Automatic calibrating device and method for temperature measuring channel of acquisition device in weather station

An automatic weather station, temperature measurement technology, used in measurement devices, thermometer testing/calibration, thermometers, etc., can solve the problems of temperature drift, coordination problems, insufficient precision resistance, etc., to eliminate temperature drift and relay contact. The influence of resistance, the effect of meeting the verification requirements and reducing the deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

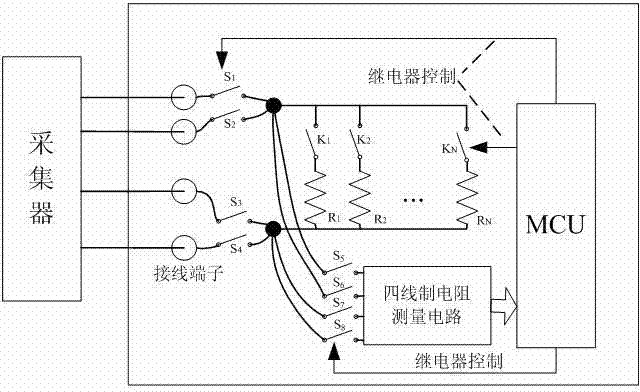

[0025] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0026] A verification device for the temperature measurement channel of an automatic weather station collector, comprising a collector, first to fourth access relays, a resistance circuit, a four-wire resistance measurement circuit, fifth to eighth access relays, and an MCU controller;

[0027] Wherein, the four connection terminals of the collector are respectively connected to the input ends of the first to fourth access relays;

[0028] The input terminals of the resistance circuit are respectively connected with the output terminals of the first and second access relays, and the input terminals of the fifth and sixth access relays;

[0029] The output terminals of the resistance circuit are respectively connected with the output terminals of the third and fourth access relays, and the input terminals of the seventh and eighth access relays;

[0030] The outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com