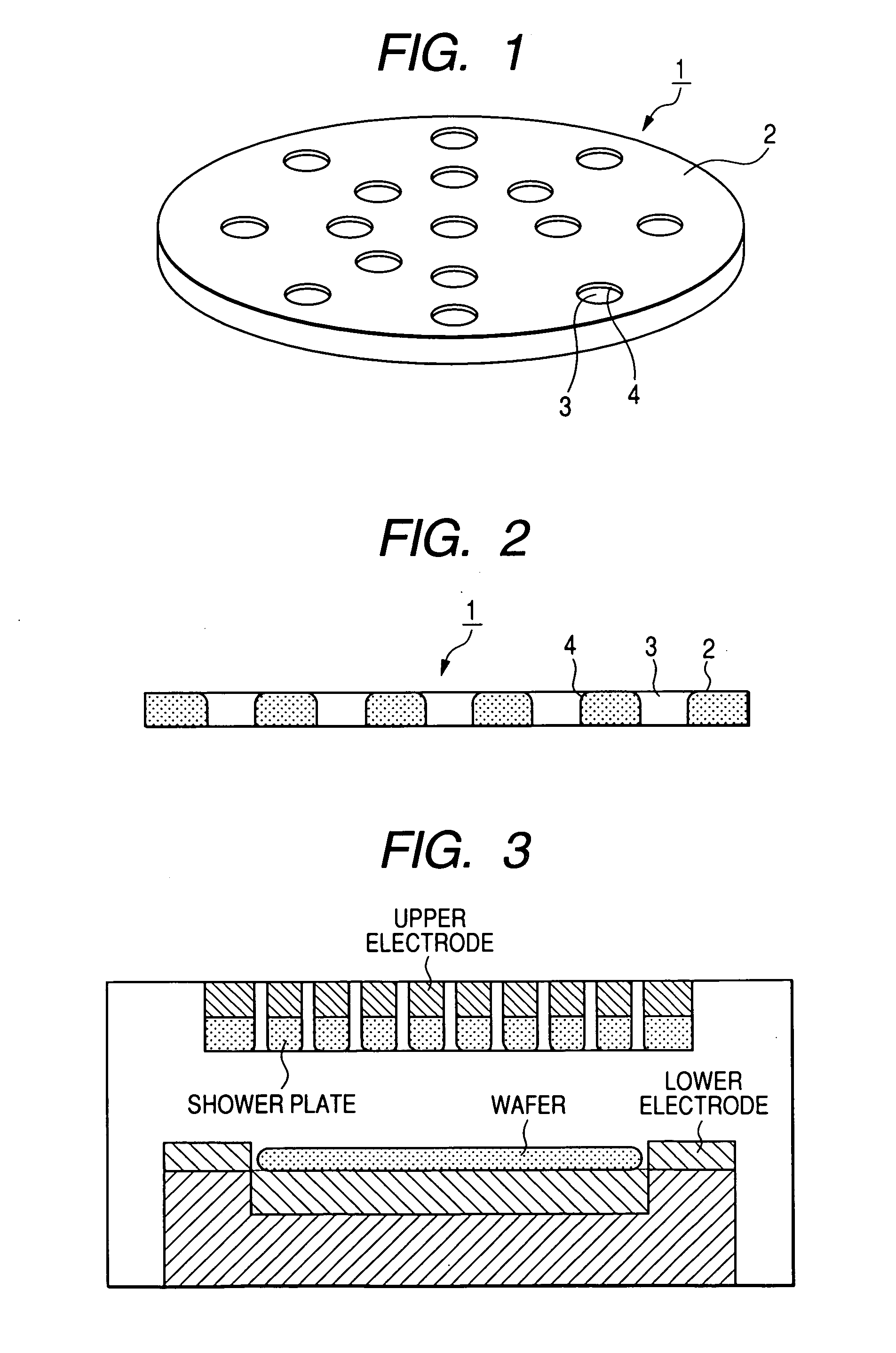

Gas dispersion plate and manufacturing method therefor

InactiveUS20070079934A1Improve corrosion resistanceImprove production yieldElectric discharge tubesSemiconductor/solid-state device manufacturingSand blastingDevice material

To provide an inexpensive gas dispersion plate having a high corrosion resistance to halogen-based corrosive gasses and a plasma thereof, and capable of preventing particle generation from the gas hole, thereby contributing to an improvement in the production yield of the semiconductor devices. The gas dispersion plate includes one or plural gas holes in a base material formed by a Y2O3 ceramic material having a relative density of 96% or more, in which an edge part of the gas hole is formed by a sand blasting process into a rounded shape with a radius of curvature of 0.2 mm or more.

