Brake beam component of gantry broken belt protector

A technology of braking beams and broken belts, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of affecting the braking effect of broken belts and insufficient strength of braking beams, and achieves convenient installation and debugging, The effect of simple processing and flexible braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

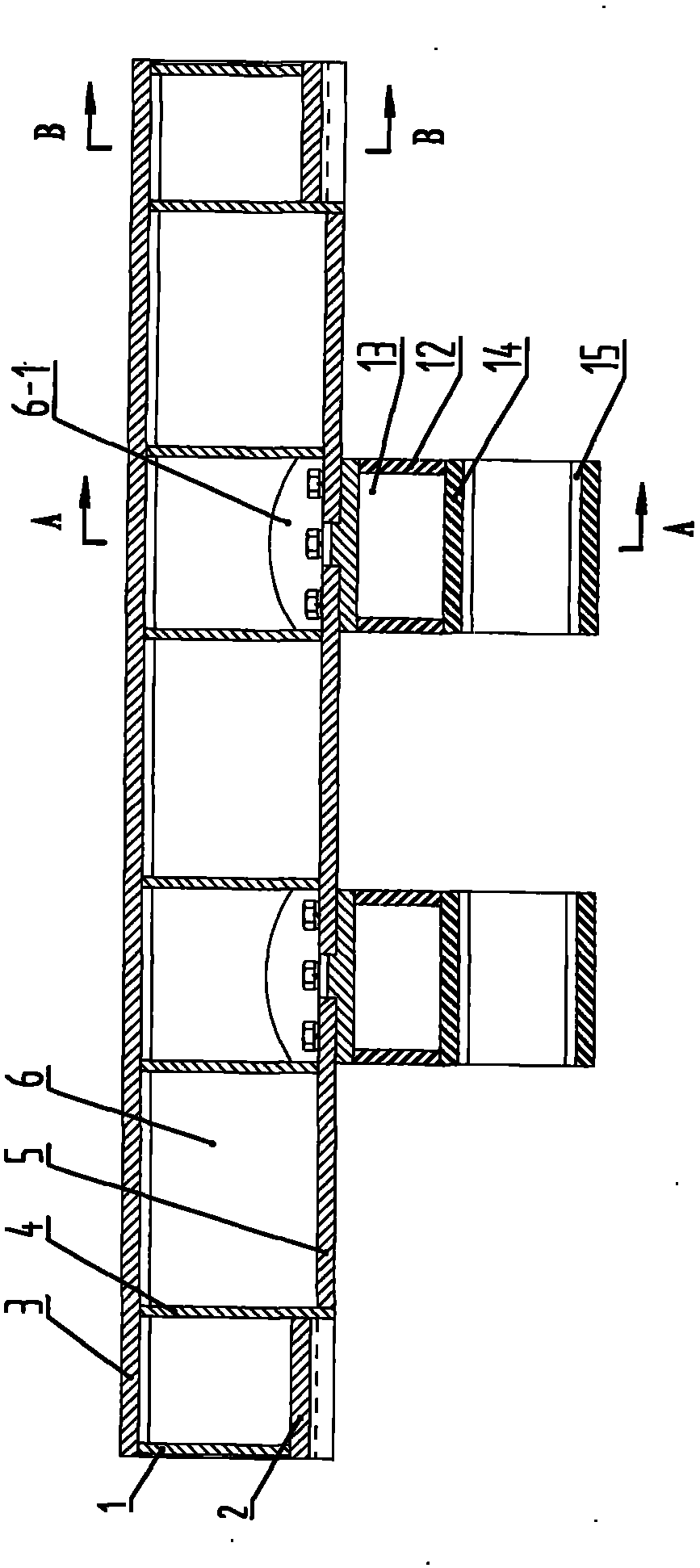

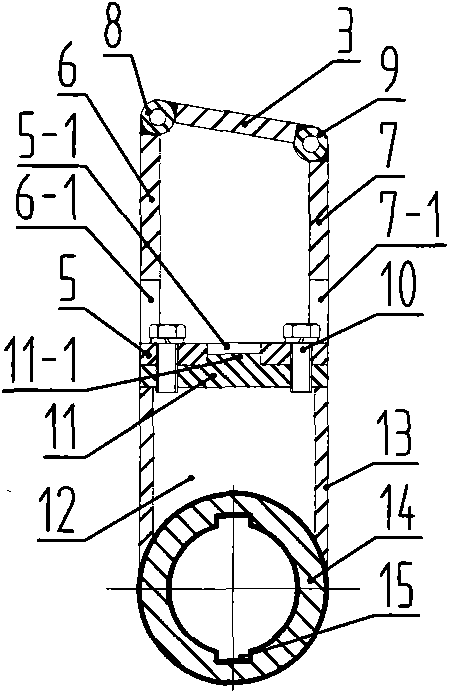

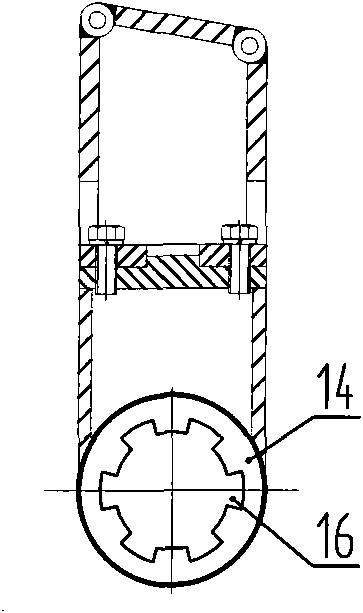

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a brake beam assembly of a door-type broken belt catcher, which is characterized in that: the assembly is composed of three parts: a brake beam, a rotating sleeve 14 and a connecting assembly; A rectangular box body formed by welding the front vertical plate 7, the rear vertical plate 6 and the fixed plate 11. The inner cavity of the rectangular box body is provided with multiple ribs 4; the two ends of the rectangular box body are welded to the end panels 1; The inner hole of the rotating sleeve 14 is made into a keyway 15 or a splined hole 16, depending on the main shaft. The connecting assembly is a rectangular tube welded by two front and rear vertical plates 12 and two left and right vertical plates 13, one end of the rectangular tube is welded to the rotating sleeve 14, and the other end of the rectangular tube is welded to the fixed plate 11; The fixing plate 11 is connected with the bottom plate 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com