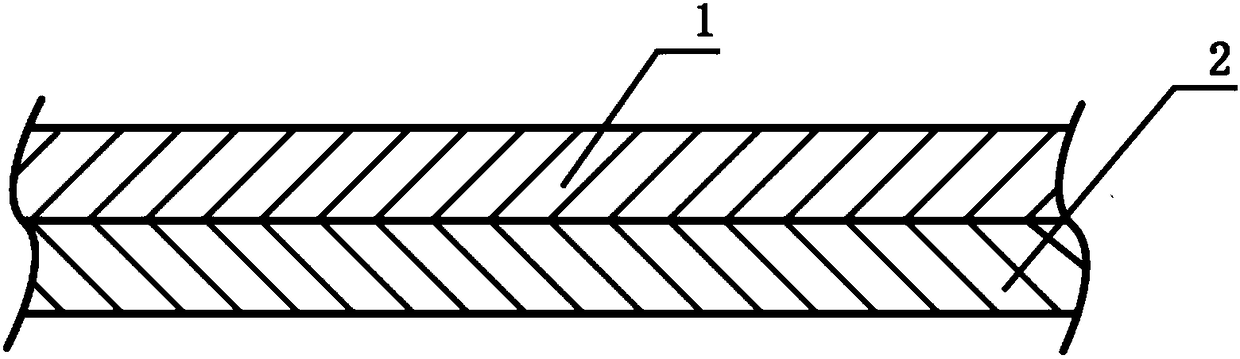

Graphene mica double-layer paper, preparation method and application of paper and mica electric heating plate containing paper or mica electric heating device containing paper

A technology of electric heating equipment and graphene, which is used in electric heating devices, ohmic resistance heating, papermaking, etc., can solve the problems of poor heat dissipation performance of mica paper, affecting the operation and service life of equipment, and inability to dissipate heat from large electric heating equipment. The effect of stable properties and excellent thermal radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation of graphene-mica double-layer paper of the present invention mainly comprises the steps such as raw material processing and papermaking and spraying, can specifically refer to as follows:

[0044] (1) Take the mica raw material and ultrasonically crush it for 1-10 hours under the power of 1000-3000W; 12m 3 / h pressure for hydraulic flotation, and then gravity flotation;

[0045] Then, the mica flakes after flotation are further filtered and classified, so that the mica scales contained in the obtained mica slurry have a size distribution between 10 and 150 meshes;

[0046] Further, the mass concentration of the obtained mica slurry is 1-10% (that is, the mass percentage of mica scales in the slurry is 1-10%), preferably 6-8%.

[0047] (2) Get raw graphene powder, and be dispersed in water, then add respectively the dispersant of 20~100% of graphene powder dry mass, and the defoamer of 0.1~1% of graphene powder dry mass, Then dissociate and disperse ev...

Embodiment 1

[0061] (1) Select an area of 3mm 2 1. The phlogopite sheet with a thickness of 5mm is used as the mica raw material, and the impurities are removed by winnowing pressure screening, and the mica raw material is stripped into mica sheets by ultrasonic treatment. The ultrasonic power is 1000W and the time is 10h;

[0062] Put the broken mica flakes in an inverted trapezoidal tank at a distance of 10m 3 / h pressure for hydraulic flotation, and then for gravity flotation, filter and classify the mica flakes through a sieving instrument, and obtain mica slurry with a size distribution of mica flakes between 10 and 120 mesh and a mass concentration of 8%;

[0063] (2) Select the biomass graphene powder with a radial size of 30 μm and a thickness of 5 nm and add it to water for dispersion, and then add polyethylene glycol and emulsified with a mass concentration of 20% and 0.1% of the total mass of the graphene powder. Silicone oil; at a rotating speed of 1500rpm, the graphene powd...

Embodiment 2

[0069] (1) Select an area of 6mm 2 1. Phlogopite sheets with a thickness of 4mm are used as mica raw materials, and impurities are removed by winnowing and pressure screening, and the mica raw materials are peeled into mica sheets by ultrasonic treatment. The ultrasonic power is 1500W and the time is 8h;

[0070] Place the broken mica sheets in an inverted trapezoidal tank at a distance of 12m 3 / h pressure for hydraulic flotation, and then for gravity flotation, filter and classify the mica flakes through a sieving instrument, and obtain a mica slurry with a size distribution of mica flakes between 10 and 150 mesh and a mass concentration of 6%;

[0071] (2) choose the biomass graphene powder that radial size is 35 μm, thickness is 6nm to join in water and disperse, then add the nanocellulose and hydroxypropyl methyl that mass concentration is respectively graphene powder absolute dry gross mass 40% Base cellulose mixture and 0.2% higher carbon alcohol; under the rotating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com