Liquid expander

A liquid expansion and casing technology, which is applied in the field of liquid expanders for low-temperature and high-pressure liquid throttling and pressure reduction, to achieve the effects of flexible braking, reduced energy consumption, and zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

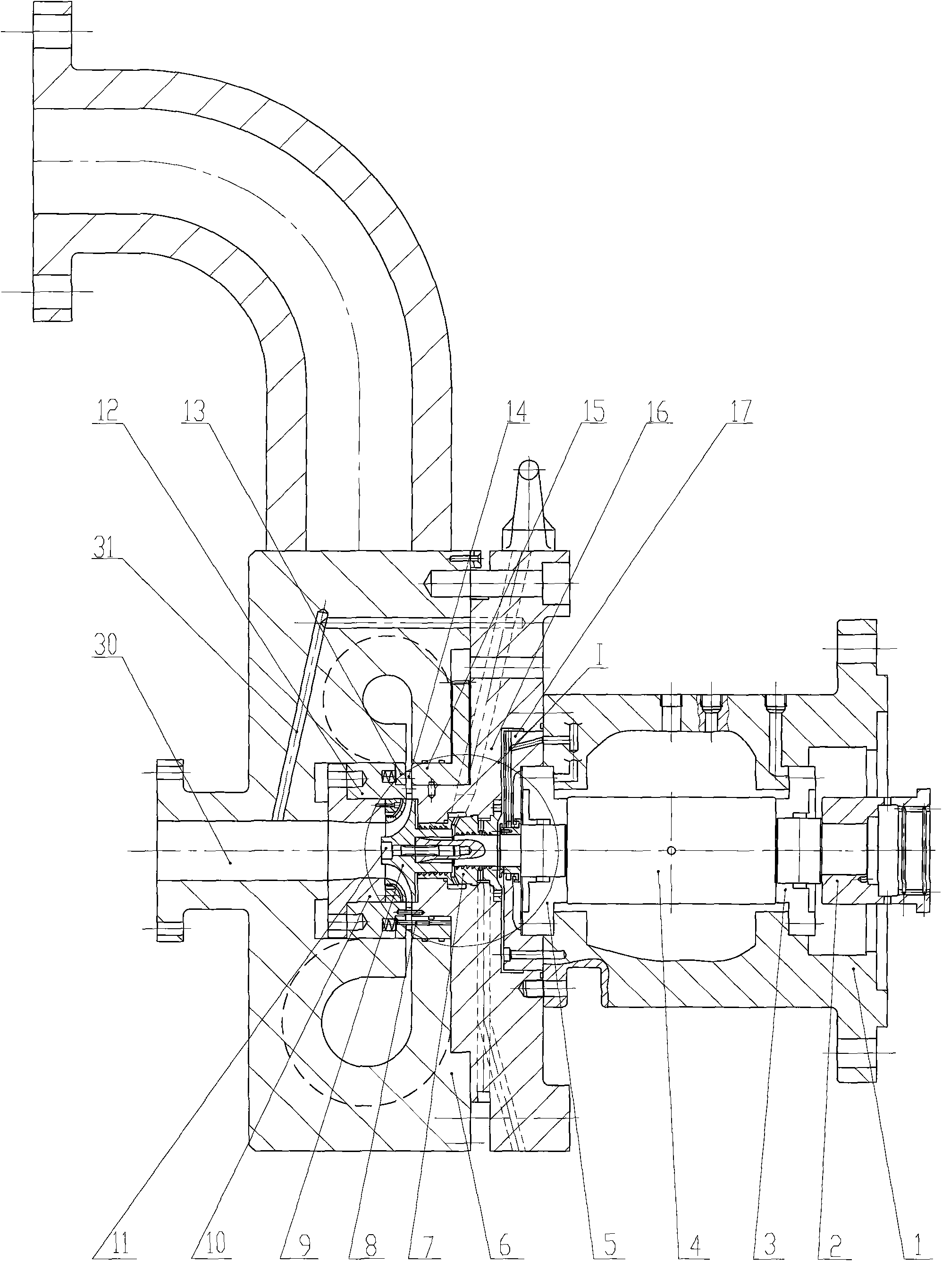

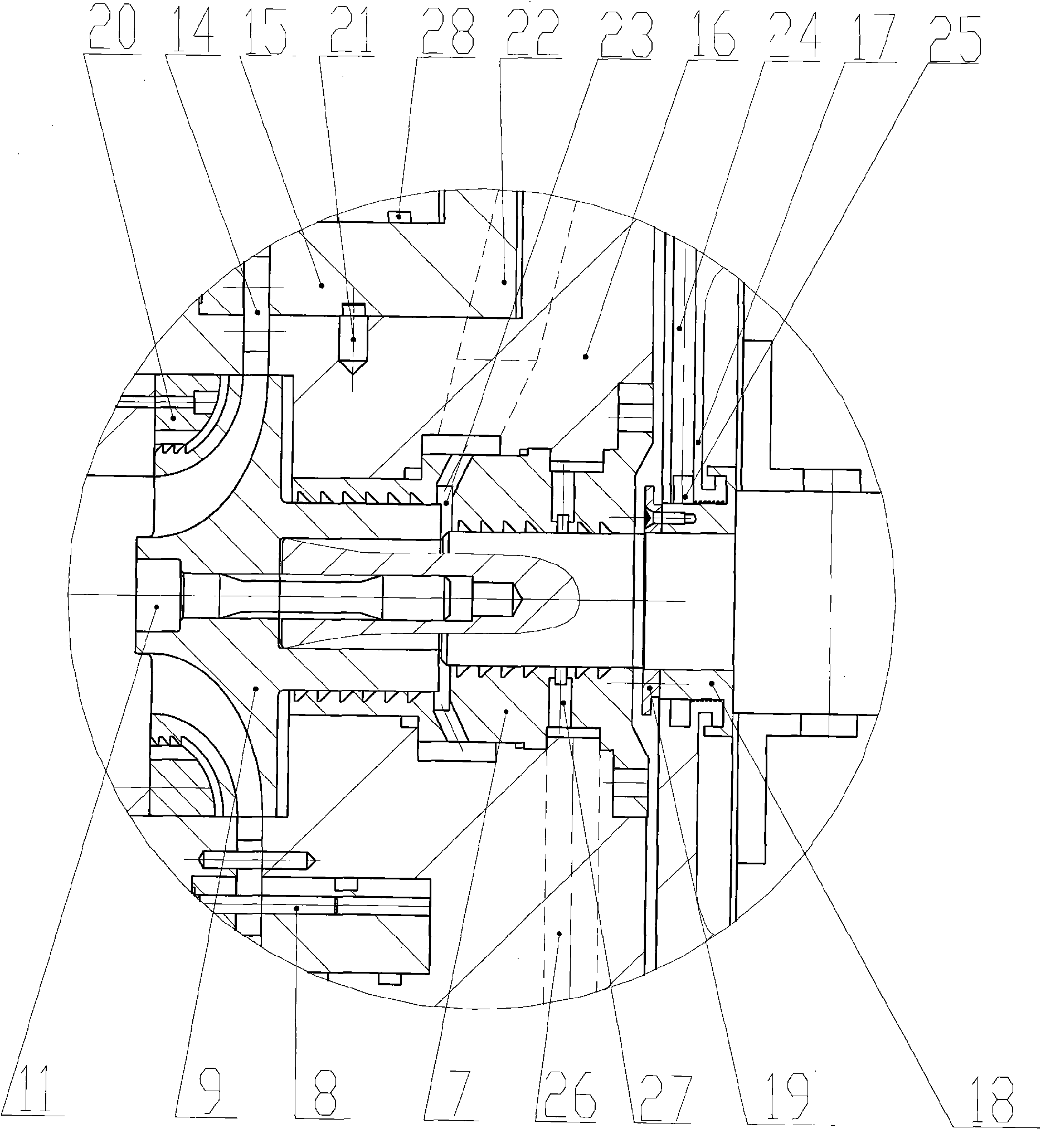

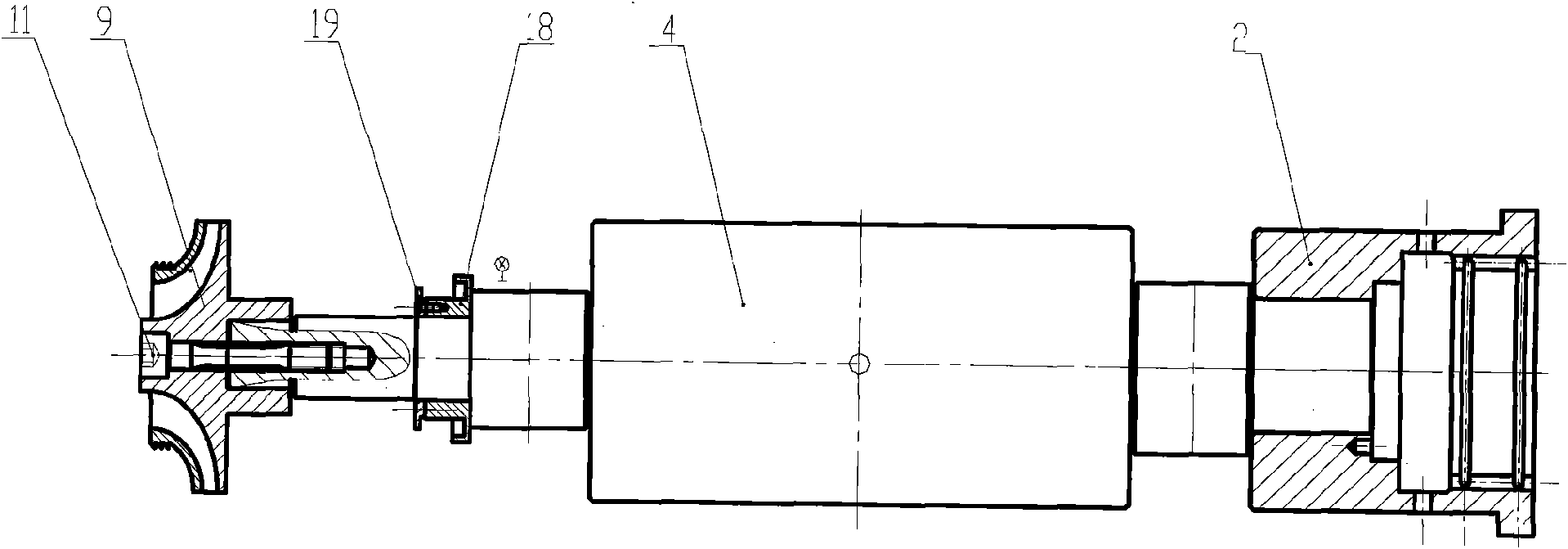

[0016] Such as figure 1 figure 2 As shown, an expander for liquid throttling includes a bearing housing 1; support-thrust bearings 3, 5, a rotor; an intermediate piece 17; a nozzle assembly; The casing 6 includes a working fluid inlet pipe and a working fluid outlet 30 , and a hole 31 and a designed volute guide channel are processed inside the casing 6 . The rotor includes a main shaft 4, an oil throwing ring 18 and an impeller 9 are arranged at the front of the main shaft 4, and the impeller 9 is connected with the main shaft through an impeller positioning screw 11, and a coupling 2 is arranged at the rear end. The nozzle assembly includes a nozzle platen 12 , a nozzle cover 13 , a nozzle vane 14 , a nozzle turntable 15 and a nozzle chassis 16 , and the nozzle cover 13 , nozzle vane 14 and nozzle turntable 15 are axially connected togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com