Owner:COVALENT MATERIALS CORP

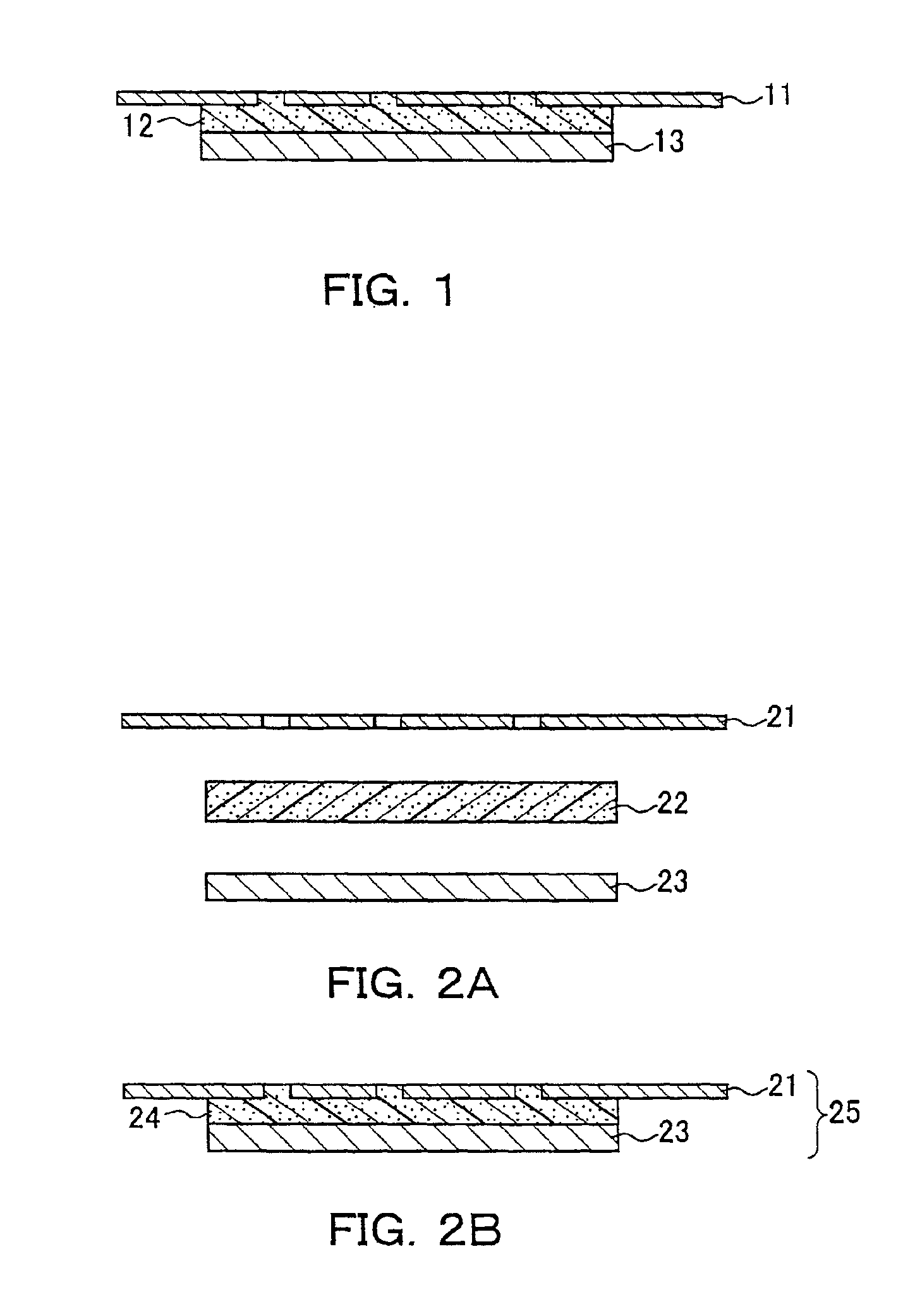

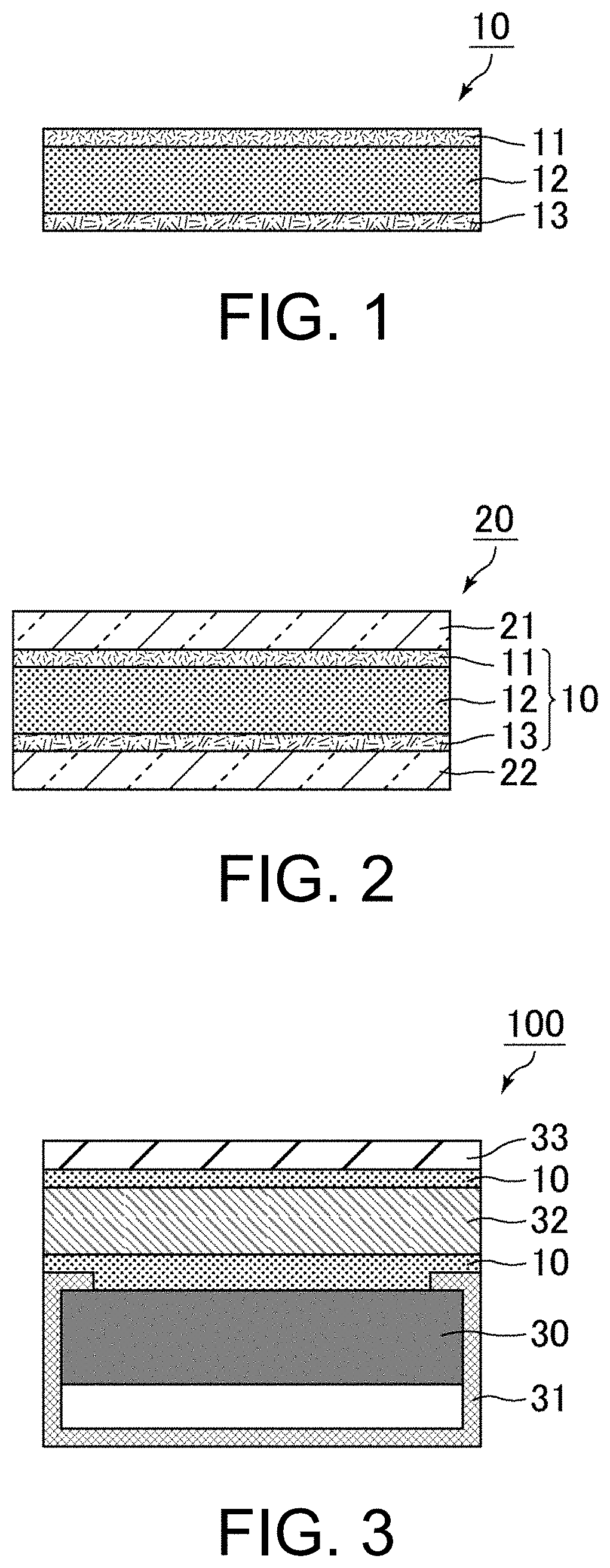

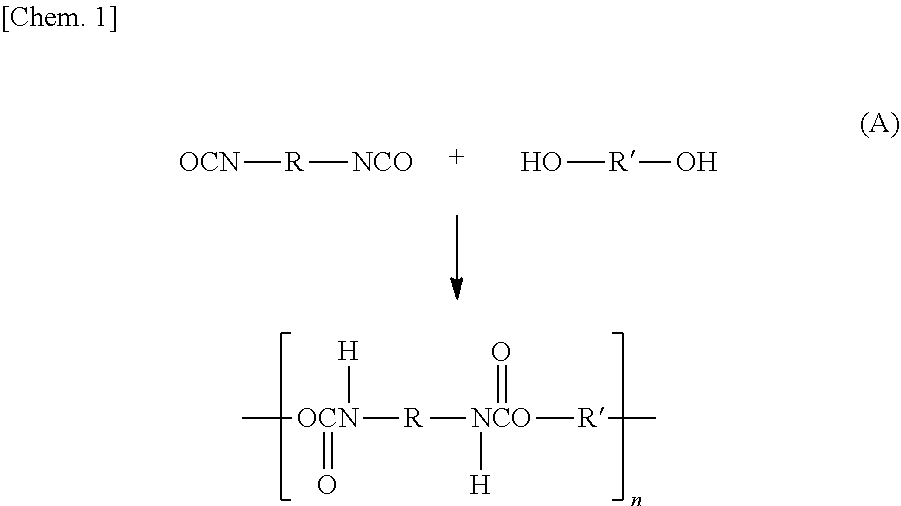

Transparent adhesive optical sheet, laminate and bonded structure

ActiveUS20200239738A1Improve handleabilityExcellent flexibilityAdhesive articlesPolyureas/polyurethane adhesivesElastic modulusPolymer chemistry

The present invention provides an optically clear adhesive sheet that has excellent flexibility and prevents delay bubbles in high temperature and high humidity environments. The optically clear adhesive sheet of the present invention sequentially includes a first surface-adhesive layer, an intermediate adhesive layer, and a second surface-adhesive layer. The first surface-adhesive layer and the second surface-adhesive layer each have a higher storage elastic modulus at 85° C. than the intermediate adhesive layer. The first surface-adhesive layer and the second surface-adhesive layer each have a storage elastic modulus at 85° C. of 3.0×104 Pa or higher and 30.0×104 Pa or lower. The intermediate adhesive layer has a storage elastic modulus at 85° C. of 1.0×104 Pa or higher and 15.0×104 Pa or lower. The intermediate adhesive layer contains polyurethane.

Owner:BANDO CHEM IND LTD

Anti-adhesive saw-dust molding sand and preparation method thereof

InactiveCN103495697AImprove smoothnessImprove adhesionFoundry mouldsFoundry coresSodium BentonitePollution

An anti-adhesive saw-dust molding sand is characterized in that the anti-adhesive saw-dust molding sand is prepared by, by weight, 200-220 parts of quartz sand, 30-35 parts of bentonite, 40-45 parts of Datong soil, 30-35 parts of saw dust, 10-15 parts of rice husk meal, 30-35 parts of fangzi soil, 18-25 parts of Longyan soil, 15-20 parts of corn flour, 5-6 parts of silane coupling agents KH550, 2-3 parts of ammonium dihydrogen phosphate, 3-4 parts of cotton seed oil and the certain amount of water. By using the quartz sand and the bentonite and the like to calcinate, calcinate at high temperature and combine and dispersing and grinding the fangzi soil and the like, the molding sand has excellent smoothness, cohesiveness, toughness and plasticity, and cohesiveness of the molding sand is improved by grinding the saw dust, the rice husk meal and the silane coupling agents KH550. By using the saw dust, the corn flour and the like, high-temperature collapsibility is improved, and the molding sand is pollution-free and low in cost. Besides, the molding sand is anti-adhesive to cast pieces, causes few peeling of the cast pieces and is good in economic benefits.

Owner:HEFEI CITY TENVER PRECISION CASTING

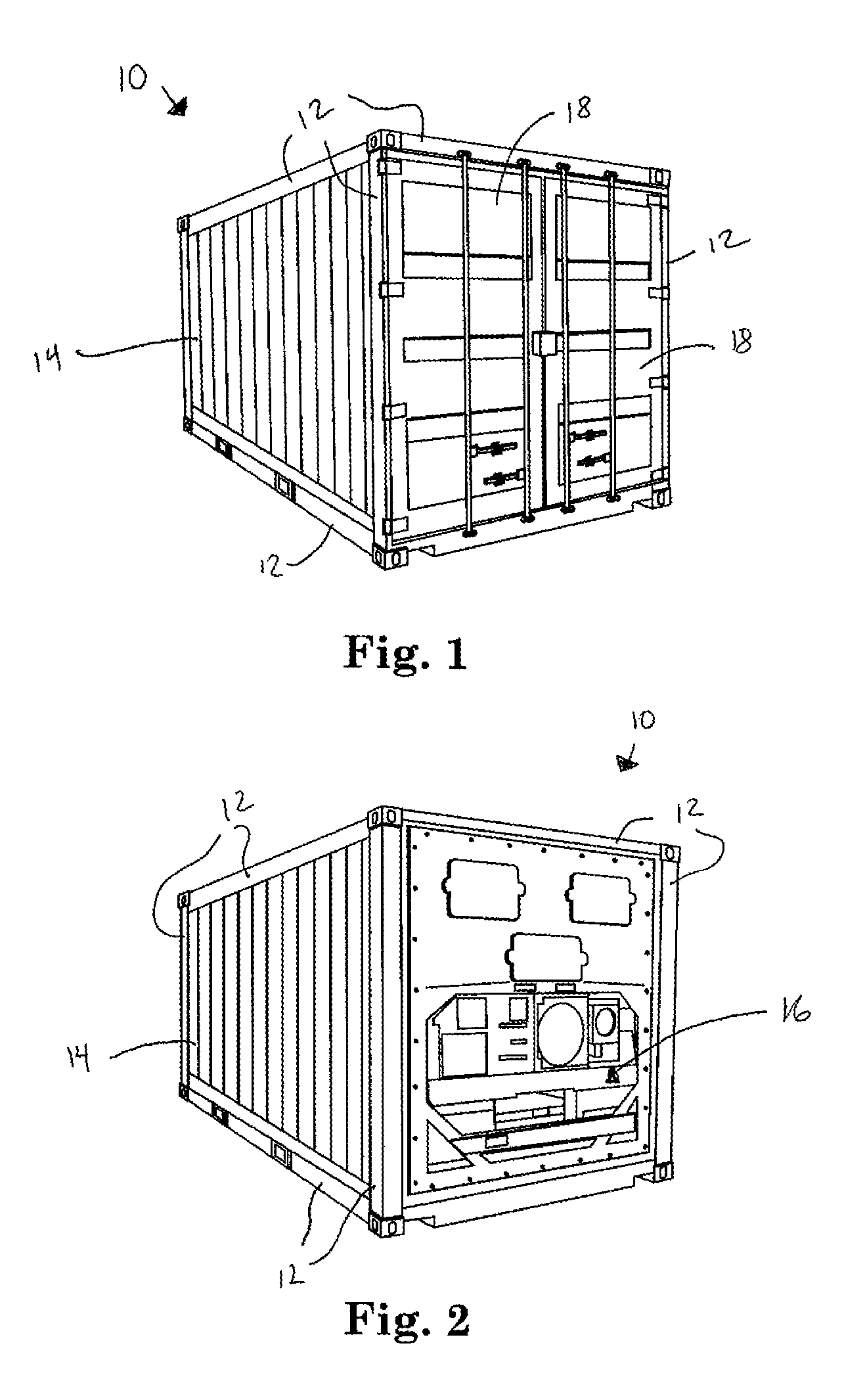

Water-based coating system with improved adhesion to a wide range of coated and uncoated substrates including muffler grade stainless steel

InactiveUS9080060B2Improve adhesionLow VOC emissionFilm/foil adhesivesAnti-corrosive paintsWater basedCoating system

