Heat tube type photovoltaic photo-thermal member

A heat pipe type, photovoltaic technology, applied in the field of solar energy utilization, can solve the problems of hindering heat transfer, reducing heat conversion efficiency, unable to fully utilize sunlight, etc., to achieve the effect of improving heat conversion efficiency and reducing air interlayers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

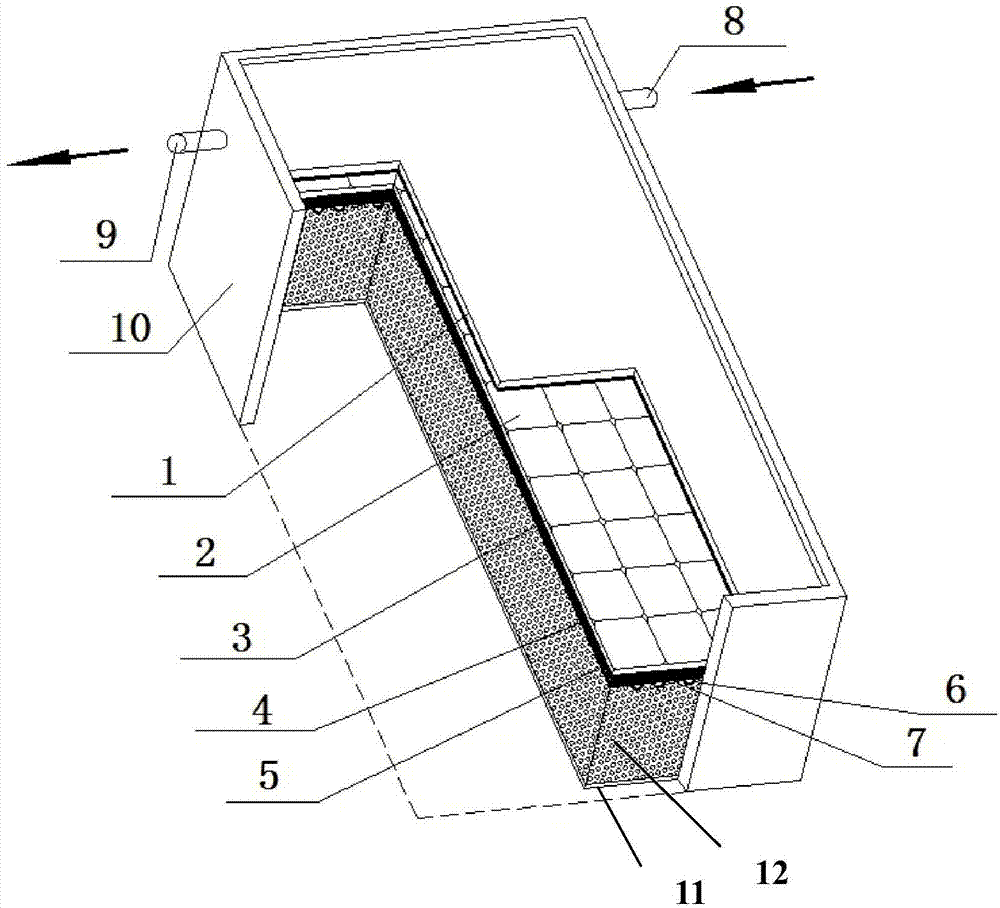

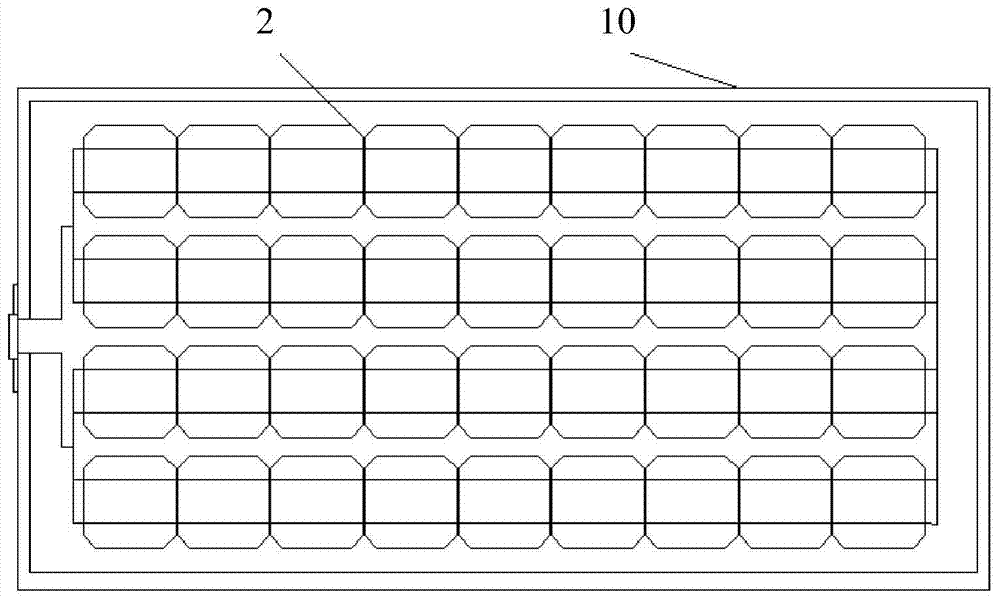

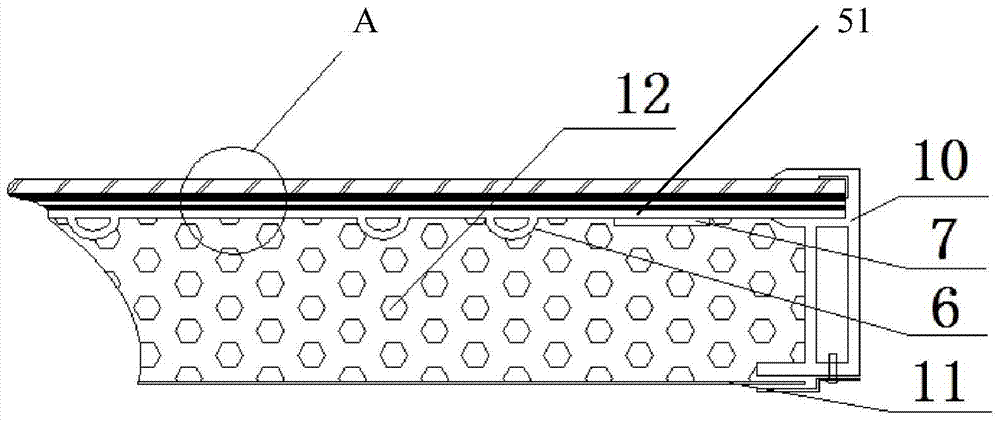

[0029] like Figure 1~4 As shown, it is a heat pipe type photovoltaic photothermal component of the present invention, which includes a glass cover plate 1, solar cells 2 connected in series and parallel rows, a packaging material TPT3, and a solar spectrum selective absorption coating for absorbing the infrared band of the solar spectrum. Layer 4, tube plate heat absorbing plate 5, heat preservation layer 12 and profile frame 10, wherein the solar cells 2 are solar cells composed of monocrystalline silicon connected in series and parallel. The glass cover plate 1, the solar battery sheet 2, the packaging material TPT3 and the solar spectrum selective absorption coating 4 are sequentially laminated and bonded from top to bottom; The heat collecting tube 6 on the plate surface is composed of the heat collecting tube 6. The cross section of the heat collecting tube 6 is a downwardly protruding arc, which together with the plate body 51 forms a channel for the flow of the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com