High-flow dynamic output control method of cartridge valve and cartridge valve

A technology of dynamic output and control method, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., and can solve the problem that the dynamic output flow rate of pressure liquid is small, increases, and cannot meet the energy supply and control stability of large hydraulic pile drivers demand and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

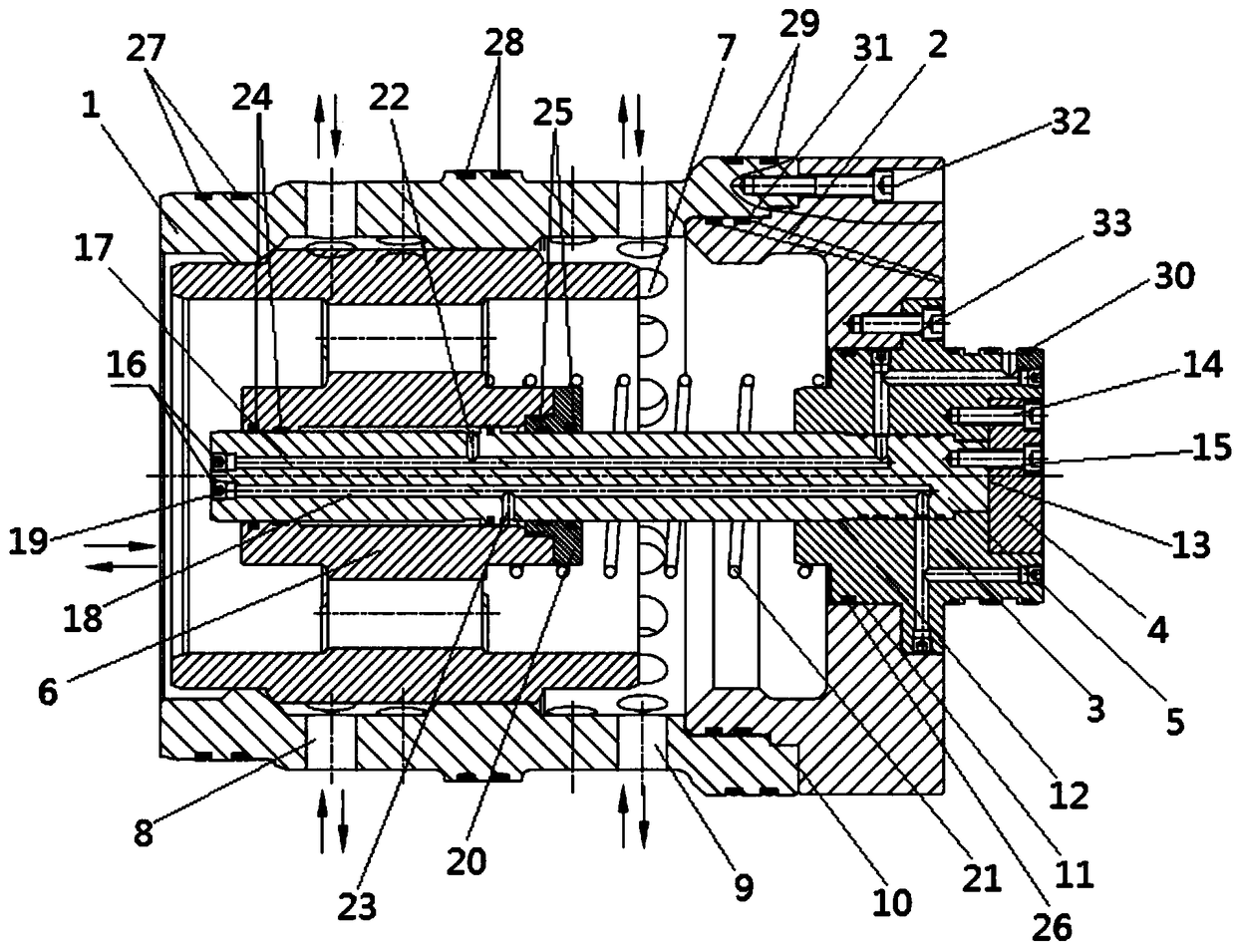

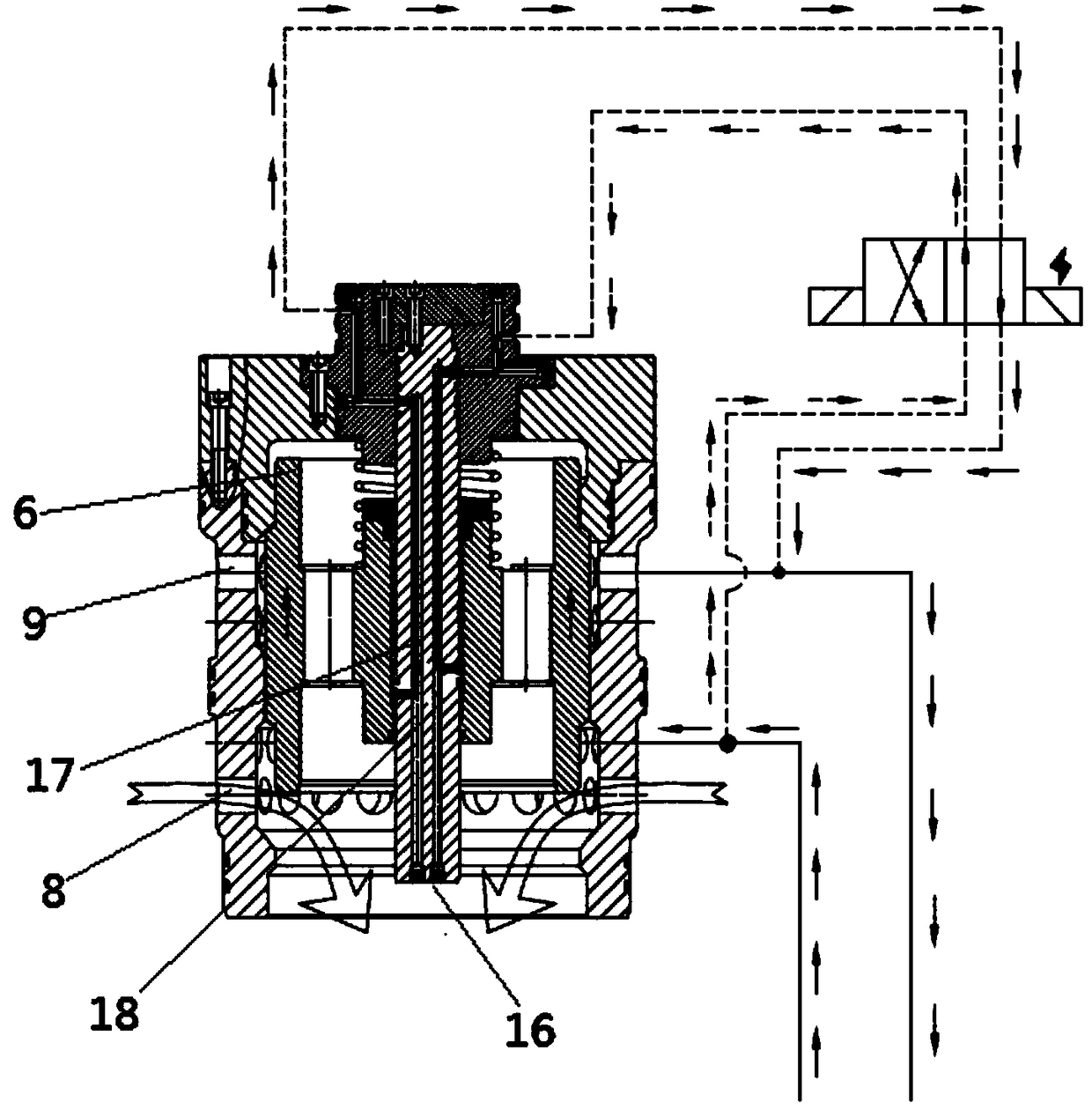