The present invention provides a water-based coating system that can be used to form a durable, abrasion resistant, tough, protective coating on a wide range of substrates. The coating system advantageously has excellent adhesion properties and can be directly coated onto stainless steel surfaces without requiring an intervening primer layer. Primer layers or other types of coatings can be used in combination with the coating system of the present invention if desired, however. The coating system is particularly effective for protecting metal-containing substrates such as intermodal, refrigerated cargo containers. The resultant coatings are flexible and impact resistant. Being water-based, the coating compositions have lower VOC emissions and less residual odor than solvent-based compositions.

Owner:SWIMC LLC

Preparation method of medicine for treating beriberi and athlete's foot

InactiveCN105287628AGood for treating beriberiShort course of treatmentSalicyclic acid active ingredientsAntimycoticsSalicylic acidBiology

The invention discloses a preparation method of a medicine for treating beriberi and athlete's foot. The medicine is prepared from the following raw materials by weight: A: 50-80 parts of salicylic acid, 10-50 parts of boric acid, 1-5 parts of menthol and 1-8 parts of talcum powder; B: 0.1-5 parts of potassium permanganate powder; C: 0.1-20 parts of glacial acetic acid; the raw materials A, B and C can be separately prepared into medicine powder for sub-packaging; the raw materials A and B can be separately pressed into medicine blocks. The medicine has a good treating effect on beriberi, has the efficacies that the treating course is short and the treating efficiency is high, can reduce dry cracking and peeling at an affected part, can relieve pain of a patient, and has the advantages that a lubricous and cool feeling is achieved, beriberi can be thoroughly cured once, and recurrence is avoided.

Owner:阮少康

Production technology of pattern leather

ActiveCN104946823AConsistent colorRich varietyPolyurea/polyurethane coatingsLeather surface finishingLacquerGlycol ethers

The invention discloses a production technology of pattern leather, and belongs to the technical field of leather production. The technology comprises the steps of performing a leather pretreatment process, performing an finishing process and performing a post treatment process, wherein in the step of performing the post treatment process, leather subjected to the finishing process is pasted with a film, then glycol ether (ECS) is sprayed to a film pasted surface of the leather, and finally the pattern leather is obtained by paint coating. The pattern leather produced by the production technology is consistent and uniform in color; various colored leather products can be presented by pasting the films, so that the requirements of a customer are met; in addition, the phenomena of layer falling of the film pasted leather after the paint coating can be reduced greatly only by adopting a glycol ether surface breaking method; the brightness maintaining valid time after paint film forming is long; and a color fresh preservation degree is high.

