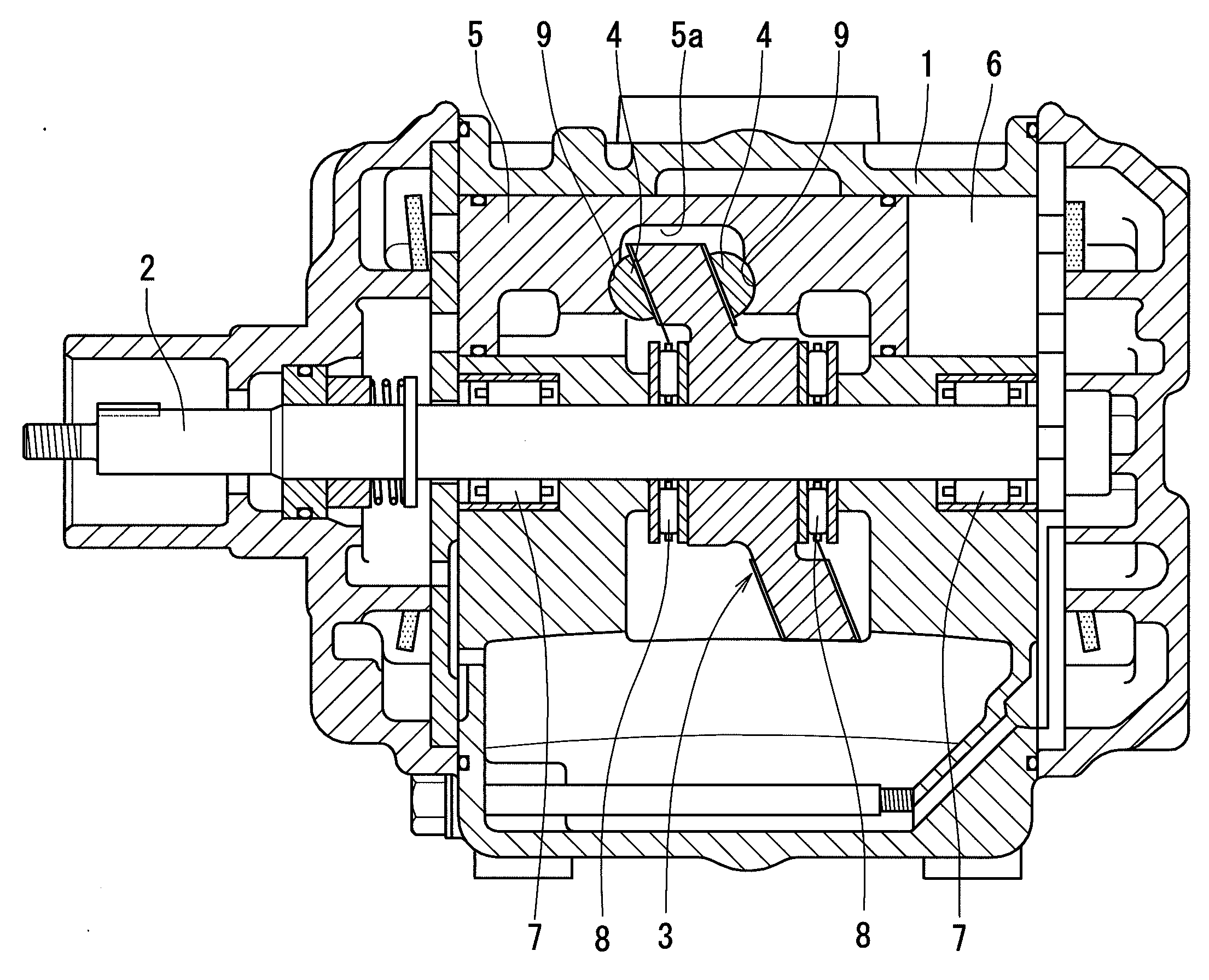

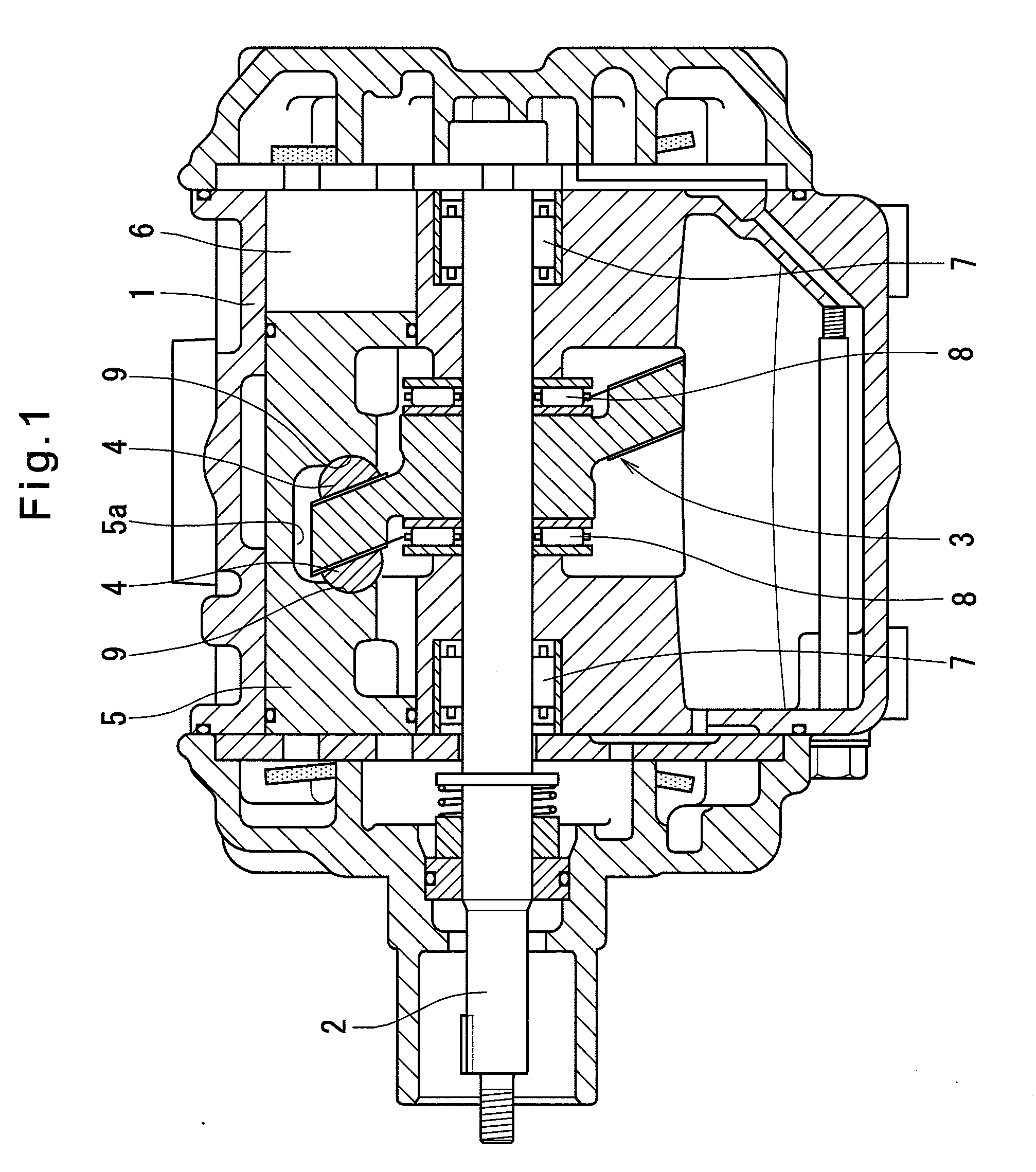

Swash plate of a swash plate type compressor and the swash plate type compressor

a compressor and swash plate technology, applied in the direction of oblique crank gearings, positive displacement liquid engines, gearings, etc., can solve the problems of reducing the flatness of the swash plate, forming a metal spray coating layer of copper, etc., and achieve good surface flatness and uniform thickness. , good surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Examples of the Invention

