Wire for coil

A coil wire, square technology, applied in the direction of coil, coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of small volume utilization coefficient and deteriorated performance, and achieve thermal radiation effect and thermal resistance improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention will be explained in more detail by way of examples.

[0043] A speaker manufactured using the coil wire of the present invention is compared with a speaker manufactured using a conventional round wire.

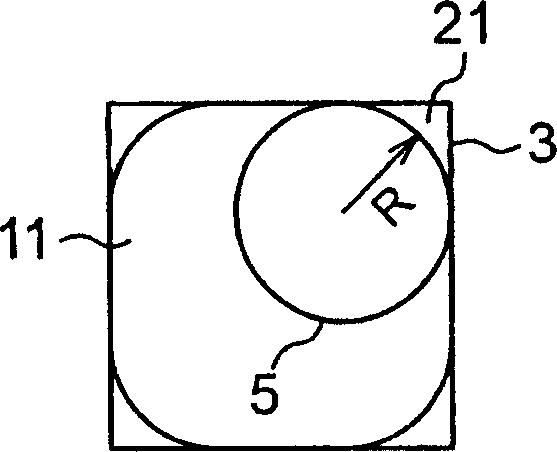

[0044] Figure 5 The length of one side D of the square cross-sectional shape of the square wire shown as the basis of the present invention is set to 0.16 mm. Prefab figure 1 The shape shown serves as the basis of the square line, that is, the four corners of the square section are chamfered so that its area becomes 1.15 times the area of the circle 4 with the same diameter D (0.16 mm), or the section The total length of the outer circumference of the shape becomes 1.09 times the circumference of the circle 4. The chamfered wire (conductor portion) of the present invention is covered with an insulating layer, thereby prefabricating the coil wire ("Example 1 of the present invention"). The length of one side of the chamfer included in the cross-se...

Embodiment 2

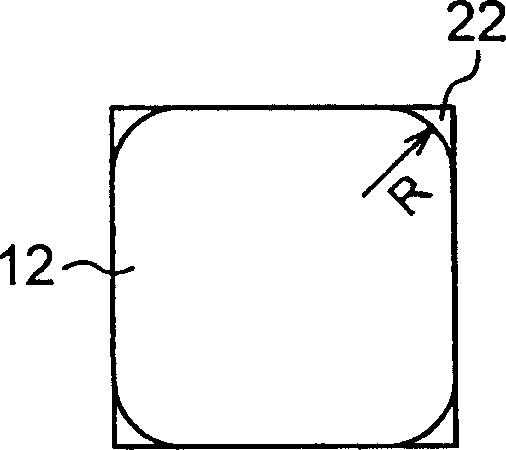

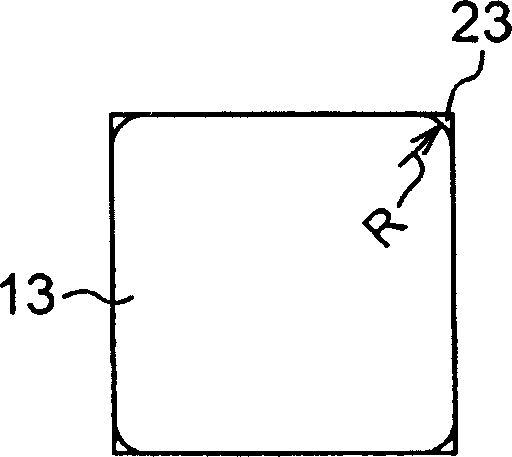

[0048] Figure 5 The length of one side D of the cross-sectional shape of the square wire shown as the basis of the present invention is set to 0.16 mm. The following coil wires are prefabricated by using the square wire as the base: figure 1 The coil wire shown and used in Example 1 of the present invention (Example 1 of the present invention); there are four corners figure 2 As shown, the cross-sectional area becomes 1.22 times the cross-sectional area of the circle 4, or the total length of the outer circumference of the cross-sectional shape becomes 1.16 times the circumference of the circle 4 (referred to as "this Invention example 2”); at the four corners such as image 3 As shown, the area of the cross-sectional shape becomes 1.26 times the area of the circle 4, or the total length of the outer circumference of the cross-sectional shape becomes 1.21 times the circumference of the circle 4 (referred to as " Example 3 of the present invention); at the four corners su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com