Owner:河南博奥皮业有限公司

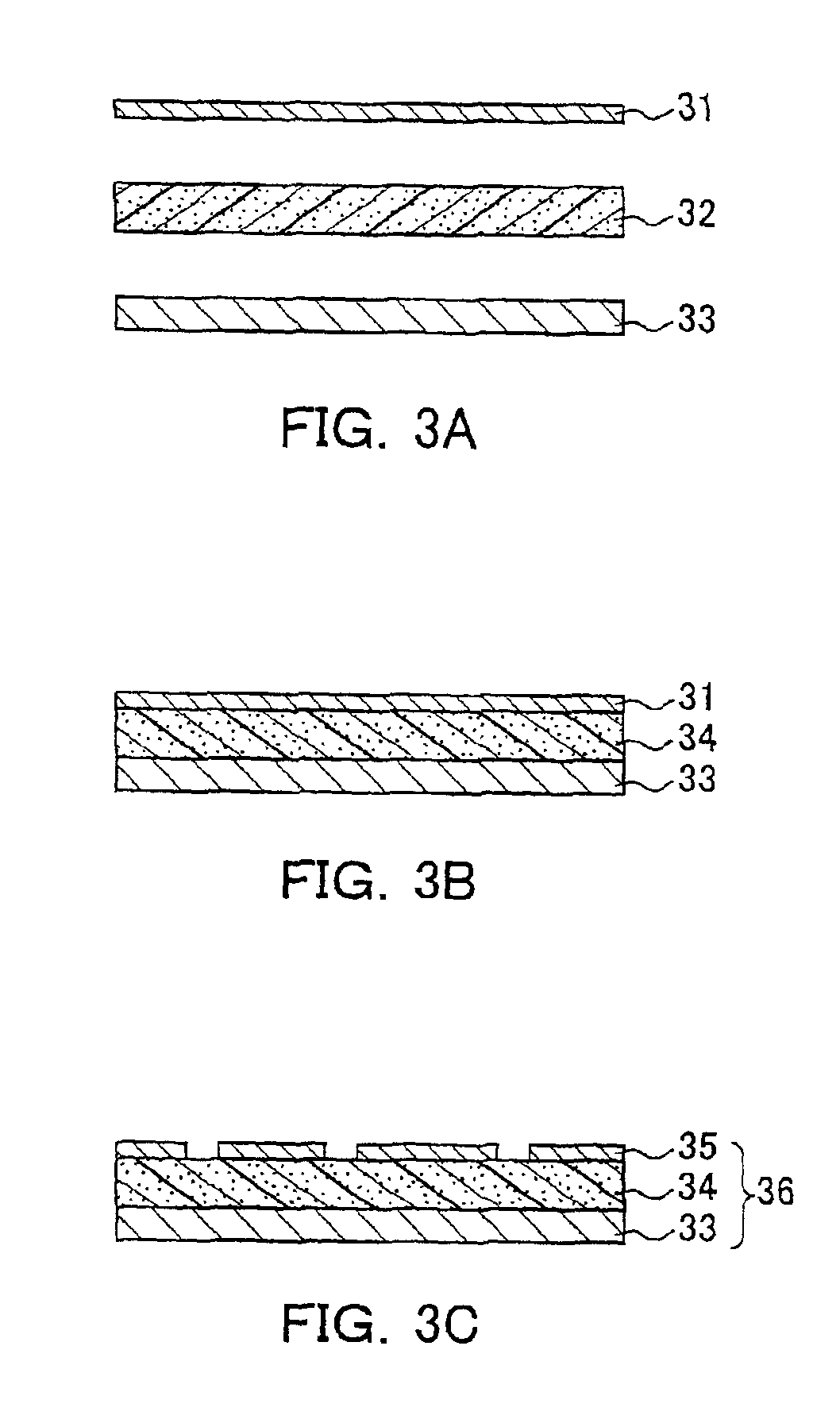

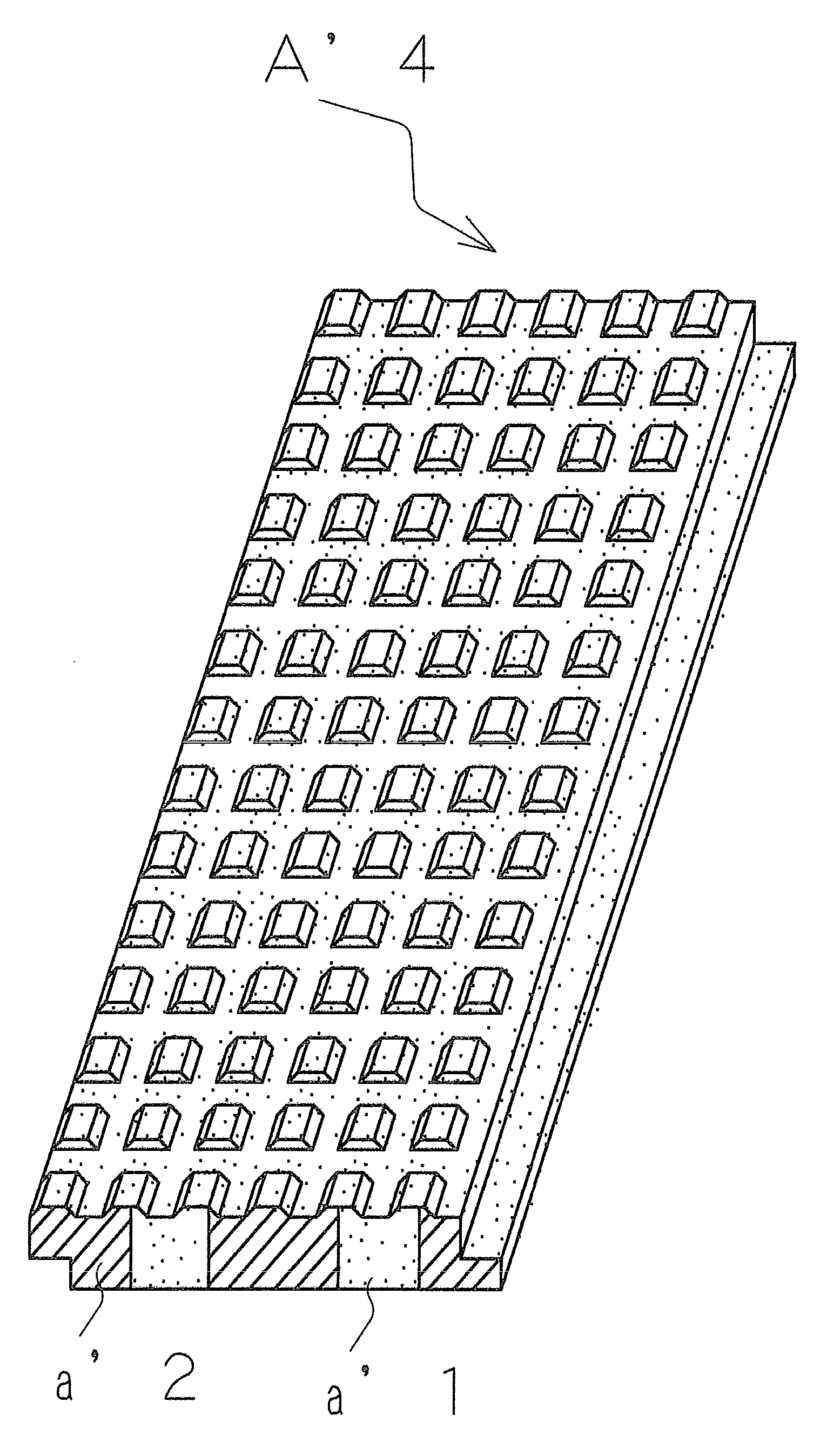

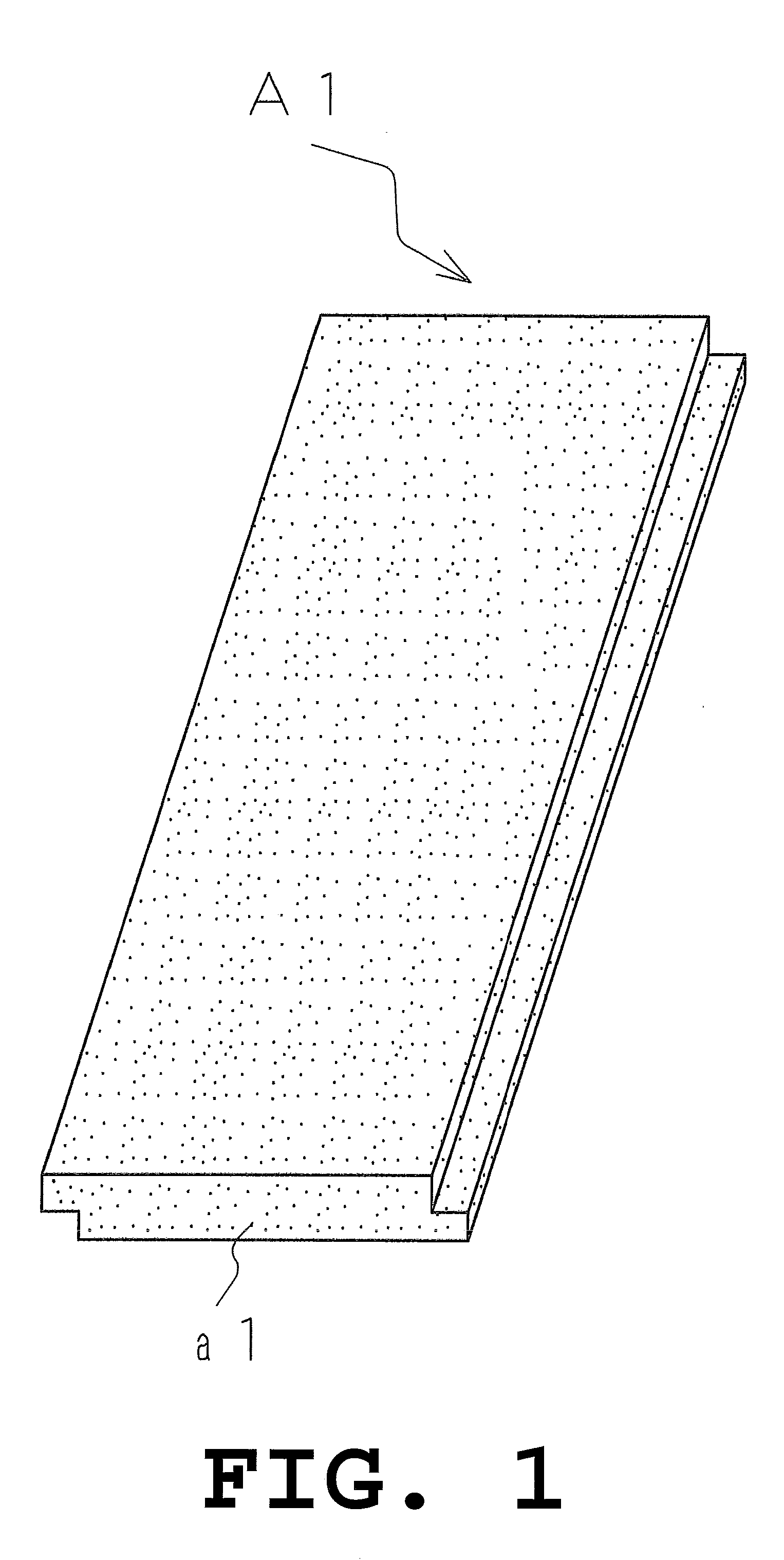

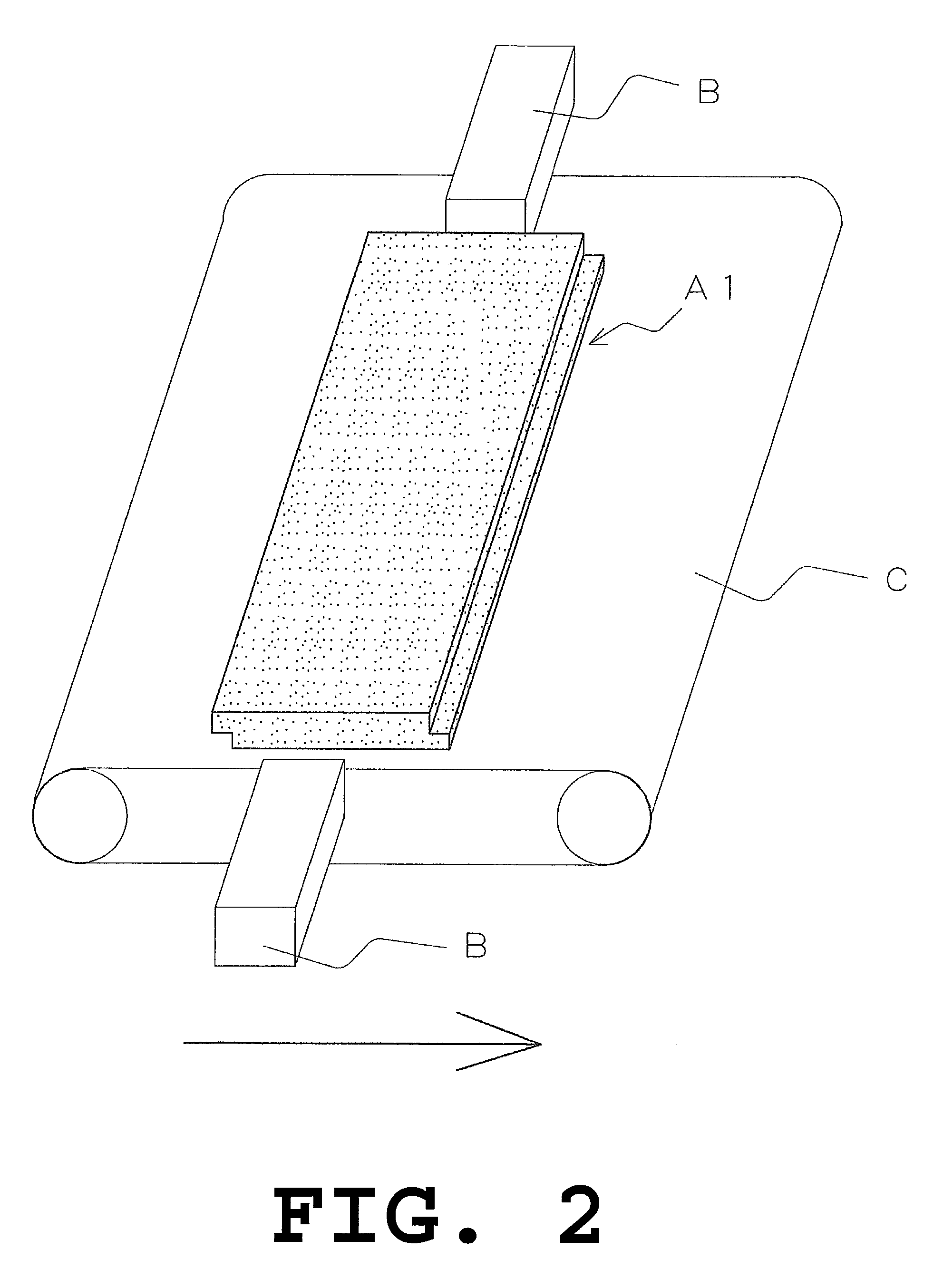

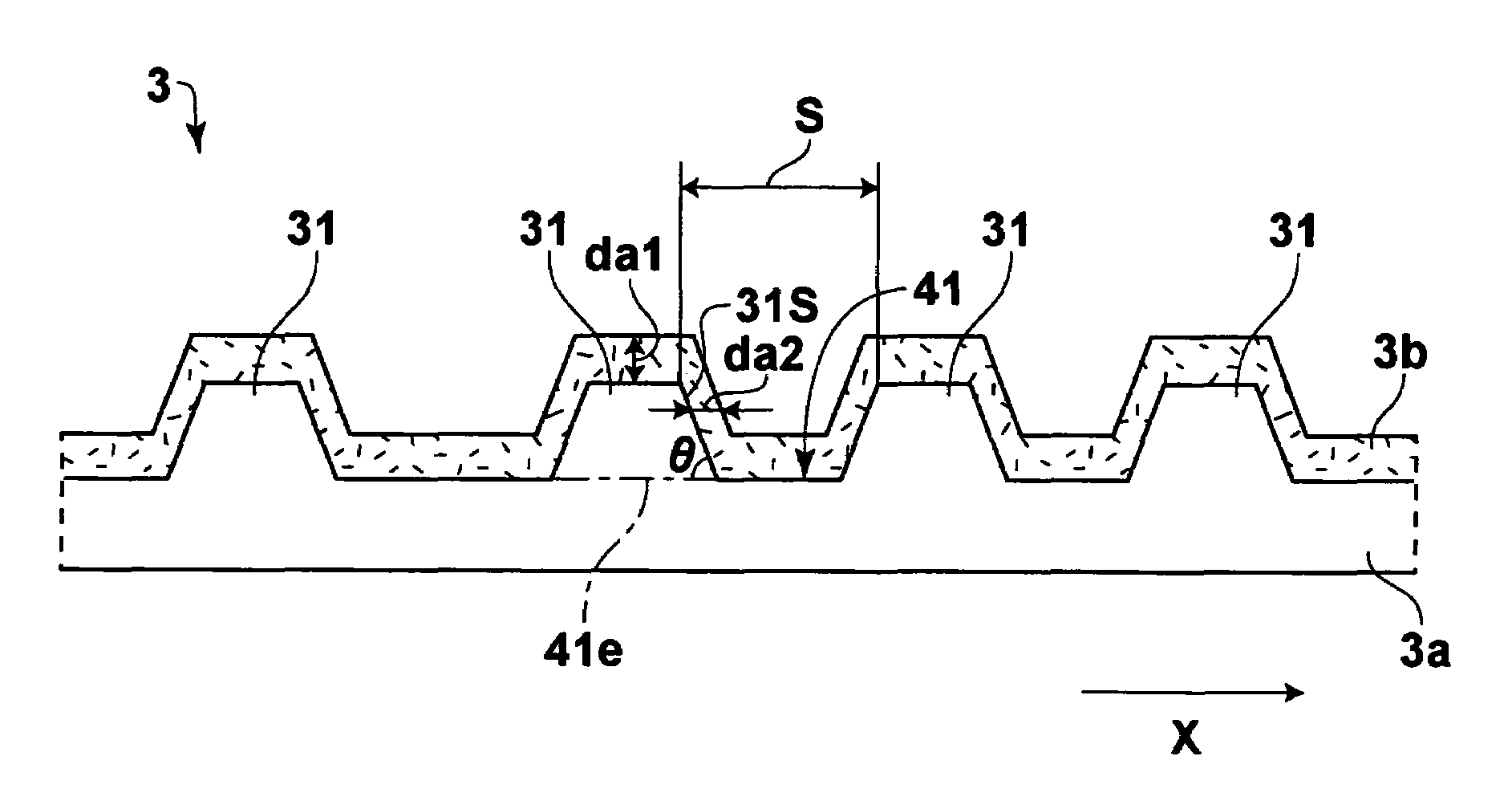

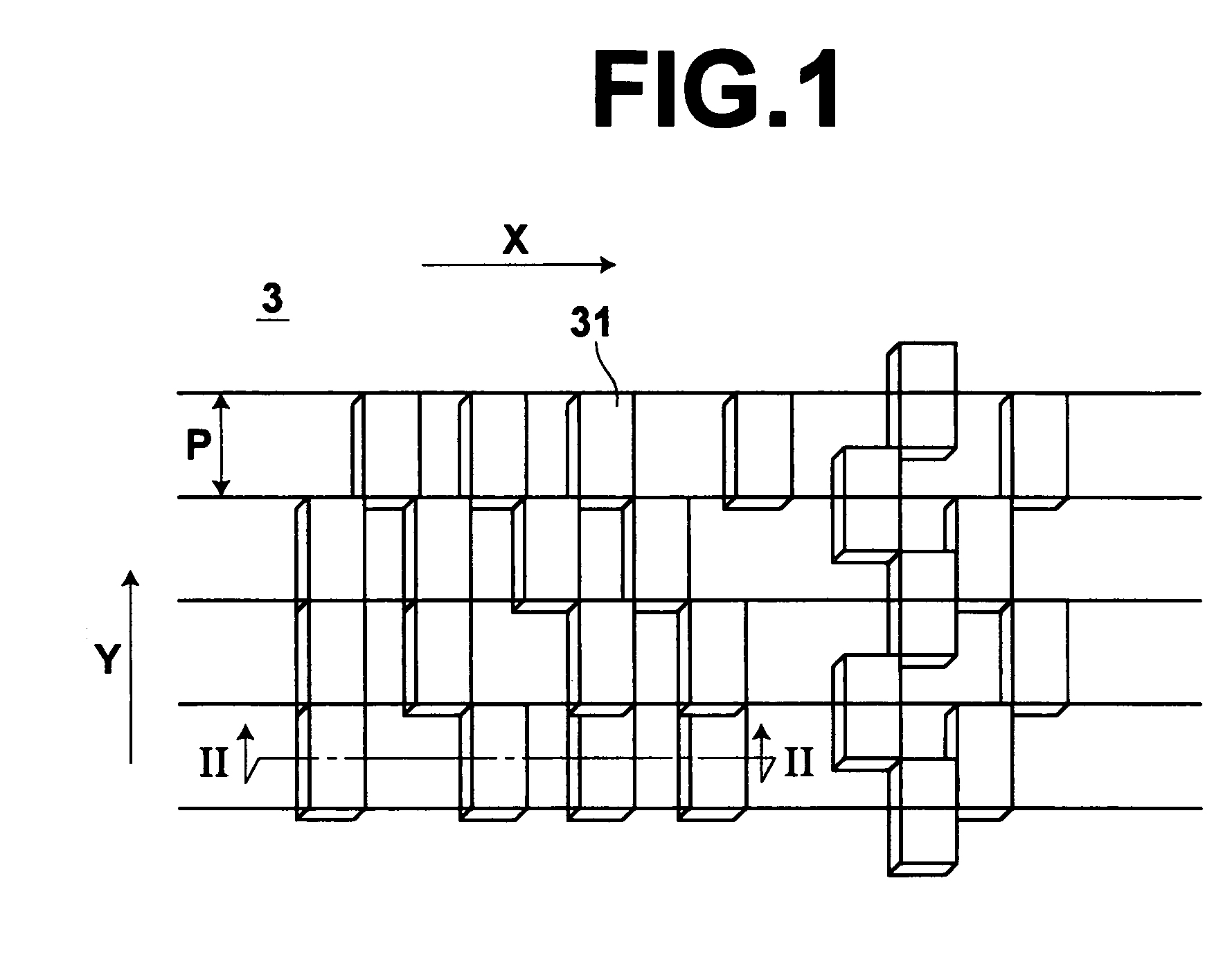

Master information carrier for magnetic transfer and magnetic transfer method

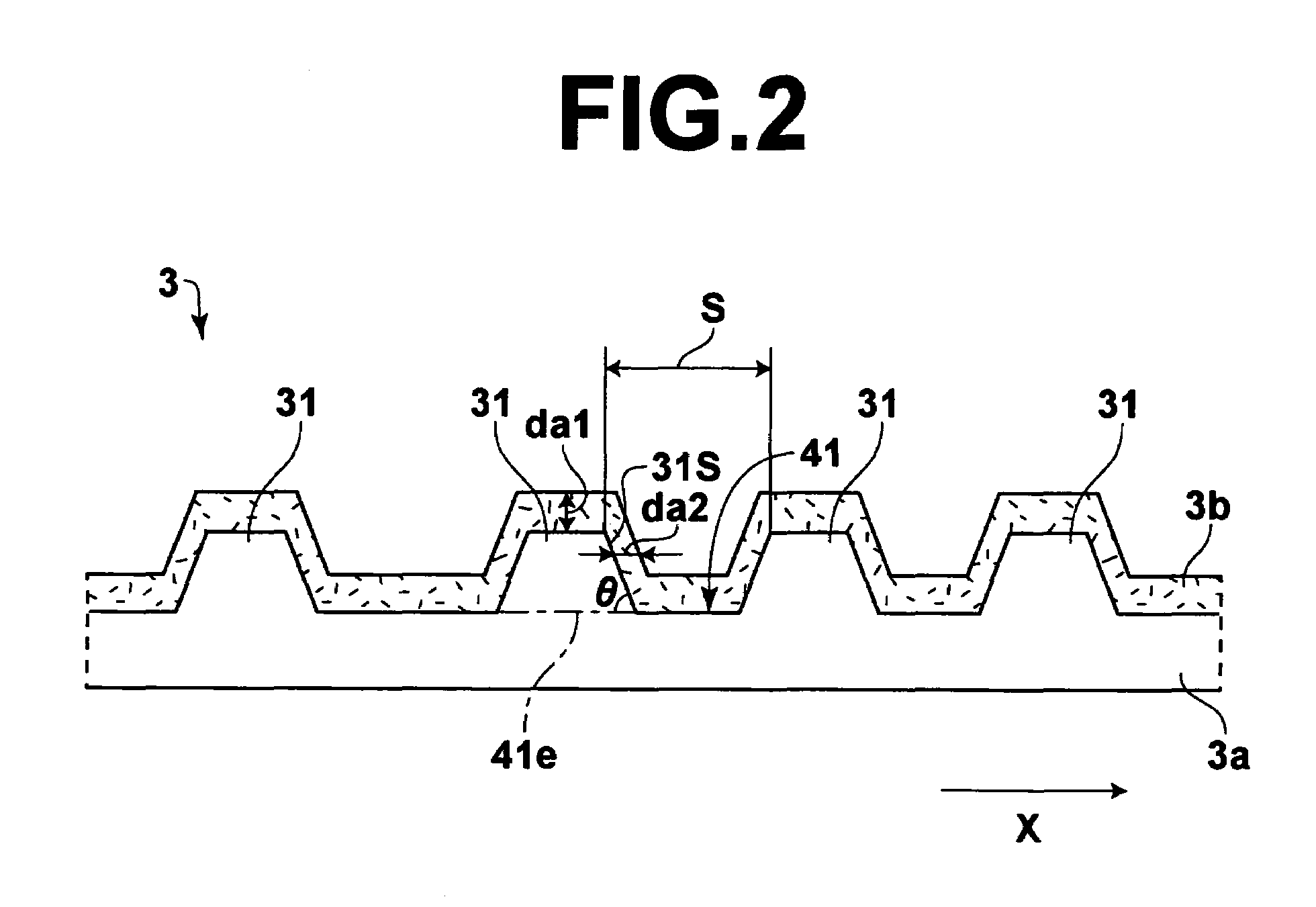

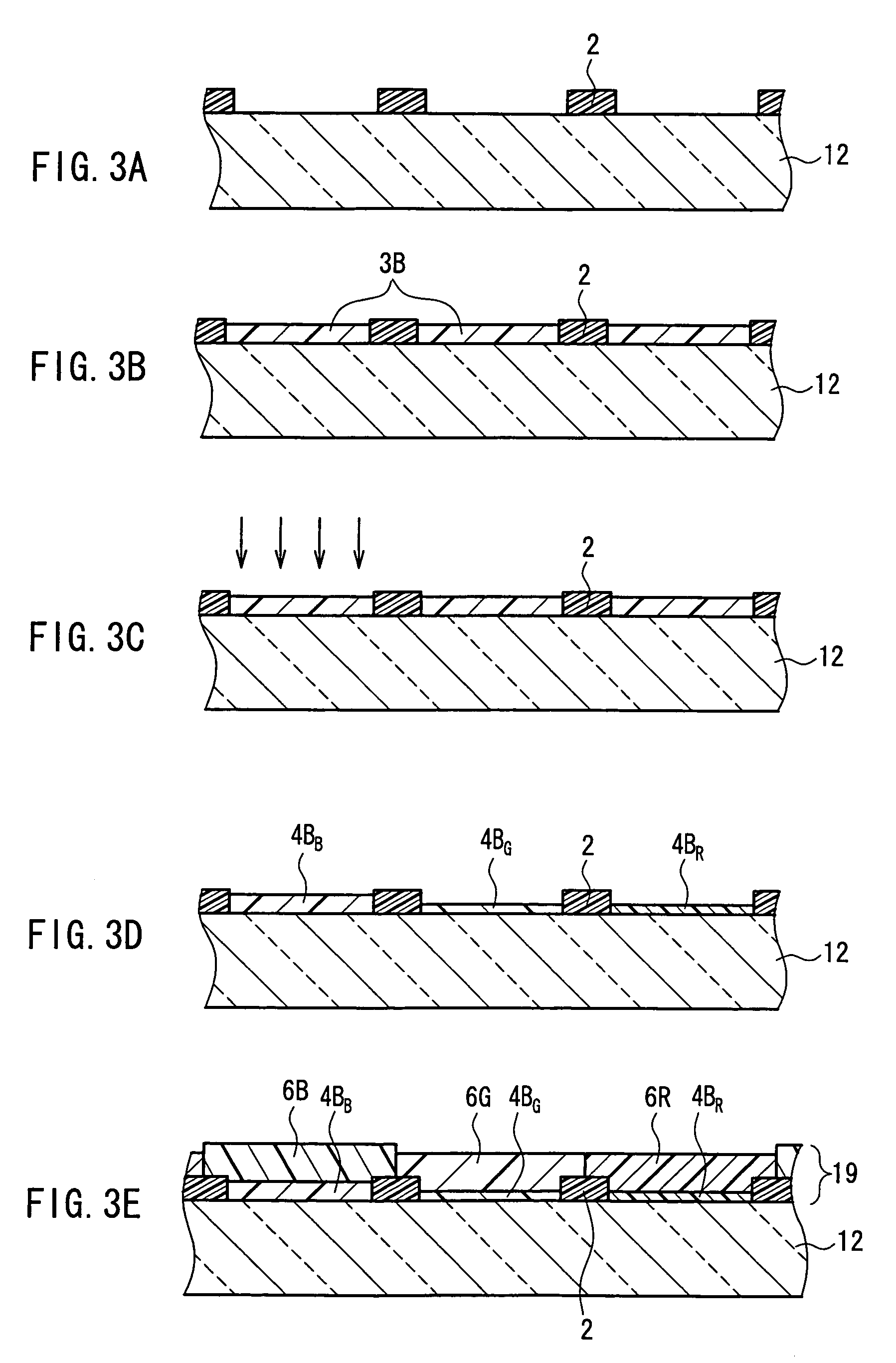

