Solar stepped heating high-temperature heat collecting system based on molten salt heat transmission and heat accumulation

A technology of cascade heating and solar energy, applied in the field of energy storage, can solve the problems of increased heat loss, reduced thermal conversion efficiency of the system, and decreased thermal efficiency, and achieves the effect of preventing excessive heat loss and improving thermal conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

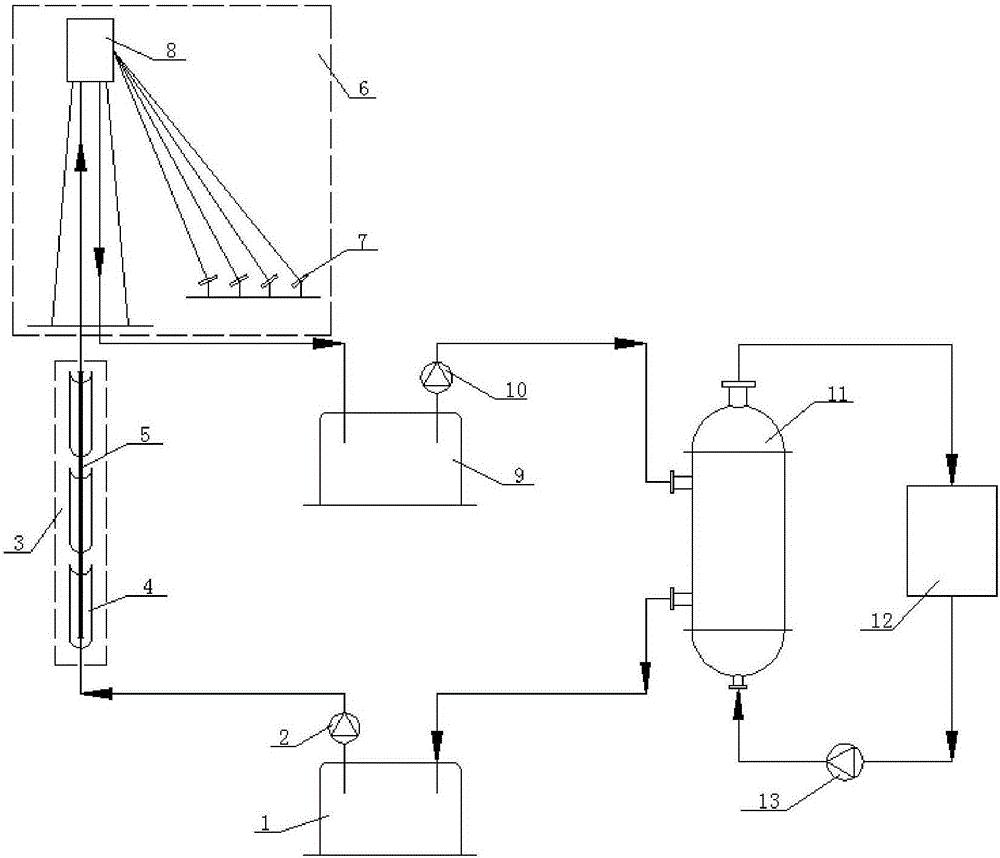

[0025] Embodiment 1: The high-temperature heat collection section 6 is a tower system composed of heliostats and tower top receivers

[0026] Such as figure 1 As shown, this embodiment includes: low temperature salt storage tank 1, low temperature molten salt pump 3, trough parabolic mirror 4, heat collecting tube 5, heliostat (concentrator 7), tower top receiver (receiver 8), High-temperature salt storage tank 9 , high-temperature molten salt pump 10 , molten salt-working medium heat exchanger 11 , heat-using equipment 12 and circulation pump 13 .

[0027] The low temperature salt storage tank 1, low temperature molten salt pump 2, trough parabolic mirror 4, heat collecting tube 5, heliostat 7, tower top receiver 8, high temperature salt storage tank 9, high temperature molten salt pump 10 and molten salt - The working medium heat exchanger 11 forms a molten salt circulation loop.

[0028] The molten salt-working medium heat exchanger 11, the heat utilization equipment 12 a...

