Device for recycling exhaust air and cooling fluid of condensator for evaporative cooling electric motor

An evaporative cooling and recovery device technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve problems such as location restrictions, small space for evaporative cooling motors, and no condenser exhaust and coolant recovery devices. achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

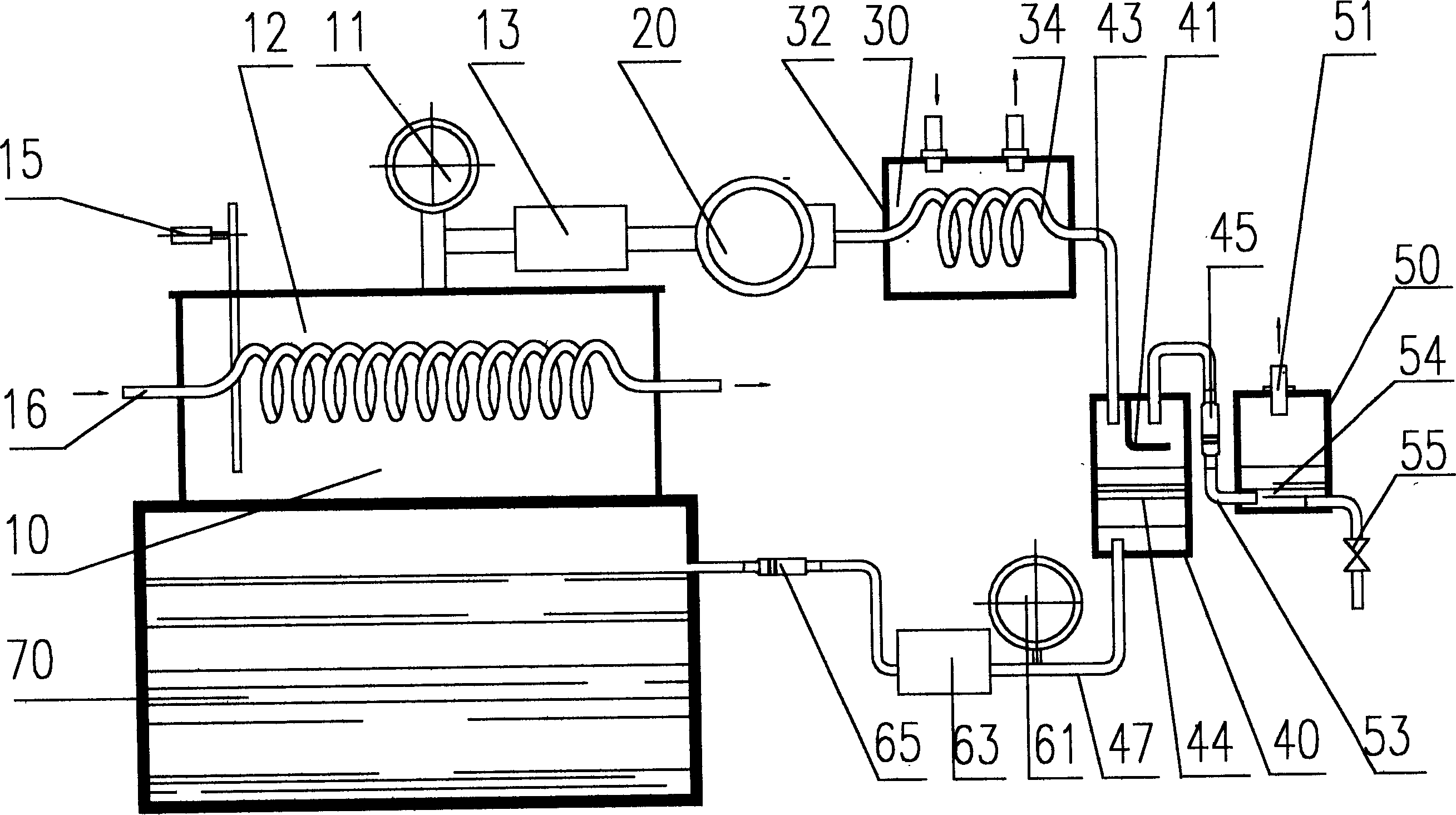

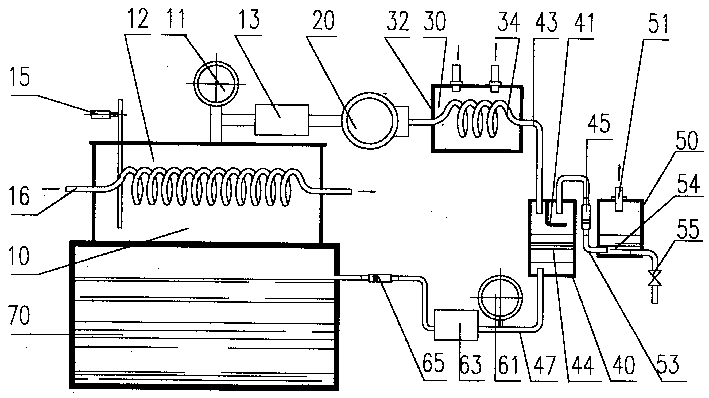

[0010] figure 1 is an embodiment of the present invention. The heat-generating parts of the stator of the evaporative cooling motor are immersed in the evaporative cooling chamber 70 , and the main condenser 10 is located above the evaporative cooling chamber 70 . The device of the present invention is installed between the main condenser 10 and the evaporative cooling chamber 70 .

[0011] The main condenser 10 is a box body, and the cooling water pipe 16 passing through the secondary cooling water runs through the box body. The upper part of the inner space of the box body is a condensation space 12, and there is a pressure controller 11 and a water leakage detector 15 above the condensation space 12 outside the box body. . In this embodiment, the pressure controller 11 selects YZX-150 electric contact pressure vacuum gauge, which has pressure display, pressure upper limit, pressure lower limit setting and corresponding electric contact. Water leakage detector 15 can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com