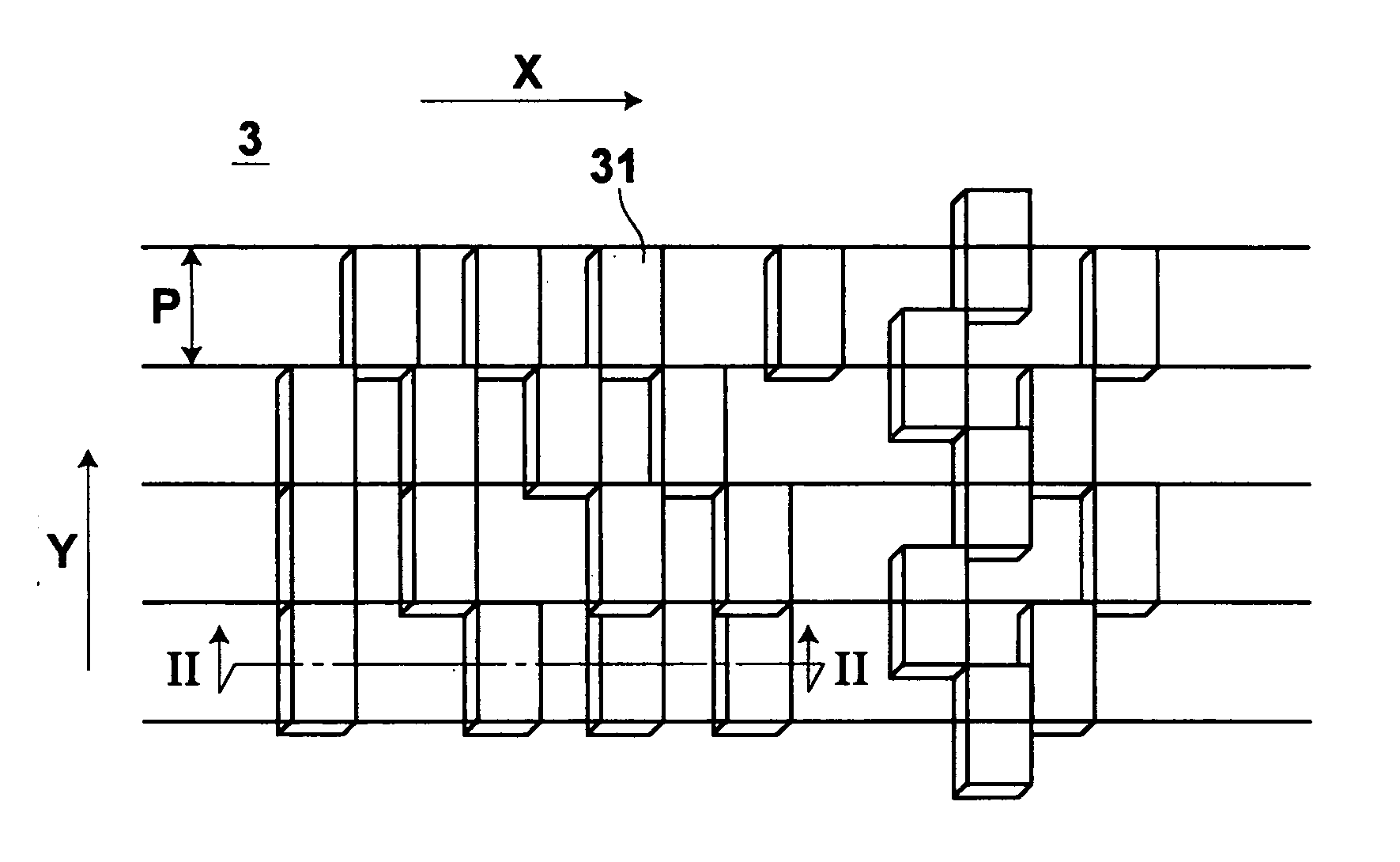

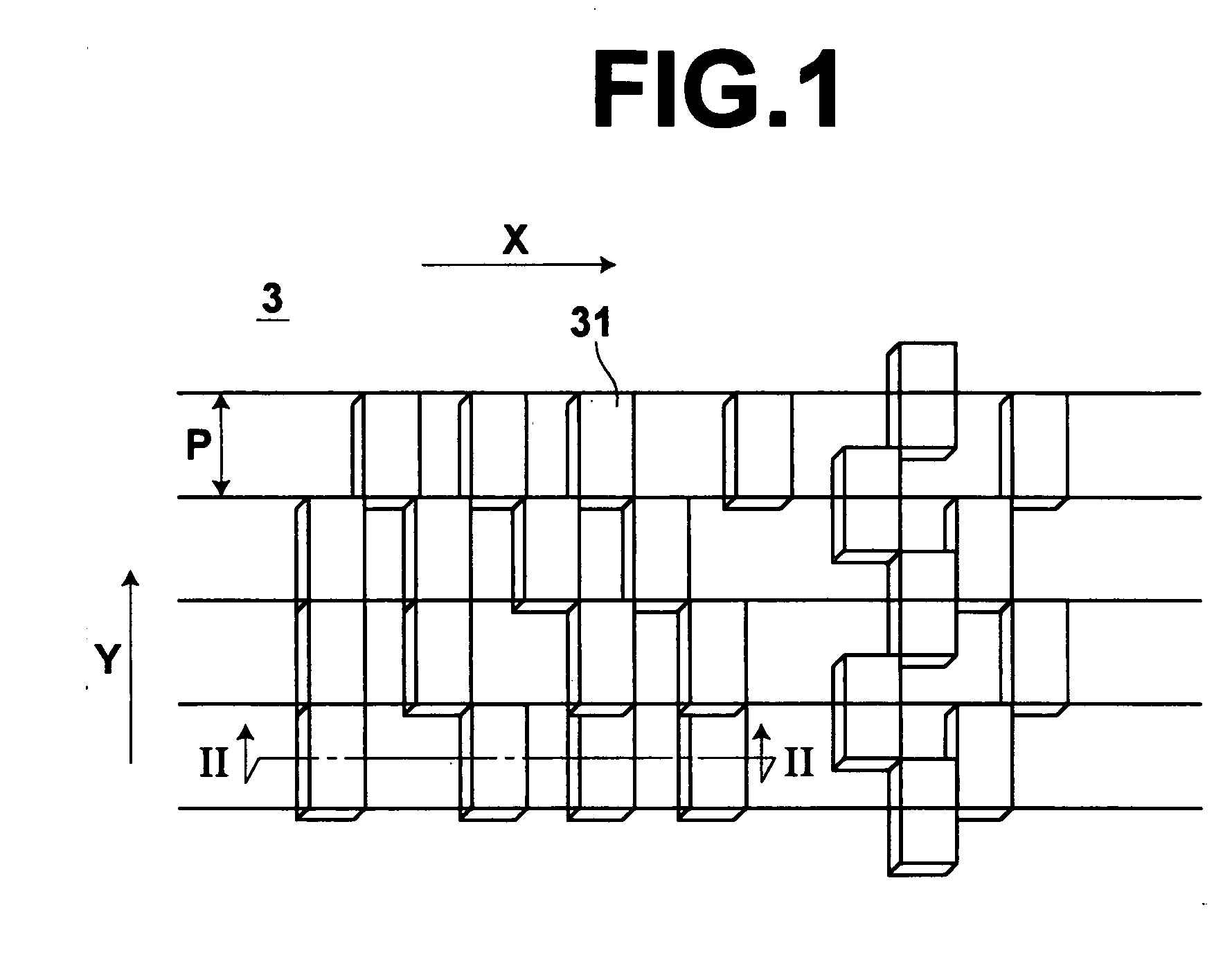

InactiveUS7094481B2Increased durabilityGood signalNanoinformaticsPatterned record carriersIn planeEngineering

A master information carrier for magnetic transfer to an in-plane magnetic recording medium includes a base sheet having an irregularity pattern representing information to be transferred to an in-plane magnetic recording medium and a magnetic layer formed along the irregularity pattern. The thickness da 1 of the magnetic layer on the upper surface of a protruding portion of the irregularity pattern and the thickness da 2 of the magnetic layer on each of the side surfaces of the protruding portion satisfy the following condition, <?in-line-formulae description="In-line Formulae" end="lead"?>0.05<da2 / da1<=1.3.<?in-line-formulae description="In-line Formulae" end="tail"?>

