Plane sealing type reversing valve

A plane sealing, reversing valve technology, applied in the field of hydraulic control valve, can solve the problems of difficult processing, poor anti-pollution ability, large reversing control force, etc. Smaller than the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further described below in conjunction with accompanying drawing:

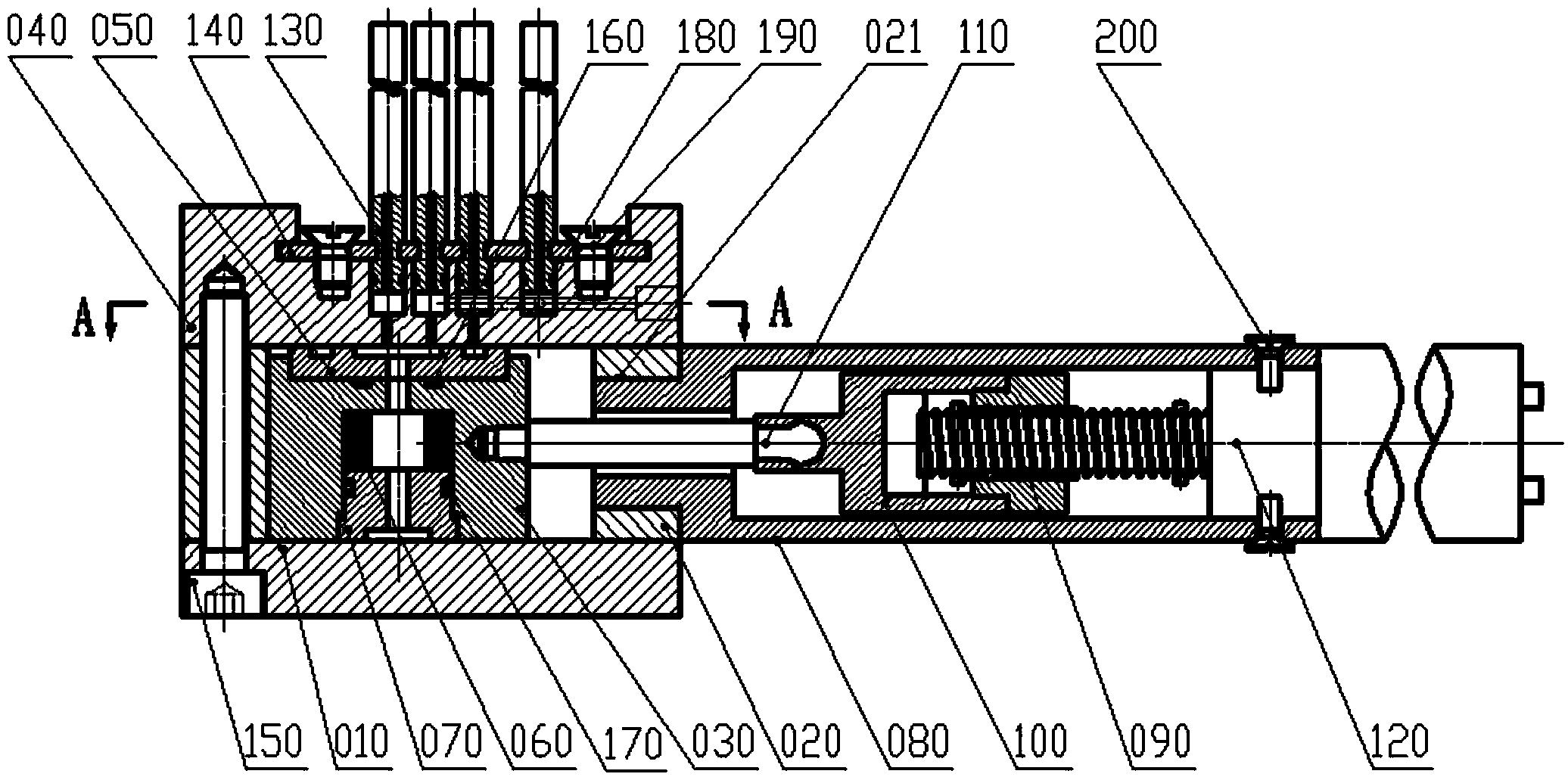

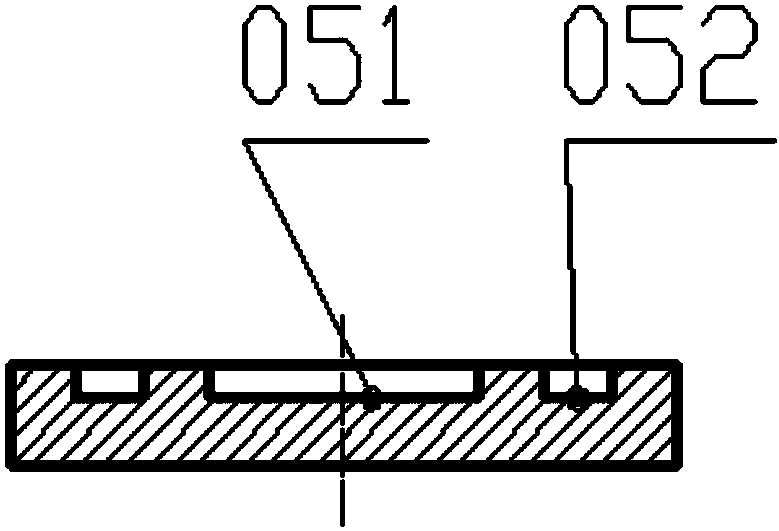

[0045] Such as figure 1 As shown, the present invention includes a lower valve seat 010, a support seat 020, a slider 030, an upper valve seat 040, a fixed valve core 050, a disc spring 060, a floating valve core 070, a sleeve 080, a ball screw assembly 090, a connecting screw Cover 100, push rod 110, geared motor 120;

