Low-temperature plane waterproof heating floor module and manufacturing method thereof

A manufacturing method and plane technology, applied in heating methods, chemical instruments and methods, floors, etc., can solve the problems of corrosion of heating elements and connecting terminals, breakdown of heating elements, easy formation of gaps, etc., to avoid corrosion damage, thermal damage, etc. High conversion efficiency and enhanced cell viability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

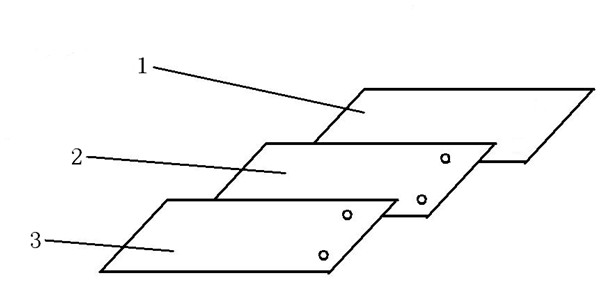

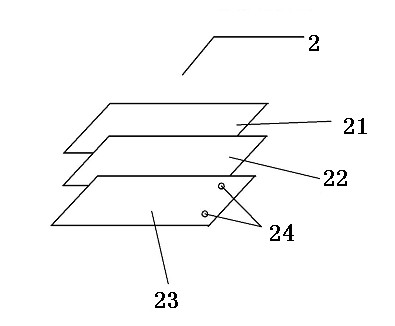

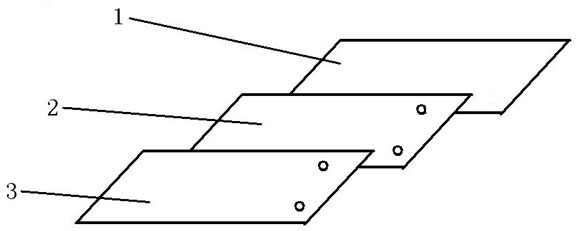

[0054] Such as figure 1 As shown, a low-temperature planar waterproof heating floor module of the present invention includes an exterior waterproof surface layer 1, a heat-generating substrate layer 2 and an exterior waterproof bottom layer 3, and the three are stacked and pasted in sequence to form a whole. Wherein, the structure of the heat generating substrate layer 2 is as follows: figure 2 As shown, it specifically includes an upper substrate layer 21 , a heat generating layer 22 and a lower substrate layer 23 pasted in sequence. Wherein, in the present invention, the heating layer 22 is made of carbon fiber conductive paper, and a pair of electrodes are arranged on the carbon fiber conductive paper for connecting wires to provide power and heat to the carbon fiber conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com