Double-optocoupler image direct voltage sensor

A DC voltage and sensor technology, which is applied in the direction of measuring current/voltage, instruments, and measuring electrical variables, etc., can solve the problems of inability to detect voltage sensing circuits, large voltage sensors, and cannot be designed and applied, so as to eliminate the phenomenon of temperature drift , light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

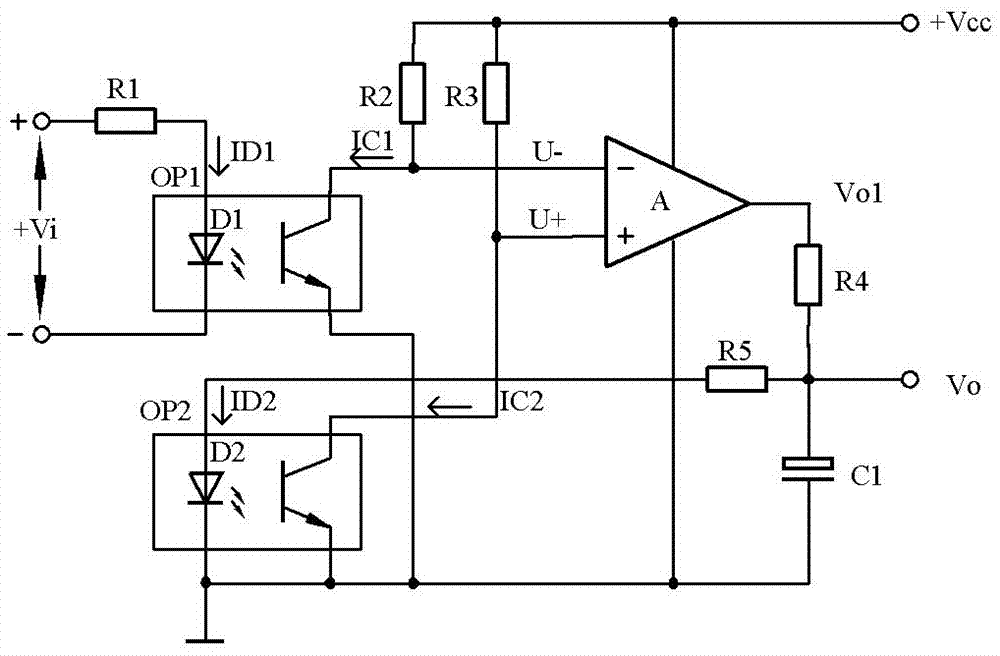

[0020] see figure 1 , the dual optocoupler mirror image DC voltage sensor of the present invention comprises a detected high voltage signal input end, a mirror image current control circuit and a detection signal output end, and the mirror image current control circuit consists of two optocouplers (optocoupler OP1, optocoupler OP1, OP2 forms double optocoupler), voltage comparator A, low-pass filter form; In work, described mirror current control circuit guarantees that the electric current of the output terminal of two optocouplers is equal; The input terminal of first optocoupler OP1 passes resistance R1 Connect the positive pole of the DC high-voltage power supply to be tested, and the output terminal is connected to the inverting input terminal of the voltage comparator through the pull-up resistor R2; the output terminal of the voltage comparator is connected to a low-pass filter circuit, and the output of the low-pass filter circuit is connected to the first The input te...

Embodiment 2

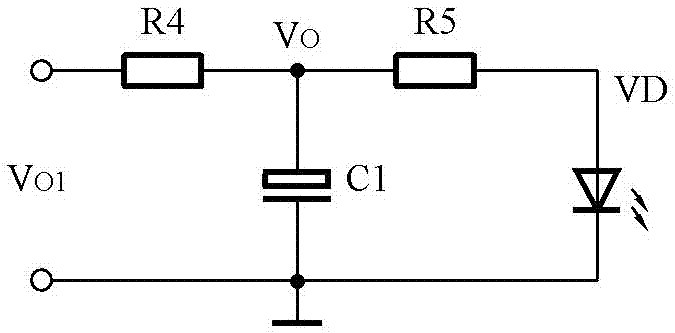

[0022] see figure 1 , the dual optocoupler mirror image DC voltage sensor of this embodiment differs from Embodiment 1 in that: the low-pass filter circuit is composed of resistors R4, R5 and capacitor C1, and the output terminal of the voltage comparator passes through resistor R4 and capacitor C1 Grounded, the node of the resistor R4 and the capacitor C1 is the detection signal output terminal, and the node of the resistor R4 and the capacitor C1 is connected to the power input terminal of the second optocoupler OP2 through the resistor R5 at the same time.