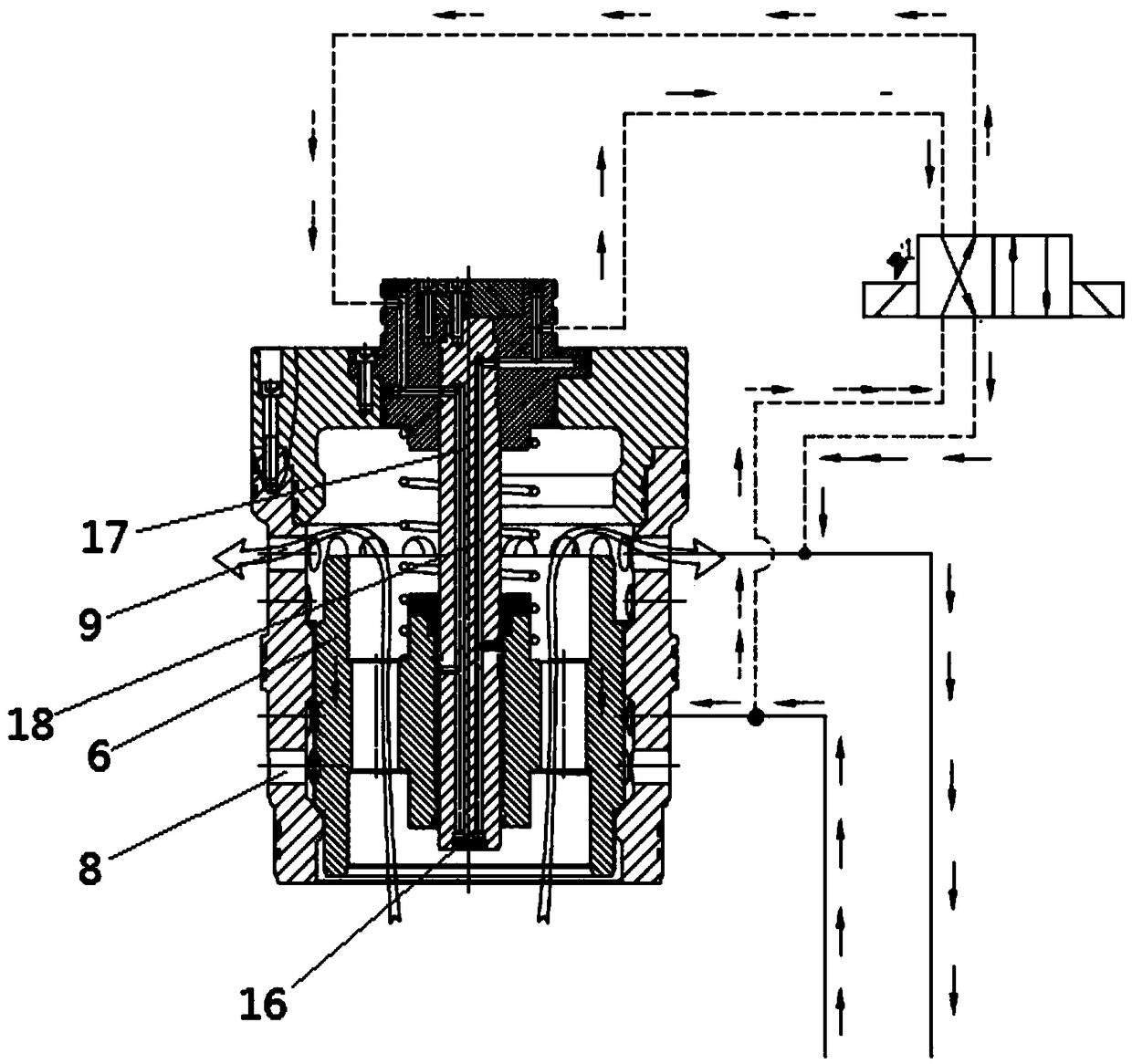

[0044] Example 1: See attached Figure 1-3 , the method for controlling the dynamic output of a cartridge valve with a large flow rate provided by the present invention comprises the following steps:

[0045] (1) A cartridge valve, a control solenoid valve, a hydraulic pump and an oil return tank are provided; the cartridge valve includes a valve sleeve 1; the control solenoid valve includes DT1 oil circuit and DT2 oil circuit;

[0046] (2) A number of oil outlet holes 7 with the same shape, orderly arrangement and equal size are set on the valve sleeve 1. The oil outlet hole 7 is composed of the first oil outlet 8 and the second oil outlet 9. The inside of the valve sleeve 1 is provided with a cavity;

[0047] (3) Set a valve sleeve end cover 2 on the valve sleeve 1, set a guide shaft fixing seat 3 on the valve sleeve end cover 2, set a guide shaft 5 on the guide shaft fixing seat 3, and set a valve core on the guide shaft 5 6. The guide shaft 5 is located inside the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com