Overload protector of single-phase AC motor

A single-phase AC motor and overload protector technology, which is applied in the direction of electrothermal protection switches, relays, thermal relays, etc., can solve the problems of easy cracking of bimetallic strips, poor ability of bimetallic strips to sense temperature or accept heat radiation, and bimetallic strips Insufficient heat radiation ability and other problems, to achieve the effect of improving the heat radiation ability of the motor, reasonable electrical structure distribution, and preventing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

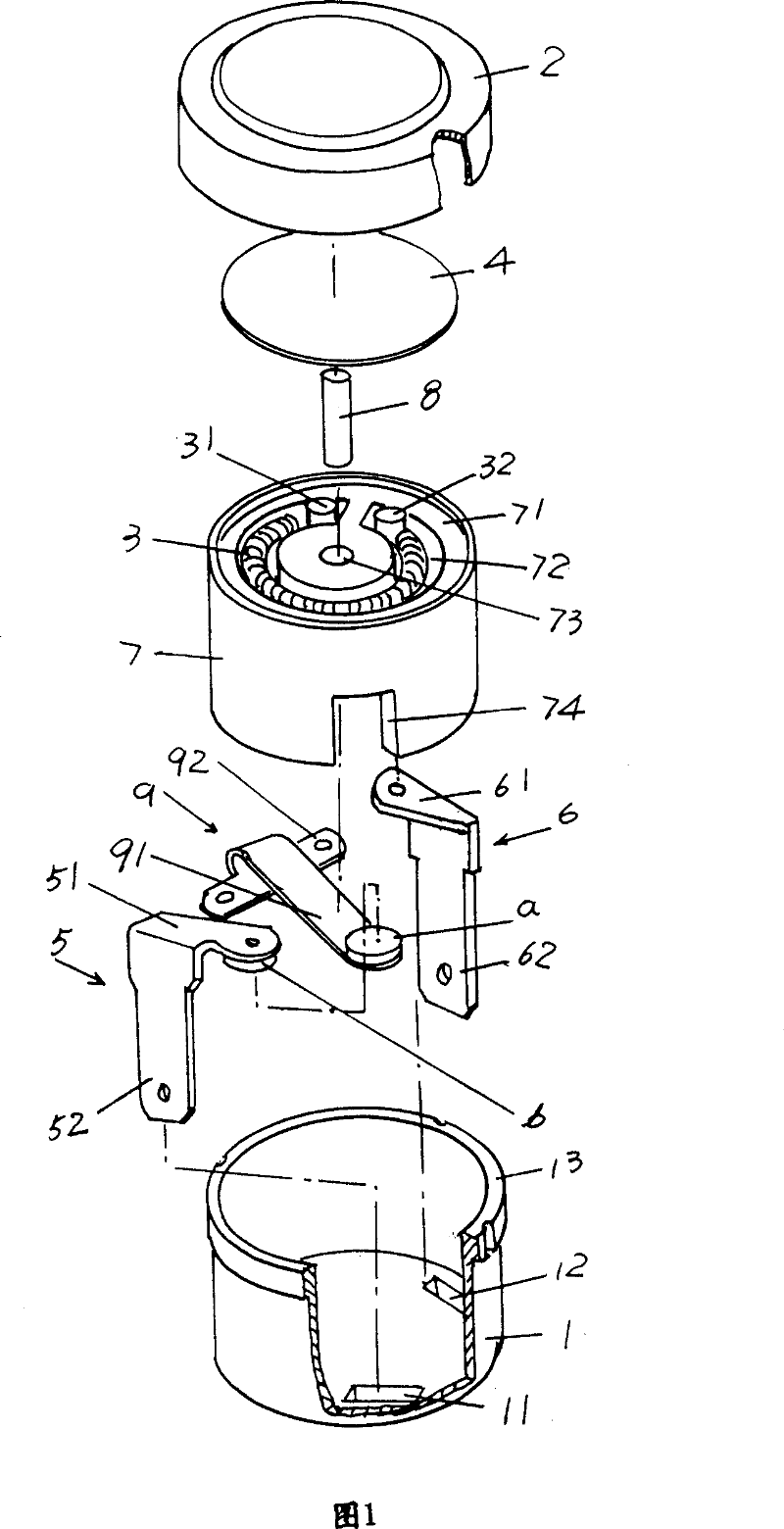

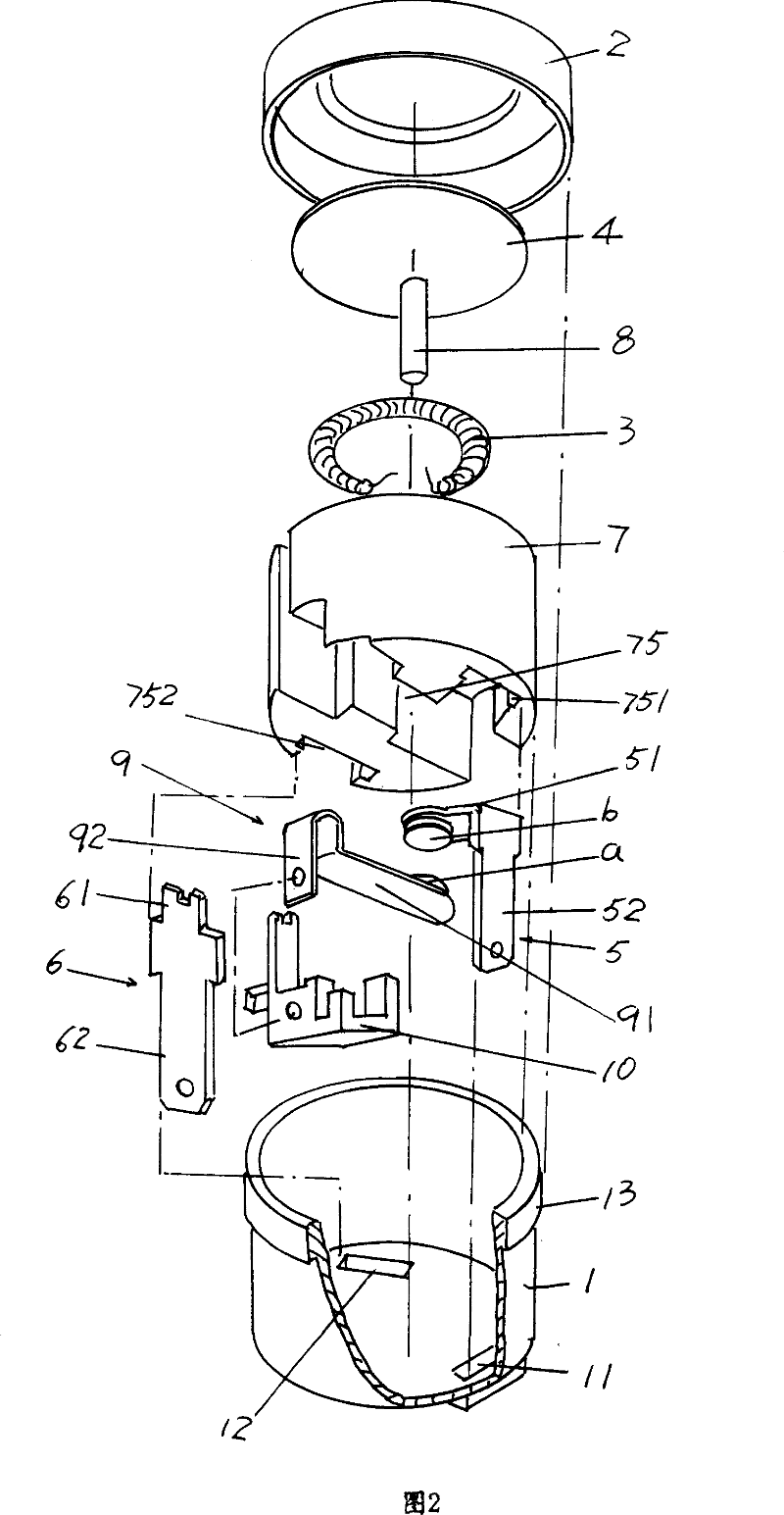

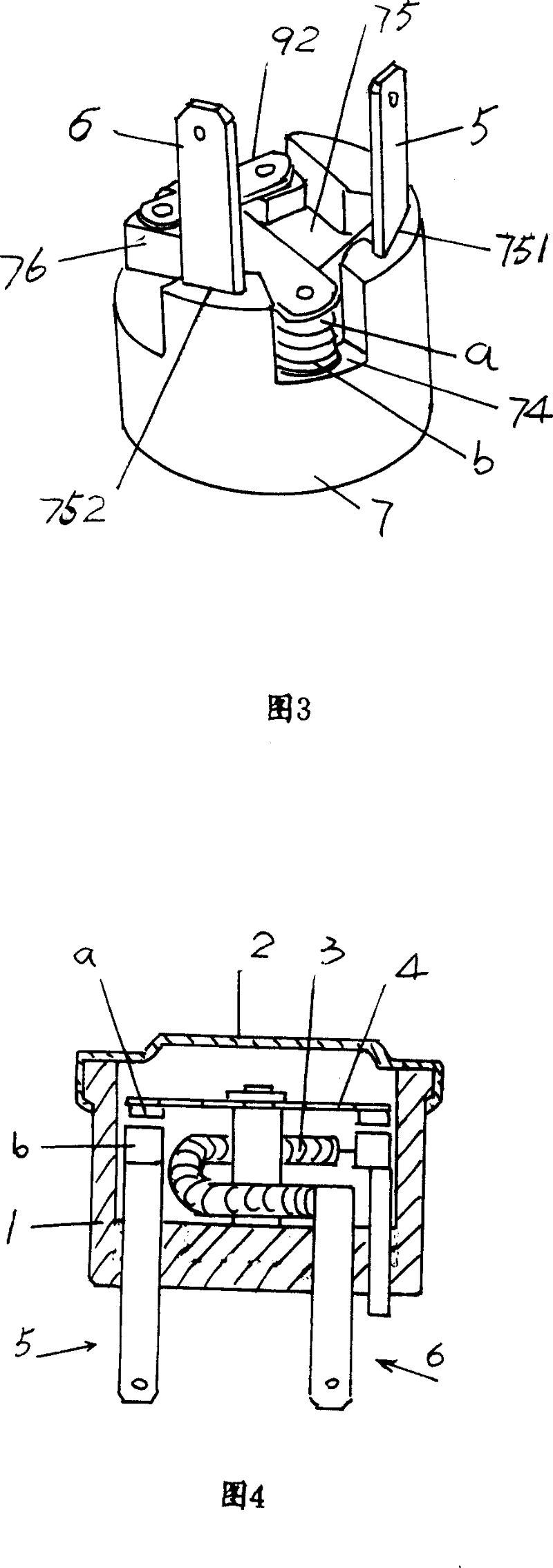

[0021] In Fig. 1 and Fig. 3, a shell 1 made of plastic has a shell cavity, and a pair of first and second ends for supplying the first and second pins 5, 6 are opened at the bottom of the shell cavity. The first and second pin holes 11 and 12 through which 52 and 62 pass, the shape and size of the first and second pin holes 11 and 12 should be compatible with the first and second ends 52 and 62 . A step 13 is expanded on the upper outer wall of the housing 1, and the cover 2 is disposed on the step 13. The cover 2 is preferably made of aluminum, and a slightly raised concave cavity is formed in the center of the cover 2. The fixing seat 7 , which can be made of ceramic or plastic, is integrally accommodated in the shell cavity of the housing 1 , and the pin cavity 75 is formed on the lower end surface of the fixing seat 7 . Specifically referring to FIG. 3 , it can be seen that the first and second ends 52 and 62 of the first and second pins 5 and 6 are inserted into the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com