Embodiment 2

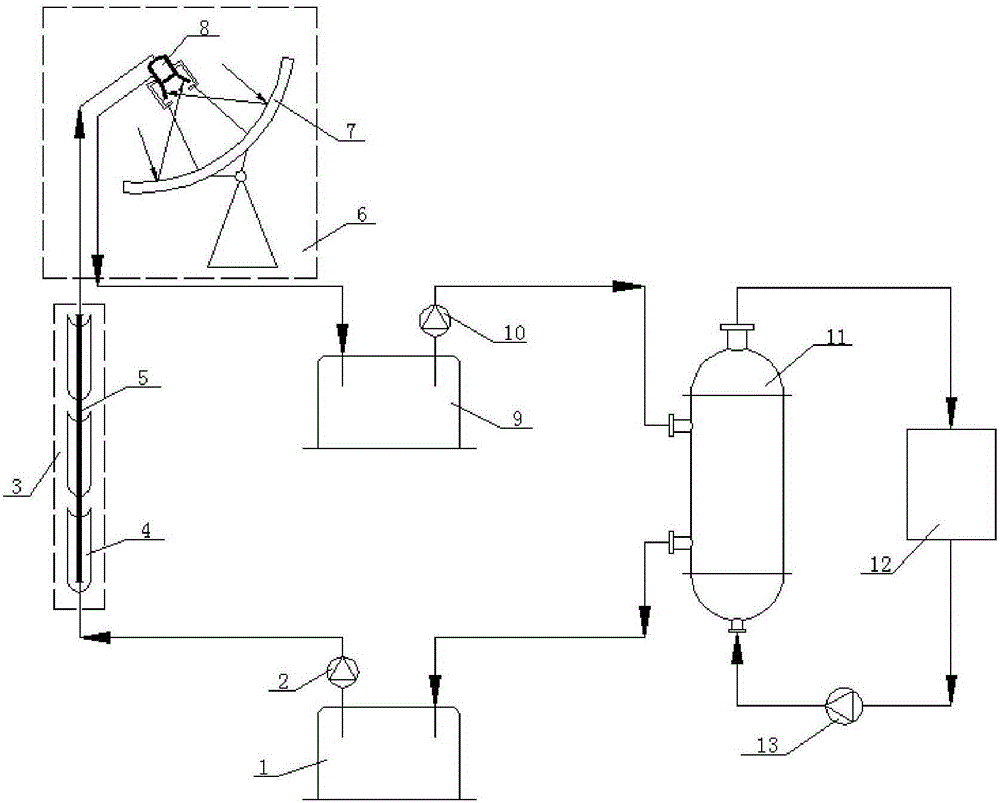

[0030] Embodiment 2: The high-temperature heat collection section 6 is a dish system composed of heliostats and tower top receivers

[0031] Such as figure 2 As shown, this embodiment includes: a low temperature salt storage tank 1, a low temperature molten salt pump 2, a trough parabolic mirror 4, a heat collecting tube 5, a dish parabolic mirror (concentrator 7), a cavity receiver (receiver 8) , high-temperature salt storage tank 9, high-temperature molten salt pump 10, molten salt-working medium heat exchanger 11, heat-using equipment 12 and circulation pump 13.

[0032] The low temperature salt storage tank 1, the low temperature molten salt pump 2, the trough parabolic mirror 4, the heat collecting tube 5, the dish parabolic mirror 7, the cavity receiver 8, the high temperature salt storage tank 9, the high temperature molten salt pump 10 and the melting The salt-working medium heat exchanger 11 forms a molten salt circulation loop.

[0033] The molten salt-working med...

Embodiment 3

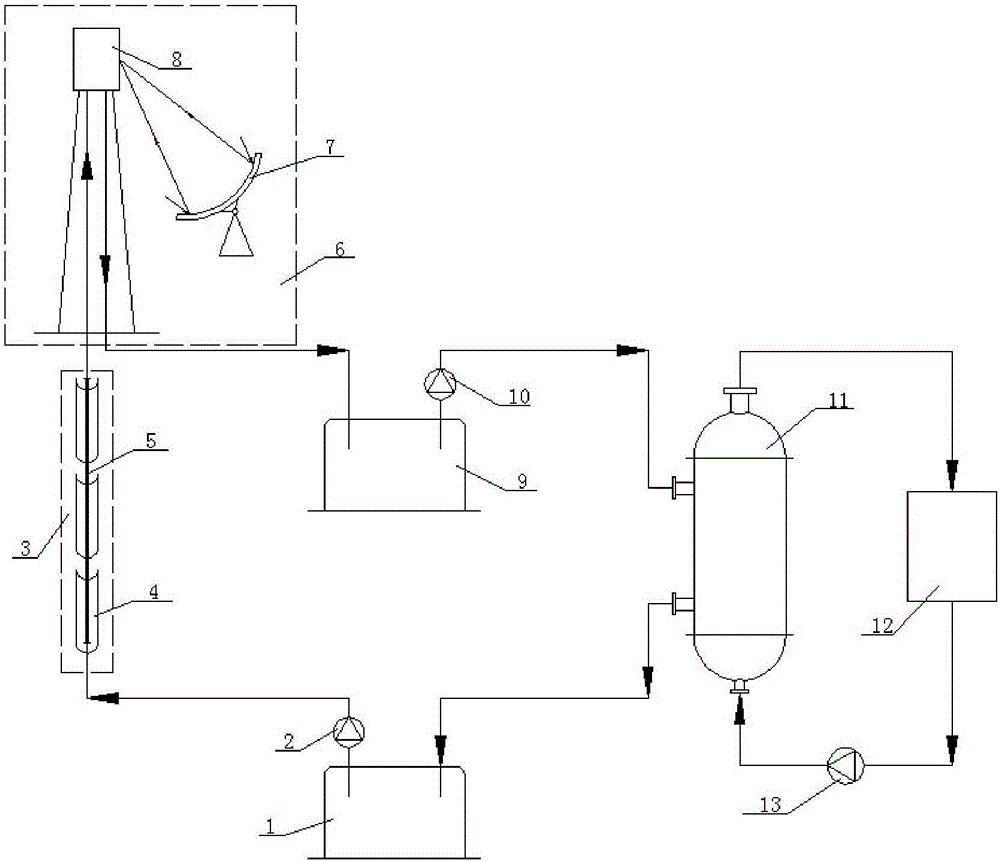

[0035] Embodiment 3: The high-temperature heat collection section 6 is a dish tower system composed of heliostats and tower top receivers

[0036] Such as image 3 As shown, this embodiment includes: a low-temperature salt storage tank 1, a low-temperature molten salt pump 2, a trough parabolic mirror 4, a heat collecting tube 5, a dish parabolic mirror (concentrator 7), and a tower top receiver (receiver 8) , high-temperature salt storage tank 9, high-temperature molten salt pump 10, molten salt-working medium heat exchanger 11, heat-using equipment 12 and circulation pump 13.

[0037] The low temperature salt storage tank 1, the low temperature molten salt pump 2, the trough parabolic mirror 4, the heat collecting tube 5, the dish parabolic mirror 7, the tower top receiver 8, the high temperature salt storage tank 9, the high temperature molten salt pump 10 and the melting The salt-working medium heat exchanger 11 forms a molten salt circulation loop.

[0038] The molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com