Production technology of pattern leather

A production process and leather technology, applied in the field of pattern leather production technology, can solve the problems of increasing manpower, material resources, lengthy production process, long operation process, etc., and achieve the effects of reducing layer drop, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

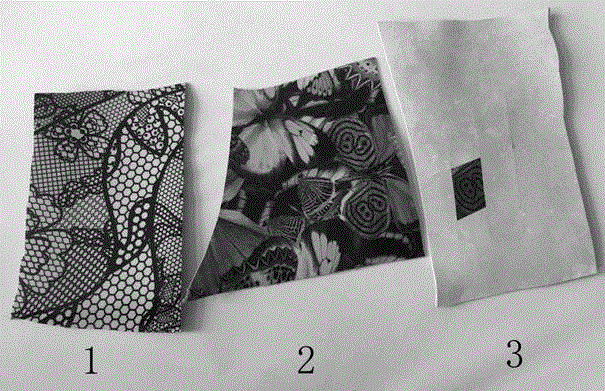

Image

Examples

Embodiment 1

[0020] Example 1 Pattern leather production process, including leather pretreatment process, finishing process and post-treatment process.

[0021] 1) The pre-treatment process is as follows: grind the obtained crust leather, clean the surface, shake, clean the surface again, seal the inside and measure the leather.

[0022] 2) The finishing process is as follows: the leather obtained after the leather pretreatment process is subjected to one finishing treatment.

[0023] 3) The post-treatment process is as follows: first apply a film to the leather after the finishing process, then spray glycol ether on the leather film surface, and finally obtain pattern leather through lacquering, in which the amount of glycol ether is 4-8 kg / thousand Ruler, the varnish is composed of the following raw materials in parts by weight: 30-50 parts of PU100, 40-60 parts of PU 909, 10-30 parts of n-butyl acetate, preferably 50 parts of PU100, 50 parts of PU 909, n-butyl acetate 20 servings.

Embodiment 2

[0024] Embodiment 2 comparative test

[0025] 2.1 Effect of different dosages of ethylene glycol ether on the bonding fastness of the paint film

[0026] Experimental method: Divide the skins from the same batch into 7 small samples, and then process them according to the process described in Example 1 to obtain samples. After standing the obtained samples for three days, draw 30 Table 1 shows the amount of ethylene glycol ether sprayed and the bonding fastness of the paint film corresponding to each group.

[0027] Bonding fastness: The bonding fastness of the paint film in the present invention is related to the number of sheets to be removed and the difficulty of removing. The more sheets are removed, the easier it is to remove, indicating that the bonding fastness of the paint film is better Difference.

[0028] It can be seen from Table 1 that when the amount of ethylene glycol ether is 0 (painting directly after the film is applied), the glossy film is easily removed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com