Embodiment 3

[0024] Such as figure 1 As shown, in the dual optocoupler mirror image DC voltage sensor of this embodiment, the optocouplers OP1 and OP2 have the same parameters, R2=R3, and A is an operational amplifier, which is used for voltage comparison here. When there is Vi input, the current of Vi is limited by R1, the LED in the optocoupler OP1 gets the current ID1 to turn on, and the collector of the phototransistor in OP1 has the current IC1, IC1=kID1, where k is the optocoupler current conversion coefficient. U-=VCC-IC1*R1.

[0025] At this time, if U+ is greater than U-, VO1 increases and ID2 increases. After photoelectric conversion by the optocoupler, IC1 increases, causing U+ to decrease. When U+ is less than U-, VO1 decreases, which causes U+ to rise in the same way, and finally the circuit reaches Steady state, at this time U+=U-, ID1=ID2. but

[0026]

[0027] The optocoupler OP1 and OP2 have the same parameter VD1=VD2=VD, sorted out

[0028]

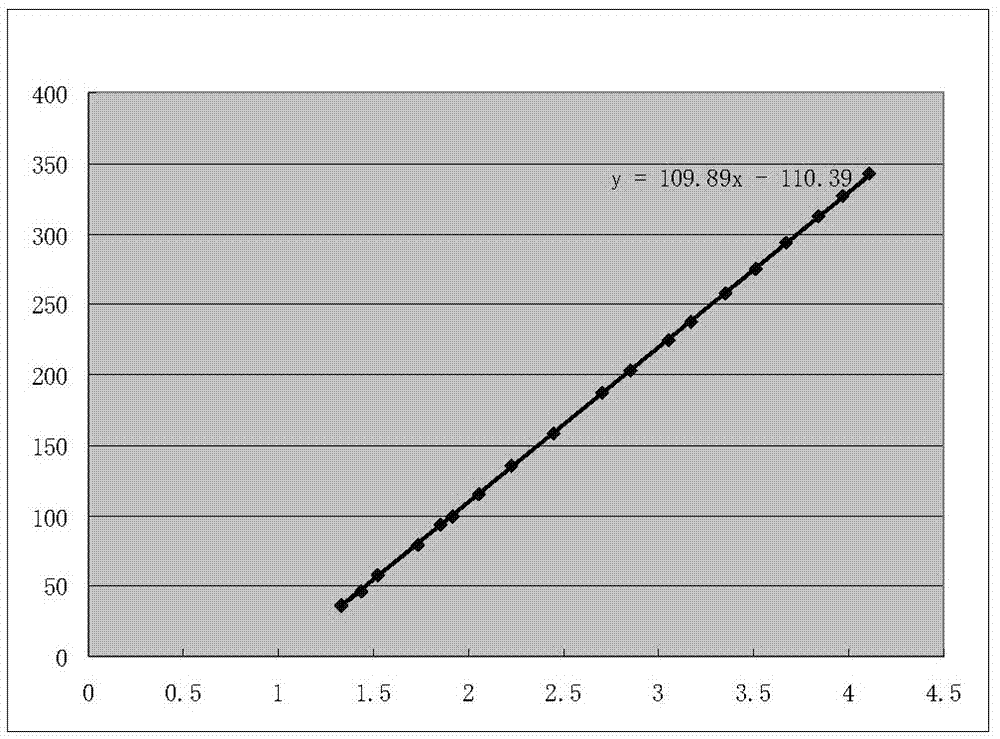

[0029] When the ID1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com