Hydraulic flexible cable cutting knife

A flexible cable and water pressure technology, applied in fluid pressure actuators, servo motor components, metal processing, etc., can solve the problems of increased pressure loss, reduced tool efficiency, poor tool adaptability, etc., and achieve small pipeline pressure loss , improve stability and improve adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

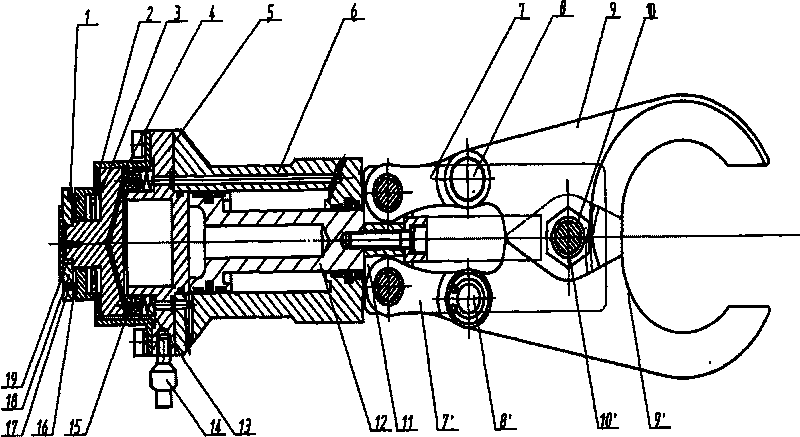

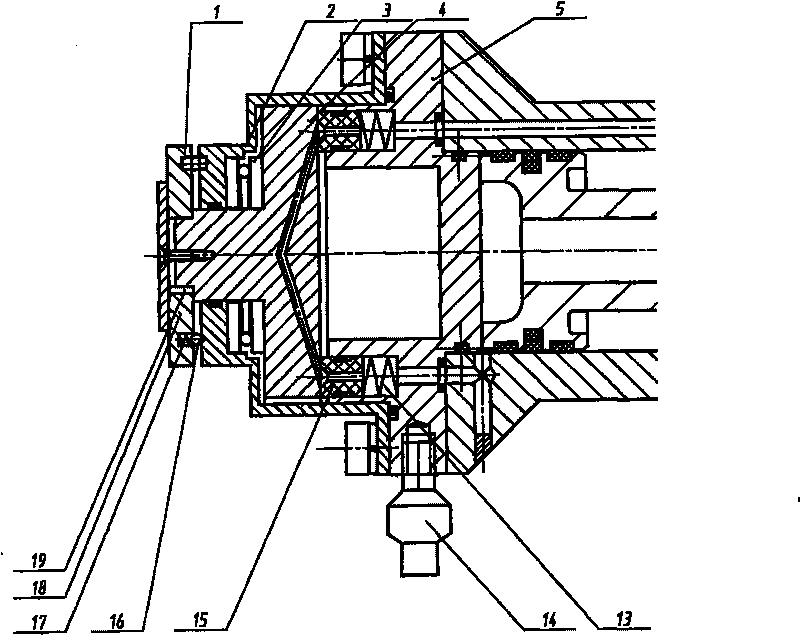

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

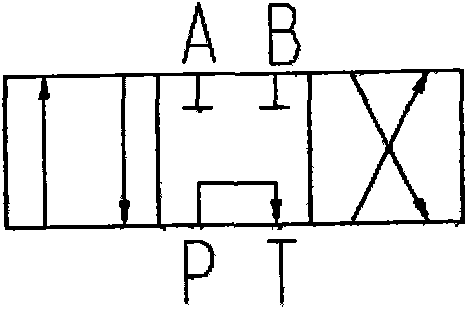

[0023] figure 1 It is a structural schematic diagram of a seawater hydraulic soft cable cutter, including a seawater hydraulic cylinder, a control valve, and a scissors movement mechanism. The control valve assembly is connected with the seawater hydraulic cylinder to control the expansion and contraction of the hydraulic cylinder; the piston rod of the hydraulic cylinder is connected with the scissors movement mechanism.

[0024] The seawater hydraulic cylinder includes a cylinder body 6, and a piston rod 12 is arranged inside the cylinder body 6. One end of the piston rod 12 protrudes from the cylinder body 6 and is connected with the scissors movement mechanism, and the other end is connected with the valve seat 5, which acts as a mounting cylinder. Body end cover, axially limit the piston rod 12, refer to figure 1 . The cavity between the tail en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com