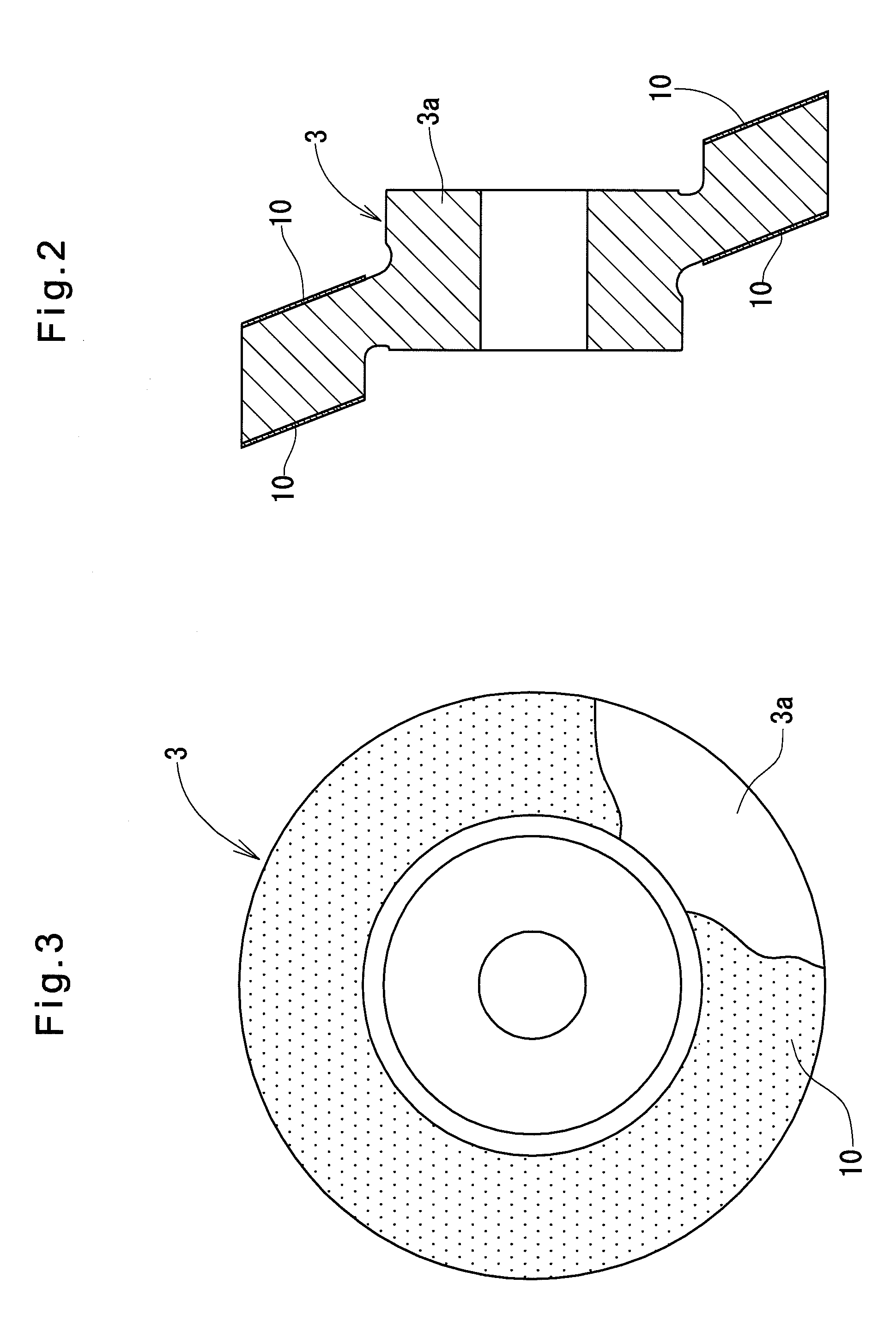

[0057]In each example of the invention, the substrate 3a of the swash plate 3 was formed as follows: A steel sheet SAPH440C was formed into a disk shape by pressing, and roughly machined by a lathe to the thickness of 6.5 mm and a diameter of 90 mm. Both sides thereof were then ground using a two-head grinding machine (grinder: #80) so that the thickness of the substrate decreases to 6.36 mm. Table 1 shows the measured accuracy values after the respective steps.

[0058]The disk substrates thus formed were subjected to shot blasting to increase their surface roughness.

[0059]Then, a low-friction resin coating composition containing formula A as solid contents were applied by spray coating to both sides of the respective specimens thus formed so that their thicknesses are 30 μm on both sides after baking. After baking, final finish machining was carried out using a two-head grinding machine (grinder: #400 for resin) (to the thickness of 6.40 mm). Measured accurac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com