[0046] A support seat 020 is placed on the lower valve seat 010. The support seat 020 is a rectangular frame with a threaded hole 021 on one side for connecting the sleeve 080. The slider 030 is placed in the support seat 020 and can slide freely. The upper valve seat 040 covers the upper end surface of the support seat 020 and the slider 030, the lower valve seat 010, the support seat 020 and the upper valve seat 040 are connected and fixed by the stud 150, and the slider 30 is closed;

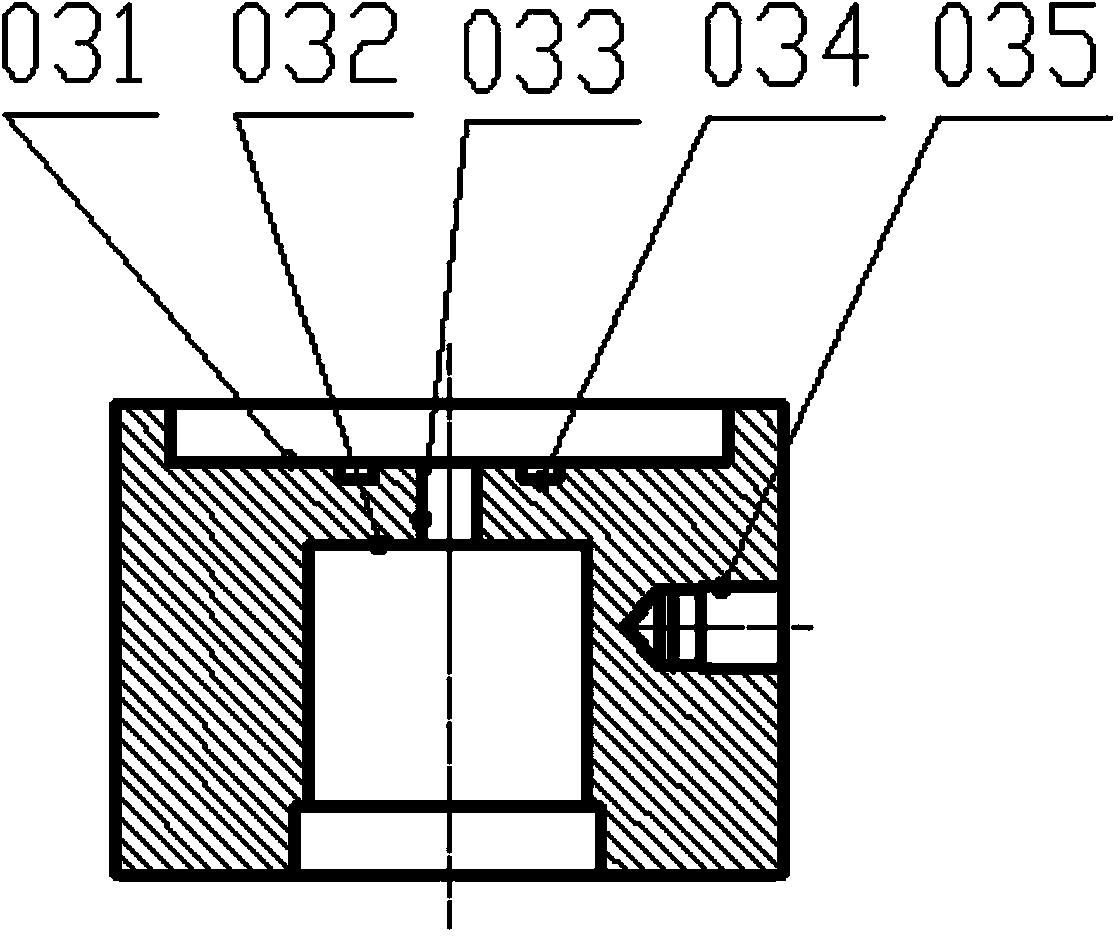

[0047] Such as figure 2 As shown, the slider 030 is a rectangular cube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com