Owner:FUJIFILM CORP

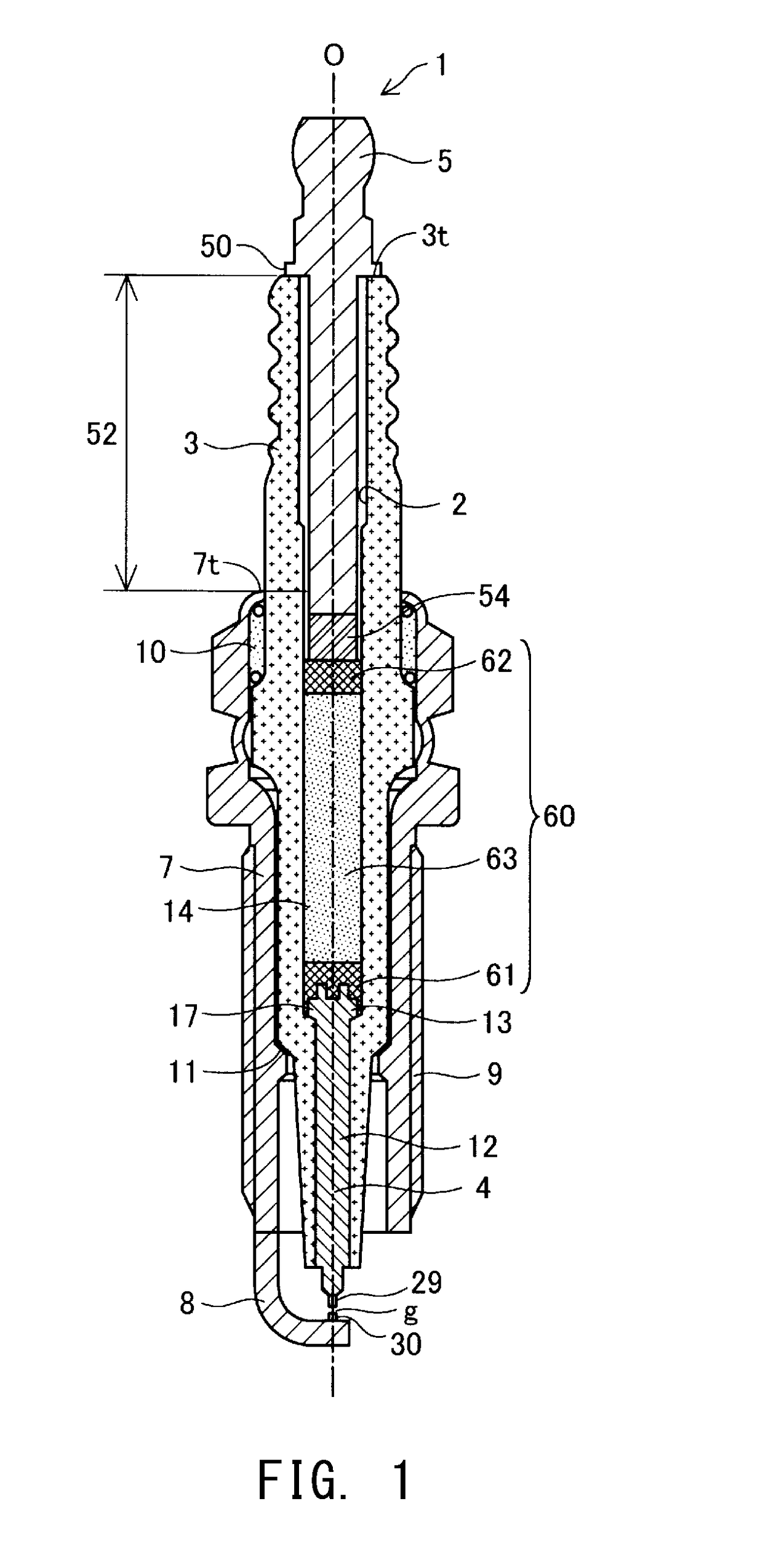

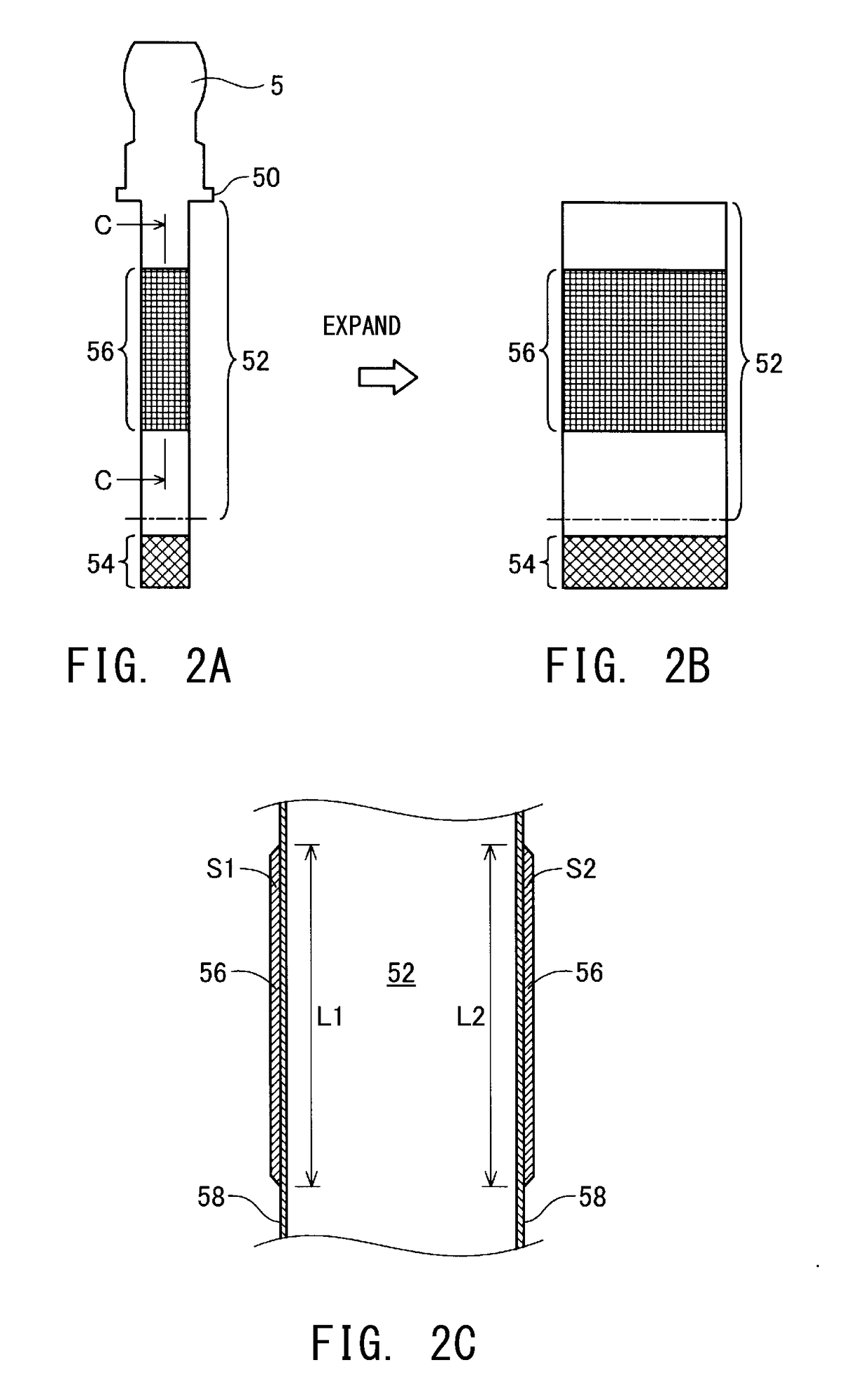

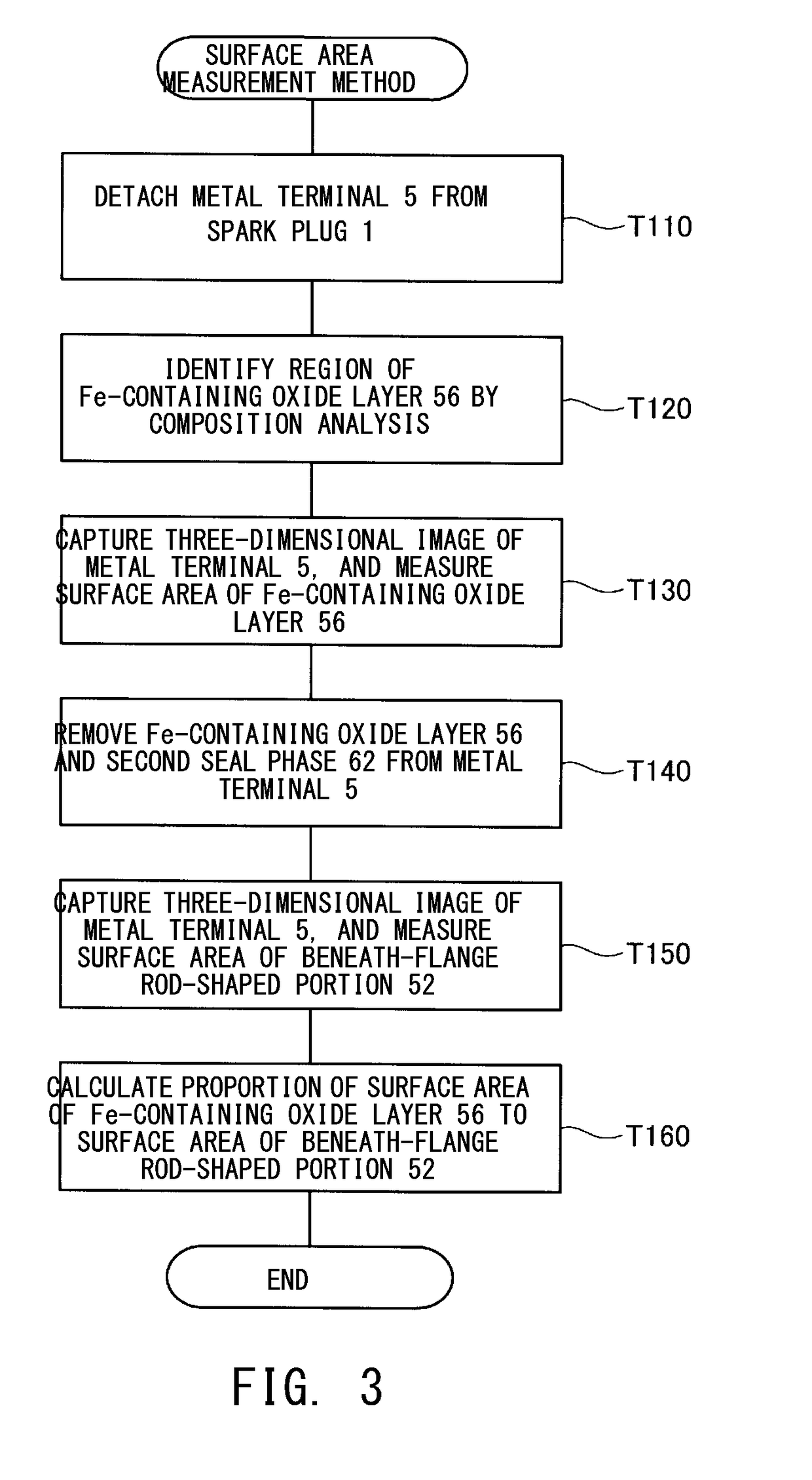

Spark plug

InactiveUS20180375298A1Reduce noiseImprove noise reductionMachines/enginesSparking plugs manufactureEngineeringMetal

The present invention allows reduction in high frequency noise of a spark plug. A Fe-containing oxide layer is formed on the surface of a beneath-flange rod-shaped portion, of a metal terminal of the spark plug, between a terminal flange portion and an upper end of a metal shell. The surface area of the Fe-containing oxide layer is not less than 10% of the surface area of the beneath-flange rod-shaped portion.

Owner:NGK SPARK PLUG CO LTD

Laminate type ceramic electronic component and manufacturing method therefor

ActiveUS8587919B2High hardnessImprove the fixing strengthFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorElectronic component

In a laminate type ceramic electronic component, when an external electrode for a laminated ceramic capacitor is formed directly by plating onto a surface of a component main body, the film that is directly plated may have a low fixing strength with respect to the component main body. As the external electrode, a first plating layer composed of a Ni—P plating film with a P content rate of about 9 weight % or more is first formed such that a plating deposition deposited with the exposed ends of respective internal electrodes as starting points is grown on at least an end surface of a component main body. Then, a second plating layer composed of a Ni plating film containing substantially no P is formed on the first plating layer. Preferably, the first plating layer is formed by electroless plating, whereas the second plating layer is formed by electrolytic plating.

Owner:MURATA MFG CO LTD

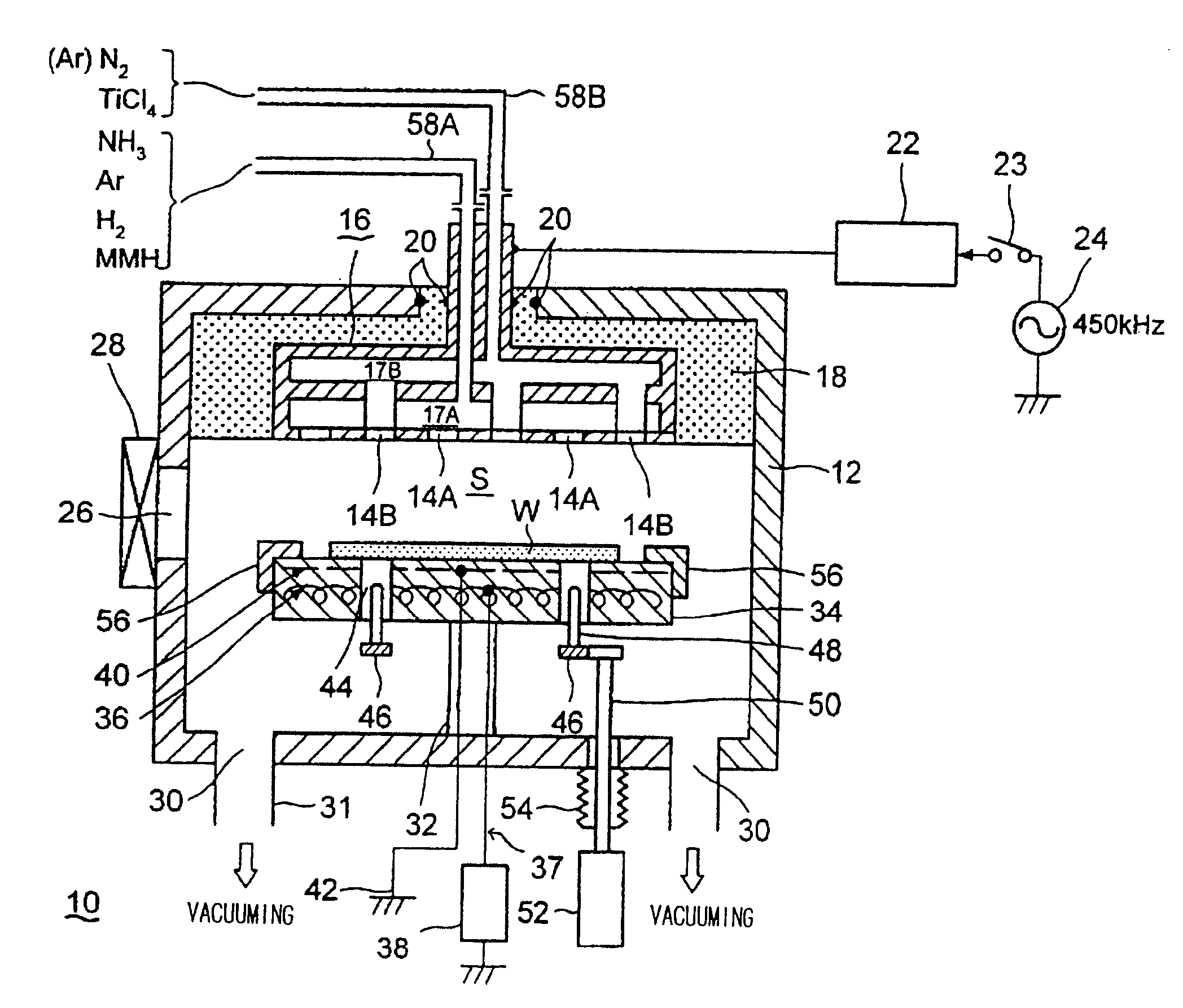

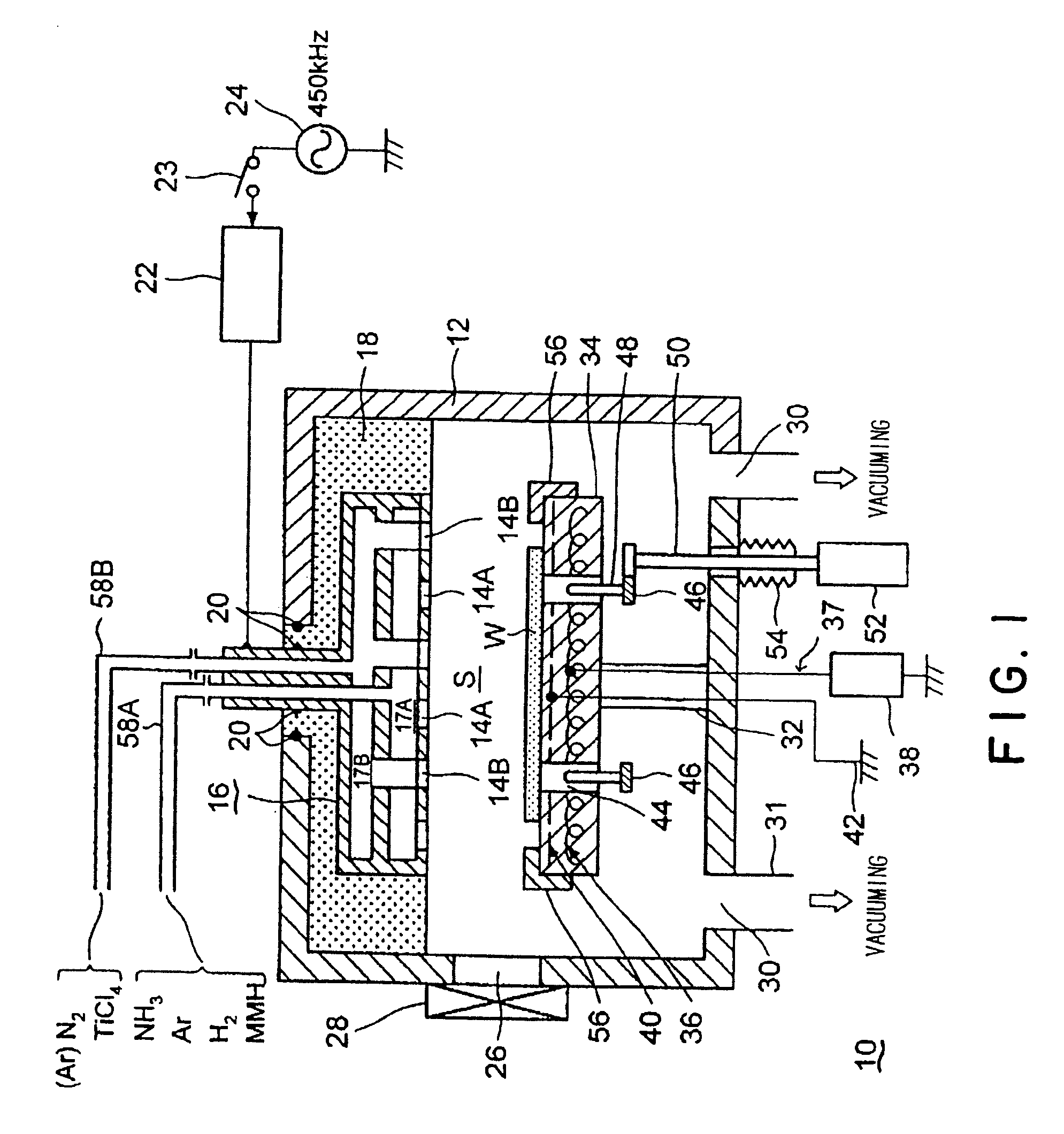

Film forming method

InactiveUS20100047472A1Reduce crackingLess peelingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenEngineering

The present invention relates to a method of forming a metal-nitride film onto a surface of an object to be processed in a processing container in which a vacuum can be created. The method of the invention includes: a step of continuously supplying an inert gas into a processing container set at a high film-forming temperature; and a step of intermittently supplying a metal-source gas into the processing container, during the step of continuously supplying the inert gas. During the step of intermittently supplying the metal-source gas, a nitrogen-including reduction gas is supplied into the processing container at the same time that the metal-source gas is supplied, during a supply term of the metal-source gas. The nitrogen-including reduction gas is also supplied into the processing container for a term shorter than a non-supply term of the metal-source gas, during the non-supply term of the metal-source gas. A film thickness of the metal-nitride film formed during the one supply term of the metal-source gas is not more than 60 nm. According to the invention, although the film-forming process is conducted at a relatively high temperature, a metal-nitride film can be deposited whose chlorine density is low, whose resistivity is low, and in which fewer cracks may be generated.

Owner:TOKYO ELECTRON LTD

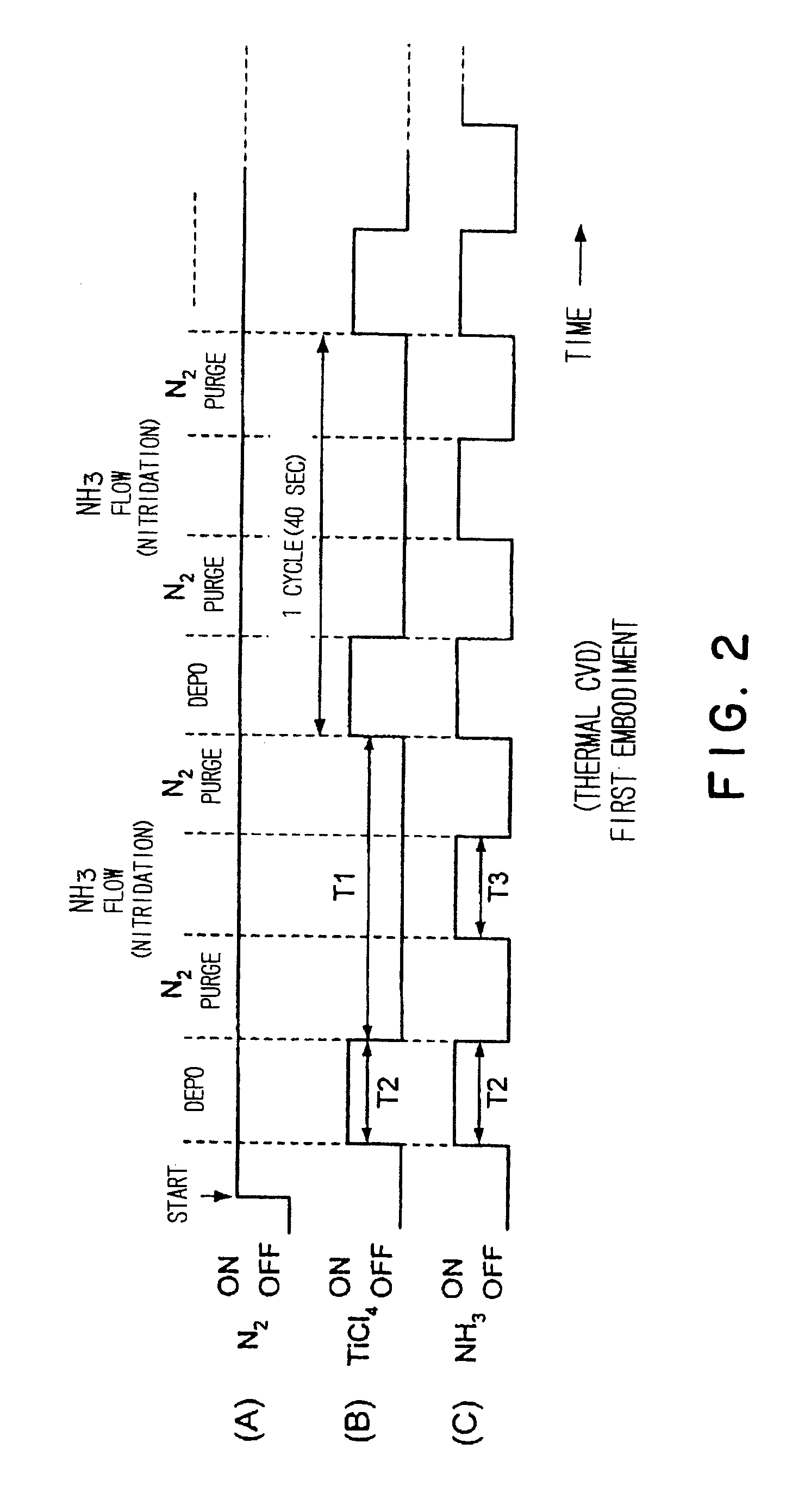

Color cathode-ray tube

InactiveUS7227302B2Low costSatisfactory yieldIncadescent screens/filtersCathode-ray/electron-beam tube vessels/containersFluorescencePhosphor

Owner:MATSUSHITA TOSHIBA PICTURE DISPLAY CO LTD

Master information carrier for magnetic transfer and magnetic transfer method

InactiveUS20050041314A1Good reproduction signalIncreased durabilityNanoinformaticsPatterned record carriersMagnetic layerEngineering

A master information carrier for magnetic transfer to an in-plane magnetic recording medium includes a base sheet having an irregularity pattern representing information to be transferred to an in-plane magnetic recording medium and a magnetic layer formed along the irregularity pattern. The thickness da1 of the magnetic layer on the upper surface of a protruding portion of the irregularity pattern and the thickness da2 of the magnetic layer on each of the side surfaces of the protruding portion satisfy the following condition, 0.05<da2 / da1≦1.3.

Owner:FUJIFILM CORP

Method for treating surface of aluminum article

InactiveUS20210172072A1Effective anchoring effectStrong adhesionLaminationLamination apparatusChemical solutionSilanes

Provided is a method for treating a surface of an aluminum article capable of imparting an effective anchoring effect to a surface of the aluminum article and enabling a strong chemical bond between the surface of the aluminum article and an organic material layer such as a coated resin layer or a laminated FRP applied to the surface without using a chemical solution that is not easy to treat. In the method for treating a surface of an aluminum article according to the present invention, the surface of the aluminum article is subjected to at least one of an etching treatment, a boehmite treatment, and a zirconium treatment, and then further subjected to at least one of a silane coupling agent treatment, an isocyanate compound treatment, and a thiol compound treatment.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com